5-axis CNC machining

With the ability to manufacture complex geometries and high repeatability, 5-axis CNC machining has become the standard option for high-performance and complex parts. From prototypes to high-volume manufacturing, Wstitanium meets demanding tolerances up to +/- .0001mm. Finishing Services include: painting, plating, precision grinding, powder coating, anodizing, heat treatment, etc.

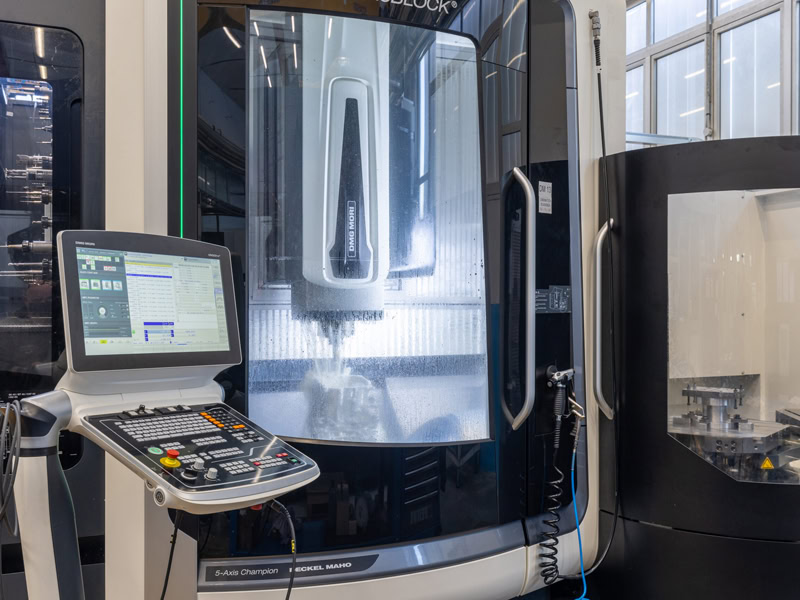

- Invested 5-axis CNC machines from DMG, Germany.

- Simultaneous 5-axis, 3+2-axis CNC machining

- Prototype, Low-Volume Manufacturing

- ROSH Certified Materials Available.

- Full-Size Quality Inspection Report.

WSTITANIUM FACTORY

Our Powerful Facilities

5-axis CNC Machining For Complex Titanium Parts

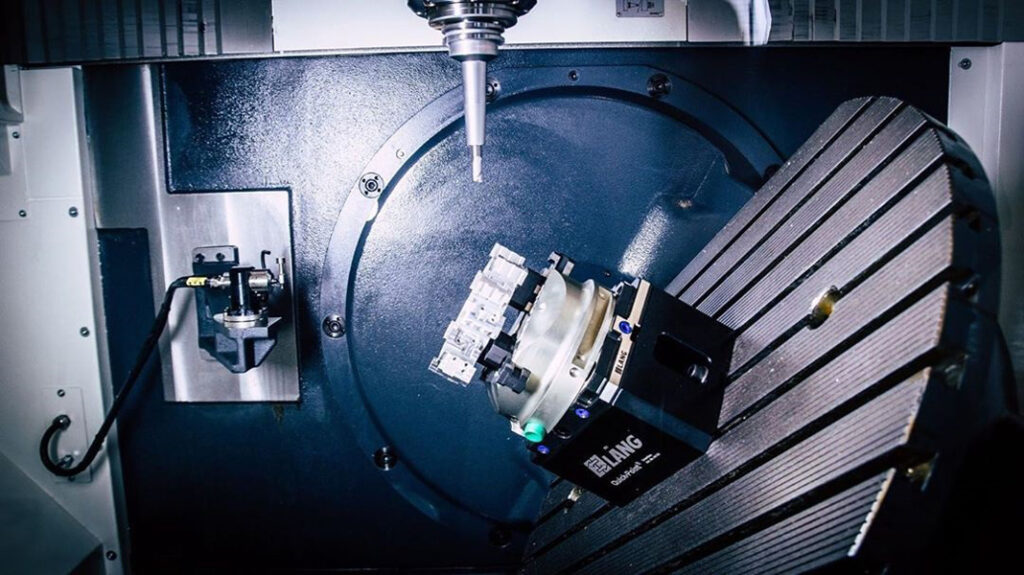

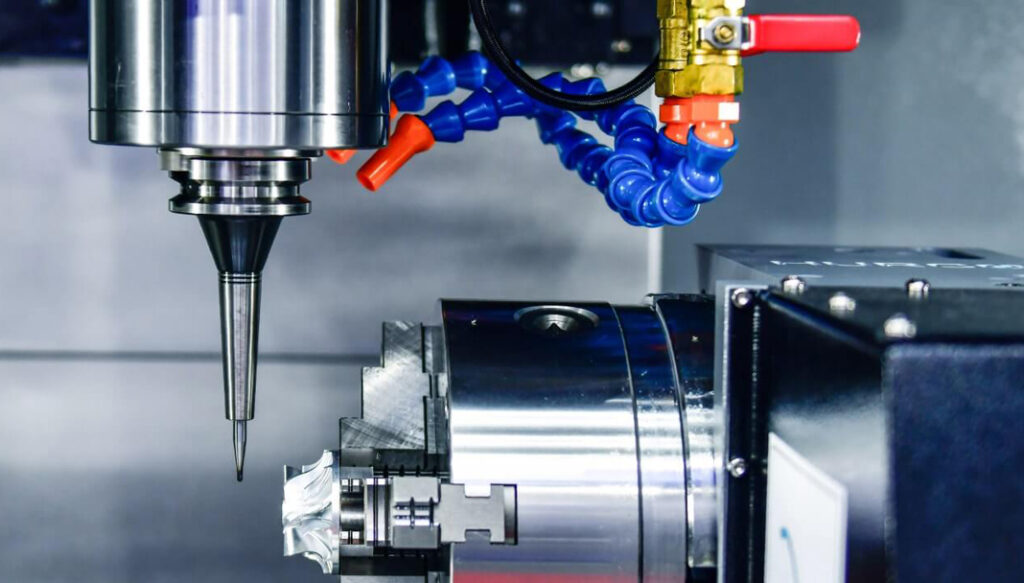

5-axis CNC machines combine multiple independent operations to improve precision due to the additional axes and the excellent mobility of the workpiece to the tool rotation axis, which significantly reduces part handling and multiple clamping stages during milling. The spindle head works closer to the workpiece, allowing the use of shorter cutting tools, less vibration and deflection, higher cutting speeds, tighter tool movement, and higher surface finishing capabilities.

Wstitanium 5-axis CNC Milling Capabilities

Backed by 15 years of experience and unparalleled creativity, Wstitanium has conquered the manufacturing of parts with complex geometries by investing in the most advanced 5-axis CNC machining machines (DMG 85, Multistar™ HSM500, HAAS UMC-750SS) from Germany, Switzerland, and the United States. These state-of-the-art CNC machines allow us to manufacture with speed and precision that exceed customer expectations. Thanks to the quality and automation of CNC machines, Wstitanium reduces the manufacturing time of complex parts by up to 84%. In addition to strong CNC machining capabilities, we are also able to reverse engineer, design or modify parts for their manufacturability.

Simultaneous 5-axis CNC Machining

Fast, Efficient, Simultaneous 5-axis CNC machining provides uninterrupted continuous motion adjustment in all five axes and features intelligent functions to ensure efficient continuous milling processes and fast turnarounds, greatly improving the surface quality of components with complex geometries.

3+2 Axis CNC Machining

When it comes to CNC projects for planes, 3+2CNC machining is very effective and can also achieve the manufacturing of parts with complex contours. However, its speed is inferior to that of the linkage 5-axis CNC machining center. It is worth noting that its machining projects are more cost-effective.

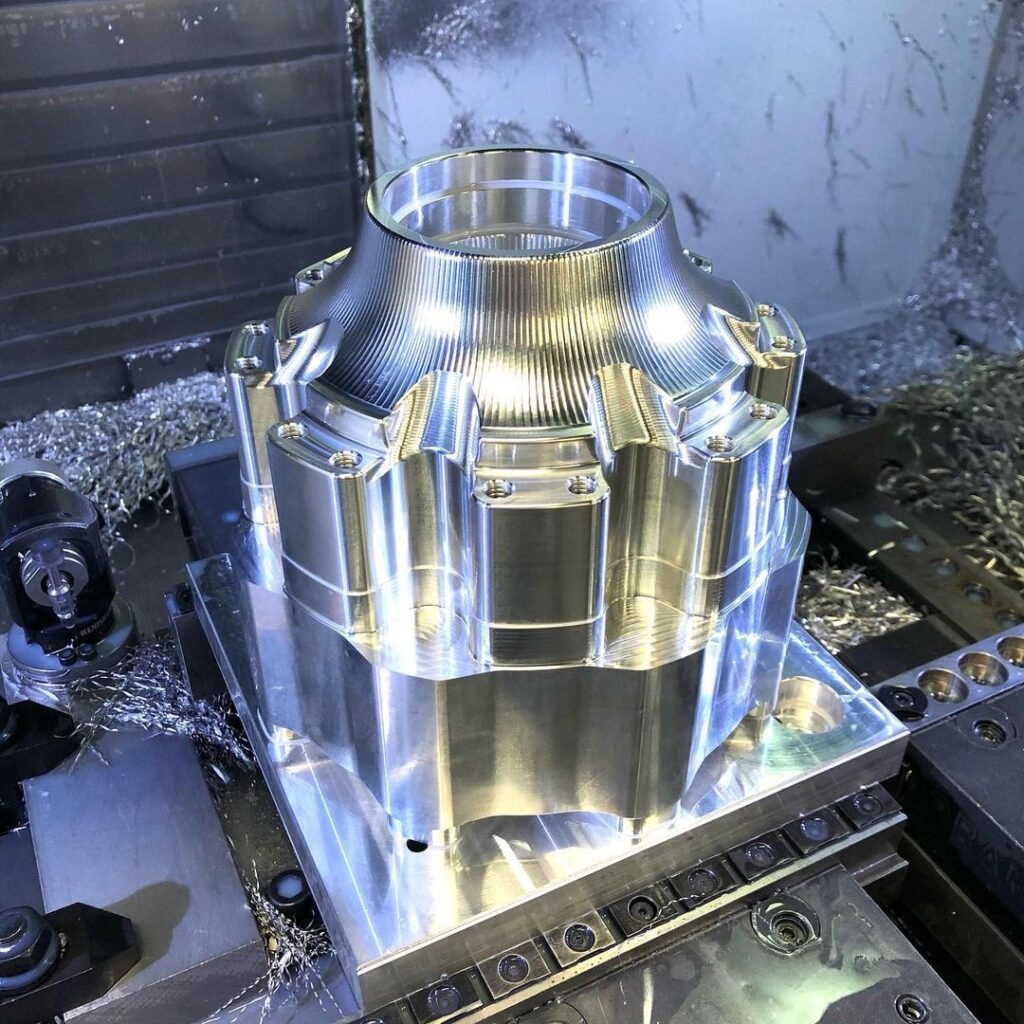

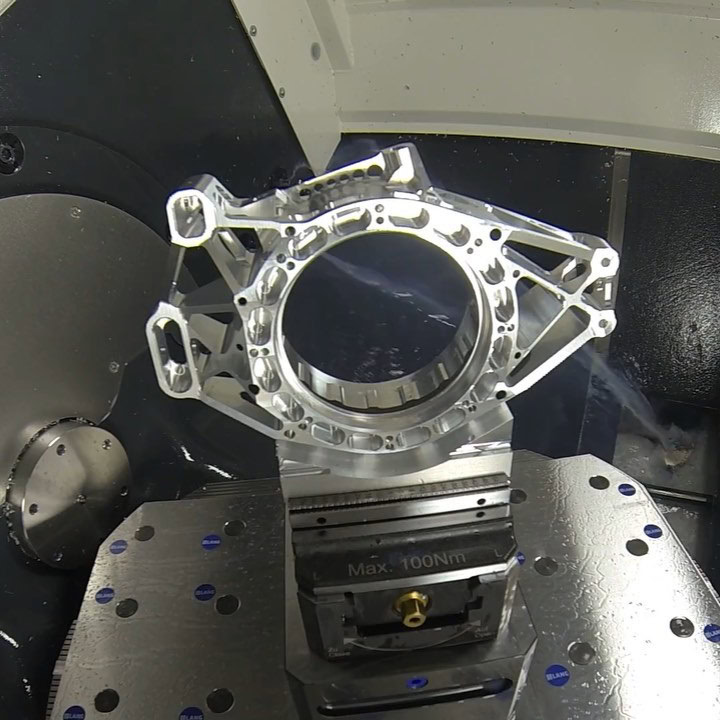

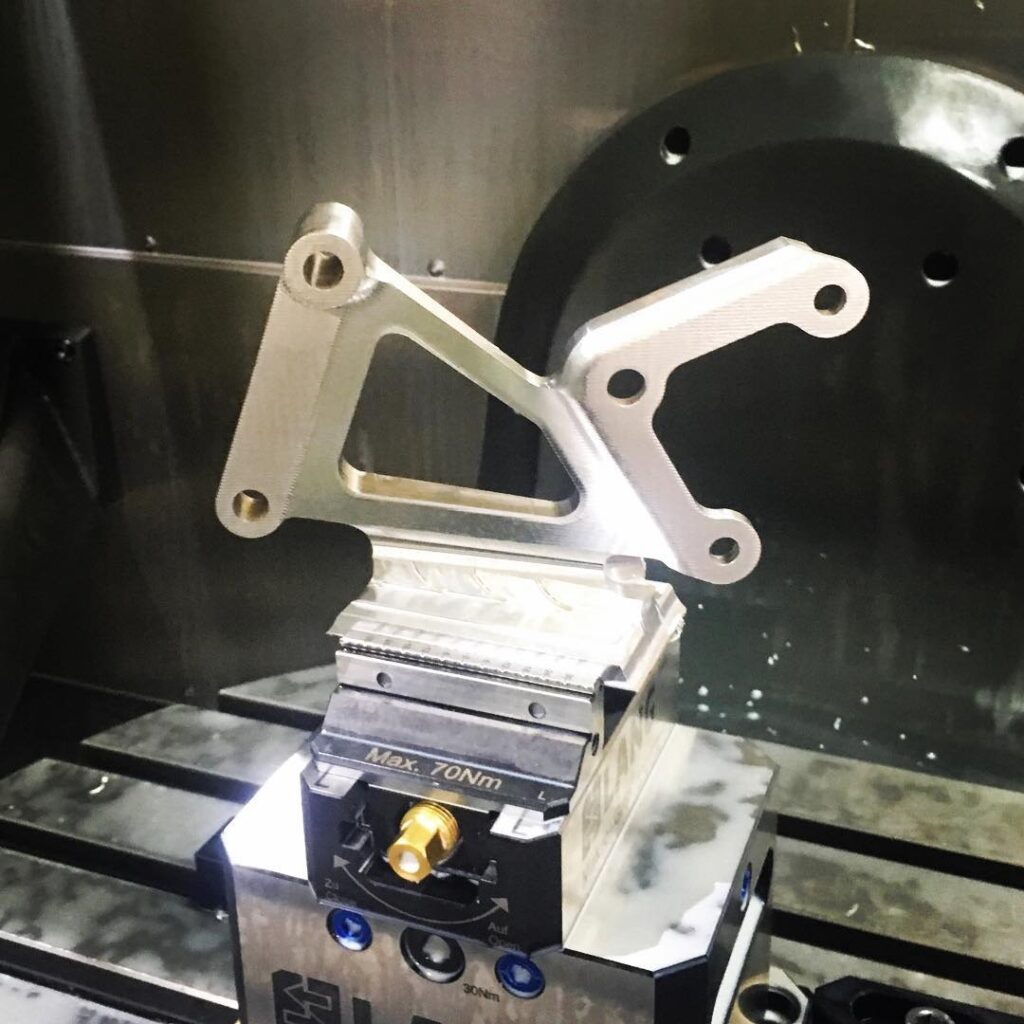

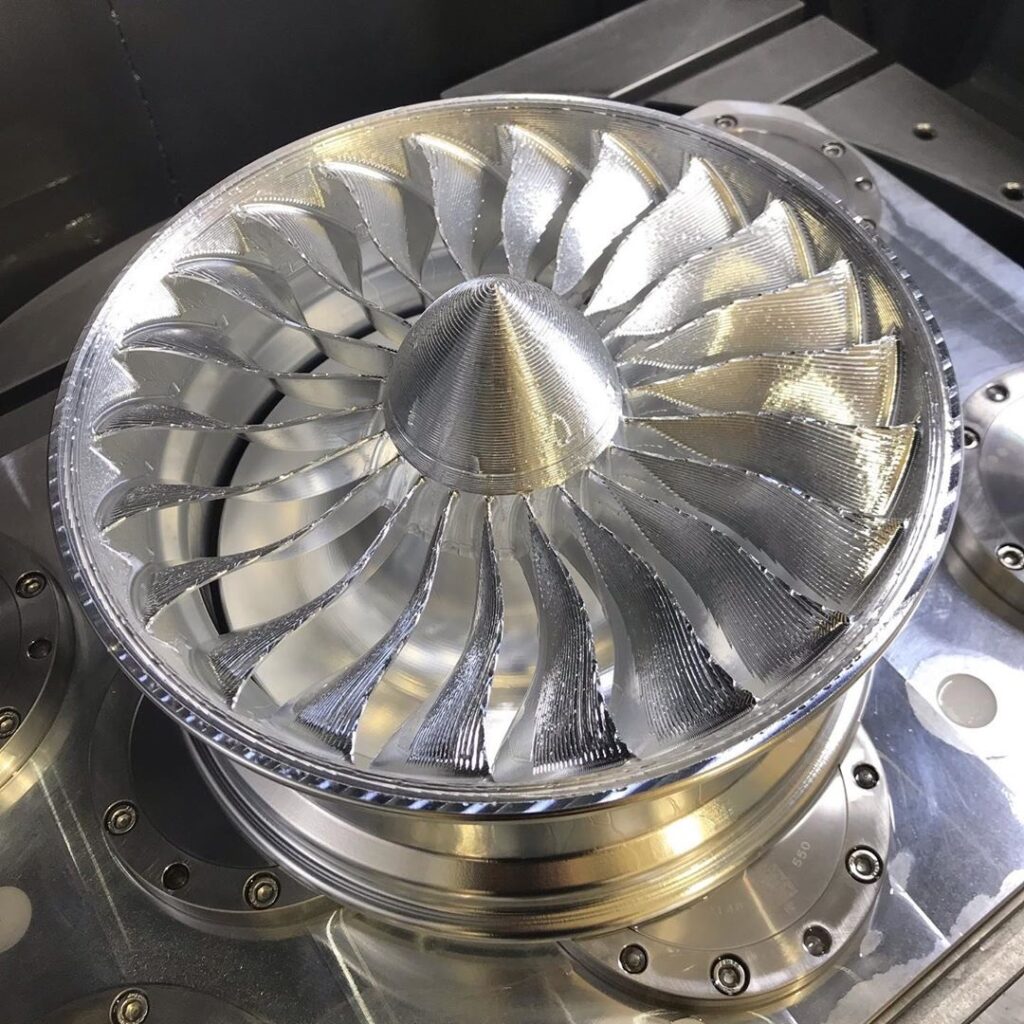

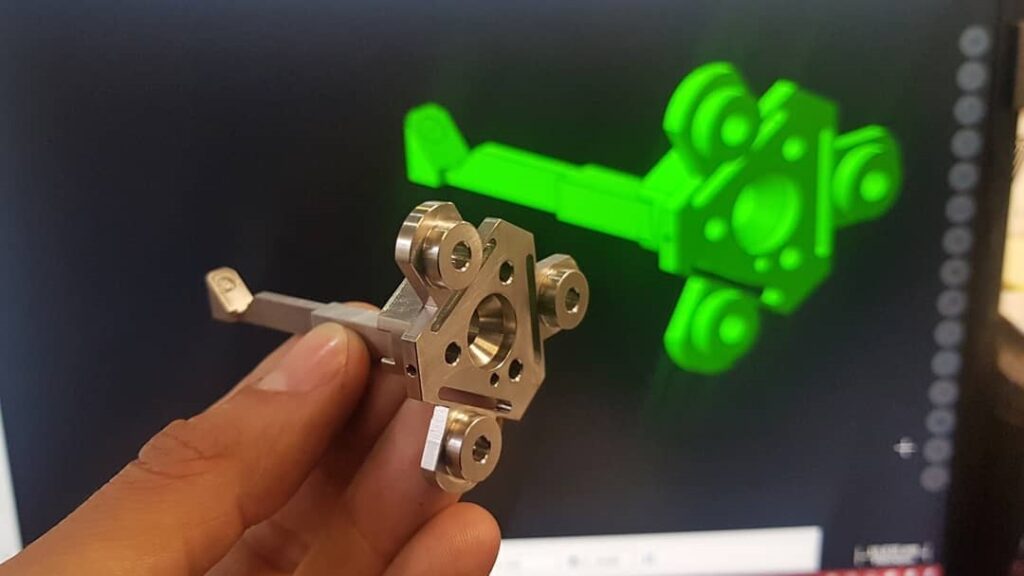

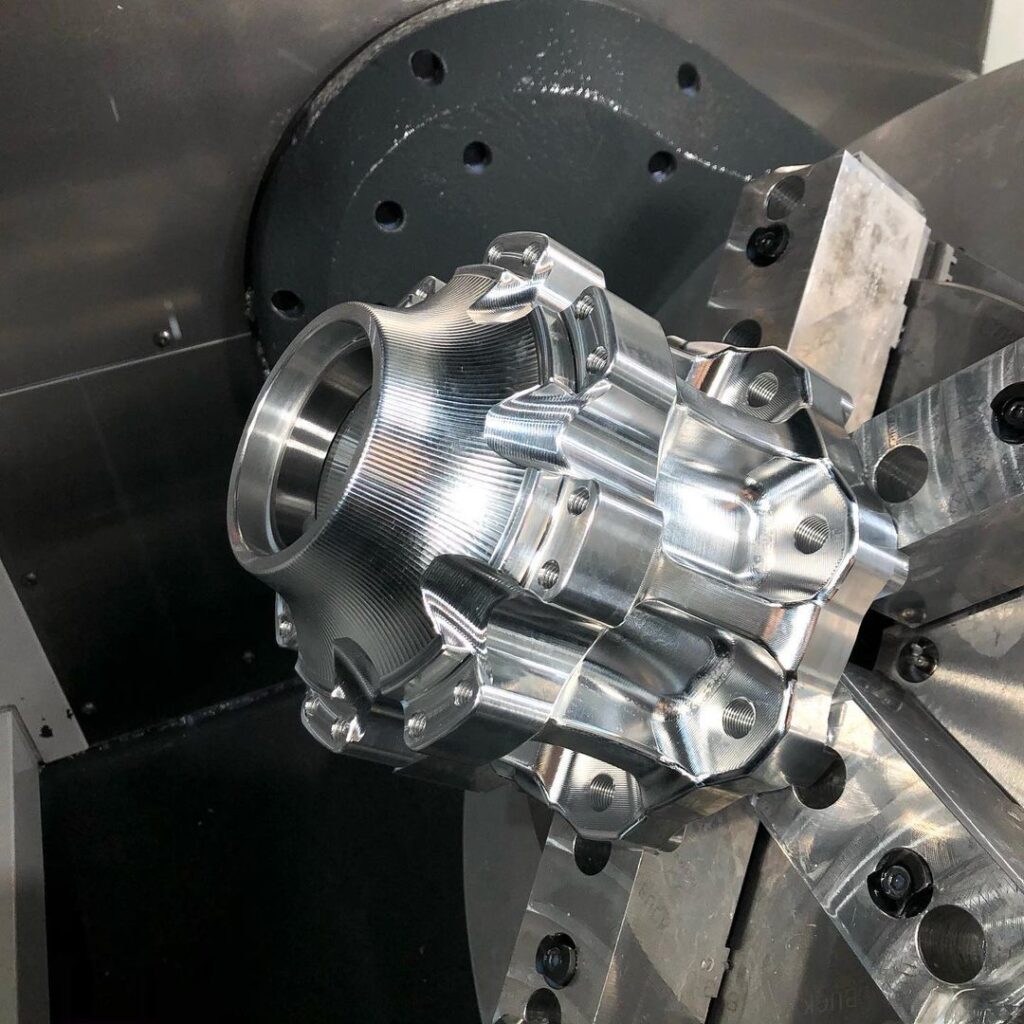

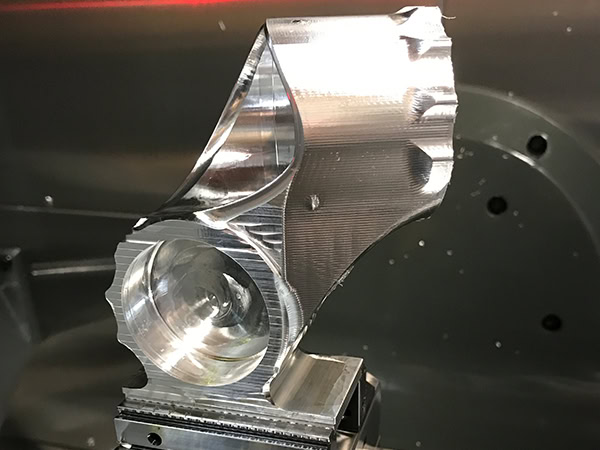

Wstitanium 5-axis CNC Milling Showing

Wstitanium 5-axis CNC Machining Parts

- Maximum Part Size: 3000×1500×600 mm

- Standard Tolerances:Metals: ISO 2768-f

- Minimum Feature Size: +/- 0.02mm

- Minimum Part Size: 2 × 2 × 2 mm

- Linear Dimension: +/- 0.005 mm

- Shaft Diameters: +/- 0.005 mm

Part Types:

Turbines, eccentric axis, multifaceted, irregular, convex, and concave parts

5-axis CNC Machining Process:

Boring, broaching, counterboring, countersinking, cutting, drilling, facing, gear hobbing, internal forming, knurling, milling, parting, pocketing, profiling, reaming, spline, tapping, threading (external, internal), turning (contour, form, taper, straight), and thread milling

Industries Served:

Aerospace, Defense, Energy, Medical Devices, Military, Mining, Optics.

Metal Types: Castings, Forgings, Welds, Billets and Bars

All standard metals, Titanium and all grades of Titanium alloys, all series of Aluminium, Magnesium alloys, Ceramics, Brass, Bronze, Chrome, Copper, Gamma Alloy, Hastelloy, Inconel, Invar, Manganese, Monel, Nickel, Nickel Nitride, Stainless Steel, Stellite, Waspaloy and various super carbides.

5-Axis CNC Machining Part Tolerances

Wstitanium’s 5-axis CNC machining services can help you achieve the tightest tolerances required for non-standard custom parts.

| Linear dimension range(mm) | ||||||||

| Type | Characteristics | 0.5 – 3 | 3 – 6 | 6 – 30 | 30 – 120 | 120 – 400 | 400 – 1000 | 1000 – 2000 |

| Dimension | Length | ± 0.001 | ± 0.002 | ± 0.005 | ± 0.01 | |||

| Diameter | 0.006 | 0.01 | 0.015 | 0.02 | —— | —— | ||

| Angle | ± 0.03 | ± 0.05 | ± 0.15 | —— | ||||

| Form | Straightness | 0.003 | 0.005 | 0.01 | 0.02 | —— | ||

| Flatness | 0.001 | 0.003 | 0.01 | 0.03 | 0.05 | 0.15 | ||

| Circularity | 0.001 | 0.002 | 0.005 | 0.01 | —— | —— | ||

| Cylindricity | 0.003 | 0.005 | 0.01 | 0.05 | —— | —— | ||

| Profile | Profile of a line | 0.005 | 0.02 | 0.05 | 0.1 | 0.15 | 0.3 | |

| Profile of a surface | 0.01 | 0.02 | 0.05 | 0.1 | 0.15 | 0.3 | ||

| Orientation | Parallelism | 0.003 | 0.005 | 0.02 | 0.05 | 0.1 | —— | |

| Perpendicularity | 0.003 | 0.005 | 0.01 | 0.05 | 0.1 | —— | ||

| Angularity | 0.003 | 0.05 | 0.1 | —— | ||||

| Location | Position | 0.01 | 0.02 | 0.05 | 0.1 | 0.2 | ||

| Concentricity | 0.003 | 0.005 | 0.01 | 0.05 | —— | —— | ||

| Symmetry | 0.01 | 0.02 | 0.05 | 0.1 | —— | |||

| Runout | Circular Runout | 0.002 | 0.005 | 0.01 | 0.05 | —— | ||

| Total Runout | 0.003 | 0.005 | 0.01 | 0.05 | —— | |||

Advantages of 5-axis CNC machining

5-axis CNC machining is a leap forward in manufacturing technology. These advanced machines enable cutting of workpieces on five sides (top, front, back, left and right) in a single setup, allowing for unmatched versatility, efficiency and capability. The freedom of motion in all directions offers many advantages over traditional 3-axis CNC machining, including:

Access to Five Sides

Unlike traditional 3-axis CNC mills that primarily operate along the X, Y and Z axes, 5-axis CNC mills access up to five sides of a part (adding A and B rotary axes). This versatility allows for complex workpiece features to be processed from different angles.

Efficiency and Simplicity

The ability to machine multiple sides at different angles simplifies the manufacturing process by reducing setups and eliminating the need for complex fixtures, significantly improving efficiency.

Complex Paths

The heart of 5-axis CNC machining lies in its controller. These advanced CNC controllers drive all five axes simultaneously, enabling the creation of complex tool paths with unparalleled flexibility. For example, they can effortlessly shape organic shapes such as turbine impellers or medical implants.

Superior Surface Finish

During 3-axis or 4-axis CNC machining, a large number of smaller cuts must be made to produce the desired surface finish. The capabilities of 5-axis CNC machines on contoured geometry can produce parts with superior surface finishes.

Applications of 5-axis CNC machining

5-Axis is well known for its ability to manufacture complex parts, such as turbine blades, propellers, or orthopedic and knee implants. 5-axis is also a wise investment if you are looking to reduce the need for highly skilled labor. Honestly, if you are currently looking for custom parts services, there is a good chance that you can achieve more by investing in 5-axis. As an ISO9001:2015 and ISO13485:2016 certified manufacturer, Wstitanium is your best partner because it knows that custom part traceability and batch control are non-negotiable requirements.

Aerospace parts: aircraft engine parts, wings, flight control parts, turbine blades

Automotive parts: engine parts, chassis parts, brake parts, transmission parts

Medical devices: surgical tools, implants, surgical instruments, sensors, medical diagnostic equipment

Energy: turbine parts, power generation equipment parts, gas turbine parts

Electronic parts: electronic equipment housings, heat sinks, connectors, panels

Semiconductor: wafer handling systems, sputtering targets

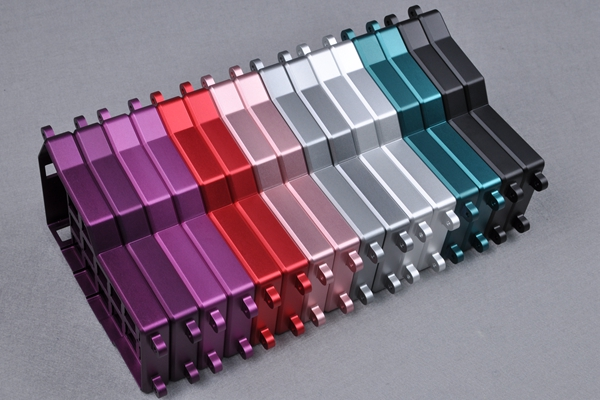

Improve the performance of parts by selecting high-quality surface finishes to improve the roughness, hardness, chemical resistance and appearance characteristics of finished parts. Wstitanium supports high-quality surface treatment requirements, covering sandblasting, oxidation, electroplating, electrophoresis, baking paint, chemical conversion film, passivation, polishing, blackening, etc., and provides adhesion reports such as film thickness, hardness, color, salt spray and other data tests.

5-Axis Machined Parts Gallery