The Ultimate Guide to High-Frequency Induction Evaporation

High-frequency induction evaporation, with its unique advantages, provides a powerful means to meet diverse coating needs. It can deposit high-quality thin films on a variety of substrates, thereby imparting new properties to the materials and expanding their application range.

- Low Cost

- Good Film Uniformity

- Higher Film Deposition Rate

- Strong Film-Substrate Bonding

- Compatible With Conductive Materials

Wstitanium Workshop

Our Powerful Facilities

A Complete Guide to High Frequency Induction Evaporation

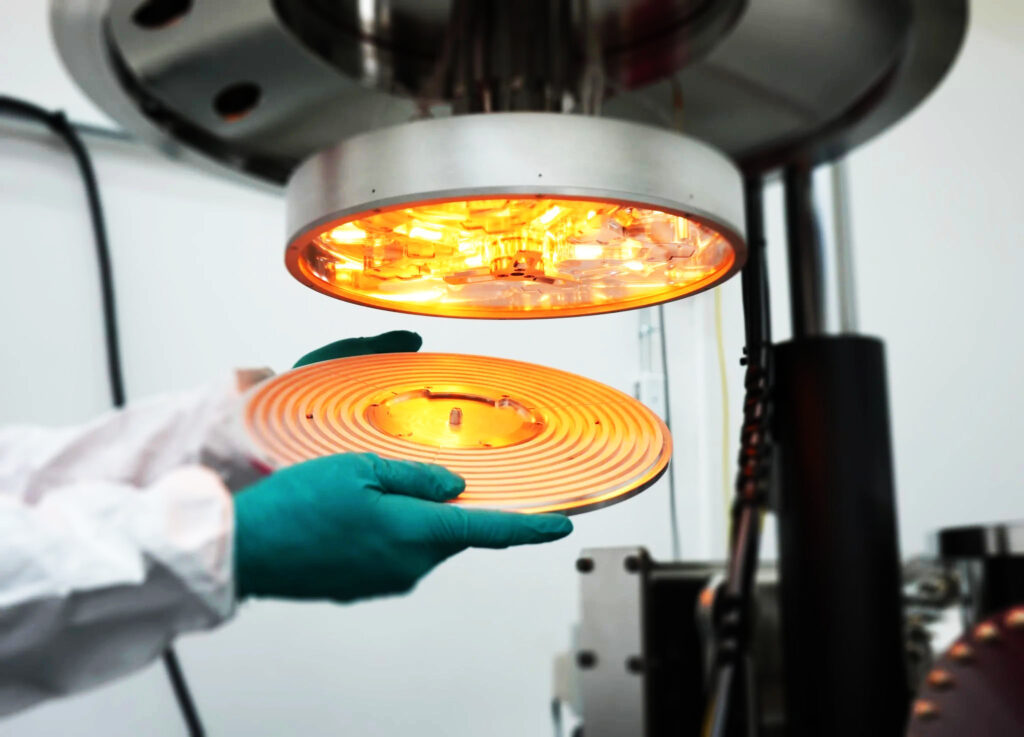

As an advanced physical vapor deposition technology, high-frequency induction evaporation coating technology has been widely used in many fields such as semiconductors, optics, and biomedicine due to its advantages such as high evaporation rate, uniform and stable evaporation source temperature, and high film quality.

What is High-Frequency Induction Evaporation Coating?

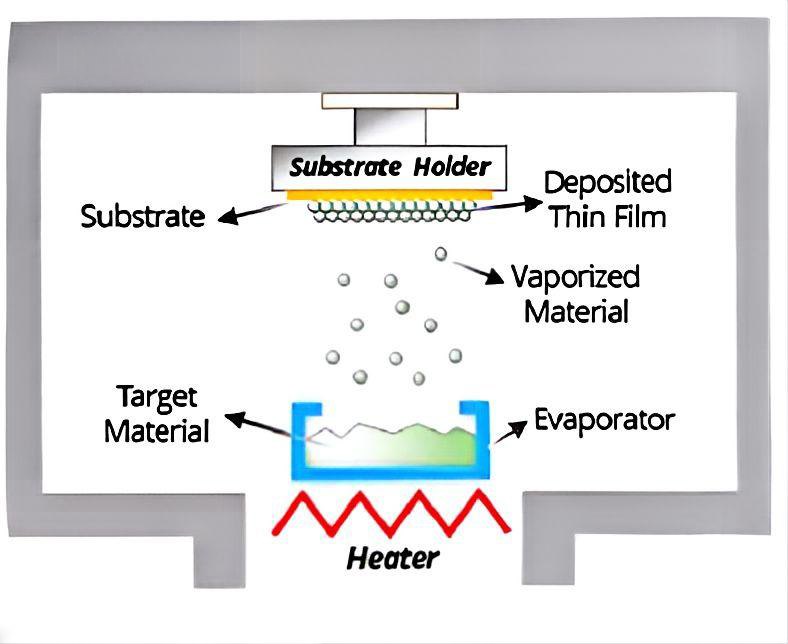

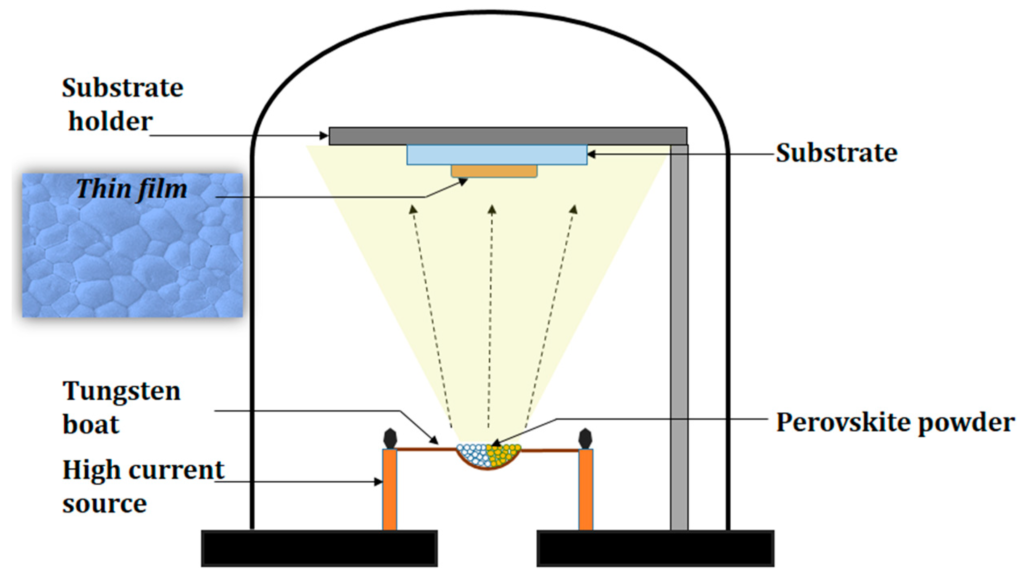

High-frequency induction evaporation coating utilizes the induction effect of a high-frequency electromagnetic field in a high-vacuum environment to heat the coating material placed in a crucible at the center of a high-frequency spiral coil. This generates strong eddy currents and hysteresis effects, leading to vaporization and evaporation. The evaporated atoms or molecules of the coating material condense on the substrate surface in gaseous form. The atoms or molecules continue to deposit and accumulate, gradually forming a uniform, dense film. The thickness, composition, and structure of this film can be precisely controlled by precisely controlling the coating parameters to meet the performance requirements of different application scenarios.

Principle

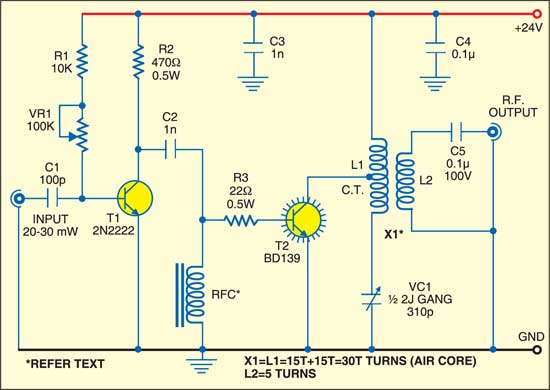

High-frequency induction evaporation coating relies on the generation of a high-frequency electromagnetic field. A high-frequency power supply converts ordinary alternating current into a high-frequency current with a frequency ranging from 10,000 to several hundred thousand hertz. When this high-frequency current is passed through a spiral induction coil made of water-cooled copper tubes, an alternating high-frequency electromagnetic field rapidly develops around the coil based on the principle of electromagnetic induction.

The crucible is placed at the center of the high-frequency spiral coil, completely within the field’s range. Induced by the high-frequency electromagnetic field, the coating material generates strong eddy currents. According to Joule’s law, when current flows through the coating material, which has a certain resistance, it generates heat, causing the coating material’s temperature to rise sharply. The vaporized atoms or molecules of the coating material move at high speed in all directions in a high vacuum environment. Because the substrate is typically placed in a specific position close to the evaporation source (crucible), with a certain temperature difference and atomic concentration gradient between the substrate and the evaporation source, the atoms or molecules of the coating material diffuse toward the substrate, continuously colliding and adsorbing on the substrate surface. The atoms or molecules gradually accumulate on the substrate surface. Over time, the accumulated atoms or molecules increase, forming atomic islands. These atomic islands continue to grow, merge, and eventually connect into a continuous film.

High-Frequency Induction Evaporation Coating System

The high-frequency induction evaporation coating system is the core element of this technology. Its complex structure requires coordinated operation to ensure a smooth coating process and consistent film quality. It primarily consists of a vacuum system, a high-frequency induction heating system, a substrate holder and drive system, a film thickness monitoring system, and a cooling system.

Vacuum System

The vacuum system is the foundation of high-frequency induction evaporation coating. Its function is to provide a high vacuum environment, reducing scattering and contamination of evaporated atoms or molecules by gas molecules, thereby ensuring the purity and quality of the film. The vacuum chamber is typically constructed of stainless steel, offering excellent sealing and mechanical strength. The size and shape of the vacuum chamber are designed based on the size and number of substrates, as well as the requirements of the coating technology. Common designs include cylindrical and square shapes.

To achieve the required high vacuum level, a multi-stage vacuum pump system is typically used. Generally, a mechanical pump (such as a rotary vane pump) is used as a backing pump to pump the vacuum chamber down to 10⁻¹Pa to 10⁻²Pa. A high-vacuum pump, such as a diffusion pump or molecular pump, is then used to further increase the vacuum level to 10⁻⁴Pa to 10⁻⁷Pa. Commonly used vacuum measuring instruments include thermocouple vacuum gauges and ionization vacuum gauges.

High-Frequency Induction Heating System

A high-frequency induction heating system is a key component in achieving evaporation of the coating material. It primarily consists of a high-frequency power supply, an induction coil, and a crucible.

The high-frequency power supply converts alternating current (AC) into high-frequency AC, providing energy for the induction coil. The frequency and power of the high-frequency power supply are critical parameters. The frequency typically ranges from 10kHz to 500kHz, and the power is adjusted based on the type of coating material and the required evaporation rate, ranging from a few kilowatts to tens of kilowatts or even higher. The stability of the high-frequency power supply directly impacts the stability of the heating process, and thus the quality of the film. Therefore, it requires excellent output stability and regulation accuracy.

The induction coil is typically made of a highly conductive material such as copper and has a spiral structure. It is water-cooled to prevent damage from high temperatures. Parameters such as the number of turns, diameter, and shape of the induction coil affect the distribution and intensity of the high-frequency electromagnetic field, which in turn influences the heating effect of the coating material. The coil is typically wound around the periphery of the crucible to concentrate the electromagnetic field on the coating material within the crucible.

Crucibles are used to hold coating materials and require high-temperature resistance, good chemical stability, and no significant reaction with the coating material. Common crucible materials include quartz, boron nitride, and alumina. Quartz crucibles are suitable for evaporating low-melting-point metals and oxides; boron nitride crucibles, with their excellent high-temperature resistance and chemical inertness, are often used to evaporate high-melting-point metals and compounds; and alumina crucibles are used in applications where purity is less critical. The shape and size of the crucible should match the induction coil to ensure uniform heating of the coating material.

Substrate Holders and Drive Systems

The substrate holder is used to hold the substrate to be coated. A drive system allows the substrate to be rotated or moved to ensure uniform film deposition. Depending on the shape and size of the substrate, it can be categorized as either flat or curved. Substrate holders are typically made of metal with a surface treatment to reduce contamination of the coating. To improve film uniformity, the substrate holder is often rotated during the coating so that all parts of the substrate receive the evaporated atoms or molecules evenly.

The drive system, consisting of a motor, reducer, and transmission mechanism, drives the substrate holder to rotate or move at a set speed and in a specific pattern. The rotation speed can be adjusted over a wide range to meet the film uniformity requirements. Large or unusually shaped substrates may require a more complex drive system to achieve multi-dimensional substrate movement.

Thin Film Monitoring System

Film thickness monitoring systems are used to measure and control thin film thickness in real time, ensuring that the thickness meets design specifications. Precise control of film thickness is crucial for ensuring film performance. For example, in optical thin films, slight deviations in thickness can lead to significant changes in optical properties.

Quartz crystal oscillator film thickness gauges are one of the most widely used film thickness monitoring devices. Their principle is that as evaporated material is deposited on a quartz crystal, the oscillation frequency decreases as the mass of the deposited material increases. The film thickness is calculated by measuring this change in frequency. Quartz crystal oscillator film thickness gauges offer high measurement accuracy and fast response speed, enabling real-time monitoring and automatic control of film thickness.

Optical film thickness monitors, based on the principle of optical interference, determine film thickness by measuring changes in the interference fringes of light reflected or transmitted through a film. This method is suitable for measuring the thickness of transparent or semi-transparent films and is particularly important in the fabrication of multilayer optical films, enabling precise control of the optical thickness of each layer.

High-Frequency Induction Evaporation Coating Parameters

High-Frequency Induction Evaporation Coating Parameters significantly impact the quality of thin films (such as thickness uniformity, composition, structure, and properties). Proper control of these parameters is crucial for obtaining high-quality thin films. Key process parameters include vacuum level, evaporation power, substrate temperature, evaporation distance, and coating time.

Vacuum Level

Vacuum level is one of the most critical parameters in high-frequency induction evaporation coating, significantly impacting the deposition process and performance of thin films. In a low vacuum environment, the density of gas molecules is high. Evaporated atoms or molecules frequently collide with gas molecules as they move toward the substrate, causing the evaporating atoms to change their direction or even be scattered back toward the evaporation source, thus affecting the deposition rate and uniformity of the thin film. As the vacuum level increases, the gas molecule density decreases, reducing the probability of collisions and allowing the evaporating atoms to more easily reach the substrate surface, thereby improving the deposition efficiency and uniformity of the thin film.

Different coating materials and film performance requirements correspond to different vacuum ranges. Generally speaking, for the preparation of metal films, the vacuum level is usually controlled between 10⁻³Pa and 10⁻⁵Pa. For semiconductor or optical films requiring higher purity, the vacuum level is higher, reaching 10⁻⁵Pa to 10⁻⁷Pa or above. The appropriate vacuum level should be selected based on the specific situation and maintained stable during the coating process.

Evaporation Power

The evaporation power directly determines the evaporation temperature and evaporation rate of the coating material and is a key parameter for controlling the thin film deposition rate.

The higher the evaporation power, the stronger the high-frequency electromagnetic field, the more heat absorbed by the coating material, the higher the temperature, and the faster the evaporation rate. By adjusting the evaporation power, the thin film deposition rate can be precisely controlled. In practical applications, the appropriate evaporation power should be selected based on the desired film thickness and coating time to ensure that the desired film thickness is deposited within the specified time. The evaporation power also affects the energy of the evaporated atoms. Higher evaporation power imparts higher energy to the evaporated atoms, making them more likely to diffuse and migrate upon reaching the substrate surface, thereby forming a thin film with higher crystallinity and a denser structure. However, excessive evaporation power may also cause the coating material to overheat, resulting in spattering and affecting film quality.

Evaporation Distance

The evaporation distance refers to the distance between the evaporation source (crucible) and the substrate, and has a significant impact on the uniformity of film thickness. Evaporated atoms or molecules travel in all directions from the evaporation source, and their distribution follows the cosine law (for a point evaporation source).

Within a certain range, increasing the evaporation distance results in a more uniform distribution of evaporated atoms on the substrate surface, as the atoms have more space to diffuse and distribute. However, excessive evaporation distance reduces the number of evaporated atoms reaching the substrate surface, reducing the deposition rate. It also increases the probability of collisions between atoms and residual gas molecules, affecting film quality. The selection of the evaporation distance requires a comprehensive consideration of the substrate size and shape, as well as the desired film uniformity. For small substrates, the evaporation distance can be appropriately reduced to increase the deposition rate; for large or irregularly shaped substrates, the evaporation distance should be appropriately increased to ensure film uniformity. Generally, the evaporation distance ranges from 10 cm to 50 cm; the specific value should be determined experimentally based on actual conditions.

Advantages of High-Frequency Evaporation Coating

High Evaporation Rate

The evaporation rate of high-frequency induction evaporation can be approximately 10 times greater than that of resistive evaporation sources. This is because the high-frequency electromagnetic field generates strong eddy currents within the coating material, rapidly absorbing a large amount of heat energy and causing the material to rapidly heat up and evaporate.

Uniform and Stable

The eddy currents generated by the high-frequency electromagnetic field within the coating material are evenly distributed, ensuring uniform heating across all parts of the coating material. This ensures a stable evaporation rate for the coating material, resulting in a uniform film thickness deposited on the substrate surface.

Reduced Spatter

Due to the uniform and stable temperature of the evaporation source, the coating material gradually heats up and evaporates in a relatively stable state, without local overheating that could cause the coating material to splash out in the form of droplets.

Simple Operation

A single charge of the evaporation source satisfies coating requirements for a specific period, eliminating the need for frequent additions of coating material. This significantly simplifies operation.

Conclusion

High-frequency induction evaporation coating technology, with its unique principle, has demonstrated significant advantages in numerous fields. Through high-frequency electromagnetic field induction heating, it achieves efficient evaporation of coating materials and the production of high-quality thin films. This applies to a wide range of materials, from common metals such as aluminum, titanium, and chromium to compounds such as titanium dioxide, titanium nitride, and silicon carbide. High evaporation rates enhance efficiency, while stable and uniform evaporation source temperatures reduce spattering and contamination. However, this technology is not without its drawbacks. For example, equipment costs are relatively high, and coating certain specialized materials may present challenges. High-frequency induction evaporation coating technology is expected to achieve further breakthroughs in equipment optimization, technological advancements, and the application of new materials in coating, further expanding its application areas.