CNC Machining Titanium

Wstitanium has been a leader in CNC Machining Titanium parts, efficiently providing customers with high-quality custom services at competitive prices. Leveraging diverse in-house capabilities and a strong local supply chain to provide turnkey solutions for your projects. ISO 9001:2015, ISO 13485, IATF 16949:2016 Certified. Providing 3-axis and 5-axis CNC milling titanium for aerospace, medical, robotics.

- 24/7 Engineering Support

- Tight tolerance: +/- 0.005mm

- Wide Range of Titanium Alloy

- 20+ Finishing Services Options

- From 1 to 100+ Parts Within 7 Days

- ISO 9001 & ISO 13485 Certificated

- All uploads are secure and confidential.

Your Trustworthy Partner Of CNC Machining Titanium Parts

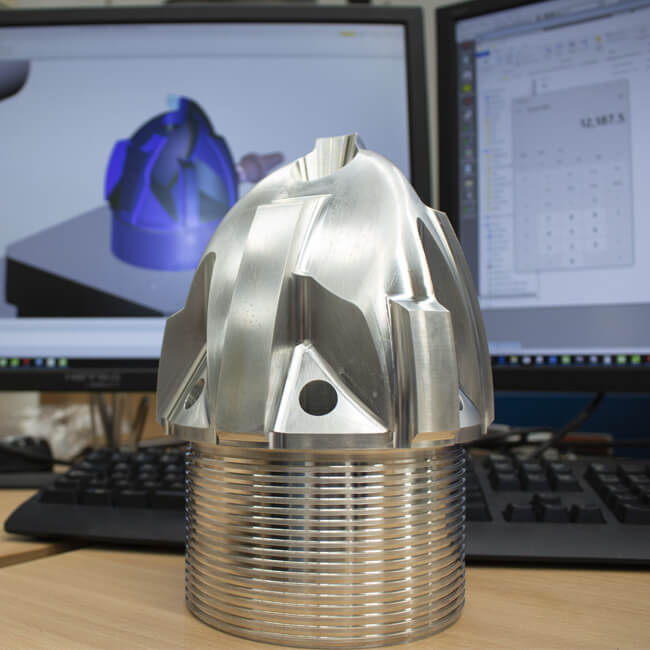

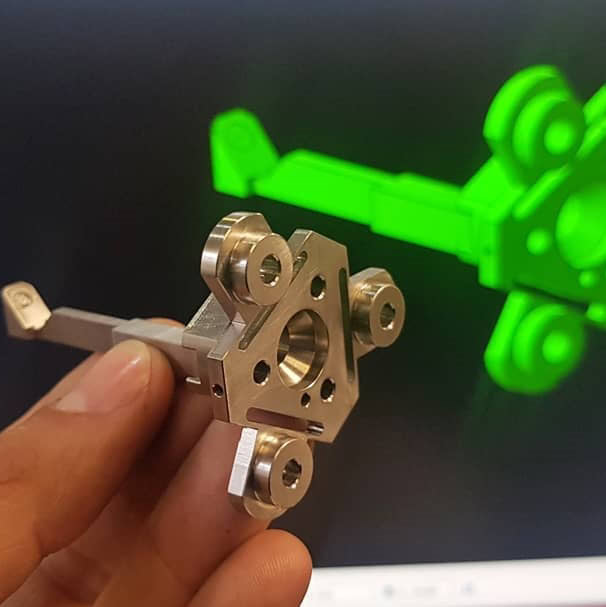

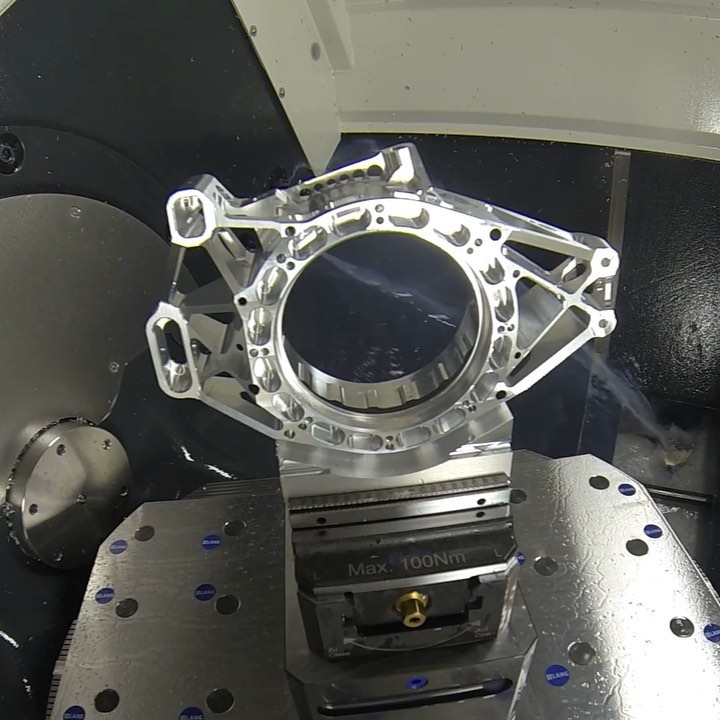

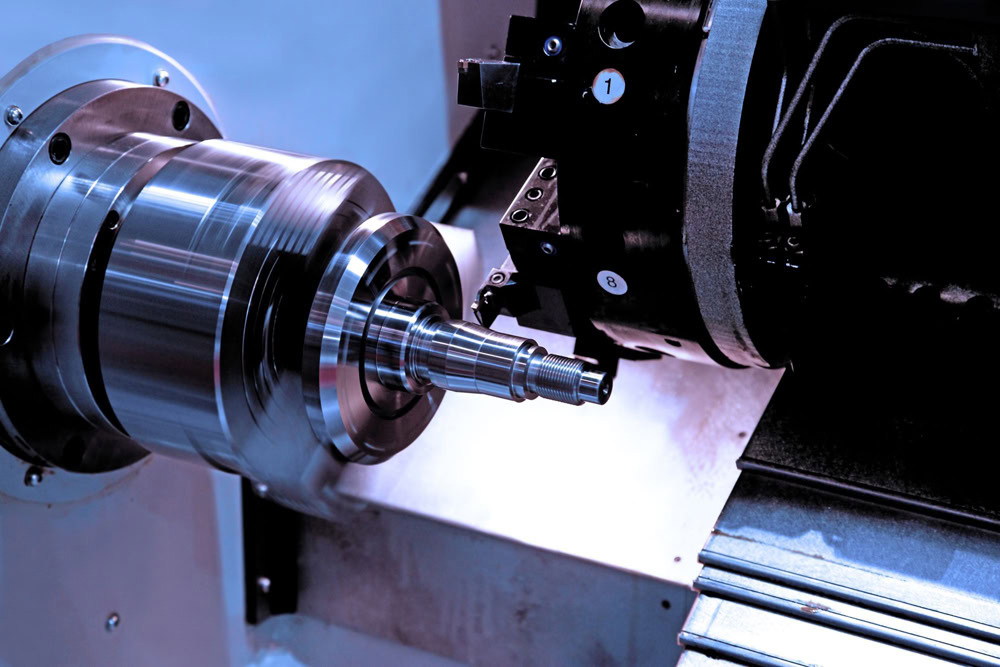

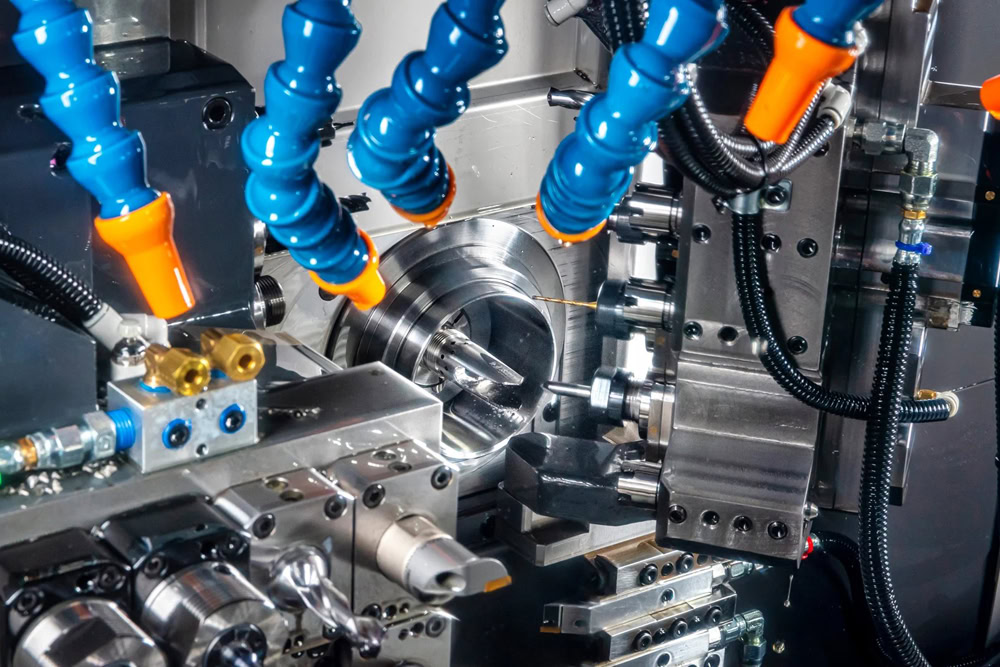

Wstitanium invests in advanced 3-axis, 4-axis, 5-axis CNC milling centers and CNC turning facilities to provide precision tolerances up to 0.005mm, and can customize various grades of titanium and titanium alloy parts. In addition to standard CNC machining, Wstitanium also provides value-added services such as drilling, tapping, boring, WEDM, EDM and precision grinding, which is very suitable for designers and product developers who are looking for high-quality custom components to realize innovative ideas. Whether your CNC project is simple or complex, our fully equipped machine shop is ready to complete the task on time. We not only guarantee excellent quality, but also fast delivery-customized simple machined parts can be shipped in just 1 day.

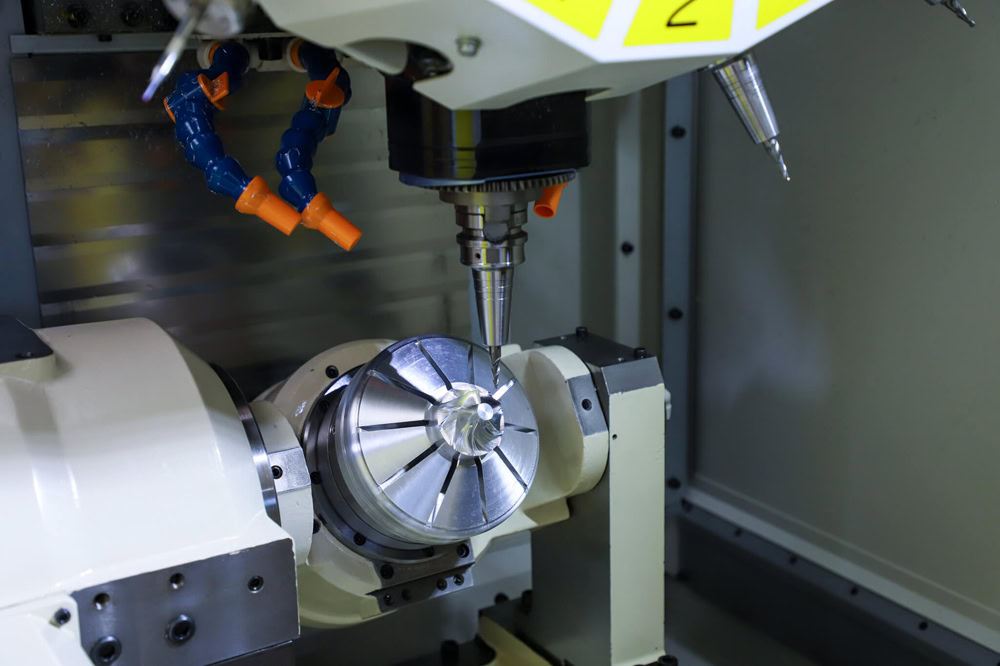

3, 4 and 5-axis CNC milling is highly flexible and accurate for manufacturing complex titanium parts with prismatic shapes, geometric cavities, and consistent tight tolerances.

CNC turning is ideal for forming titanium bars, focusing on cylindrical parts with deep holes, threads, and an excellent surface finish. Ensure dimensional consistency.

Swiss CNC Machining quickly and accurately manufactures extremely small and even complex titanium parts in large quantities. This includes milling, threading, drilling, boring, turning.

Grinding capabilities range from 0.1mm to 300mm diameter and 2mm to 1200mm length, with tolerances as tight as ±0.002mm and micro finishes as tight as 0.2 Ra.

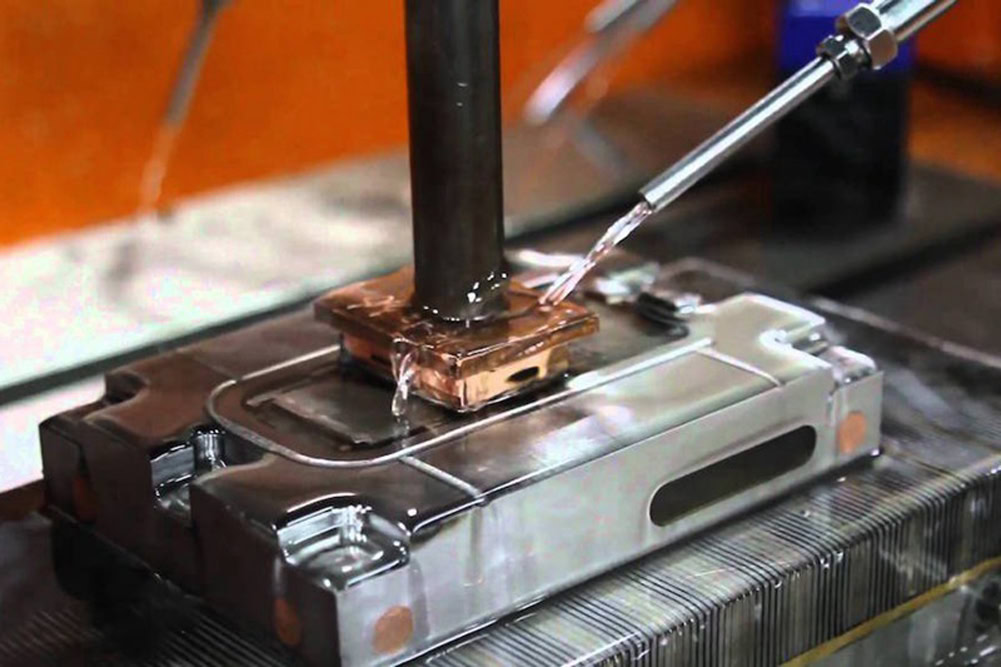

CNC drilling is the process of cutting a hole using a sharp, rotating drill bit. When drilling holes in titanium, coolant is often used to reduce heat buildup, maintain accuracy, and extend tool life.

CNC tapping is the process of using a tap to cut threads in a drilled hole to allow a screw or bolt to be inserted. This is critical for components that require fasteners to be assembled.

5-axis CNC milling relies on the tool moving in five different directions – X, Y, and Z, as well as A and B, around which the tool rotates. 5-axis CNC milling saves time and is ideal for creating complex parts with high precision.

Wire EDM services are used to create high-quality, complex parts with tight tolerances. The process is ideal for creating parts with complex shapes, sharp corners, and delicate features that are not possible with traditional machining methods.

EDM utilizes rapid pulsed high voltage discharges (sparks) across the gap between an electrode and a grounded workpiece to remove material from the workpiece by erosion to create structurally complex parts.

Production Capacity

Wstitanium has established a modern CNC machine shop, 45 3-axis, 4-axis, 5-axis CNC machining centers, including world-renowned brands (HAAS\DMG), CNC turning centers, CNC grinding, EDM, WEDM machining centers. Wstitanium knows that advanced equipment is the basis for manufacturing customized titanium parts. Of course, the manufacturing level of the machinist is still one of the most important factors. Therefore, monthly internal training and external further studies are the reasons why Wstitanium has mastered flexible manufacturing technology.

Common CNC Machining of Titanium Grades

Titanium (or Ti in the periodic table) is a lightweight metal with several useful properties, from corrosion resistance to strength retention at extreme temperatures. Titanium has an impressive strength-to-weight ratio and is 40% lighter than steel. This makes titanium an ideal material choice for high-tech industries such as aerospace, automotive, medical technology, and energy. It is available in both pure titanium and alloy forms. Pure titanium contains trace amounts (less than 1%) of iron and oxygen. Advanced titanium alloys significantly enhance the overall strength. Of these, grade 5 titanium, or Ti 6Al-4V, is the most popular titanium alloy.

| Grade | Hardness Rockwell 30T | Tensile Strength Ultimate | Tensile Strength, Yield | Elongation at Break | Tensile Modulus | Feature |

|---|---|---|---|---|---|---|

| Grade 1 Titanium | 70 HR30T | 240 MPa | 170 MPa | 24% | 105 GPa | High Corrosion Resistance |

| Grade 2 Titanium | 80 HR30T | 345 MPa | 275 MPa | 20% | 105 GPa | Excellent Strength-to-Weight Ratio |

| Grade 5 Titanium | 36-38 HR30T | 880 MPa | 830 MPa | 10% | 114 GPa | High Strength |

| Grade 9 Titanium | 80 HR30T | 900 MPa | 830 MPa | 15% | 118 GPa | Excellent Balance of Strength, Toughness, and Workability |

| Grade 23 Titanium | 40-45 HR30T | 860 MPa | 790 MPa | 10% | 114 GPa | High Biocompatibility |

Grade 1 & 2 Titanium is a soft and ductile alloy consisting of 99% titanium with trace amounts of other elements. It has high corrosion resistance and is preferred by the medical and dental industries for its excellent biocompatibility.

Grade 1 & Grade 2

Grade 3 Titanium commercially pure titanium is a non-alloyed, high-strength commercially pure titanium with excellent corrosion resistance and good weldability. This titanium is primarily used for airframe and aircraft engine components.

Grade 3

Grade 4 has a high titanium content and is the strongest of the four commercially pure titanium grades, with good formability and corrosion resistance. It is used almost exclusively in aircraft engine parts, ships, and surgical implants.

Grade 4

Grade 5 titanium alloy, or Ti6Al4V, is a popular titanium alloy for CNC machining due to its excellent properties and is one of the strongest titanium alloys available. Grade 5 is a common material choice for engine components and aircraft fuselages.

Grade 5

Grade 6 Titanium (Ti5Al-2.5Sn) 5% aluminum and 2.5% tin, has good strength, weldability and corrosion resistance due to the presence of tin. Suitable for chemical processing, marine engineering and aerospace, frames and jet aircraft.

Grade 6

Grade 7 titanium alloy is similar to grade 2 and contains 0.12% to 0.25% palladium, 0.3% iron, 0.25% oxygen, and some other elements. Grade 7 titanium is the most corrosion resistant among all titanium alloys. It is the most corrosion resistant in reducing acids.

Grade 7

Grade 9 titanium alloy consists of 2.5% vanadium and 3% aluminum and is an alpha-beta alloy. This titanium grade has a good balance of weldability, strength and corrosion resistance. This type of titanium metal is used in chemical processes, aerospace applications, sports equipment and biomedical devices.

Grade 9

Grade 11 titanium, also known as CP Ti-0.15Pd, contains 0.2-0.4% palladium. It has good ductility, impact toughness, and very high resistance to crevice corrosion. It is more ductile and less tolerant of other impurities. It is less strong than Grade 7 and is used in the maritime and chlorate production industries.

Grade 11

Grade 23 Titanium is also known as Ti-6Al-4V ELI. ELI stands for Extra Low Interstitial. Very similar to Grade 5, but Grade 23 titanium alloy has lower oxygen, nitrogen and iron content. Grade 23 titanium has better ductility and fracture resistance than Grade 5. Commonly used in chemical, medical, aerospace.

Grade 23

CNC Machining Parts Dimension & Tolerance

The tolerances listed in this table for CNC machined titanium parts are ideal minimums. Depending on the process, titanium alloy grade, or part geometry, looser tolerances may be required. If you do not have detailed requirements for your titanium part tolerances, we follow the general ISO2768-F tolerance table.

- Minimum Part Size: 4×4 mm

- Maximum: 4000×1500×600 mm

- Minimum Feature Size: Φ 0.05 mm

- Threads and Tapped Holes: Φ 1.5-5 mm

- Diameter: 0.002mm

- Precise Hole: 0.002mm

- Chamfer Heights: 0.01mm

- Linear Dimensions: 0.005mm

- Flatness: 0.002mm

- Straightness: 0.002mm

- Perpendicularity: 0.002mm

- Angular Dimensions: 0.5°

- Symmetry: 0.002mm

- Parallelism: 0.002mm

- Concentricity: 0.002mm

- Wall Thickness: 0.3mm

Surface treatments enhance the durability and aesthetics of custom titanium parts, adding additional protection against corrosion and wear. At Wstitanium, we offer a variety of surface treatment options based on your needs, ensuring your components achieve the desired look and functionality. They include polishing, anodizing, passivation, powder coating, sandblasting, and more. Each finish offers unique benefits, all ensuring your parts meet aesthetic and functional specifications.

As Machined

Titanium parts are removed from CNC machines to retain the machined surface, showing tool marks without additional processing. It is an economical choice. Ra<0.8

Anodizing

Anodizing of titanium parts, which gives them vibrant colors and enhanced corrosion and wear resistance, is often used in medical and decorative applications.

Sand Blasting

Sandblasting is suitable for titanium parts to give them a matte, textured effect. It enhances the wear resistance, corrosion resistance and fatigue resistance of titanium.

Polishing

Polishing is to remove flaws, oxide layers and burrs on the surface of titanium parts to make them smooth and bright, thus improving their appearance.

Electropolish

Electrolytic polishing can give titanium parts a bright reflective surface, enhance their smoothness, and improve their corrosion resistance. It is an environmentally friendly way.

Powder Coating

Titanium parts are powder coated with a thick, wear-resistant layer that offers outstanding color and texture. Coating has excellent corrosion resistance, wear resistance, hardness.

Electroplating

Electroplating bonds a thin metal layer to titanium parts, increasing surface hardness, wear resistance, corrosion resistance, oxidation resistance, improving its conductivity.

Brushed Finish

The brushed finish of the titanium parts creates a unidirectional satin texture, reducing the visibility of surface marks and scratches. Flatter and more beautiful.

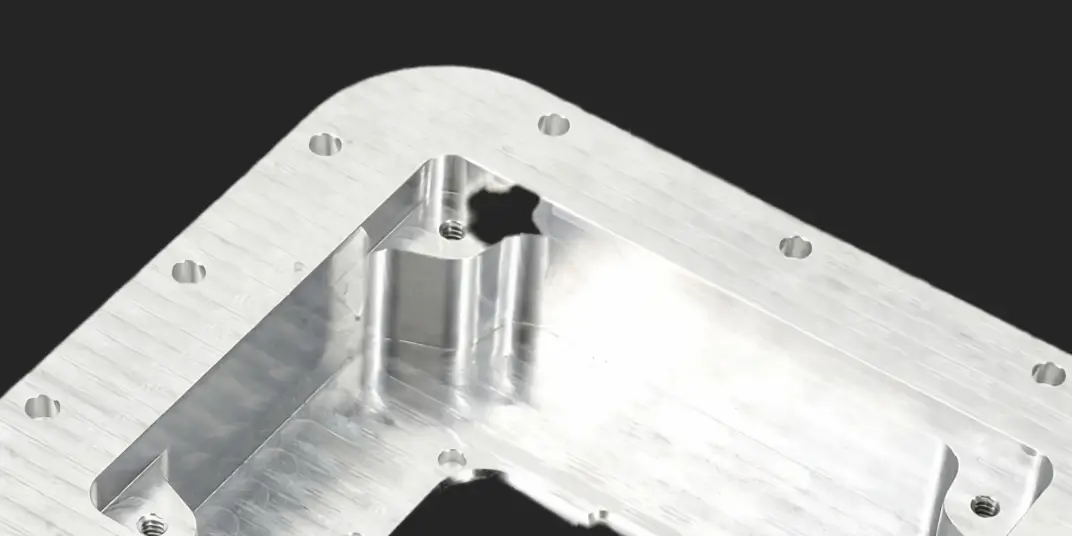

CNC machining is a widely used manufacturing technology that can be used to create custom components for a variety of industries, not just limited to aerospace, automotive, medical, optical, robotics, etc. The precision and accuracy inherent in the CNC machining process enables the production of complex titanium parts with tight tolerances. This ensures that they meet the stringent requirements of critical applications in different industries. The digitization of Wstitanium’s custom CNC machining services is helping more and more manufacturers turn their ideas into products. To help you understand our CNC machining capabilities, here are some of our previous CNC projects, as well as demonstration parts designed by our engineers.