Trustworthy

Titanium Products & Sputtering Target Manufacturer

- From Rapid Prototyping to on-demand Production

- 80+ Titanium Grade Manufacturing Experience

- Custom Parts Manufacturing & MOQ 1

- Quality Parts in Days

- DFM analysis

From Titanium Prototype To Mass Production Services

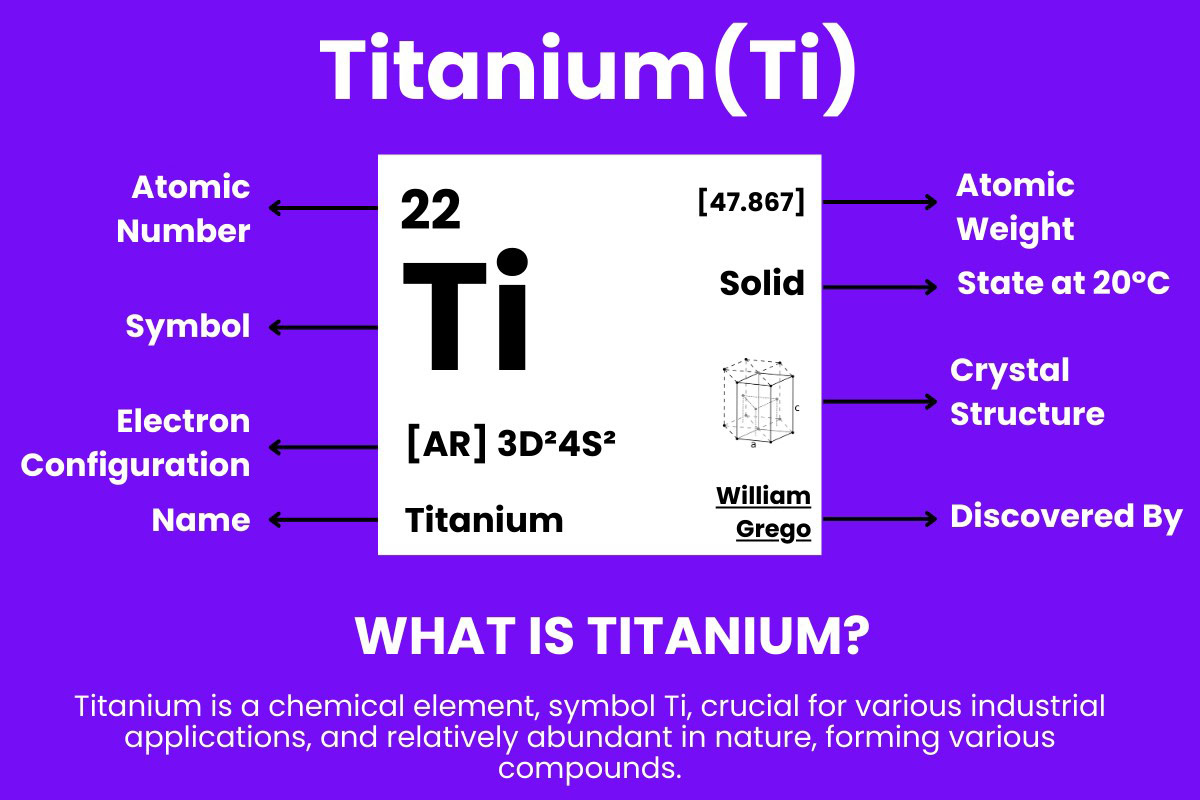

Wstitanium is an ISO9001 & ISO13485 certified titanium products & custom titanium parts & Sputtering Target manufacturer and supplier, located in Baoji, China. Since its establishment in 2011, Wstitanium has mastered the knowledge of 80+ titanium grades and formed an internal white paper. The in-house advanced production facilities determine the manufacturing capabilities of a wide range of titanium products, following international standards such as ASTM/ ASME/ DIN/ JIS/GB. Please try to cooperate with Wstitanium from a small order to Establish an initial trust relationship. We know the three foundations of cooperation with you: Competitive Price, Excellent Quality, Fast Response.

Rich Titanium Knowledge

17 years of experience in manufacturing a full range of titanium alloys.Internally accumulated manufacturing experience white paper.

- TA1-TA28

- TB2-TB11

- TC1-TC26

- Full Series Titanium Alloy Grades

Manufacturing Solutions

Internal investment in CNC machines, 3D printing, forging, casting, sheet metal, heat treatment and CMM for quality inspection.

- Lower Cost

- Fast Delivery

- Rich Manufacturing Skills

- Full Dimension Inspection Report

Customized Titanium Parts

Customized titanium rods, ingots, tubes, plates, titanium fasteners, titanium anodes, titanium parts, titanium wires, titanium flanges etc..

- For Aerospace

- For Medical \ Automotive

- For Robotics \ Yachts\Bicycle

- Professional Engineer Working With You

One-stop Solution For Titanium Products

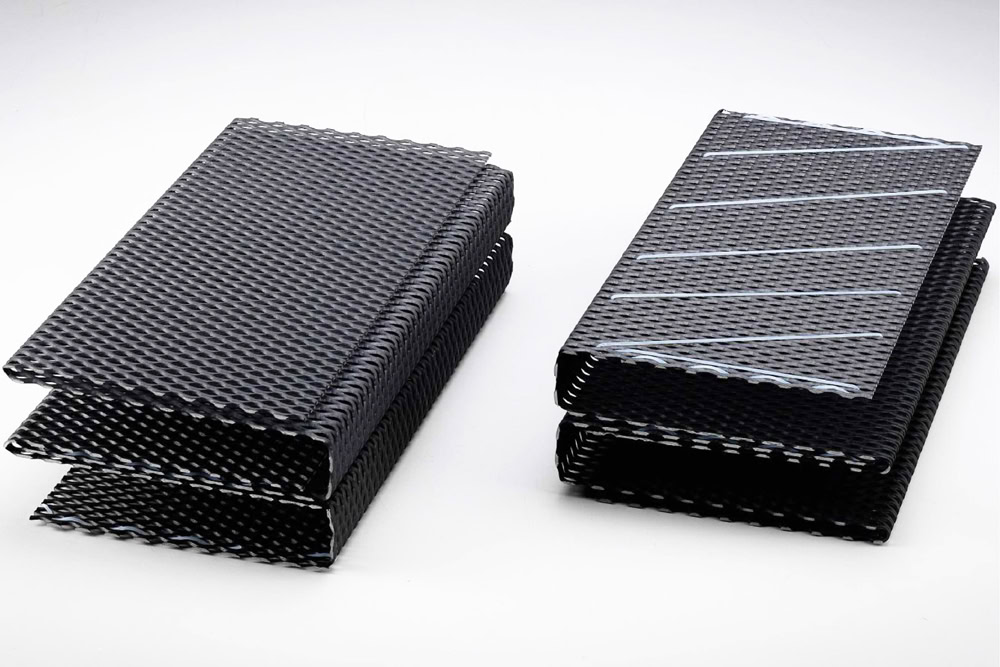

At Wstitanium, we provide a one-stop solution for titanium products & Sputtering Target, widely applied in aerospace, medical, robotics, marine, chemical and other fields. Including sponge titanium, titanium fasteners (screws, nuts, bolts, studs, etc.), titanium anodes, titanium ingots, titanium rods, titanium tubes, titanium plates, titanium wires, titanium heat exchangers, titanium flanges, titanium sputtering targets and OEM customized CNC machining titanium parts.

- Competitive Price

- Diameter: Ø 30 - 2000 mm

- Ti-Al, Ti-Cr, Ti-Zr, TiSi,TiN etc

- Titanium content greater > 99.6%

- Rapid Prototype

- On-Demand Production

- Custom CNC Milled Parts

- Custom CNC Turned Parts

- Iridium Tantalum Anode

- Platinum Titanium Anode

- Tantalum Titanium Anode

- Ruthenium Titanium Anode

- Standard: GB DIN ISO

- M3-M30*10mm-200mm

- TA1,TA2,TC4,Gr1,Gr2,Gr5

- Sandblasting\Polishing\Anodizing

- Ø 25.26mm ~ 210mm

- Thickness: 4mm ~ 30mm

- TA8,TA9,TA10,TA18,TC4

- Length: 500mm ~ 18000mm

- ASTM B337 & ASTM B337

- TA1-TA10, TC4

- Diameter: Ø 4 - 470 mm

- Titanium Grade 5 (3.7164)

- Titanium Grade 7 (3.7235)

- Titanium Grade 23 (3.7165)

- φ20mm-960mm

- ASTM B348 & ASTM B265

- TA1-TA18 TC3-TC26 TB5-TB13

- For Aerospace & Medical, etc.

- Impurities: Fe≤3ppm, O≤160ppm

- Thickness: 0,5 - 100 mm

- Titanium Grade 1 (3.7025)

- Titanium Grade 2 (3.7035)

- Titanium Grade 5 (3.7164)

- Titanium Grade 7 (3.7235)

- Length: 300-600 mm

- Thickness: 0.005~0.1mm

- TA1 TA2 TC4 TA9 TA10

- ASTM B265 & ASTM F67

Heat Exchanger

- TA0, TA1, TA2, TA9, TA10

- Diameter: φ4~500mm

- Thickness: δ0.2~4.5mm

- Length: within 15m

- Φ0.1~Φ7.0mm

- TA9, TA, TA18, TC1, TC2, TC4

- ASTM B863 & ASTM F136

- Pickled /Polished Surface

- TA1/ TA2/TA9/TA10

- ANSI B16.5 & ANSI B16.47

- PL & SO & WN & BL & SW & TH

- Aerospace, Medical, Chemical etc.

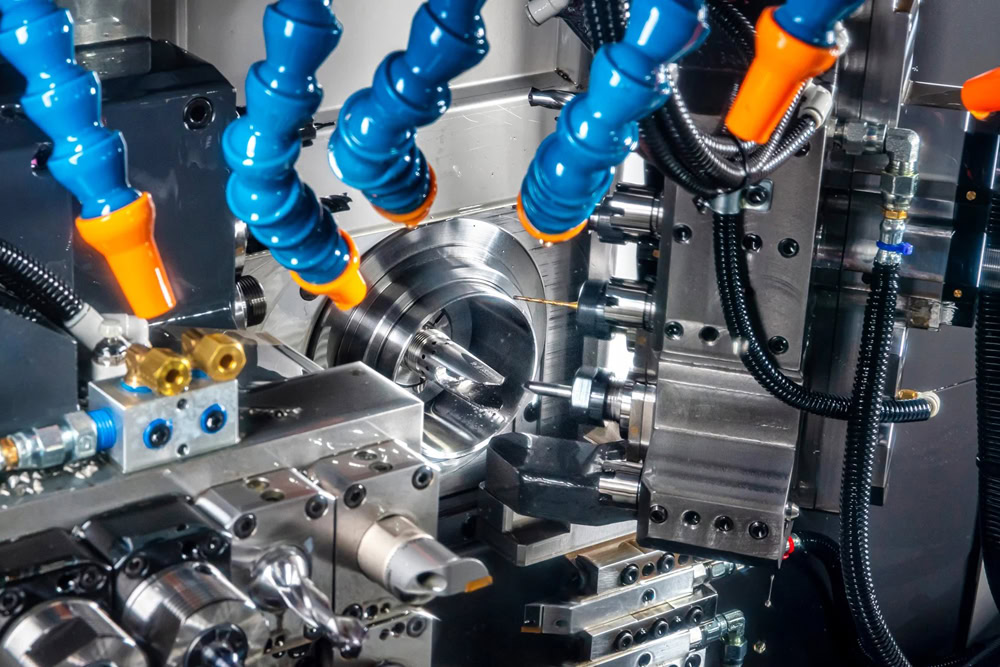

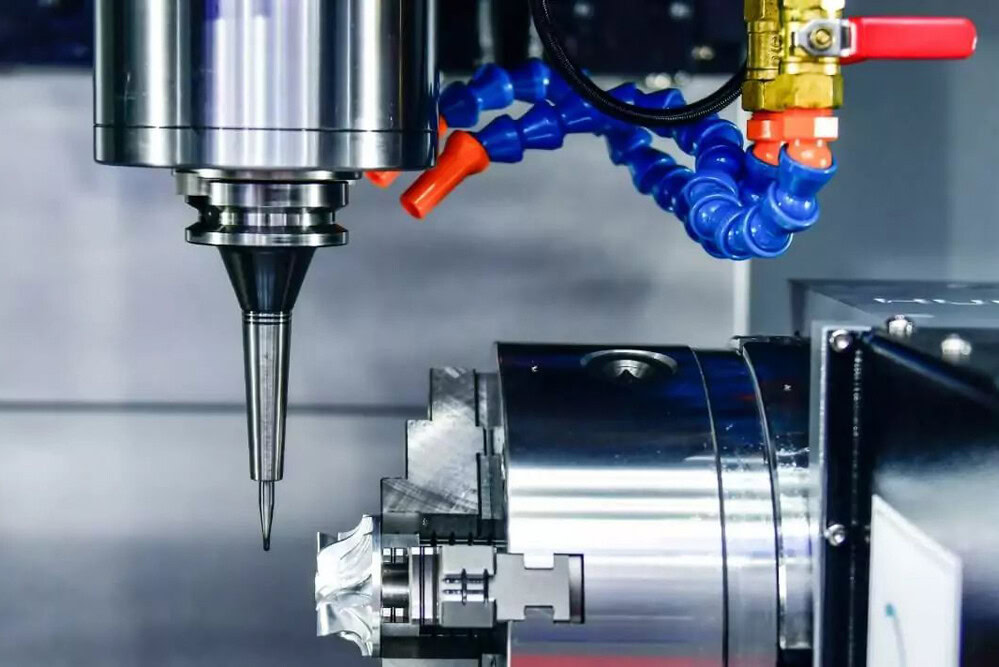

Advanced Full Manufacturing Capabilities

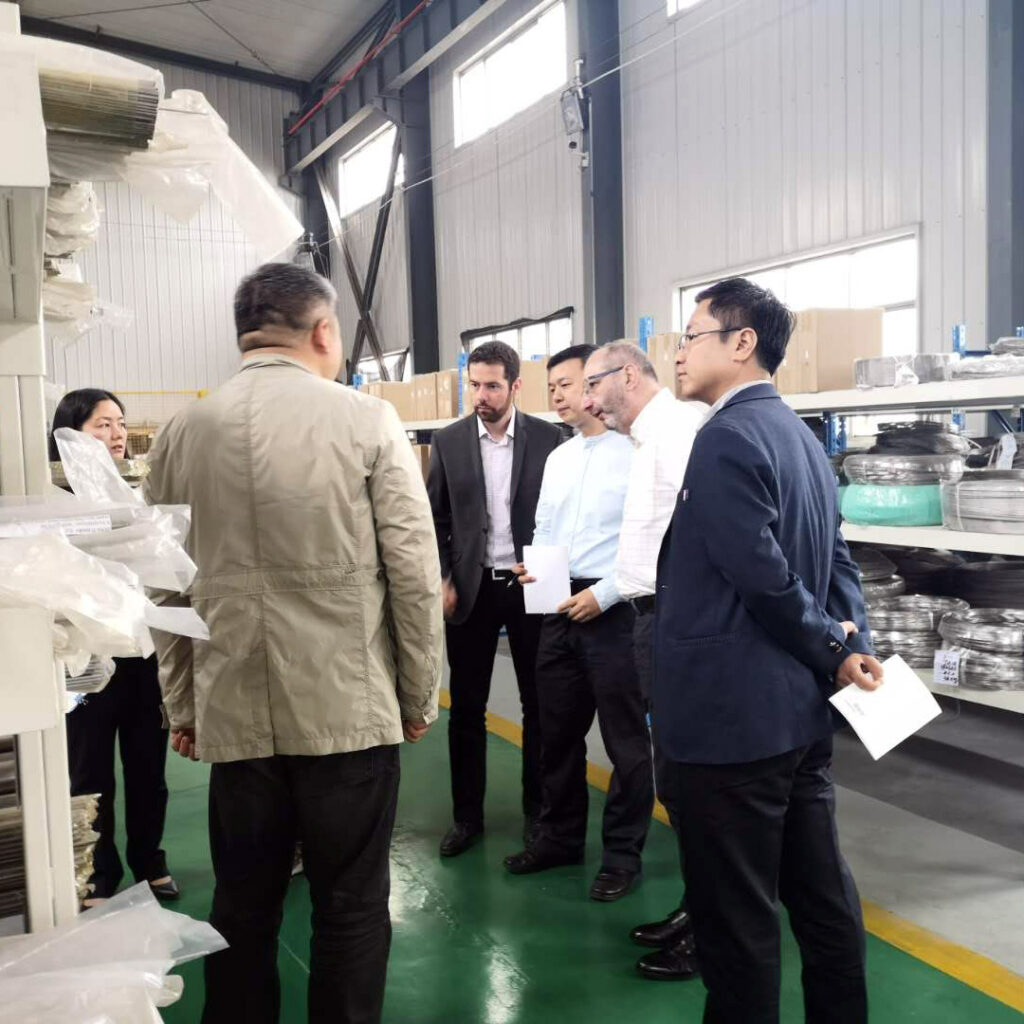

Wstitanium has a 12,000+ square meter workshop and 48 professional engineers. ISO9001 and ISO13485 Certified quality systems in 2018, with more than 38,000+ project experience in titanium product & Sputtering Target manufacturing. Internal investment in 100+ CNC machines, 3D printing, casting, forging, heat treatment and CMM quality inspection equipment. 80+ certified titanium grades in stock, and 20+ Finishing services options.

VIEW VIDEO

Learning More Our Factory

Advanced Titanium Manufacturing Solutions

Wstitanium has invested $28 million in mechanical facilities, including HAAS 5-axis CNC machines, CNC lathes, grinders, Sodick EDM, 10,000-ton hydraulic machines, forging machines, high frequency weld pipe mill line, CMM and other advanced equipment. Fully capable of solving all problems related to the manufacturing of titanium products & titanium parts & Sputtering Target.

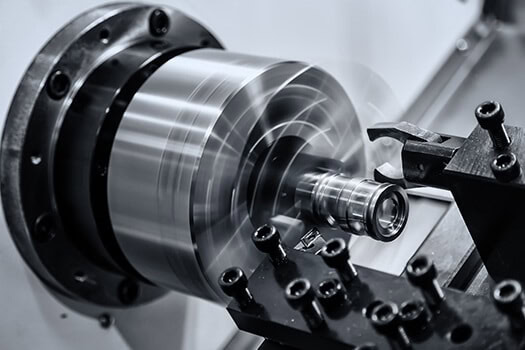

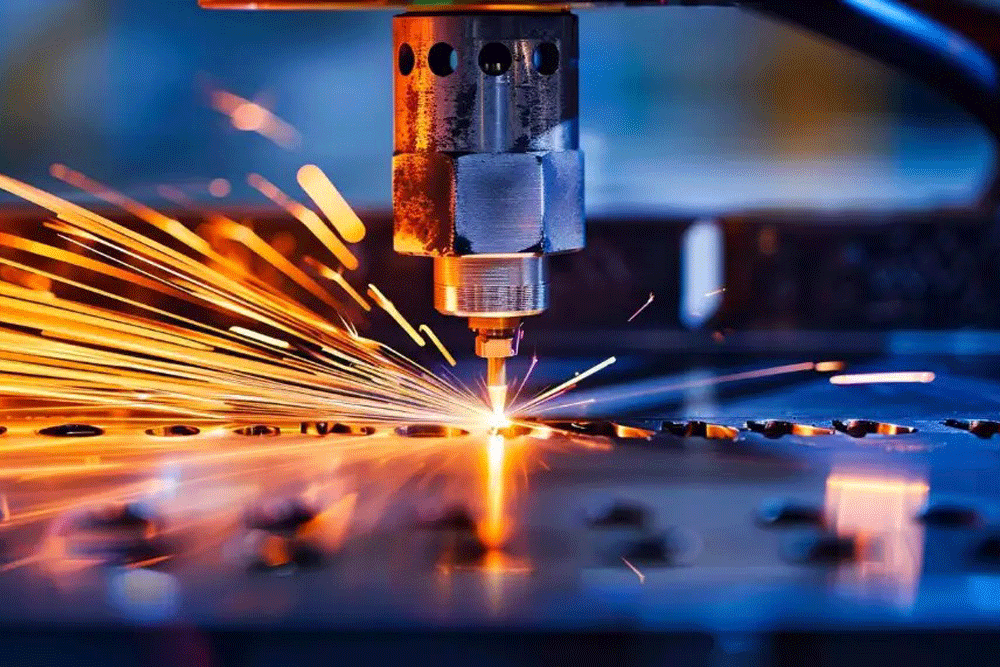

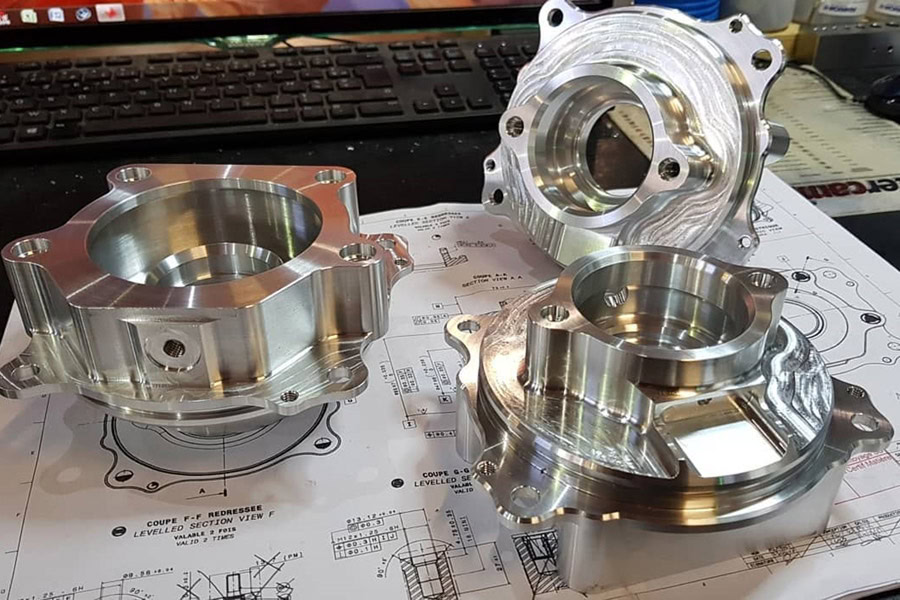

CNC milling titanium creates various shapes of planes, contours, etc. CNC drilling creates holes of different diameters and depths. CNC turning creates outer circles, inner holes, end faces, etc. CNC grinding improves the surface quality and accuracy.

CNC Swiss machining is suitable for manufacturing slender shaft-type titanium parts. Comprehensive milling, turning, drilling and other technologies can monitor the machining process in real time to ensure strict control of the dimensional tolerance.

CNC turning titanium uses special tools to accurately complete operations such as outer circles, inner holes, cones, and threads to ensure the dimensional accuracy and surface quality of titanium parts to meet the application requirements of aerospace, medical, etc.

Investment casting enables the manufacture of complex precision titanium parts, such as impellers. Sand casting is low-cost and suitable for the manufacture of large titanium parts, but the precision and surface quality are relatively poor.

3D printing of titanium refers to layer-by-layer stacking. Powder bed melting, electron beam melting, and binder jetting enable large-scale manufacturing of titanium parts, which are widely used in medical implants and high-end equipment.

High-energy-density laser beams instantly melt or vaporize titanium sheets with high precision, and can create complex structures without the need for additional molds. Auxiliary gases (such as high-purity nitrogen and argon) prevent oxidation of the cut.

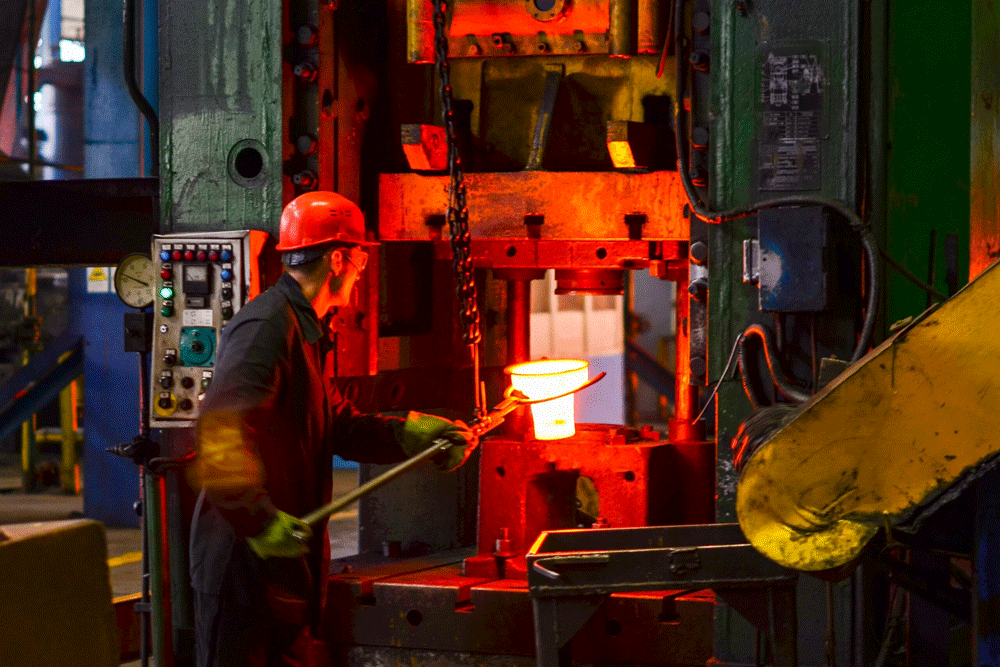

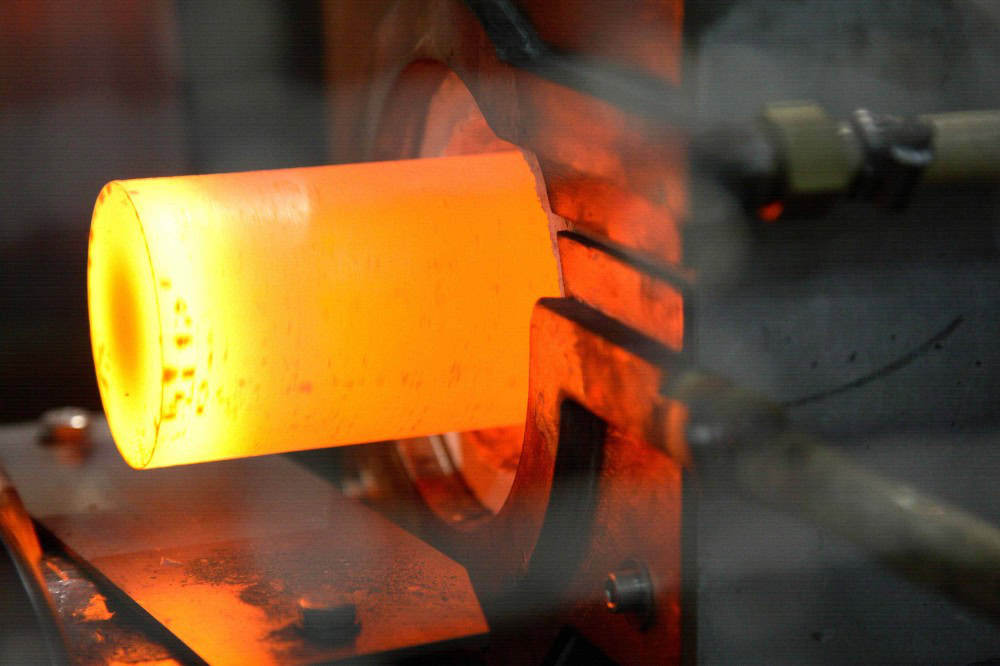

Titanium forging is a key technology to improve the microstructure and properties of titanium and titanium alloys through plastic deformation. It includes upsetting, drawing, die forging, etc., which gradually breaks up the coarse original grains, refines the structure, and improves the comprehensive properties such as strength and plasticity.

Titanium is easy to react with oxygen, nitrogen, hydrogen, etc. at high temperatures, resulting in embrittlement of the welded joint, so the requirements for welding titanium are harsh. Tungsten inert gas shielding (TIG) uses high-purity argon to protect the molten pool, isolate the air, and achieve high-quality welding.

EDM Machining Titanium is a special machining technology that uses the electro-erosion effect of pulse discharge to remove materials. It realizes the manufacture of complex curved parts with high precision and low surface roughness. The tolerance can reach +/- 0.0002mm. But the machining efficiency is relatively low.

Heat treatment is a key technology to improve the performance of titanium alloys. By controlling heating, heat preservation and cooling, its microstructure is changed. It includes annealing (eliminating stress, eliminating hardening), normalizing (refining grains), solution treatment (improving strength), etc.

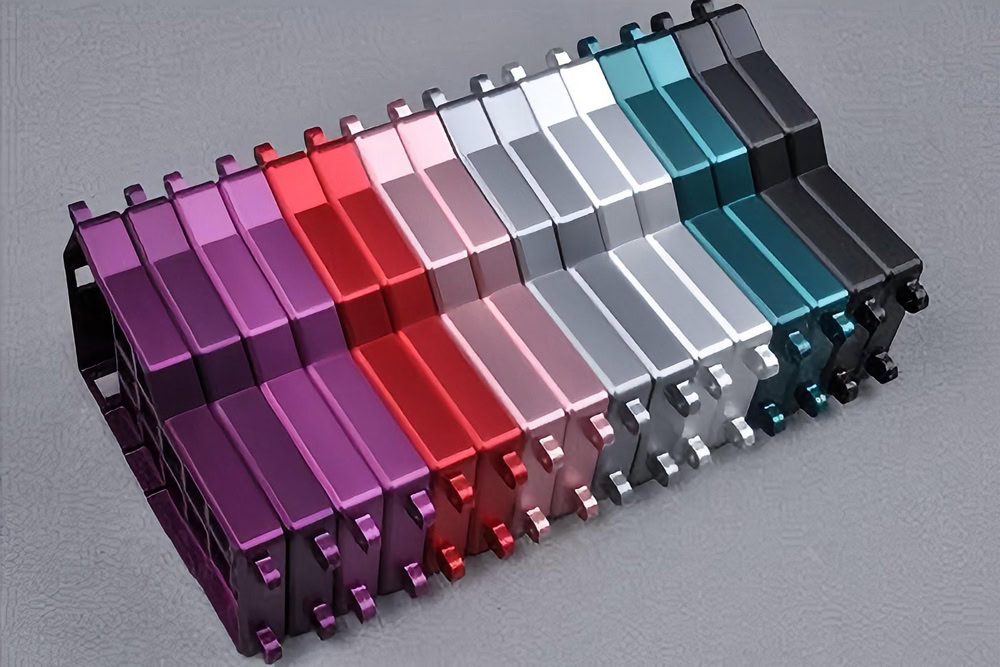

The surface treatment of titanium aims to improve its corrosion resistance, wear resistance, biocompatibility and aesthetics. It includes anodizing, micro-arc oxidation, chemical plating and electroplating, physical vapor deposition (PVD), chemical vapor deposition (CVD), sandblasting, polishing, etc.

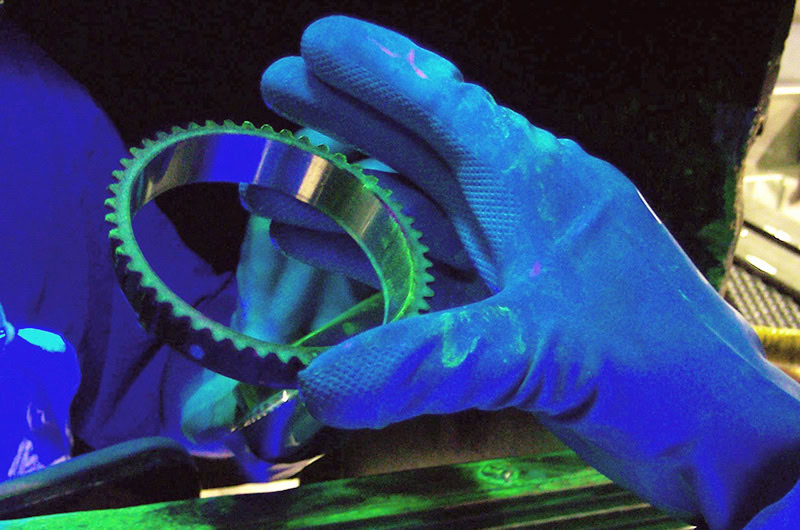

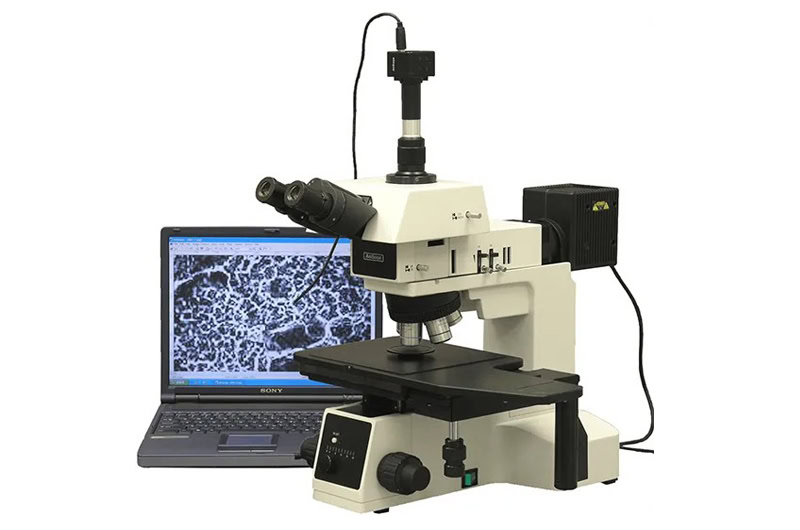

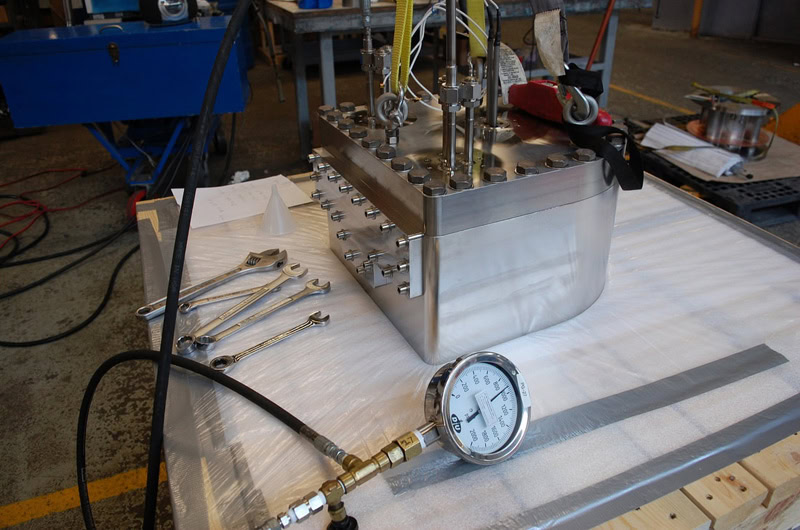

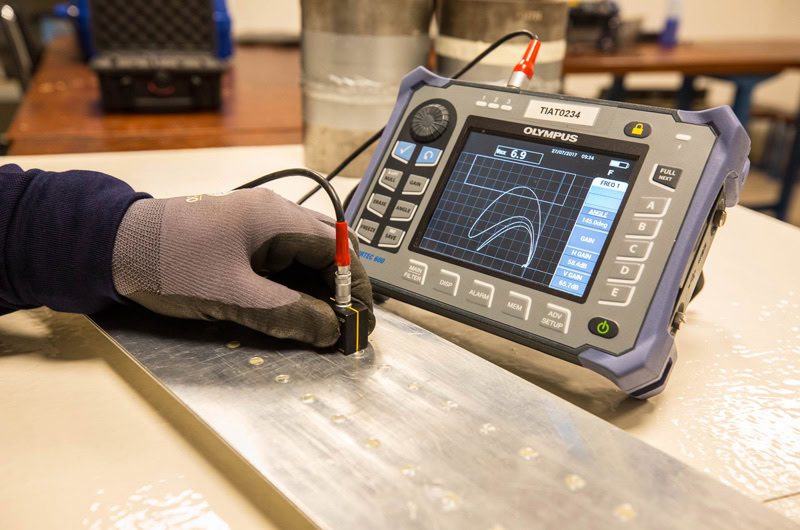

Titanium parts quality inspection covers many aspects such as material properties, dimensional accuracy, surface quality and internal defects. Including chemical composition, tensile, hardness, metallographic analysis, tolerance, surface roughness, non-destructive testing of pores, cracks, scratches, etc.

ISO 9001 & 13485 Certified

More Than 2300+ Project Engineers Trust Watitanium

Saving Your Projects Time

At Wstitanium, you can get all solutions about titanium in time, one-stop purchase of titanium products or customized titanium parts. Time is always the most expensive.

Saving Your Projects Cost

Compared with Europe and United States, Our advanced all-round manufacturing efficiency improvement and effective internal cost control will save you at least 20% of costs.

Reduce Your Projects Risk

Wstitanium integrates the entire titanium industry chain with a large inventory of titanium products. Every order is accompanied by a full-size inspection report. Reduce risk by 60%.

Industry Experience

Wstitanium’s engineers follow the master’s tradition and invest a lot of money in external training of engineers to adapt to the needs of various industries.

Massive Network

Wstitanium does not exist in isolation, but works closely with other titanium manufacturers to establish long-term and strong partnerships with unlimited production capacity.

38K+ Projects Delivered

More than 38K projects have been sent to more than 30 countries around the world and have received numerous praises, including Siemens, ABB, Mitsubishi, etc.

Manufacturing Process of Custom Titanium

Everything starts with titanium ore, which is refined into titanium tetrachloride and then chemically reacted with magnesium metal in a sealed stainless steel tank to produce titanium sponge. This process includes steps such as chlorination process and reduction-distillation process. Titanium sponge is pressed into electrodes by a press to form dense titanium sponge pressed block electrodes. Under vacuum conditions, the titanium sponge pressed block electrodes are melted and cast to form titanium ingots. Titanium ingots are finally formed into titanium rods through processes such as heating and forging. This process includes steps such as heating, forging, grinding, cutting, annealing, straightening, polishing, and flaw detection.

Industries we serve

Titanium alloys have a series of excellent properties, including high strength, heat resistance, corrosion resistance, non-magnetic, low damping characteristics, good compatibility with the human body, superconducting properties, shape memory and hydrogen absorption properties, etc., and are widely used in but not limited to aerospace, medical, chemical, energy, automobile, robotics and other industries.

Quality is the foundation of Wstitanium’s survival. We always take the quality of titanium products as the highest level and follow the ISO quality management system. We have invested a lot of money to purchase advanced testing equipment. The testing items are not limited to: dimension, ultrasonic testing, eddy current testing, X-ray testing, metallographic structure testing. We conduct internal defect detection on titanium alloy sheet materials and welded joints. Mechanical performance testing: including tensile, compression, bending and other performance tests to evaluate the strength, toughness and other mechanical properties of titanium parts.

Titanium Screws

Turning & Milling

Titanium Anode

Coating & Welding

James

The United States

We have been working with Wstitanium for 8 years and no matter how complex the design, starting with a rough concept, to prototyping, and finally high volume production, it always comes out the best. What is amazing is the competitive pricing of Wstitanium.

Serps

France

Wstitanium’s strengths are excellent service, price and quality. They worked hard to earn our business. Wstitanium fully understands our intentions. Every order comes with a full-size inspection report, which is very important to me. In my opinion, Wstitanium is the first choice for us to work with.

Modric

Slovakia

Wstitanium has manufactured over 1000 titanium parts for us. I have witnessed firsthand the entire process of cooperation, whether in terms of design capabilities, craftsmanship and quality. The meticulous service, quick response impressed me. Of course, what makes us so cheap is the price.

内藤雅仁

Japan

Wstitanium provides timely manufacturing progress reports and delivery updates for every order I place. Our engineering department’s first choice for casting suppliers. The quality is consistent and reliable, and importantly, the delivery is on time.