Titanium Anode Application in Water Softening

Wstitanium Custom Manufacturing’s titanium anodes are used in water softening systems. Advanced electrolysis technology effectively processes calcium and magnesium ions, not only providing softer water, but also environmentally friendly.

- Iridium-coated titanium anode

- Platinum-coated titanium anode

- Ruthenium-coated titanium anode

- Mixed oxide-coated titanium anode

- Titanium electrolytic cell

- Palladium-coated titanium anode

- Carbon-titanium composite anode

- Metal-metal oxide composite anode

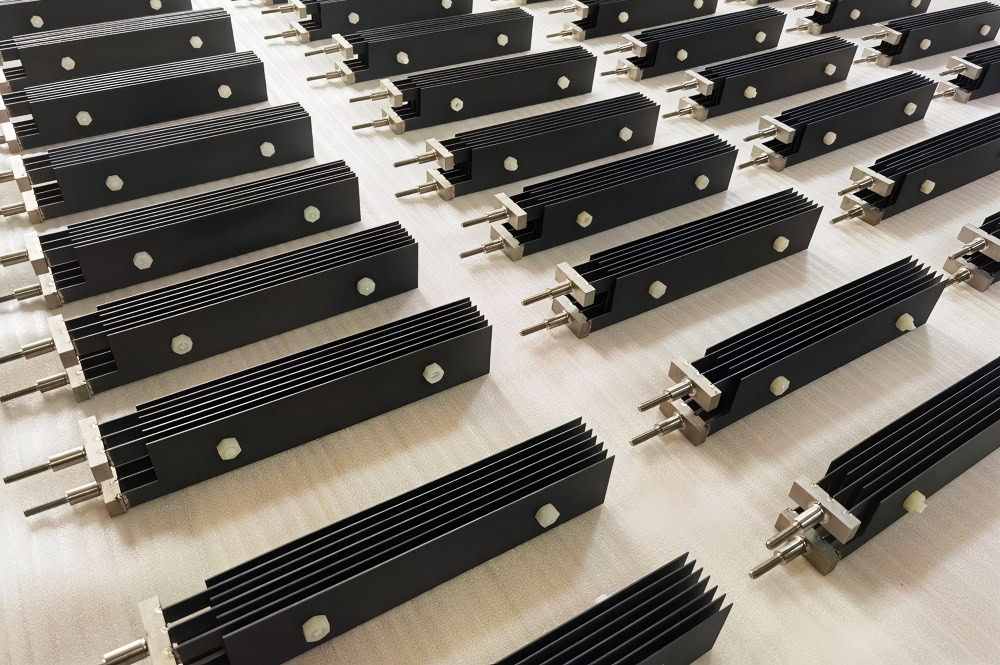

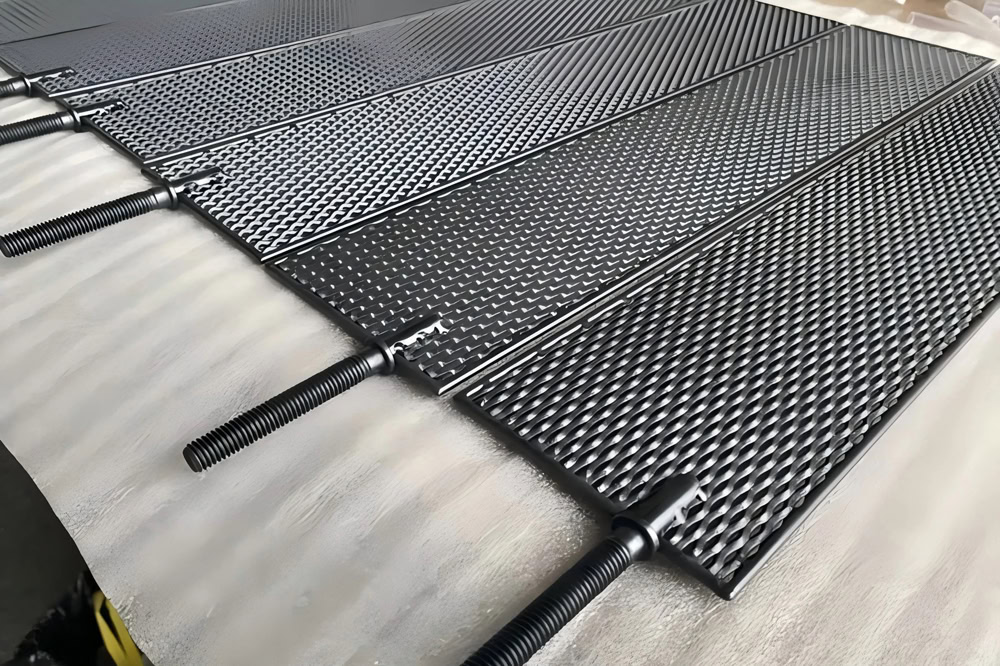

Custome Manufaturing Titanium Anodes for Water Softening Solutions

Electrodes play a key role in water softening technology, and their performance directly affects the efficiency, energy consumption and stability of softened water. Traditional electrodes have problems such as easy corrosion, short life, high energy consumption and high maintenance cost. Titanium anodes have gradually emerged in the field of softened water with their unique performance advantages and have become an ideal electrode material in softened water applications. At Wstitanium, we recognize the inherent complexity of water softening needs. Each application presents unique demands, providing custom solutions. Whether you require a tubular, linear, disc or mesh configuration.

Why soften water?

Hard water contains a large amount of calcium, magnesium and other ions, which are easy to form scale, which not only reduces the heat exchange efficiency and increases energy consumption, but also may cause blockage and corrosion to pipes and equipment, shortening their service life. Therefore, softening water technology came into being. By removing or reducing calcium and magnesium ions in water, the hardness of water is reduced to meet the requirements of water quality in different fields.

Titanium Anode Type

Titanium-based oxide-coated anode is the most common type of titanium anode currently used in water softening applications. It uses titanium as a substrate and achieves specific electrochemical properties by coating a specific metal oxide coating. Commonly used metal oxide coating materials include ruthenium (Ru), iridium (Ir), platinum (Pt) and their mixtures.

Ruthenium-coated titanium anode performs well in the chlorine evolution reaction, quickly oxidizing the chloride ions in the water, and the generated chlorine reacts with water to generate hypochlorous acid and hydrochloric acid. Hydrochloric acid reacts with calcium carbonate, magnesium carbonate, etc. in the water to dissolve them, thereby reducing the hardness of the water. The life of this type of anode generally ranges from several years to ten years.

Iridium-coated titanium anode has excellent corrosion resistance, especially in highly oxidizing environments. It effectively catalyzes the oxidation of water molecules to generate hydroxyl radicals. Free radicals have strong oxidizing properties, oxidizing and decomposing organic matter in water, and can also oxidize heavy metal ions into a high-valent state that is easier to precipitate, achieving the dual purpose of softening and purifying water.

Platinum coated titanium anode has extremely high chemical stability and electrocatalytic activity, and has good catalytic effect on a variety of redox reactions. It is used in some high-precision electrolysis, such as in laboratory research. It quickly catalyzes the discharge of hydrogen ions and hydroxide ions in water, promotes chemical reactions in water, and thus achieves the purpose of softening water. The disadvantage is that the cost is high.

Palladium-coated titanium anode

Palladium-coated titanium anode has unique catalytic properties for the oxidation and reduction reactions of hydrogen. Palladium-coated anode plays an important role in softening water where oxidizing substances are removed from water by electrochemical reduction. Palladium-coated anode is suitable for softening water scenarios with high water quality requirements and containing oxidizing substances.

Mixed oxide-coated anodes combine the advantages of multiple metal oxides and obtain more optimized electrocatalytic performance and stability by rationally adjusting the proportions of different oxides. For example, mixing ruthenium oxide and iridium oxide and coating them on a titanium substrate can not only improve the electrocatalytic activity of the anode, but also enhance its corrosion resistance.

Carbon-titanium-based composite anode

Carbon materials improve the conductivity of the anode, reduce resistance, and reduce power loss. At the same time, carbon materials also have certain adsorption properties and can adsorb some organic matter and impurities in water. Carbon-titanium-based composites have good application prospects in the softening of industrial wastewater containing more organic matter.

Advantages of Titanium Anode in Water Softening

In addition to achieving the main function of reducing water hardness, titanium anodes can also purify water to a certain extent. As mentioned above, titanium-based oxide-coated anodes produce active substances such as hydroxyl radicals with strong oxidizing properties. These active substances can not only participate in the softening reaction of water, but also undergo oxidation reactions with organic matter, bacteria, viruses, etc. in the water to decompose or inactivate them. At the same time, for bacteria and viruses in water, the strong oxidizing property of hydroxyl radicals can destroy their cell structure and genetic material, achieving the effect of sterilization and disinfection.

- Excellent corrosion resistance

Titanium is a metal with good corrosion resistance. In industrial circulating water softening systems, various chemical agents such as corrosion inhibitors and scale inhibitors are usually added to the circulating water, which may have a certain corrosive effect on the electrode material. Titanium anodes can resist the erosion of these chemicals and dissolved oxygen in this environment.

- High electrocatalytic activity

Metal oxide or precious metal coating has high electrocatalytic activity, which reduces the activation energy of water molecules decomposing into hydrogen ions and hydroxide ions and promotes the generation of hydrogen ions and hydroxide ions. These ions further react with calcium and magnesium ions in the water to form precipitation, thereby achieving the purpose of softening water.

- Long life

For example, in large industrial boiler softening water systems, titanium anodes can work stably for a long time and provide high-quality softened water for boilers. Long service life reduces the frequency of electrode replacement, reduces the downtime caused by electrode replacement, improves continuity and reliability, and is of great significance for the stable operation of industrial production.

- Environmental protection

Titanium anodes do not produce harmful substances during the application of softened water, which meets environmental protection requirements. The titanium anode itself has stable chemical properties, and the coating material on its surface has also been carefully designed and selected. Its environmental performance gives it greater application advantages in the field of softened water.

Titanium anodes have shown strong competitiveness in the field of softened water applications due to their excellent corrosion resistance, high electrocatalytic activity, long service life, environmental protection and many other advantages. Different types of titanium anodes, such as titanium-based oxide-coated anodes, titanium-based precious metal-coated anodes and titanium-based composite anodes, each have unique performance characteristics, and are not only widely used in industrial fields such as electricity, chemical industry, energy and other industries, but also play a greater role in the field of softening domestic water.