Custom Casting Titanium Valve Services In China

With its diverse titanium grade options, rich valve types and advanced manufacturing technology, Wstitanium has cast a series of high-quality titanium valves for multiple industrial fields.

- 24/7 Online Service

- OEM/ODM Support

- ASTMB367 / JIS 5801 / DIN

- SGS, BV and CE Certificated

- ISO 9001:2015

- ISO 13485:2016

- Investment Casting

- Gr1, Gr2, Gr5, Gr7, Gr12

Powerful Casting Titanium Valve Factory-Wstitanium

Wstitanium cast titanium valves have shown significant advantages in many complex and harsh working conditions. From the perspective of materials and performance, with the unique chemical and physical properties of titanium, they excel in corrosion resistance, high strength and light weight, as well as high and low temperature performance, providing reliable guarantee for the stable operation of key equipment in various industries.

- Minimum Thickness:0.8mm

- Surface Roughness:Ra3.2~12.5μm

- Max size:Φ2000 × 1000

- Maximum Weight:1000KG

Titanium Grades For Casting Valves

When Wstitanium casts titanium valves for you, there are multiple titanium grades to choose from. Each grade is suitable for different application scenarios due to its unique chemical composition and performance characteristics.

- Grade 1

Grade 1 is low-strength, high-plasticity pure titanium with a high purity of >99.5% and low impurity content. It is widely used in the manufacture of valve parts that do not require high strength but have requirements for corrosion resistance and forming, such as the valve body and valve cover of small valves.

- Grade 2

Grade 2 is also industrial pure titanium, and its strength is slightly higher than Grade 1. It has good corrosion resistance and is stable in many corrosive media. It is often used to manufacture key valve components, such as valve seats and valve cores, to ensure reliable operation in complex environments.

- Grade 5 (Ti - 6Al - 4V)

Grade 5 is the most widely used α + β type titanium alloy, with aluminum (Al) and vanadium (V) as the main alloying elements. The addition of aluminum improves the strength and thermal stability of the alloy, while vanadium improves the processing performance and toughness of the alloy. Grade 5 has high strength, good toughness and plasticity, as well as excellent corrosion resistance and welding properties. Grade 5 cast valves are widely used in aerospace, petrochemical, shipbuilding and other fields that require extremely high valve performance. For example, in the fuel control system of aircraft engines, high-pressure pipelines in petrochemicals, etc.

- Grade 7 (Ti - 0.2Pd)

Grade 7 is based on pure titanium with 0.2% palladium (Pd) added. The addition of palladium significantly improves the corrosion resistance of titanium in reducing acids. For example, in reducing acid media such as hydrochloric acid and sulfuric acid, Grade 7 shows better corrosion resistance than pure titanium.

- Grade 12 (Ti - 0.3Mo - 0.8Ni)

Grade 12 contains molybdenum (Mo) and nickel (Ni), and performs well in resistance to crevice corrosion and stress corrosion cracking. In media containing chlorides, Grade 12 cast valves effectively ensure the normal operation of the valves and are often used in petrochemical, marine and other fields.

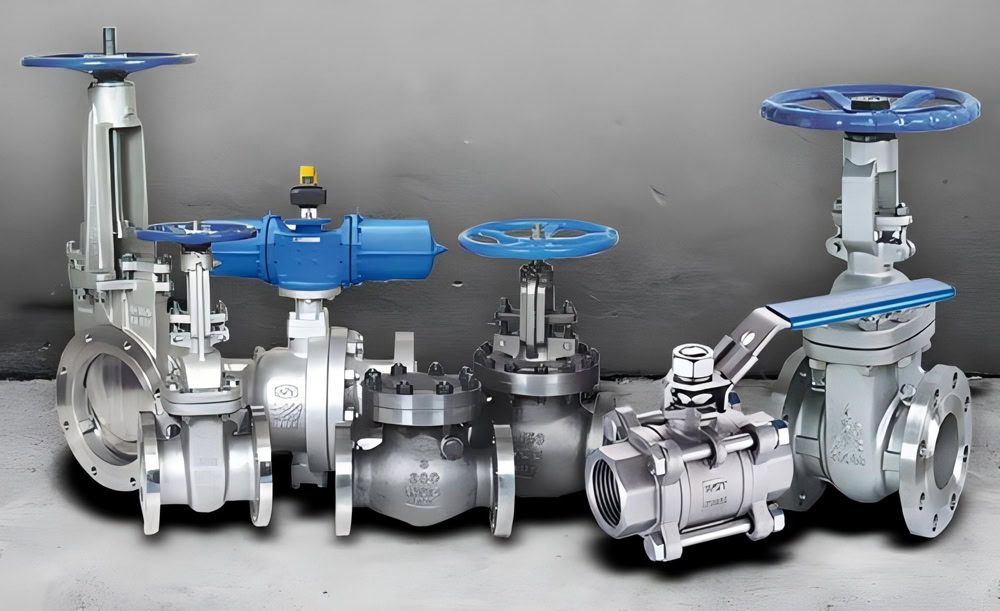

Types of cast titanium valves

Wstitanium manufactures a wide variety of cast titanium valves that can meet the diverse needs of different industrial fields.

Ball valve is a common type of valve that is opened and closed by rotating the ball. In industries such as petrochemicals and natural gas transportation, valves need to be opened and closed frequently to control the flow of the medium. Titanium ball valves can respond quickly to operating instructions, and their good sealing performance can effectively prevent medium leakage.

Globe valve closes the valve by fitting the valve disc with the valve seat, and has the function of regulating flow and cutting off the medium. In the chemical industry, it is often necessary to accurately control the flow of the fluid. Titanium globe valves can meet this demand by adjusting the opening of the valve disc. Wstitaniuc Cast globe valves have good sealing and high adjustment accuracy.

The function of the check valve is to prevent the medium from flowing back and only allow the medium to flow in one direction. For example, in an oil pipeline, a titanium check valve can prevent the oil from flowing back in the pipeline, ensure the smooth progress of the transportation process, and protect pumps, compressors, etc. from the impact of the backflow medium.

The valve disc of the gate valve is perpendicular to the flow direction of the fluid, and the valve is opened and closed by raising and lowering the valve stem. In some occasions with low requirements for fluid resistance, such as large steam pipeline systems, titanium gate valves can reduce the resistance of steam flow. At the same time, its good sealing performance ensures that steam will not leak.

The disc-shaped butterfly plate in the butterfly valve rotates around the valve shaft to open and close the valve. Titanium butterfly valves meet the needs of large-diameter pipelines in fields such as urban water supply and sewage treatment, which require smaller flow resistance and fast opening and closing performance. Its corrosion resistance ensures long-term stable operation.

Titanium Plug Valve

Titanium plug valve controls the fluid on and off and flow rate by rotating the plug body. It uses the corrosion resistance, high strength and high temperature resistance of titanium materials. It is suitable for harsh environments such as chemical, marine, and pharmaceutical industries. It works stably in acids, alkalis, salts and high-temperature media to achieve precise interception or regulation.

Casting Titanium Valves

Wstitanium uses advanced investment casting titanium valves. This technology produces titanium valve castings with high dimensional accuracy, good surface quality and complex shapes, meeting the strict requirements of various industrial fields.

Wax Model

According to the design drawings of the valve, use computer-aided design (CAD) software to perform three-dimensional modeling. Take full account of the structural characteristics and dimensional accuracy requirements of the valve, and optimize the design of the model, such as reasonably setting the casting fillet and draft angle. Wstitanium uses special zircon powder or corundum powder as refractory aggregate, and mixes it with binders such as silica sol to prepare the surface coating. Immerse the wax model in the surface coating so that its surface is evenly coated with a layer of coating. Put the prepared shell into a steam dewaxing kettle or a hot water tank for dewaxing treatment, so that it is heated and melted and flows out of the shell. Then put the shell into a high-temperature roasting furnace for roasting, and the roasting temperature is generally between 900℃ – 1100℃.

Melting and Pouring

Wstitanium uses an advanced vacuum consumable arc furnace (VAR) to melt titanium alloys. The vacuum consumable arc furnace uses the arc generated between the consumable electrode and the water-cooled copper crucible in a vacuum to melt the titanium alloy raw materials and form high-quality titanium liquid. The shell is preheated to a certain temperature (generally 800℃ – 1000℃), and then the titanium liquid is quickly poured into the shell. During the pouring process, a bottom-pouring or side-pouring pouring system is used to ensure that the titanium liquid fills the shell cavity smoothly and quickly to avoid defects such as turbulence and air entrainment. At the same time, the pouring speed and pouring amount are controlled to ensure the dimensional accuracy and internal quality of the casting.

Heat Treatment

After pouring, wait for the casting to cool to room temperature. According to different titanium grades and valve use requirements, the casting is appropriately heat treated. Common heat treatment processes include annealing, solution treatment and aging treatment. Annealing can eliminate residual stress inside the casting and improve the uniformity of organization and performance. Solution treatment can fully dissolve alloy elements in the matrix and improve the strength and toughness of castings. Aging treatment further improves the strength and hardness of castings by precipitating strengthening phases. Through reasonable heat treatment, cast titanium valves can achieve the best mechanical properties and performance.

Finishing

In order to further improve the corrosion resistance and surface quality of cast titanium valves, Wstitanium provides a variety of surface treatment options. For example, passivation treatment forms a dense passivation film on the surface of the casting to enhance its corrosion resistance. Polishing, using mechanical polishing, electrolytic polishing and other methods, so that the surface of the casting reaches the required finish, meeting some application scenarios with high requirements for surface quality. Sandblasting burrs, oxide scale and other casting residues to improve surface roughness, fatigue resistance and corrosion resistance.

Quality Inspection

Visual inspection and optical instrument inspection are combined to conduct a comprehensive inspection of the appearance of cast titanium valves. The inspection content includes surface roughness, dimensional accuracy, and the presence of defects such as cracks, sand holes, and pores. For valves with high surface quality requirements, a microscope is also used for microscopic inspection to ensure that the surface quality meets the standard requirements.

Dimension Inspection

Three-coordinate measuring instrument, caliper, micrometer, etc. are used to measure the key dimensions of the casting. The measurement results are compared with the design drawings to ensure that the dimensional deviation is within the specified tolerance range. For some valves with complex shapes, digital measurement technology, such as laser scanning measurement, is also used to accurately measure and analyze the shape and size of the entire casting.

Nondestructive Testing

Commonly used nondestructive testing includes radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), penetrant testing (PT), etc. Radiographic testing can detect defects such as pores, inclusions, shrinkage cavities, etc. in castings; ultrasonic testing is mainly used to detect internal cracks, delamination and other defects; magnetic particle testing is suitable for detecting surface and near-surface ferromagnetic defects; penetrant testing is used to detect surface opening defects. Through the comprehensive application of a variety of non-destructive testing methods, the internal quality of cast titanium valves is ensured to be reliable.

Mechanical Properties

Including tensile test, impact test, hardness test, etc. Through testing, the tensile strength, yield strength, elongation, impact toughness, hardness and other mechanical performance indicators of the casting are obtained to ensure that they meet the relevant standards and design requirements. For some valves with special applications, high temperature mechanical properties tests and low temperature mechanical properties tests will also be carried out to evaluate the performance of the valve under extreme working conditions.

Wstitanium cast titanium ball valves, globe valves, butterfly valves, check valves and gate valves meet the various functional requirements of different industries for flow control, cutoff, backflow prevention, etc. With the continuous development of industrial technology and the continuous growth of demand for high-performance valves, Wstitanium will continue to invest resources in material research and development, technological innovation and design optimization. Continuously improve the performance of existing titanium grades, further improve the precision and efficiency of casting, and develop more valve types that meet the needs of emerging industrial fields.