CNC Machining For Custom Titanium Valves Services

As a leader in the field of titanium valves, Wstitanium is your trusted partner, With internal investment in advanced 5 Axis CNC machining centers, forging, casting, heat treatment and CMM, we have built a complete manufacturing and quality control system, as well as in-depth research and rich practice on more than 80 titanium grades.

- ASME B16.34-2017

- 24/7 Online Service

- OEM/ODM Support

- 5 Axis CNC Machining

- ISO 9001:2015

- ISO 13485:2016

- SGS, BV and CE Certificated

- High Tolerance +/-0.005mm

Reputable CNC Machining Titanium Valve Factory - Wstitanium

Wstitanium’s all-round excellence in the field of CNC machining titanium valves provides high-quality, customized solutions for many industries. In-depth communication with you from the design stage ensures that the design not only meets functional requirements but also takes into account cost-effectiveness. The quality management system certified by ISO 9001 and ISO 13485 covers the entire manufacturing process from raw materials, CNC milling, turning, grinding, tapping, drilling, etc.

Advantages of CNC Machining Titanium Valves

CNC machining achieves micron-level or even higher precision control, effectively reducing machining errors caused by human factors and ensuring the consistency and stability of product dimensional accuracy. Titanium valves have extremely high requirements for precision, and even slight dimensional deviations may lead to problems such as reduced sealing performance and unstable fluid control.

- High Precision

The CNC machining center is equipped with advanced numerical control systems, which have high-speed computing capabilities and precise position control algorithms. The dimensional information on the design drawings is accurately converted into the motion instructions of the coordinate axis, and the motion trajectory of the tool is accurately controlled to ensure that the dimensional accuracy of the inner diameter, outer diameter of the valve seat, and the flatness and roughness of the sealing surface reaches an extremely high level. Usually, the dimensional tolerance can be controlled within ±0.005 microns.

- Complex Shape Manufacturing Capability

The design of valves is becoming more and more complex to meet the special needs of different application scenarios. The Wstitanium 5-axis CNC machining center is the core equipment for complex shape machining. The 5-axis linkage drives the tool to move in multiple directions, and can complete the machining of multiple faces and complex curved surfaces of the workpiece in one clamping. For example, titanium valves with special-shaped flow channels.

- Fast Turnaround

The five axes of the 5-axis CNC machining center can move in coordination at the same time. The tool has the ability to cut at high speed in linear motion on the X, Y, and Z axes and rotary motion on the A and B axes. For example, while milling one face of a special-shaped titanium valve, the rotary axis is used to drill the holes on the valve body at the same time, realizing multiple tasks in parallel, greatly shortening the machining time.

CNC Turning Titanium Valves

CNC turning is a common manufacturing technology for titanium valves, mainly used for shaft parts, rotating parts, and parts with cylindrical surfaces, conical surfaces, threads and other features. Its principle is based on the rotary motion and the linear motion of the tool, and the workpiece is cut by accurately controlling the relative motion trajectory between the two. Wstitanium summarizes the parameters of CNC turning titanium valves: The cutting speed of carbide tools for turning titanium alloys is usually between 50-150m/min. The feed rate can be controlled between 0.1-0.3mm/r. During finishing, the feed rate can be reduced to 0.05-0.15mm/r. The cutting depth can generally be controlled between 0.5-2mm; during finishing, the cutting depth is usually between 0.1-0.5mm.

CNC Milling Titanium Valves

The core principle of CNC milling is to convert the design drawings of titanium valves into digital codes that can be recognized by computers. These codes contain detailed information such as the tool’s motion trajectory, cutting parameters, and spindle speed. The code accurately controls the movement of the milling machine, realizes the relative movement between the tool and the titanium valve workpiece, gradually removes excess material, and finally manufactures a titanium valve that meets the design requirements. The maximum speed of the 5-axis linkage CNC milling machine can reach 24000r/min. The cutting speed is 100-150m/min, the feed rate is 0.02-0.08mm/z, and the cutting depth is 0.05-0.2mm to achieve the titanium valve size tolerance of ±0.005mm, the cylindrical tolerance is 0.001mm, and the surface roughness Ra reaches 0.15μm.

Quality Inspection

Wstitanium has built a comprehensive quality control process, from strict inspection of raw materials, to real-time tracking of processing monitoring, to meticulous inspection of finished products, each link is closely linked to ensure impeccable product quality. At the same time, with the help of advanced testing equipment and technology, such as three-coordinate measuring machine, roughness tester, hardness tester, non-destructive testing equipment and optical testing technology, accurate control of quality is achieved. In addition, the quality culture of continuous improvement is deeply rooted in the hearts of the people. Through measures such as quality awareness training for all employees, quality problem analysis and improvement mechanism, quality data collection and analysis, and customer feedback and satisfaction surveys, we continue to promote the improvement of titanium valve quality and service level….

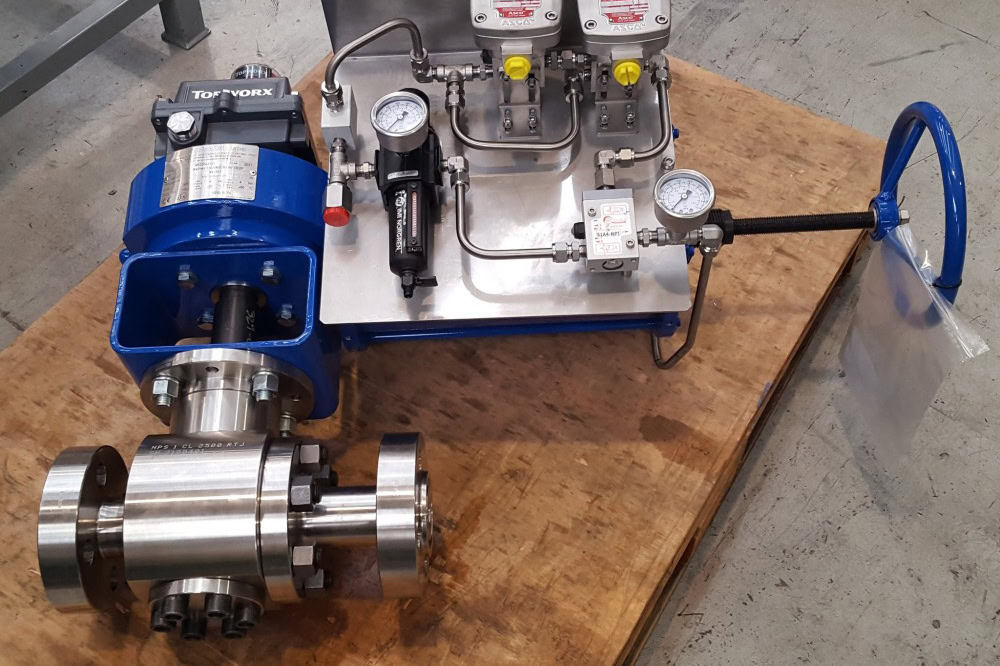

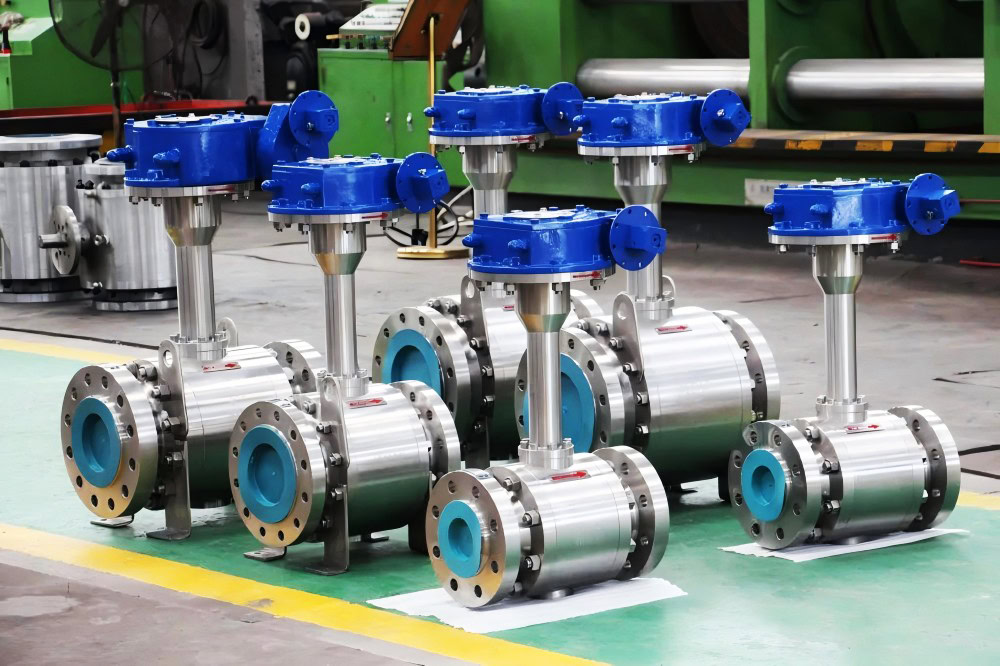

CNC Machined Titanium Valve Gallery

Wstitanium has a strong ability to manufacture complex-shaped titanium valves through 5-axis CNC machining technology, advanced CAM software programming and rich experience. We provide you with a variety of customized services to meet increasingly diverse needs and help you gain an advantage in the fierce market competition.