The Ultimate Guide to Titanium Heat Exchanger Applications

The emergence of titanium heat exchangers is like a shining new star in the field of industrial heat exchange, bringing new hope and direction to solving problems such as corrosion and complex factories. It inherits the unique physical and chemical properties of titanium, and shows significant advantages over traditional heat exchange equipment in many aspects. It is gradually emerging in various industries and becoming an ideal choice for modern industrial heat exchange.

- Gr.1

- Gr.2

- Gr.3

- Gr.4

- Gr.5

- Gr.7

- Gr.9

- Gr.10

- Gr.11

- Gr.12

- Gr.16

- Gr.17

- Gr.23

- Gr.27

- Gr.29

- Length: up to 16.5 m

- Surface:Polished/Pickling

- Wall Thickness: 0.89 - 5.52 mm

- Standard: ASTM B 338 & ASTM B 861

- Customization available

You Should Know Titanium Heat Exchanger Applications

In the industrial field, heat exchange is a ubiquitous key process. Traditional heat exchangers have gradually exposed many limitations in terms of corrosion resistance, heat exchange efficiency, and adaptability to complex working conditions. Titanium heat exchangers have been widely used in many industries such as chemical industry, seawater desalination, oil and gas, electricity, food and beverage, and pharmaceuticals due to their outstanding advantages such as excellent corrosion resistance, anti-fouling, and low maintenance costs.

Understanding Titanium Heat Exchangers

Titanium heat exchangers are equipment made of titanium or titanium alloy as the main material. Through ingenious structural design, it realizes the effective transfer of heat from hot fluid to cold fluid, thereby meeting the needs of temperature control and heat utilization in different industrial processes. Titanium heat exchangers follow the basic physical law of heat transfer, that is, heat always spontaneously transfers from high-temperature objects to low-temperature objects. In practice, hot fluids (such as high-temperature steam, hot process liquids, etc.) and cold fluids (such as low-temperature water, cooling media, etc.) are guided into the titanium heat exchanger and heat is exchanged through titanium heat exchange surfaces (such as heat exchange tubes, heat exchange plates, etc.). The hot fluid transfers its own heat to the titanium wall, and then the titanium wall transfers the heat to the cold fluid on the other side, so that the temperature of the cold fluid increases and the temperature of the hot fluid decreases, and finally the purpose of heat exchange is achieved.

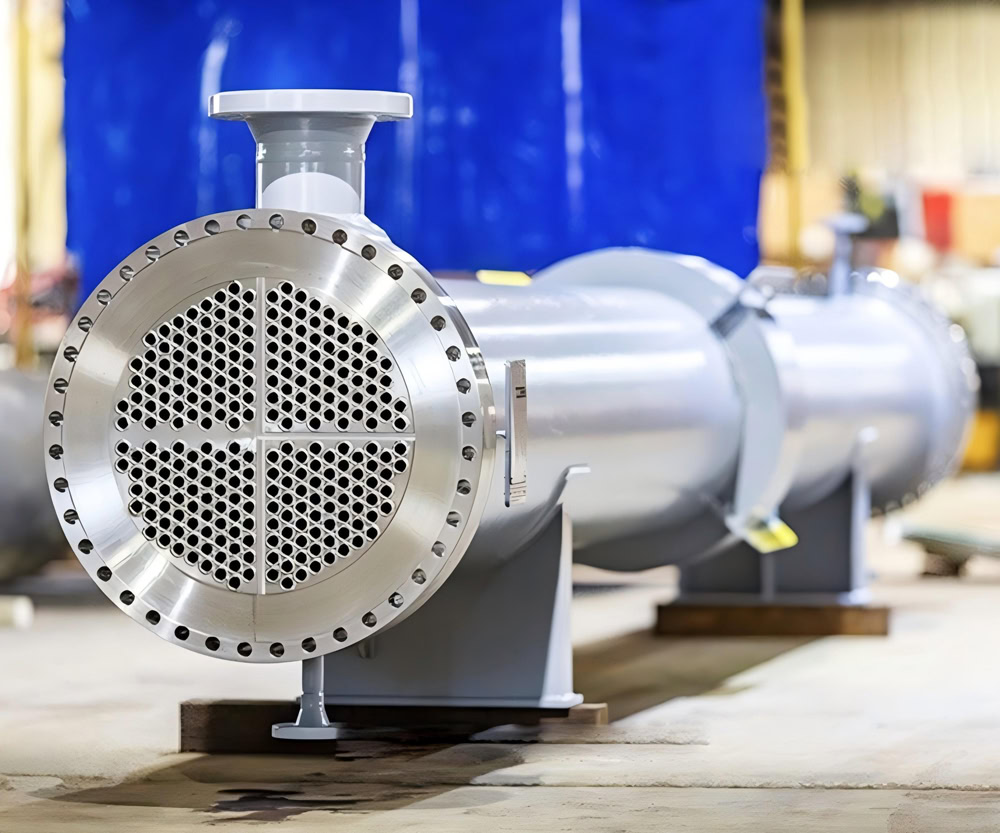

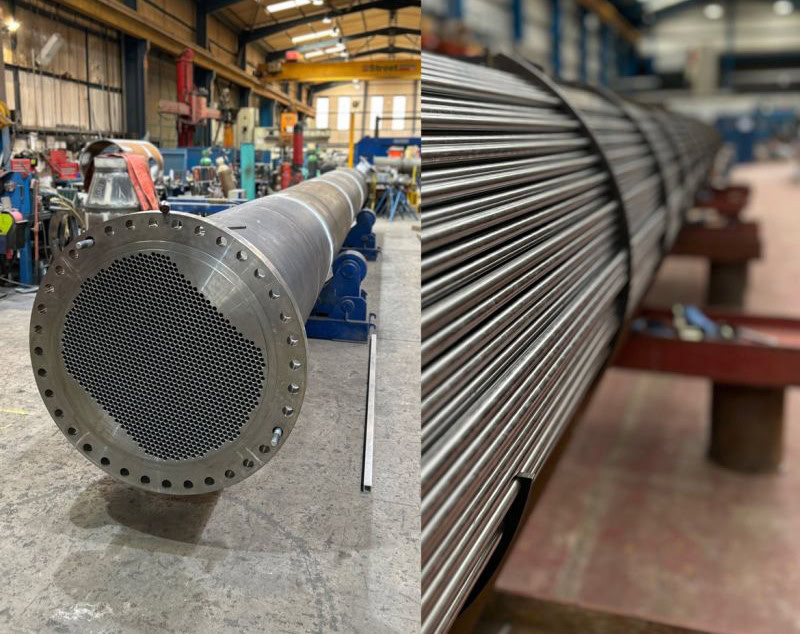

The structural design of titanium heat exchangers is exquisite and diverse to adapt to different application scenarios. Common shell and tube titanium heat exchangers are mainly composed of shells, tube bundles, tube sheets, baffles, etc. The shell is the outer shell that contains the heat exchange process. It is usually made of titanium or titanium alloy and can withstand certain pressure and temperature. The tube bundle is composed of a large number of closely arranged titanium tubes. It is the core area of heat exchange. The hot fluid and the cold fluid flow inside and outside the tube respectively, and heat is transferred through the tube wall; the tube sheet is used to fix the tube bundle to ensure the stable position of the tube bundle in the shell, and at the same time play the role of separating the two fluids; the baffle is set in the shell. Its unique shape and position arrangement can change the flow direction of the fluid, so that the fluid forms a complex flow path in the shell, enhance the turbulence of the fluid, and thus improve the heat exchange efficiency.

In addition to the shell and tube type, there is also a plate titanium heat exchanger. It is composed of a series of titanium plates with special corrugated shapes, and narrow fluid channels are formed between adjacent plates. Hot fluids and cold fluids flow alternately through these channels and exchange heat through the plates. The plate titanium heat exchanger has a compact structure, a large heat exchange area, and high heat transfer efficiency. It is especially suitable for occasions with high space requirements and more delicate heat exchange requirements. Titanium heat exchangers with different structures have their own characteristics and applicable scope. In practical applications, they need to be reasonably selected based on specific process conditions, fluid properties, installation space and other factors.

Titanium Heat Exchanger Application

From corrosive media in the chemical industry, to seawater desalination to deal with seawater erosion, to food and beverage and pharmaceutical industries to ensure product quality and safety, titanium heat exchangers play an irreplaceable and important role.

Chemical Industry

The chemical industry is a field involving many chemical reactions and complex processes. It often needs to handle various highly corrosive media, such as strong acids such as sulfuric acid, hydrochloric acid, and nitric acid, strong bases such as sodium hydroxide and potassium hydroxide, and various salt solutions and organic compounds. These corrosive media place extremely high demands on the materials of heat exchange equipment, and ordinary metal materials are difficult to meet the needs of long-term stable operation.

Titanium heat exchangers have been widely used in the chemical industry due to their excellent corrosion resistance. In sulfuric acid production, from the roasting of pyrite to the catalytic oxidation of sulfur dioxide, to the absorption of sulfur trioxide, each link involves the treatment of high-temperature, highly corrosive gases and liquids. Titanium heat exchangers are used in key parts such as cooling furnace gas, preheating raw gas, and circulating cooling of absorption towers. They can effectively resist the corrosion of sulfuric acid and its vapor, ensuring continuous and stable production.

In the chlor-alkali industry, in the process of electrolyzing salt water to produce chlorine, hydrogen, and caustic soda, there are highly corrosive media such as high-concentration salt water, chlorine, and sodium hydroxide. Titanium heat exchangers play an important role in process links such as brine preheating, chlorine cooling, and alkali liquid concentration. Their corrosion resistance greatly extends the service life of the equipment, reduces the frequency of equipment maintenance and replacement, and reduces production costs.

In organic synthetic chemicals, many reactions need to be carried out under specific temperature conditions, and the reaction medium is often corrosive. For example, in the production of pharmaceuticals, pesticides, plastics, etc., titanium heat exchangers are used to heat or cool reaction materials. While ensuring heat exchange efficiency, they can resist the corrosion of organic compounds and catalysts to ensure product quality and production safety.

Desalination

With the increasing shortage of fresh water resources worldwide, desalination, as an important way to obtain fresh water resources, has received more and more attention. Desalination involves a series of heat exchange operations such as heating, evaporation, and condensation of seawater. Seawater is rich in salt, microorganisms and other impurities, and is extremely corrosive, posing a severe challenge to the material and performance of heat exchange equipment.

Titanium heat exchangers have become the preferred equipment in the desalination industry due to their excellent resistance to seawater corrosion. In distillation desalination, titanium heat exchangers are used to heat seawater to evaporate it and condense steam into fresh water. Because titanium can effectively resist the erosion of seawater, it will not corrode and scale in seawater like ordinary metals, thus ensuring the long-term and efficient operation of the heat exchanger. In reverse osmosis desalination, although the main separation process is achieved through a semipermeable membrane, a heat exchanger is still needed to adjust the water temperature in the pretreatment and post-treatment stages. Titanium heat exchangers can work stably in these stages, ensuring the normal operation of the reverse osmosis system and improving the output efficiency and quality of fresh water.

In addition, the anti-fouling performance of titanium heat exchangers also gives them unique advantages in seawater desalination. Microorganisms and impurities in seawater are difficult to adhere to and breed on the titanium surface, reducing the decline in heat exchange efficiency and equipment clogging caused by dirt accumulation, and reducing equipment maintenance costs and operating risks.

Oil and Gas Industry

The oil and gas industry is a large and complex industrial system. From oil and gas exploration and production to transportation, processing and storage, heat exchange equipment is indispensable in all links. In the production of oil and gas, it is often necessary to deal with oil and gas mixtures containing corrosive media such as hydrogen sulfide, carbon dioxide, and brine. In oil refining and chemical industry, various high-temperature, high-pressure, and highly corrosive process fluids are involved.

In the wellhead equipment and gathering and transportation systems of oil and gas production, titanium heat exchangers are used to cool high-temperature oil and gas mixtures to prevent equipment from being damaged due to overheating, and can resist the corrosion of hydrogen sulfide and brine. In refineries, titanium heat exchangers are used in many key parts such as crude oil preheating, top condensation of fractionating towers, and cooling of hydrogenation reactors. Titanium heat exchangers can not only withstand high temperature and high pressure working conditions, but also effectively resist the erosion of corrosive substances such as sulfides and cyclohexane acids in crude oil, ensuring the efficient and stable progress of the refining process.

In the natural gas industry, such as the production and storage of liquefied natural gas (LNG), titanium heat exchangers are used to cool and condense natural gas, converting it into liquid for easy storage and transportation. Because titanium still has good mechanical properties and corrosion resistance in low temperature environments, it can meet the strict requirements of equipment in LNG production.

Power industry

The power industry is an important pillar of national economic development, which involves a large amount of heat energy conversion and transfer. Whether it is traditional thermal power generation, or emerging nuclear power generation, solar power generation, etc., they are inseparable from efficient and reliable heat exchange equipment.

In thermal power generation, titanium heat exchangers are mainly used in steam turbine condensers, boiler feed water preheaters and other parts. The function of the steam turbine condenser is to condense the exhaust steam discharged from the steam turbine into water, recover the heat therein and establish a vacuum environment to improve the efficiency of the steam turbine. Since the condenser needs to contact a large amount of circulating cooling water, and the cooling water may contain various impurities and corrosive substances, such as chloride ions, dissolved oxygen, etc., ordinary carbon steel or stainless steel condensers are prone to corrosion and leakage. Titanium heat exchangers have excellent corrosion resistance, can effectively resist the erosion of circulating cooling water, and extend the service life of condensers. In boiler feed water preheaters, titanium heat exchangers are used to heat boiler feed water and improve the thermal efficiency of boilers. Their good high temperature resistance and heat transfer performance ensure the high efficiency and stability of the feed water preheating process.

In the field of solar thermal power generation, titanium heat exchangers are used to transfer the heat collected by solar collectors to the working medium. Since solar thermal power generation systems usually operate in high temperature and high radiation environments, high requirements are placed on the heat exchanger’s high temperature resistance and durability. The good mechanical properties and high temperature resistance of titanium heat exchangers enable them to adapt to this special working environment and provide support for the efficient operation of solar thermal power generation.

Food and Beverage Industry

The food and beverage industry has strict requirements on product quality and safety. The equipment used in the production process must meet hygiene standards and will not cause pollution to food and beverages. Titanium heat exchangers have the advantages of non-toxicity, non-magnetism, and good biocompatibility, and are very suitable for use in the food and beverage industry.

In food processing, such as milk sterilization, juice concentration, beer brewing, etc., precise temperature control is required. Titanium heat exchangers can ensure that food and beverages are not contaminated during processing while ensuring efficient heat exchange. Its surface is smooth, not easy to breed bacteria and dirt, easy to clean and disinfect, and meets the hygiene requirements of the food industry. Compared with traditional stainless steel heat exchangers, titanium heat exchangers will not react chemically with certain ingredients in food, will not affect the taste and nutritional content of food, and can better ensure the quality and quality of food.

In beverage production, especially some high-end beverages and functional beverages, the requirements for heat exchange equipment are more stringent. Titanium heat exchangers can meet the high-precision temperature control requirements in the production of these special beverages, while ensuring the purity and safety of beverages, providing strong technical support for the development of the beverage industry.

Pharmaceutical industry

The pharmaceutical industry is an industry with extremely high requirements for product quality and production environment. The production of drugs must strictly follow relevant regulations and standards to ensure the safety, effectiveness and stability of drugs. Heat exchange equipment plays a vital role in the pharmaceutical process and is used in multiple links such as heating, cooling, concentration, and crystallization of drugs.

Titanium heat exchangers have been widely used in the pharmaceutical industry for their excellent performance. First, titanium has good chemical stability and will not react with various chemical components in drugs, avoiding the impact on drug quality. Secondly, the surface of the titanium heat exchanger is smooth, not easy to adsorb impurities and microorganisms, easy to clean and disinfect, and can meet the pharmaceutical industry’s strict requirements for equipment hygiene. In the sterile production environment of drugs, titanium heat exchangers can operate reliably to ensure the continuity and stability of the drug production process.

In drug synthesis, many chemical reactions need to be carried out under specific temperature conditions. Titanium heat exchangers can accurately control the reaction temperature and improve the yield and selectivity of the reaction. In the concentration and crystallization of drugs, titanium heat exchangers can efficiently achieve heat transfer to ensure the purity and quality of drugs. In addition, the corrosion resistance of titanium heat exchangers enables them to operate stably in some pharmaceutical processes containing corrosive solvents and catalysts.

Conclusion

Titanium heat exchangers, with their unique performance advantages, have played an irreplaceable and important role in many industrial fields. From the treatment of highly corrosive media in the chemical industry, to the strict requirements of health safety and material compatibility in the food and pharmaceutical industries, to the urgent needs for equipment durability and efficient heat exchange in the fields of marine engineering and power, titanium heat exchangers have delivered satisfactory results with their excellent corrosion resistance, good physical properties and outstanding chemical stability.