CNC Milling Services

On-demand CNC milling services for prototyping, low volume manufacturing, high volume production. High precision CNC milling services with tight tolerances up to 0.005mm. Competitive pricing with no minimum order quantity,

- ISO 9001:2015, ISO 13485 Certified.

- Tolerances Up to ± 0.005mm

- 100% Quality Guaranteed.

- Global Delivery

Wstitanium Workshop

Our Powerful Facilities

Powerful High Quality CNC Milling Titanium Service

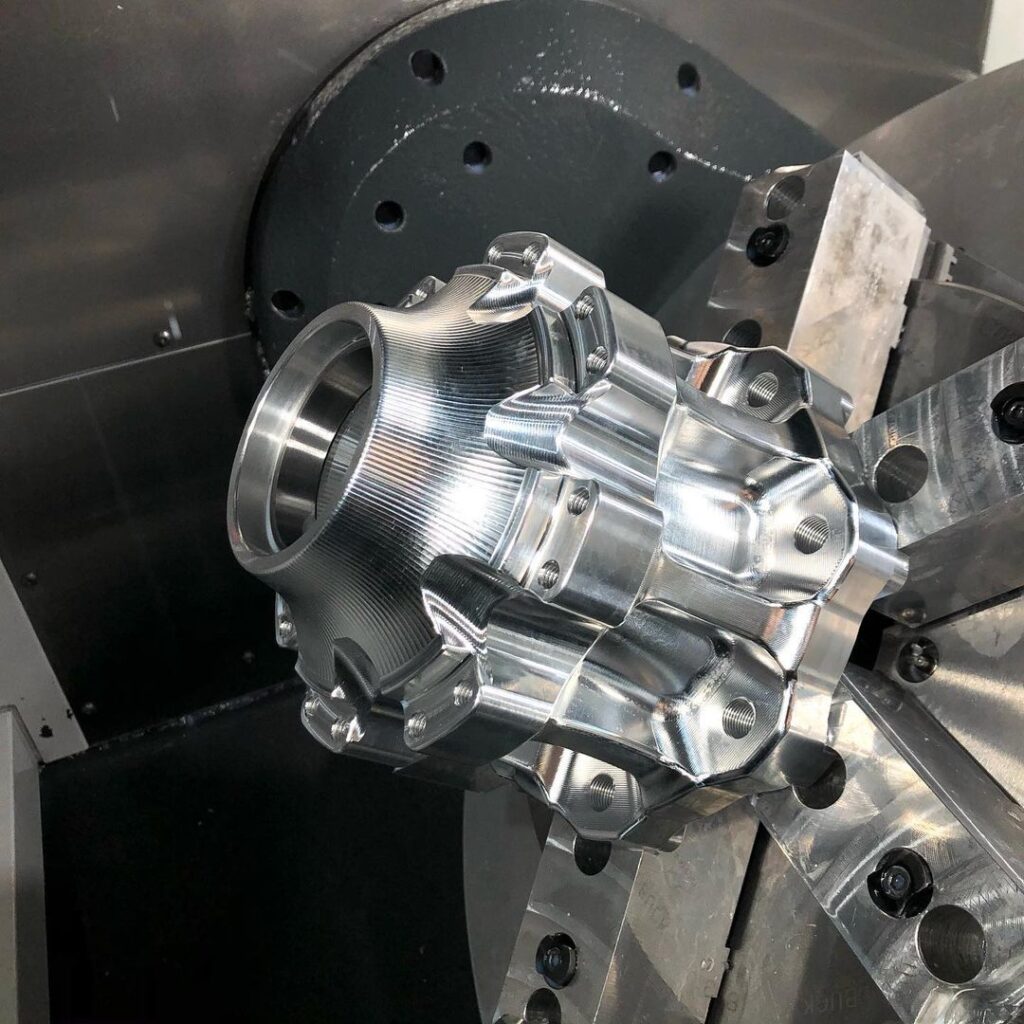

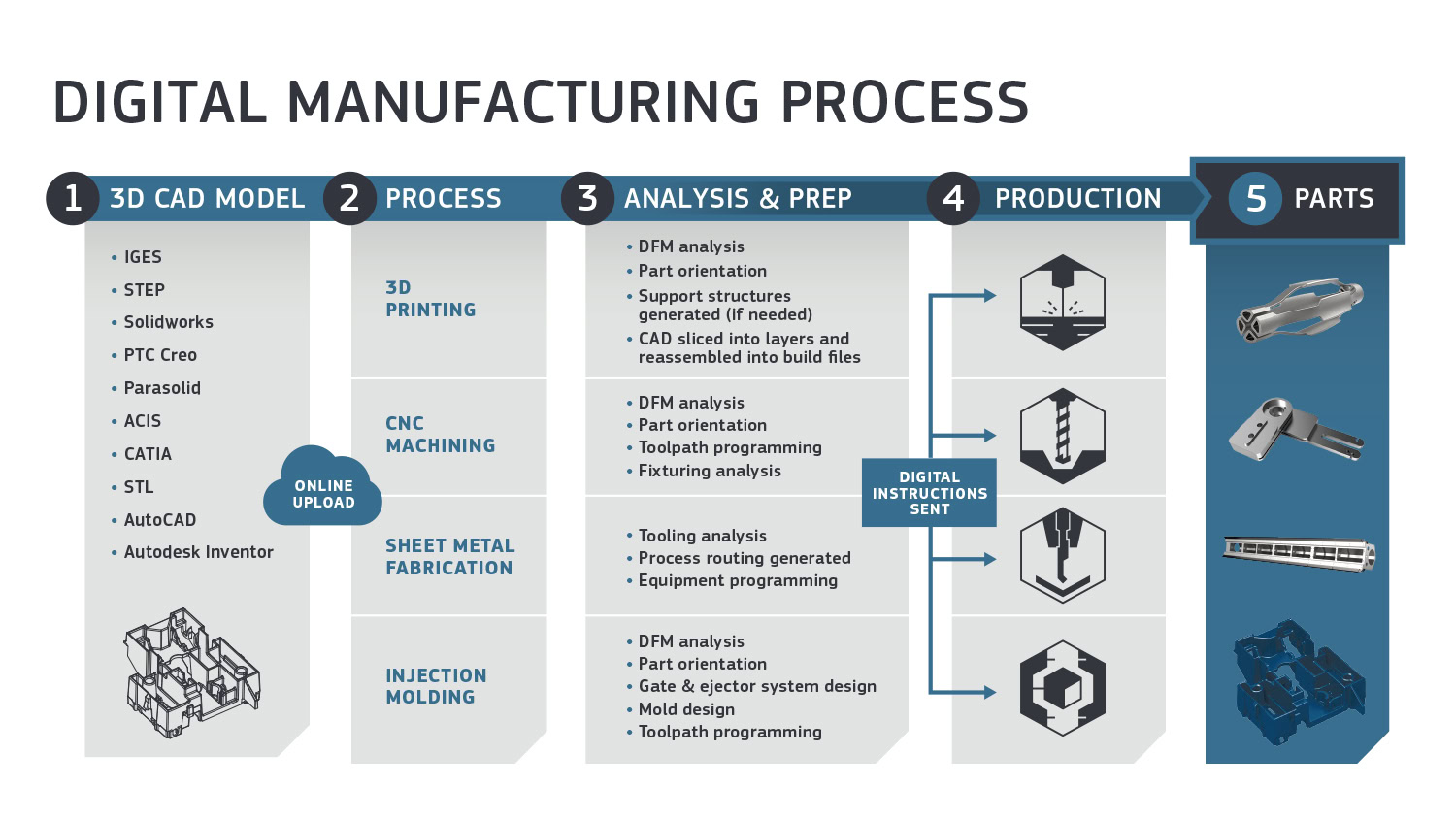

Wstitanium provides custom CNC milling titanium alloy services for engineers, product developers, designers, etc. Wstitanium’s in-house advanced CNC machines, including DMG, HAAS CNC mills and lathes, Hexagon CMMs and Olympus XRF analyzers, are able to guarantee that your CNC project is manufactured with the correct titanium alloy grade and size. Experienced engineers have accumulated rich and deep experience from many CNC machining projects in various industries, which have been formed into in-house white papers. Machinists have the ability to handle any type of close tolerance CNC machined parts with complex geometries. Providing consistent high-quality CNC parts, these parts are fully inspected by the quality control department when ready to ship to ensure that the parts meet specifications and are defect-free, and full-dimensional reports are provided. In-house facilities and qualified manufacturing network have sufficient capacity to provide fast turnaround CNC milling services.

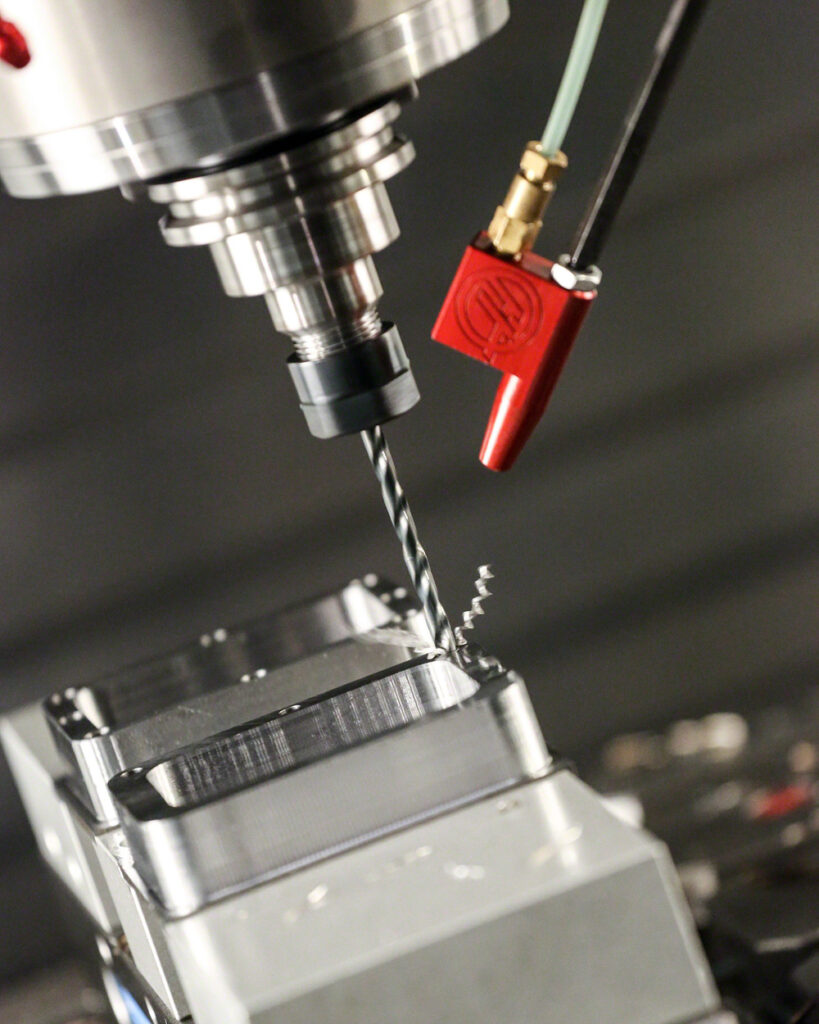

3 Axis CNC Milling

3-axis CNC milling is the most commonly used CNC machine that is both precise and affordable. For simple parts that require precision, it is your economical option.

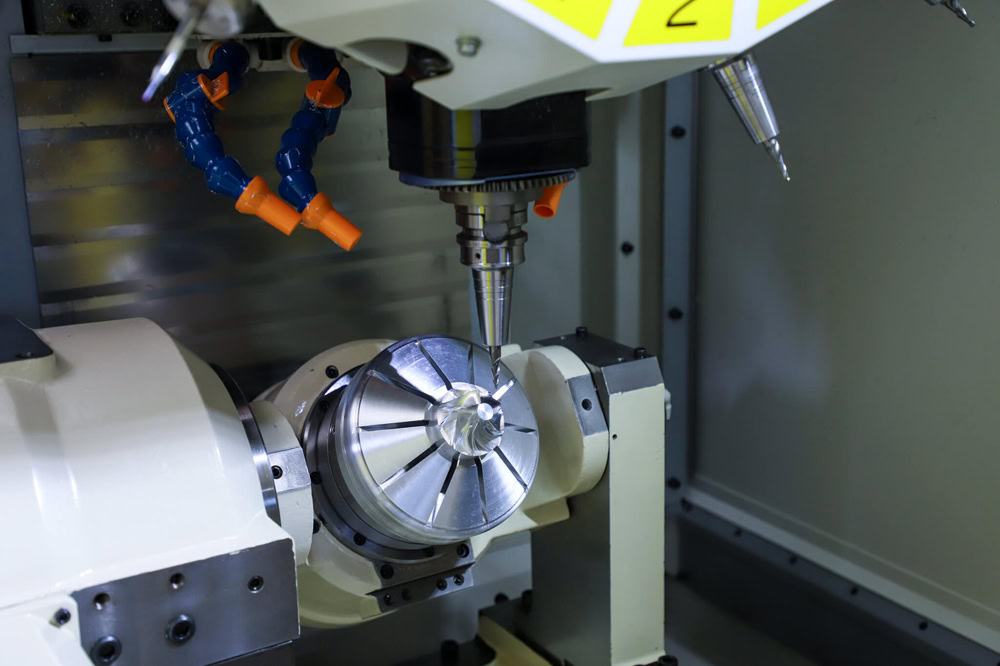

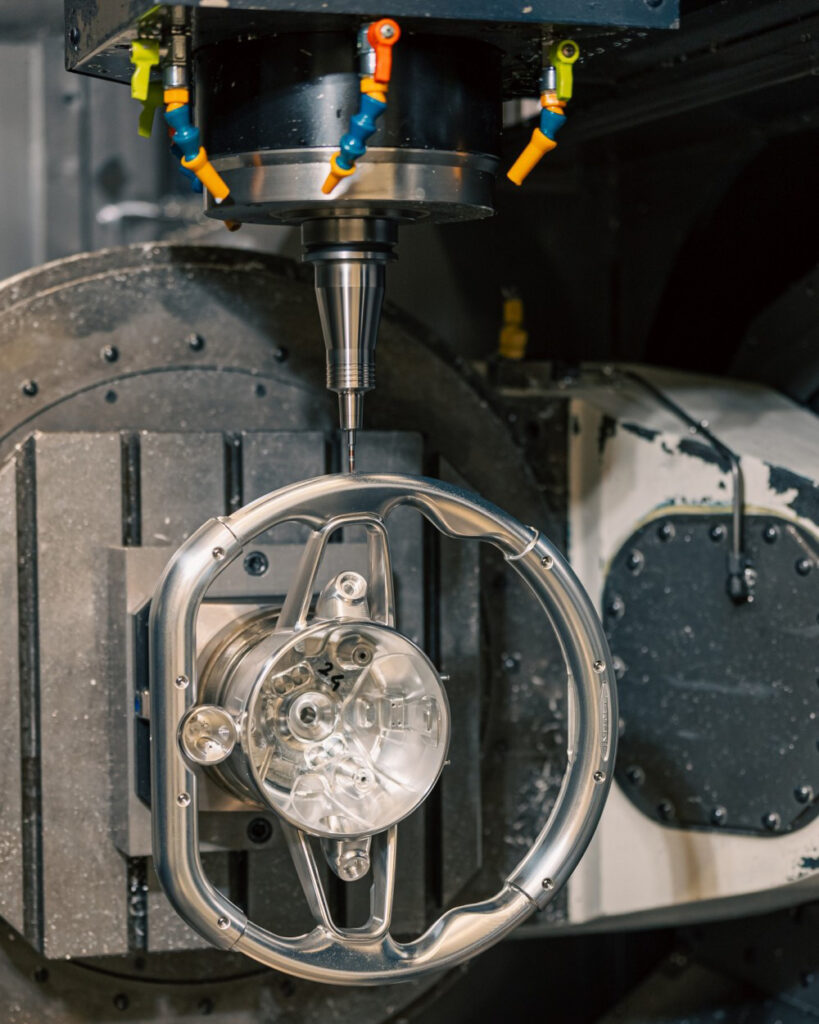

5 Axis CNC Milling

For high-precision, accurate, complex titanium parts with extremely complex geometries. 5-axis CNC milling is the key. Helps you realize ambitious designs with tight tolerances as low as 0.005mm.

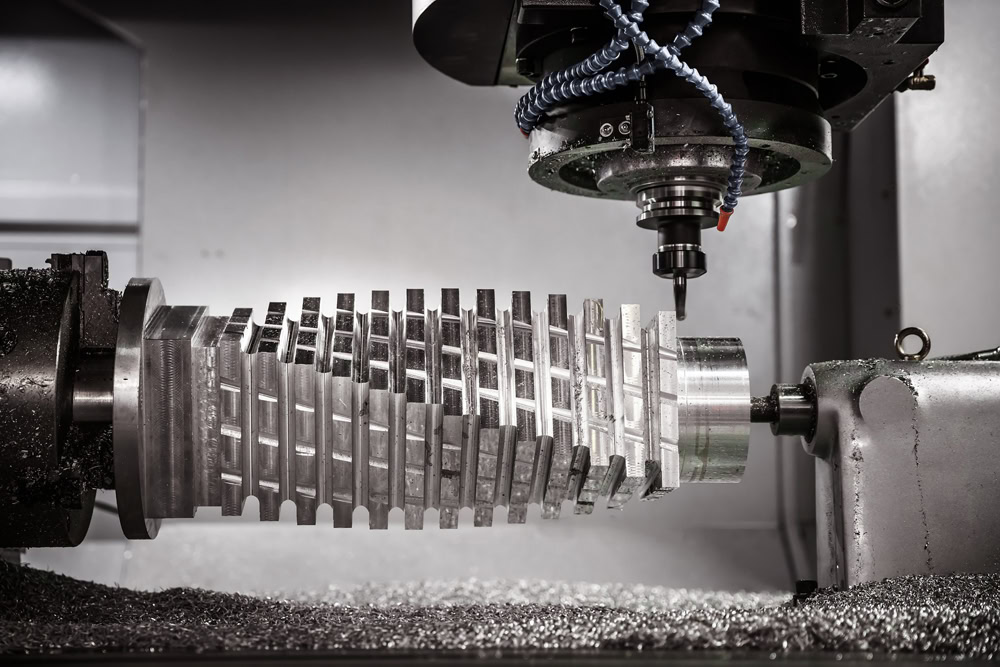

4 Axis CNC Milling

4-axis CNC milling handles a wider range of features than 3-axis milling; manufacturing complex titanium components with fewer setups, higher speeds, and more accurate results.

Dimension & Tolerances for CNC Milling

Wstitanium ensures accuracy in CNC milling tolerance standards. Committed to precise measurement, we provide you with consistent, high-quality results, optimized for search visibility. For those not marked, the standard tolerance for CNC milling metal is ISO 2768-m.

| 3-Axis CNC Milling | 4-Axis CNC Milling | 5-Axis CNC Milling | |

| Maximum Part Size | 1000 x 500 x 500 mm | 1000 x 500 x 500 mm | 4000 x 1500 x 600 mm |

| Minimum Part Size | 5 x 5 x 5 mm | 5 x 5 x 5 mm | 5 x 5 x 5 mm |

| General Tolerances | ±0.01 mm | ±0.005 mm | ±0.01 mm |

| Leading Time | Delivery of simple parts can be as fast as 1 day. | 5 bussiness days for most projects. | 5 bussiness days for most projects. |

CNC Milling Titanium Parts

Titanium and its alloys are widely used in high-tech fields such as aerospace, medical devices and chemicals due to their unique properties, such as high strength, low density and excellent corrosion resistance. However, these properties also make titanium processing, especially CNC milling, face many challenges. In order to effectively meet these challenges and achieve efficient processing, Wstitanium’s investment in dedicated CNC milling equipment has advantages that cannot be ignored.

For example, HAAS VF2SS has extremely high rigidity and structural stability to withstand the huge stress generated during processing and maintain processing accuracy. The DMU 85 5-axis CNC machining center is equipped with an efficient cooling system, such as high-pressure coolant and multi-point spray system, which can quickly remove the heat generated by cutting, extend tool life and improve workpiece quality.

Why Choose Wstitanium For CNC Milling Services

Wstitanium’s in-house CNC machining department and supplier network will smoothly handle your CNC milling project. We provide complete and fast turnkey solutions for your next CNC project. So you can focus on bringing your product to market. If you need a CNC milling company you can trust, Wstitanium is always one of the best choices!

24/7 Engineering Support

Wstitanium engineers provide the most reasonable solutions for titanium part design, grade, surface treatment according to your project requirements.

Precision Tolerances

Follow strict ISO9001 quality management, full dimension and material inspection reports. CNC milled titanium parts are tight to strict tolerances of ±0.005mm.

Fast Turnaround

Wstitanium understands the importance of on-time delivery and has state-of-the-art CNC machines in-house to speed up the manufacturing of prototypes or high-volume parts.

Friendly Service

One-to-one project support service, quick response in as fast as 1 minute, always paying attention to every detail of yours. Excellent customer experience.

Rich experience

Strong comprehensive manufacturing capabilities, including in-house manufacturing and surface treatment, integrating relevant manufacturing resources.

Cost Effective Solutions

Wstitanium is the best "Made in China" supplier you are looking for, providing more cost effective solutions and more competitive prices. This is what customers say.

Popular CNC Milling Titanium Grades

As the demand for titanium becomes more and more popular, there are 10 common millable grades. They differ in the percentage of titanium with other elements, including oxygen, palladium, nickel or molybdenum. Different titanium alloy elements determine that each grade has different mechanical properties. This means that your choice of titanium alloy depends on the application. Check out the table below to learn more about each titanium alloy.

| Grade | Description | Advantages | Disadvantages | Applications |

| Grade 1 Commercially pure titanium with low oxygen content. | One of the most commonly used grades of titanium. It is the most ductile and the softest titanium alloy. | Excellent relative formability and machinability, corrosion resistance, and impact toughness. | Lower strength compared to the other titanium grades. | Chemical processing, desalination, medical industry, automotive parts, airframe structure. |

| Grade 2 Commercially pure titanium with standard oxygen content. | Pure titanium, known as the workhorse of the titanium industry. | High corrosion resistance, good weldability, strength, ductility, and formability. High relative machinability. | Not as strong as other titanium grades, but stronger than grade 1 | Aircraft engines, hydrocarbon processing, chlorate manufacturing, medical industry. |

| Grade 3 Commercially pure titanium with medium oxygen content. | Grade 3 is the least commercially used, but it possesses good mechanical properties. | High strength and corrosion resistance. Good relative machinability. | Less formability than grades 1 and 2. | Medical industry, marine industry, aerospace structures. |

| Grade 4 Commercially pure titanium with high oxygen content. | Known as the strongest of the four commercially pure grades. | Very high strength and corrosion resistance. Okay relative machinability. | Hard to machine, requires slow speeds, high coolant flow, and high feed rates. | Cryogenic vessels, heat exchangers, CPI equipment, surgical hardware, airframe components. |

| Grade 5 Titanium alloy – Ti6Al4V | This is the most commonly used alloy of titanium. It contains 6% aluminum and 4% of vanadium. | High corrosion resistance and high formability. Poor relative machinability. | Less strong than the other alloys. | Critical airframe structures, power generation, marine & offshore applications. |

| Grade 6 Titanium alloy – Ti5Al-2.5Sn | The most commonly used for airframe and jet engine applications. | Good weldability, stability, and strength at elevated temperatures. | Intermediate strength for titanium alloy standards. | Airframe & jet engine applications, liquid gas & propellant containment for rockets and space vehicles. |

| Grade 7 Titanium alloy, sometimes considered “pure” – Ti-0.15Pd | Similar to grade 2, but this one contains small quantities of palladium, enhancing corrosion resistance. | Extremely good corrosion resistance, excellent weldability, and formability. | Not as strong as other titanium alloys. | Chemical processing & production equipment components. |

| Grade 11 Titanium alloy, sometimes considered “pure” – Ti-0.15Pd | Similar to Grade 7, but with a lower tolerance for other impurities. | Excellent corrosion resistance, optimum ductility, and formability. | Even lower strength relative to grade 7. | Marine applications, chlorate manufacturing, desalination. |

| Grade 12 Titanium alloy – Ti0.3Mo0.8Ni | This highly durable alloy contains 0.3% of molybdenum and 0.8% of nickel. | Great weldability, excellent strength at high temperatures, excellent corrosion resistance. | It costs more than the other alloys. | Shell and heat exchangers, hydrometallurgical applications, aircraft & marine components. |

| Grade 23 Titanium alloy – T6Al4V-ELI | Also known as TAV-EIL in the market, which stands for Extra Low Interstitial. It is similar to Grade 5 but with higher purity. | Great ductility and formability, good fracture toughness. Optimum biocompatibility. Poor relative machinability. | Has a lower strength than the other Titanium Alloys. | Orthopedic pins & screws, orthopedic cables, surgical staples, orthodontic appliances. |