Titanium Rivets Manufacturer and Supplier In China

Wstitanium is a Chinese titanium rivet manufacturer with many years of rich experience and excellent technical strength in the field of titanium machining to meet the strict requirements of different industries for connecting parts.

- Shoulder Rivets

- Semi-Tubular Rivets

- 24/7 Online Service

- DIN、GB、ANSI、ISO、JIS

- Solid Rivets

- Over 100,000 Orders

- 10+ Finishing Options

- 15+ Titanium Grade Options

Customized Titanium Rivet Solutions

Wstitanium provides high-quality and high-performance titanium rivet products to customers around the world with its advantages in raw material selection, manufacturing technology, quality control, and application. Whether in aerospace, automobile, shipbuilding, or medical equipment, Wstitanium’s titanium rivets will become your trusted connection solution.

Titanium Rivets With Different Head Types

The round head, flat head, countersunk head, semicircular head, oblate head and crown head titanium rivet heads, each with its unique shape and structure, meet the requirements of connection strength, appearance, sealing performance and other aspects in different application scenarios. In the design stage, accurately determine the head size, optimize the head shape, reasonably design the transition between the head and the rod, and fully consider the influence of surface treatment. Each key point is directly related to the final performance and use effect of the titanium rivet head.

Round Head Titanium Rivet

The head of the round head titanium rivet is hemispherical. Its appearance is smooth and round, which can effectively reduce the resistance of air or fluid. For example, in the aircraft skin and automobile exterior parts in the aerospace field, the round head titanium rivet is subjected to a relatively uniform force during the riveting process, which can better disperse the riveting force and reduce local damage to the connected materials.

Flat Head Titanium Rivet

The head of the flat head titanium rivet is flat and fits tightly with the surface of the connected material. This head form is suitable for applications with high requirements for surface flatness. For example, in the assembly of the housing of electronic equipment, the flat head titanium rivet can make the housing surface smoother. In some structures that need to save space, flat head titanium rivets also have certain advantages and can meet the requirements of compact design.

Countersunk Head Titanium Rivet

The head of the countersunk head titanium rivet is conical, and after riveting, it can be embedded in the surface of the connected material to keep the surface of the connection part flat. Such as the interior of the ship. Countersunk titanium rivets are also widely used in aircraft wings, fuselages and other parts to reduce air resistance. In addition, the conical design of countersunk titanium rivets can also improve the shear resistance of rivets to a certain extent.

Semi-round Head Titanium Rivets

The head shape of semi-round head titanium rivets is between round head and flat head, with a certain curvature, but not completely hemispherical like round head. This head form combines some of the advantages of round head and flat head, which can not only provide a certain degree of beauty, but also fit the surface of the connected material to a certain extent. Such as automotive interior parts, medical device shells, etc.

Oval Head Titanium Rivets

The head of the oval head titanium rivet is wide and flat, with a large contact area. This head form can provide greater load-bearing capacity and is suitable for connection parts that need to bear large loads, such as structural parts of mechanical equipment. The larger contact area of the oval head titanium rivet can also reduce the pressure on the connected material, reduce the risk of local deformation, and improve the reliability of the connection.

Crown Head Titanium Rivet

The top of the crown head titanium rivet is convex, similar to a small hat. This unique head design enables the crown head titanium rivet to provide better sealing performance after riveting, and is suitable for some occasions with high sealing requirements, such as pressure vessels, pipeline connections, etc. In addition, the raised part of the crown head titanium rivet can also enhance the pull-out resistance of the rivet to a certain extent.

Custom Titanium Rivet Solutions

Wstitanium provides you with customized titanium rivet solutions. According to the application, the specific functional requirements of titanium rivets are clarified. This may include load-bearing capacity (such as tensile strength, shear strength), corrosion resistance, high temperature resistance, biocompatibility, conductivity, etc. For example, in the application of automobile engine compartment, titanium rivets need to have good high temperature resistance and vibration resistance; in marine engineering, titanium rivets need to have excellent seawater corrosion resistance.

Open End Blind Rivet

Painted Rivets

Peel Blind Rivet

Structural Bulb Tite Blind Rivet

Anlock Blind Rivet In Bolt

Anlock Blind Rivet Out-Bolt

Bulb Tite Blind Rivet

Hem Luk Rivets

High Strength Blind Rivet

Multi Grip Blind Rivet

Sealed Blind Rivet

Drive Rivet

Wstitanium Manufactures Titanium Rivets

Forging, cold heading, CNC machining and surface treatment work together to ensure that titanium rivets can meet design requirements while having good quality and stability. Different manufacturing technologies have their own advantages and disadvantages. Through reasonable selection and optimal combination, efficient production and high-quality manufacturing of titanium rivet heads can be achieved.

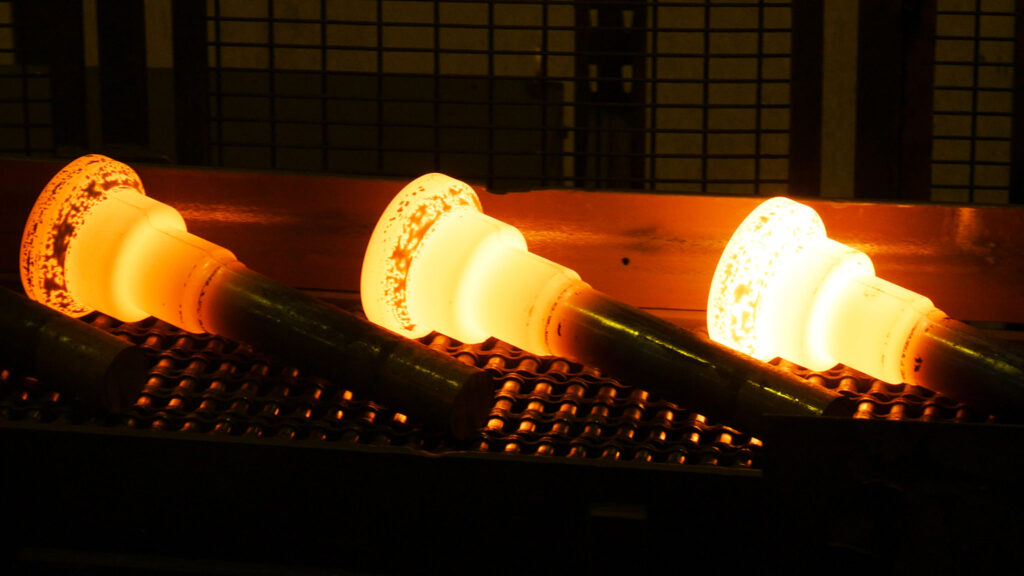

Forging is a common technology for manufacturing titanium rivets, which makes the structure of titanium materials denser and improves its strength and toughness. First, the titanium blank is heated to a suitable temperature, and then pressure is applied to it through a die to cause it to plastically deform and form the desired titanium rivet. Forging can produce titanium rivets of various shapes and sizes, and can ensure their internal quality and mechanical properties. However, the forging process also has some disadvantages, such as low production efficiency and high mold cost.

Cold Heading

Cold heading is a method of making titanium rivets from titanium wire or rod at room temperature. Cold heading has the advantages of high efficiency, low cost and high dimensional accuracy. Pressure is applied to the titanium wire or rod through a die to cause it to undergo plastic deformation in a local area. Cold heading can produce titanium rivets of various shapes, such as round heads, flat heads, countersunk heads, semi-circular heads, oblate heads and crown heads. Cold heading has high requirements for the plasticity of titanium. For some titanium alloys with poor plasticity, appropriate pretreatment, such as annealing, may be required to improve their plasticity.

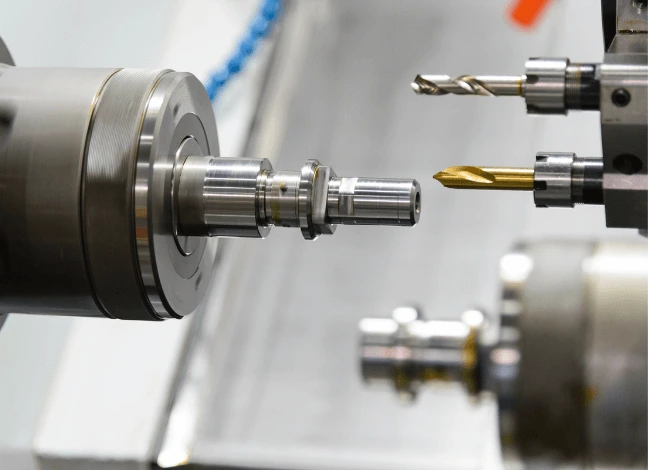

CNC Machining is the manufacture of titanium rivets by cutting to produce high-precision and complex-shaped titanium rivets, which are suitable for applications with high requirements for dimensional accuracy and surface quality. CNC lathes, CNC milling machines, CNC grinders, etc. are usually used to process titanium blanks to form the desired shape. However, CNC machining has low efficiency and high cost.

Surface treatment

Surface treatment is an important technology to improve the performance and aesthetics of titanium rivets. Common titanium rivet surface treatment processes include anodizing, passivation, electroplating, chemical plating, etc. Anodizing is to form a dense oxide film on the surface of the titanium rivet head to improve its corrosion resistance and wear resistance, and it can also be given different colors by dyeing. Passivation is to form a passivation film on the surface of the titanium rivet head through chemical treatment to improve its corrosion resistance. Electroplating and chemical plating are to plate a layer of metal or alloy, such as nickel, chromium, gold, etc., on the surface of the titanium rivet head to improve its corrosion resistance, wear resistance and conductivity. The surface treatment process needs to select appropriate methods and process parameters according to specific application requirements to ensure the effect and quality of the surface treatment.

Titanium Rivet Application

Since aerospace vehicles have extremely high requirements for structural weight, strength, corrosion resistance and high temperature resistance. Titanium rivets can ensure that the connection of aircraft structures is firm and reliable, while reducing the weight of the aircraft, improving flight performance and fuel economy.

The use of titanium rivets in the body structure, engine compartment, chassis and other parts of the car reduces the weight of the car, improves fuel economy and handling performance. At the same time, it improves the strength and rigidity of the car body. In addition, the corrosion resistance of titanium rivets increases the service life.

Shipbuilding

The excellent corrosion resistance of titanium rivets makes it an ideal choice for the shipbuilding industry. The use of titanium rivet heads in parts such as hulls, decks, and cabins can effectively prevent corrosion. At the same time, the high strength and high toughness of titanium rivets ensure the stability and reliability of ship structures.

Titanium rivets are often used to fix fracture sites, connect artificial joints, etc. Its good biocompatibility can be well combined with human bone tissue to promote bone healing. In addition, in the shells and structural components of medical devices, titanium rivets can also improve the corrosion resistance and aesthetics of medical devices.

Electronics

Titanium rivets are used to connect the shells and structural components of some high-end electronic products. Titanium rivets have good conductivity, corrosion resistance and aesthetics. For example, in the shells of mobile phones, tablets, etc., titanium rivets can make the shells more durable.

Architecture

In the curtain walls, decorative lines and other parts of some high-end buildings, the use of titanium rivet heads can increase the beauty and modernity of the building. In addition, the high strength and high toughness of the titanium rivet heads can also ensure the stability and safety of the building structure.