Custom Forging Titanium Valve Services In China

Titanium valves play an irreplaceable role in many fields with their unique characteristics. They have significant advantages in corrosion resistance and strength-to-weight ratio, and are widely used in highly corrosive environments such as chemical industry and marine engineering.

- 24/7 Online Service

- OEM/ODM Support

- ASTMB367 / JIS 5801 / DIN

- SGS, BV and CE Certificated

- ISO 9001:2015

- ISO 13485:2016

- Gr1, Gr2, Gr5, Gr7, Gr12

- Free Forging / Die Forging

One-stop forged titanium valve factory-Wstitanium

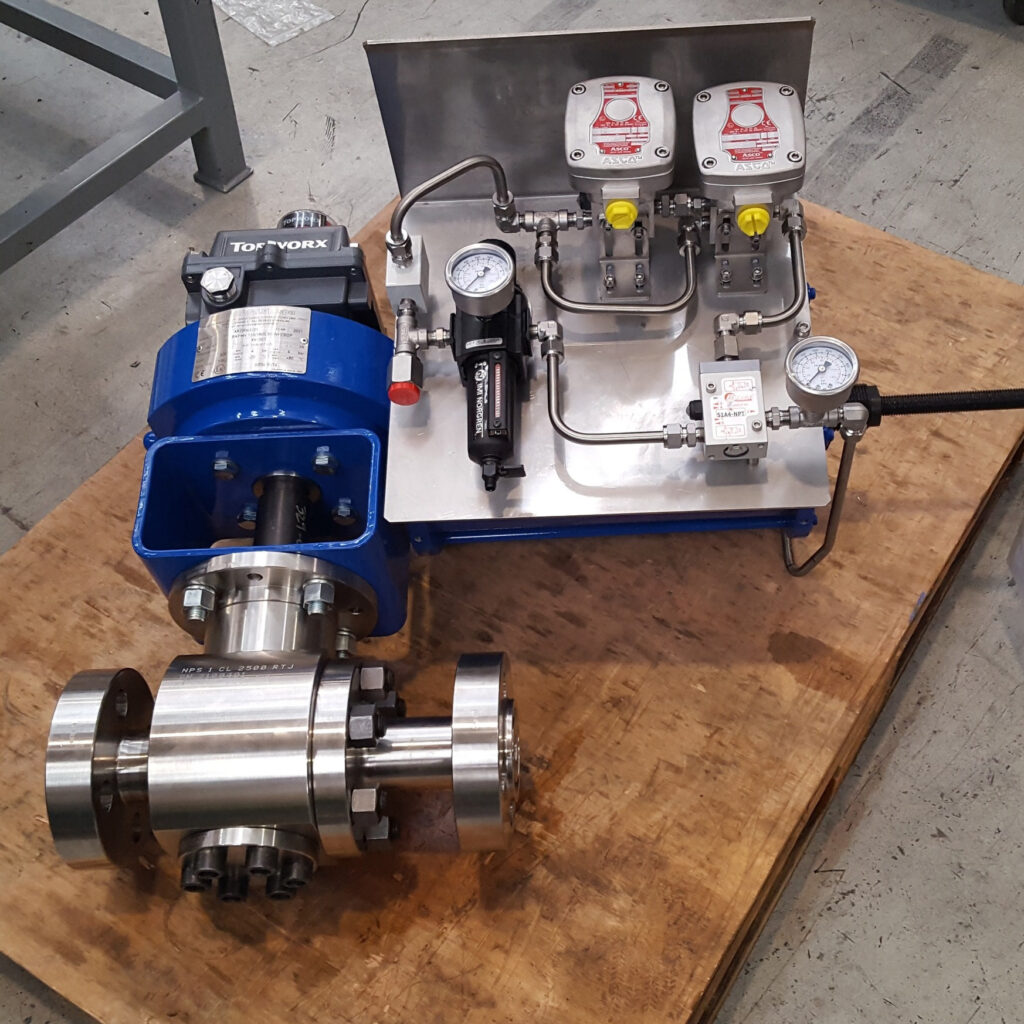

Wstitanium forged titanium valves, from strict control of raw materials, to advanced forging technology, precision CNC machining and surface treatment, to full-size quality inspection, every link is refined. With an in-depth understanding and application of the characteristics of different titanium grades (GR1\2\3\5\7\9\12\23), we forge various types of high-quality titanium valves that meet various working conditions, such as ball valves, globe valves, check valves, gate valves, butterfly valves, plug valves, etc.

Forged Titanium Valve Specifications

Specification | Details |

Material | Titanium Grade 1、2、3、5、7、9、12、23 |

Type | Forged Valve (Ball, Gate, Globe, Check, etc.) |

Pressure Rating | ANSI 150, 300, 600, 900, 1500, 2500 (depending on size and design) |

Size Range | 1/4″ to 4″ (varies by valve type and pressure class) |

Temperature Range | -320°F to 800°F (-196°C to 427°C) |

End Connections | Flanged (RF, FF), Threaded, Socket Weld, Butt Weld |

Face-to-Face Dimension | As per ANSI B16.10 (varies by valve type) |

Flange Rating | ANSI B16.5, DIN, JIS (depending on application) |

Face-to-Face Length | As per ASME B16.10 (standard face-to-face dimensions) |

Testing Standards | API 598, ISO 5208, ASME B16.34 |

Leakage Class | Class IV or Class VI (depending on valve type) |

Flow Coefficient (Cv Value) | Varies by size and type of valve |

Seat Material | PTFE, PEEK, or other elastomers (depending on valve type) |

Design Standard | ASME B16.34, API 602, ISO 9001 |

Pressure Test | 1.5 times the working pressure or as per manufacturer |

Corrosion Resistance | Exceptional resistance to corrosion in seawater, chlorides, acids, and other aggressive environments |

Applications | Aerospace, chemical processing, marine, power generation, desalination plants, heat exchangers |

Certification | CE, UL, ISO 9001, PED (if required) |

Material Composition | ~99.5% Titanium, with trace elements of Fe, C, O, N, and H |

Mechanical Properties | – Tensile Strength: 50-70 ksi (345-485 MPa) |

Welding | Excellent weldability with TIG, MIG, and other standard welding processes |

Surface Finish | Typically Ra 3.2 µm to 6.3 µm (depending on application) |

Resistance to Stress Corrosion Cracking | Excellent, especially in chloride-rich environments and seawater |

Fatigue Strength | High fatigue strength, making it ideal for cyclic loading conditions |

Wstitanium deeply understands the great potential and application prospects of titanium in the field of valve manufacturing. It has formed a research and development team composed of experts in materials science, mechanical design, manufacturing and other fields, dedicated to overcoming a series of technical difficulties in titanium valve forging. For example, hot isostatic pressing (HIP) is used to effectively eliminate the pores and defects inside the titanium material, improve the density and uniformity of the material, and thus improve the overall performance of the valve. The 5-axis CNC machining center and precision molds realize the high-precision manufacturing of valve parts, as well as a series of perfect quality management systems, strictly follow international standards, and provide customized solutions for industries such as petrochemicals, electric power, marine engineering, aerospace, and biomedicine.