Free Forging Titanium Services

No matter what titanium forged product you need, Wstitanium offers better pricing and quality control than the competition. This is because Wstitanium is a manufacturer of titanium raw materials.

- Rods, Rings, Ingots, Discs, Tubes

- ISO13485 ^ ISO 9001 Certified

- 2,000-4,000 Ton Drop Weight

- Invest in Technical Team

- ASTM B381

Wstitanium Workshop

Our Powerful Facilities

Free Forging Titanium Manufacturer

As an important forging process, free forging plays a key role in the manufacture of titanium parts. Titanium and titanium alloys are widely used in many high-end fields such as aerospace, medical, and chemical industries due to their unique properties, such as low density, high strength, good corrosion resistance, and biocompatibility. The free forging process can further tap the performance potential of titanium materials and manufacture parts that meet the needs of various complex working conditions. Wstitanium is a trusted titanium forging service provider in China, committed to providing reliable, high-quality and cost-effective titanium products worldwide. Our extensive product line includes pipes, fittings, rods, bolts, flanges, foils, plates, and wires in various grades, sizes, and shapes.

What is free forging titanium?

Free forging refers to a manufacturing process in which the titanium billet is plastically deformed by impact force or pressure between the upper and lower anvils of the forging equipment to obtain the desired shape and size. During the free forging process, the titanium billet is constrained in contact with the upper and lower anvils, and the rest of the surface can flow freely in all directions, so it is called free forging.

Plastic deformation

Under the action of pressure, the grains inside the titanium billet slip and rotate, causing the grain shape and orientation to change, thereby achieving plastic deformation of the billet. The crystal structure of titanium is close-packed hexagonal (α-Ti) or body-centered cubic (β-Ti). Different crystal structures have different numbers and activation modes of slip systems during plastic deformation, which has an important impact on the forging performance of titanium.

Dynamic recrystallization

When the degree of deformation reaches a certain value and the temperature is high enough, dynamic recrystallization will occur inside the titanium billet, improving the organization and performance of the material. During the free forging process, by reasonably controlling parameters such as forging temperature, deformation speed and deformation degree, dynamic recrystallization can be promoted to obtain a fine and uniform grain structure.

Comparison with other forging processes

Die forging is to put titanium billets into a die with a certain shape for forging, which can produce forgings with complex shapes and high dimensional accuracy. Free forging is more suitable for single-piece, low-volume manufacturing and large forgings. Its equipment and molds are relatively simple and the cost is low, but the dimensional accuracy and surface quality of forgings are not as good as die forging.

Rolling is mainly used to manufacture plates, pipes, etc., and the billets are deformed by continuous rolling to obtain the required shape and performance. Free forging focuses more on manufacturing forgings with irregular shapes and high performance requirements, such as large shaft parts and special-shaped forgings. Rolling has high production efficiency, but is not suitable for manufacturing parts with complex shapes.

Invest in titanium forging facilities and technical team

Wstitanium’s investment in titanium forging equipment is based on accurate insight into market trends and long-term planning for its own development. Only with advanced titanium forging equipment and a technical team can we stand out in the fierce market competition and occupy the commanding heights of the industry.

Vacuum Consumable Arc Furnace

In terms of smelting equipment, Wstitanium invested in advanced vacuum consumable arc furnaces. This equipment can melt titanium in a highly vacuum environment, effectively avoiding the mixing of impurities during the smelting process, and ensuring the high purity and uniformity of titanium ingots. During the operation of the vacuum consumable arc furnace, by precisely controlling parameters such as current and voltage, the smelting process can be precisely controlled, thereby producing titanium ingots with stable quality and excellent performance. This provides a high-quality raw material foundation for subsequent forging processes, and guarantees the quality of titanium products from the source.

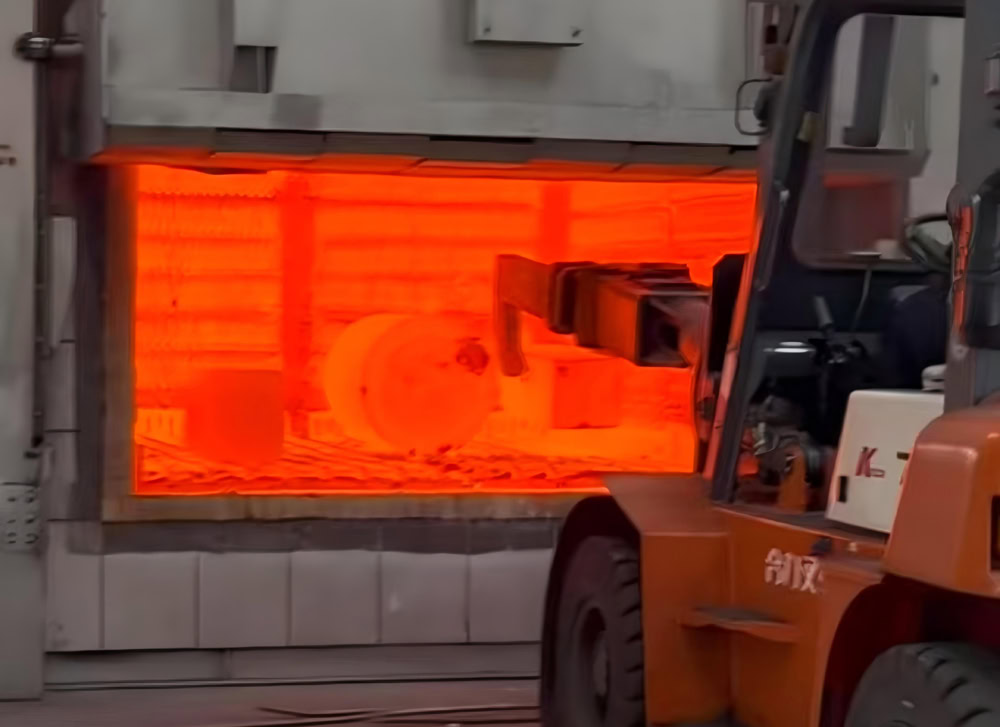

Resistance Furnace

The resistance furnace is one of the commonly used heating equipment for free forging titanium. Its working principle is to generate heat through current through resistance wire, thereby heating the billet in the furnace. The resistance furnace has the advantages of uniform heating and high temperature control accuracy, and can meet the strict requirements of titanium alloy forging for heating temperature. Common resistance furnaces include box-type resistance furnaces and pit-type resistance furnaces, which are suitable for heating small and medium-sized billets.

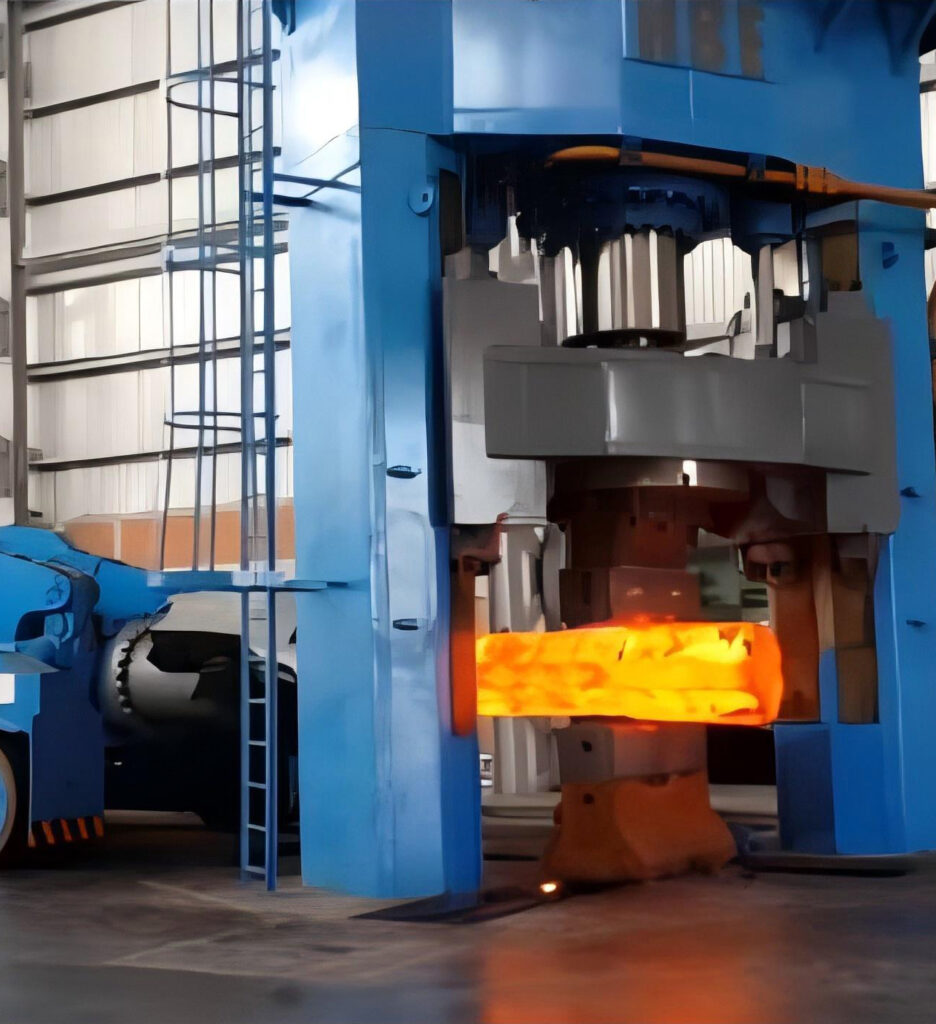

Forging Machines

Forging is a key step in determining the shape and performance of titanium products. Wstitanium has purchased a number of large hydraulic fast forging machines of different specifications, such as 3,000-ton and 6,000-ton hydraulic fast forging units. These equipment have strong forging capabilities and can exert huge pressure on titanium billets, causing them to undergo plastic deformation in a short period of time, thereby obtaining the required shape and dimensional accuracy. The hydraulic fast forging machine is equipped with an advanced automatic control system. Operators can accurately set forging parameters such as forging times, forging pressure, forging speed, etc. through computer programming, thus achieving highly automated and precise control of the forging process.

Heat Treatment Facilities

In order to further improve the internal organizational properties of titanium forgings, Wstitanium has also invested in the construction of advanced heat treatment furnaces. The equipment can accurately control heat treatment process parameters such as heating temperature, holding time and cooling rate according to the characteristics of different titanium alloys and product requirements. Through a reasonable heat treatment process, the internal grains of titanium forgings are refined and the organizational structure is more uniform, thereby significantly improving the comprehensive mechanical performance indicators of titanium products such as strength, toughness and fatigue performance.

Wstitanium Technology Team Investment

Wstitanium not only invested a lot of money to purchase advanced forging equipment, but also paid more attention to the training of technical teams. Further understand the physical and chemical properties of titanium alloys, so that technicians can choose the appropriate titanium grade according to product applications. Fully understand the process of titanium alloy forging, such as the key points and precautions of heating, forging, cooling and other links, and how to control process parameters to ensure product quality, such as the influence of forging temperature, deformation speed, deformation amount and other parameters on the structure and performance of titanium alloys.

Temperature of forging titanium

Precise temperature control is required during titanium forging to achieve the desired material properties. Pure titanium (grades 1-4) is forged at temperatures of 1,200°C to 1,300°C (2,200°F to 2,400°F) to achieve adequate ductility. To achieve a balance of machinability and properties, the most popular titanium grade, Ti-6Al-4V (grade 1) 5), is typically forged at temperatures roughly comparable to pure titanium.

| Titanium Grade | Temperature Of Forging | Titanium Grade | Temperature Of Forging |

| Grade 1 (Commercially Pure) | 2,200°F – 2,400°F (1,200°C – 1,300°C) | Grade 7 (Ti-0.2Pd) | 2,200°F – 2,400°F(1,200°C – 1,300°C) |

| Grade 2 (Commercially Pure) | 2,200°F – 2,400°F (1,200°C – 1,300°C) | Grade 26 (Ti-6Al-4V ELI with 0.25% Pd) | 2,100°F – 2,300°F(1,150°C – 1,250°C) |

| Grade 3 (Commercially Pure) | 2,200°F – 2,400°F) (1,200°C – 1,300°C) | Grade 23 (Ti-6Al-4V ELI) | 2,100°F – 2,300°F (1,150°C – 1,250°C ) |

| Grade 4 (Commercially Pure) | 2,200°F – 2,400°F (1,200°C – 1,300°C) | Grade 9 (Ti-3Al-2.5V) | 2,100°F – 2,300°F( 1,150°C – 1,250°C) |

| Grade 5 (Ti-6Al-4V) | 2,200°F – 2,400°F (1,200°C – 1,300°C) | Grade 29 (Ti-6Al-4V ELI with 0.8% Mo) | 2,100°F – 2,300°F( 1,150°C – 1,250°C) |

| Grade 12 (Ti-0.3Mo-0.8Ni) | 2,200°F – 2,400°F ( 1,200°C – 1,300°C) |

Popular Forged Titanium Products

Free forging can better improve the internal structure of titanium materials, making the grains refined and evenly distributed, thereby significantly improving the overall performance of the product. Free forging has high flexibility and can produce titanium products with complex shapes and various sizes. From basic titanium ingots to various types of titanium rods, titanium plates, titanium tubes, titanium shafts, titanium flanges, etc., these free-forged titanium products are widely used in aerospace, medical, energy, chemical industry and many other fields.

Free-forged titanium rods have excellent strength and toughness. Their internal structure is uniform and they perform well when subjected to complex stresses such as tension, compression and torsion.

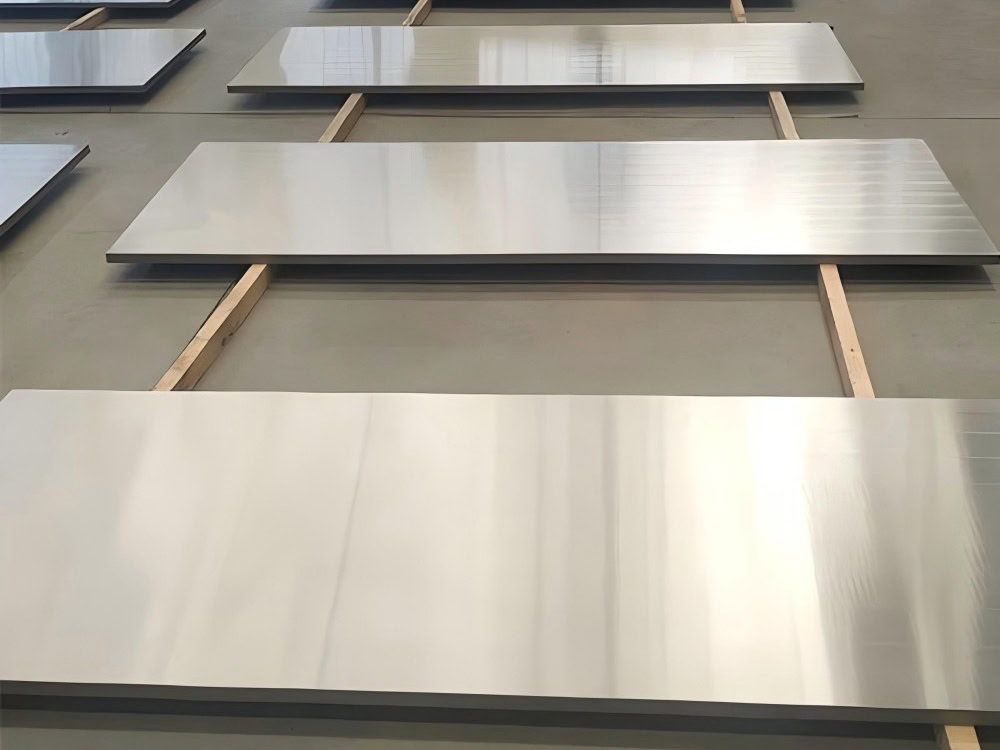

Free-forged titanium plates have good flatness and surface quality. Their thickness can be flexibly adjusted according to demand.

Free-forged titanium ingots have dense internal structures and uniform composition. High-quality titanium ingots lay a solid foundation for subsequent manufacturing.

Free-forged titanium tubes have excellent corrosion resistance and pressure bearing capacity. They are widely used in the marine and chemical industries to effectively prevent safety accidents and environmental pollution caused by pipeline leakage.

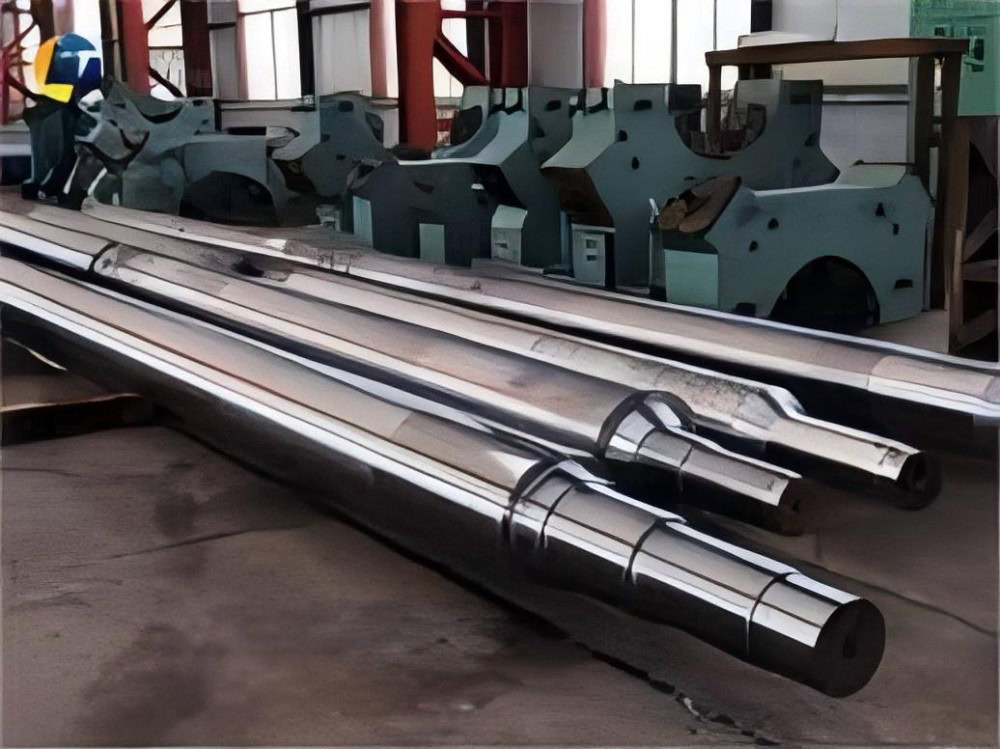

Titanium shafts

Free-forged titanium shafts have high precision, high strength and good stability. In high-end mechanical equipment, such as the spindle of precision machine tools, titanium shafts can maintain extremely low vibration and noise at high-speed rotation to ensure processing accuracy.

Free-forged titanium flanges have good sealing performance and connection strength. In the pipeline connection system, the titanium flange is tightly connected to other pipeline components by bolts to ensure the sealing and stability of the pipeline system.

Quality Inspection

Free forging titanium is a complex processing process. In order to ensure the quality of free forged titanium parts, a series of testing equipment is required. Common testing equipment includes hardness tester, spectrometer, metallographic microscope, ultrasonic flaw detector, X-ray flaw detector, etc., which are used to detect the hardness, chemical composition, metallographic structure, internal defects, etc. of forgings.

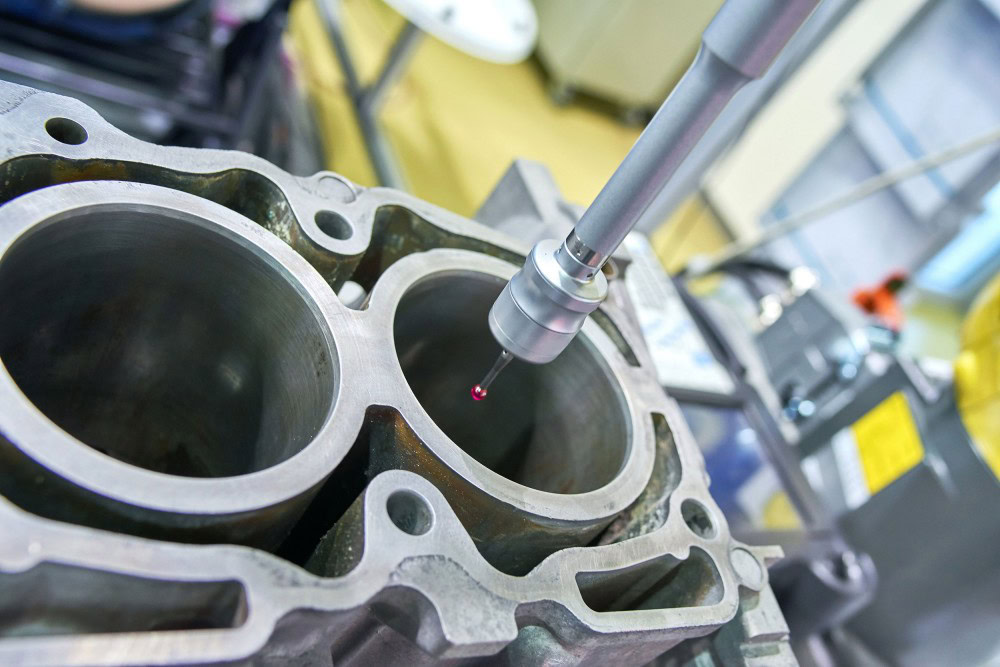

Dimension inspection

First, the shape and size of the titanium forgings are inspected. Use calipers, micrometers, templates and other tools to measure the key dimensions of the forgings such as length, width, height, diameter, etc. to ensure that they meet the design requirements of the drawings. For forgings with complex shapes, such as parts with curved surfaces or special contours, a three-coordinate measuring machine is required to accurately measure their geometry and check whether there are shape deviations caused by forging defects.

Ultrasonic Flaw Detection

Ultrasonic flaw detectors emit high-frequency ultrasonic waves. When ultrasonic waves encounter internal defects such as pores, inclusions, cracks, etc., reflection and refraction will occur. The flaw detector receives these reflected signals and determines the location, size and nature of the defects based on parameters such as signal strength and time. This method can detect tiny defects deep inside the forgings and causes less damage to the material.

Metallographic Structure Analysis

Metallographic analysis of titanium forgings is carried out to observe the grain size, shape, grain boundary state and the presence of second phase structure of titanium under a microscope. Normal free forging titanium should have uniform and fine grain structure, and excessively large grains may affect the mechanical properties of the material. The quality of forgings can be judged by metallographic structure analysis.

Tensile test

Tensile test refers to stretching titanium forgings on a testing machine to measure its yield strength, tensile strength, elongation and cross-sectional reduction. Yield strength reflects the critical stress at which titanium parts begin to undergo plastic deformation. Tensile strength is the maximum tensile stress that the material can withstand, and elongation and cross-sectional reduction indicate the plastic deformation capacity of the material.

In today’s highly competitive industrial market, finding a trustworthy titanium forging service company is a key decision for many companies regarding product quality, production efficiency and long-term development of the company. Wstitanium stands out with its profound background, advanced technology, excellent quality control and comprehensive quality services in the field of titanium forging, and has become the only trustworthy choice in the minds of many customers.