Custom Manufacturing Threaded Titanium Flange Services

With its profound accumulation and excellent technology in the field of titanium manufacturing, Wstitanium is committed to providing high-quality threaded titanium flanges to meet the stringent requirements of high-performance pipeline connections in chemical, marine engineering, aerospace and other industries.

- ISO9001 & ISO13485

- Tight Tolerances +/- 0.002”

- Minimum Order Quantity: 1

- Full Size Inspection Report

- ASME B1.20.1

- FF、RF、MFM、TG

- Class 150LB - Class 2500LB

- For Chemical, Marine, Medical

Good Reputation Threaded Titanium Flange Factory -Wstitanium

As an important component of pipeline connection, threaded titanium flange has a unique and ingenious design. Compared with other types of flanges, threads have the significant advantages of easy installation and disassembly. With the continuous advancement of industrial technology, more stringent standards have been put forward for the performance and quality of threaded titanium flanges. Wstitanium continues to optimize production processes and is committed to manufacturing higher-quality and more reliable threaded titanium flanges by investing in advanced internal facilities and strict quality control systems.

What is a Threaded Titanium Flange?

Threaded titanium flange is a part that connects pipes to pipes or pipes to equipment through threads. It is installed at the end of the pipe and fastened to the matching flange through bolts and gaskets to achieve a sealed connection, prevent leakage of the medium in the pipeline, and ensure the normal operation of the pipeline system. Titanium and titanium alloys have a series of excellent properties, making them ideal materials for manufacturing threaded flanges. Compared with traditional steel materials, titanium flanges of the same volume are lighter, which is of great significance in fields such as aerospace and marine engineering where weight is strictly restricted. It has high strength and can withstand greater pressure and external force, ensuring the stability of the connection under complex working conditions such as high pressure and vibration.

Excellent corrosion resistance, not easily corroded in various chemical media and harsh environments, such as in the chemical industry, seawater desalination and other industries, can greatly extend the service life of the pipeline system and reduce maintenance costs; good biocompatibility, so that it can also be used in medical equipment pipeline connections.

Gr1 /Gr2 Threaded Titanium Flange

Pure titanium has excellent formability and weldability, low strength, high toughness, and good corrosion resistance. It is suitable for food, chemical, marine, pharmaceutical and low-pressure pipeline systems, and the cost is relatively low.

Gr3 Threaded Titanium Flange

Industrial pure titanium has further improved strength while maintaining good corrosion resistance. It is suitable for occasions with certain strength requirements, such as some high-pressure chemical pipelines, oil pipelines, etc.

Gr4 Threaded Titanium Flange

The highest grade of industrial pure titanium, with higher yield strength and tensile strength, and still has excellent corrosion resistance and toughness. It is often used in occasions that require high strength and certain corrosion resistance.

Gr5 (Ti-6Al-4V)

Gr5 has excellent comprehensive performance and can withstand extreme conditions such as high load, high temperature and strong corrosion, such as the connection of key components in aerospace, shipbuilding, chemical, petroleum, etc.

Gr7 (Ti - 0.2Pd)

Palladium is added to pure titanium, which greatly improves corrosion resistance, especially in reducing acids, such as chemical pipelines and seawater desalination pipelines in acidic media, especially suitable for harsh corrosive environments.

Gr12 (Ti - 0.3Mo - 0.8Ni)

It has good comprehensive performance and outstanding corrosion resistance, especially for media containing chloride ions. It is commonly used in sewage pipelines and chemical pipelines containing chlorine media.

Custom Manufacturing Threaded Titanium Flange

Wstitanium conducts strict quality inspections on raw materials, including chemical composition analysis, mechanical properties testing, metallographic structure inspection, etc., to ensure compliance with relevant standards and design requirements. According to the size specifications of the flange, suitable blanks are cut from titanium rods or ingots by sawing, shearing, plasma cutting and other methods. During the cutting process, the dimensional accuracy must be strictly controlled to reduce the processing allowance and improve the material utilization rate.

Forging improves the internal structure of titanium, improves the strength and toughness of the material, and eliminates defects in the raw materials (such as pores, looseness, etc.). Forging can also make the metal streamline distribution reasonable and improve the overall performance of the flange. Common forging methods are free forging and die forging. Free forging is suitable for small batches and large size flanges, and the forging process parameters can be flexibly adjusted according to actual needs. Die forging is suitable for large batches of flanges with high dimensional accuracy requirements, which can ensure the consistency and stability of quality. During the forging process, parameters such as forging temperature, deformation and forging speed must be strictly controlled to ensure the forging quality.

Wstitanium’s internal CNC lathes, milling machines, drilling machines, etc. remove most of the excess from the forged blanks to initially form the shape and size of the flange. Thread lathes, thread rolling machines, etc. are used to create threads on the flange. According to the specifications and precision requirements of the threads, appropriate technology and tools are selected. Strictly control the parameters such as the mean diameter, pitch, and tooth angle of the threads to ensure that the precision and surface quality of the threads meet the standard requirements. Flat sealing surfaces can be CNC turned or CNC ground. The raised face sealing surface needs to be CNC ground on the basis of CNC turning to ensure the flatness and roughness of the sealing surface. The concave and convex surface and the tongue and groove surface sealing surface need to be CNC milled to ensure the concave and convex matching accuracy and sealing performance.

Finishing Services

In order to remove the oxide scale, oil stains and other impurities on the flange surface and improve the surface corrosion resistance, the flange is usually pickled and passivated. During the pickling process, a specific pickling solution is used to remove the metal oxides on the surface. Passivation forms a denser oxide film on the surface to enhance corrosion resistance. Under some special working conditions, if it is necessary to further improve the corrosion resistance or meet specific anti-corrosion requirements, the surface of the threaded titanium flange can be coated, such as anti-corrosion paint, thermal spray anti-corrosion coating, etc. The coating treatment must be carried out strictly in accordance with the coating process requirements to ensure the adhesion and uniformity of the coating.

Quality Inspection

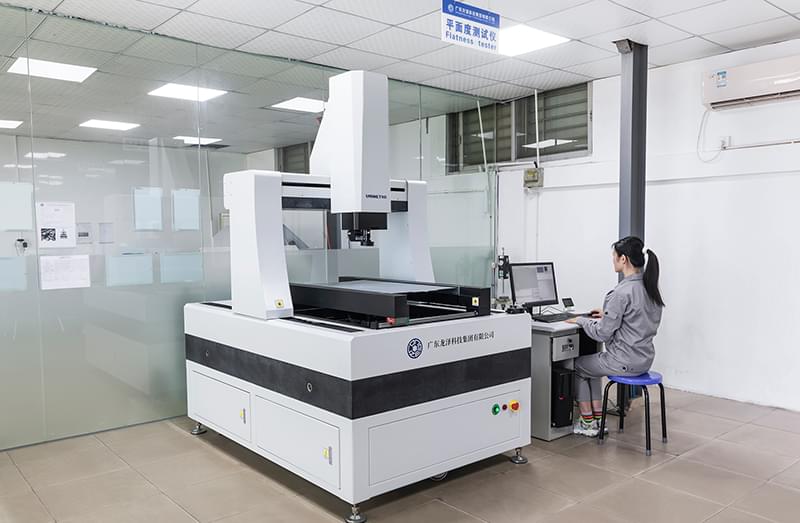

Wstitanium uses high-precision measuring tools such as calipers, micrometers, and three-coordinate measuring machines to conduct comprehensive and detailed measurements of key dimensions such as the outer diameter, inner diameter, thickness, sealing surface size, and bolt hole spacing of threaded titanium flanges. The three-coordinate measuring machine can achieve high-precision measurement of parts with complex shapes. By collecting and analyzing data from multiple measuring points, it can accurately determine whether the dimensions of threaded titanium flanges are within the range specified by the design and standards. For each measured dimension, a strict tolerance range is set. Once the dimensional deviation is found to exceed the allowable range, it will be analyzed and adjusted immediately to ensure that the dimensional accuracy meets the requirements.