Custom Manufacturing Titanium Butterfly Valves Services In China

Wstitanium manufactures titanium butterfly valves to cope with various harsh working conditions, such as chemical, petroleum, marine, food, medicine and other industries with extremely high requirements for medium purity and equipment corrosion resistance.

- 24/7 Online Service

- OEM/ODM Support

- DIN、GB、ANSI、ISO、JIS

- SGS, BV and CE Certificates

- For Marine

- For Chemicals

- For Aerospace

- For Pharmaceuticals

Your Resource For Titanium Butterfly Valves Factory - Wstitanium

The titanium butterfly valves manufactured by Wstitanium have established a good reputation in the global industrial field with their excellent performance, advanced manufacturing technology, strict quality inspection system and flexible and diverse customized services. From carefully selected titanium grades to a variety of valve types; from a series of processes covering casting, forging, CNC machining, welding, surface treatment, etc., to rigorous and precise manufacturing processes; from following international standards and providing customized sizes, multiple end connection methods, sealing solutions and operating mechanisms, to comprehensive and strict quality inspections, every link reflects Wstitanium’s persistent pursuit of quality and deep understanding of your needs. It is your trustworthy partner.

Grade1 Titanium Butterfly Valve

Grade1 has good corrosion resistance, especially in relatively weak corrosive environments. It is easy to manufacture various complex valve components, such as valve seats, small butterfly plates, etc.

Grade2 Titanium Butterfly Valve

Grade2 pure titanium achieves a good balance between corrosion resistance and strength. It is suitable for medium and low pressure pipeline systems with high salt content and strong corrosion.

Grade3 Titanium Butterfly Valve

Compared with Grade1 and Grade2, Grade3 has improved strength while still maintaining good corrosion resistance. It is suitable for the transportation of some corrosive oils and chemicals.

Grade4 Titanium Butterfly Valve

Grade4 is often used in occasions with high strength requirements, such as butterfly valves on offshore oil platforms. It can withstand strong corrosion from seawater and cope with high pressure.

Ti - 6Al - 4V (Grade5)

Ti – 6Al – 4V has high strength, good corrosion resistance and excellent high temperature performance. It meets the requirements of high temperature, high pressure and high reliability.

Ti-5Al-2.5Sn (Grade6)

It has good strength, toughness and corrosion resistance, especially in extreme environments such as high temperature and deep sea. It can withstand huge water pressure and seawater corrosion.

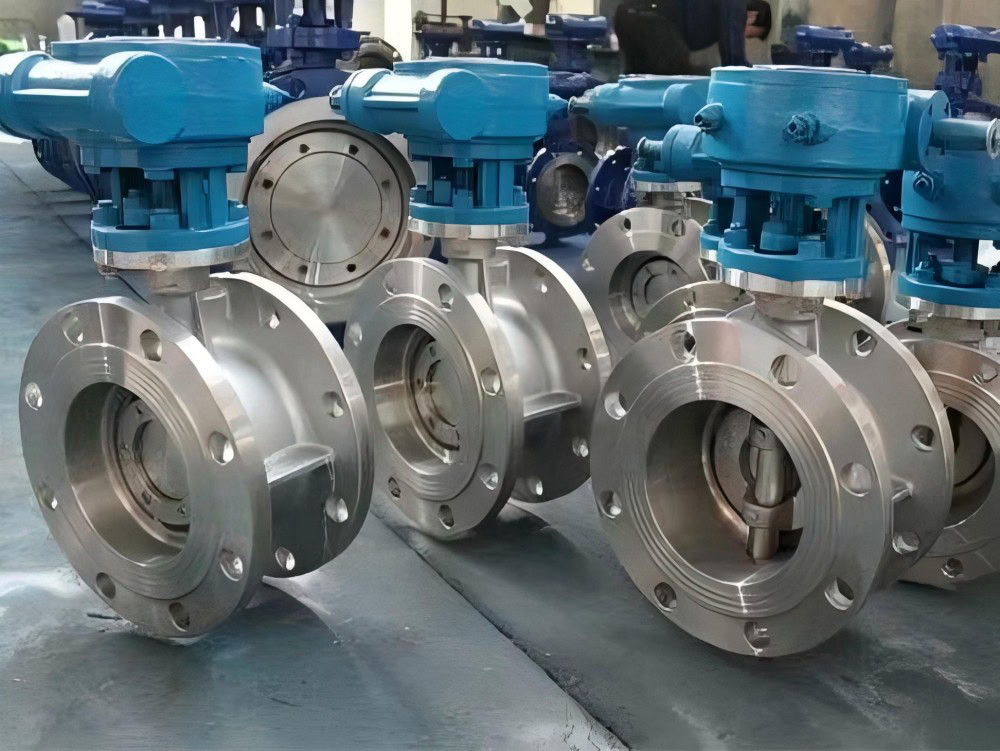

Manufacturing Titanium Butterfly Valves

Wstitanium uses a series of advanced technologies in the manufacturing process of titanium butterfly valves to ensure the high quality and high performance of the valves. These technologies cover all aspects from raw materials to finished product assembly, and each link strictly follows the international standards and ISO9001:2015 quality control system.

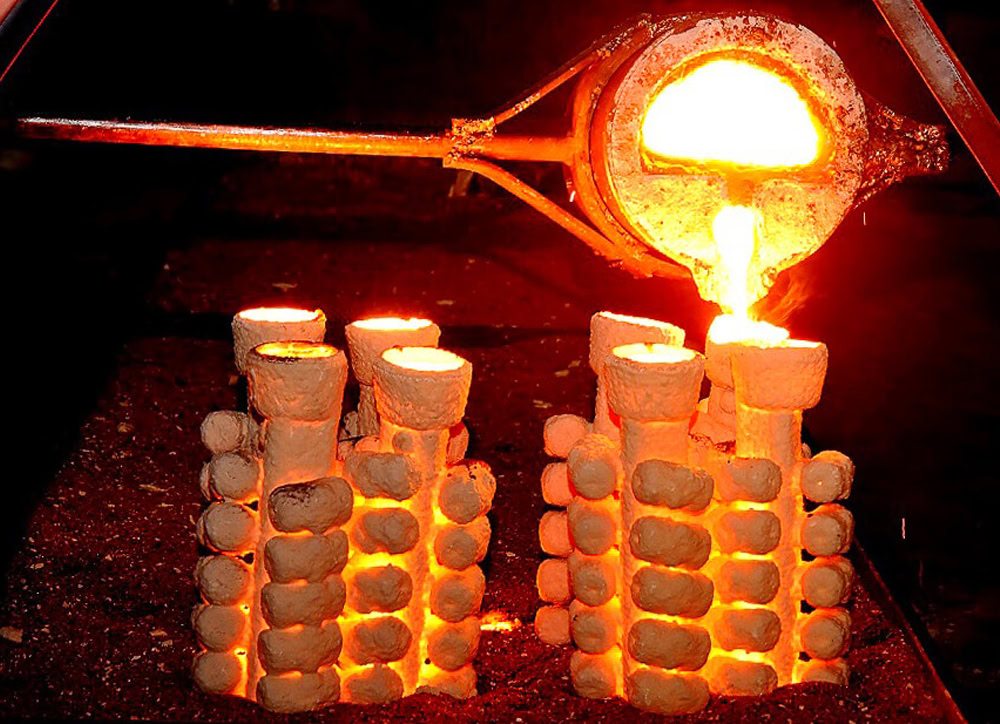

For some complex titanium butterfly valve components, such as valve bodies, Wstitanium uses advanced investment casting. This technology first uses a wax mold to make a model with the same shape as the valve body, and then coats the surface of the wax mold with multiple layers of high-temperature resistant ceramic slurry to form a solid shell. After the shell is dried and hardened, the wax mold is melted and removed, leaving a hollow shell. Then, under vacuum or inert gas protection, the molten titanium alloy liquid is injected into the shell, and after cooling and solidification, a high-precision valve body casting can be obtained. The investment casting process can produce valve bodies with high dimensional accuracy and good surface quality.

For some key force-bearing parts of titanium butterfly valves, such as valve stems and butterfly plates, Wstitanium uses forging technology. Forging is to heat the titanium blank to a suitable temperature range (generally around 700-1000℃), and then use forging equipment (such as forging hammers, hydraulic presses, etc.) to apply pressure to the blank so that it undergoes plastic deformation under pressure to obtain the desired shape and performance. The forging process can significantly improve the internal structure of titanium materials, make the metal grains more refined and uniform, and improve the strength, toughness and fatigue performance of the material. For example, after forging, the strength and wear resistance of the valve stem are greatly improved.

The titanium butterfly valve parts after casting and forging need to be subjected to precise CNC machining to achieve the dimensional accuracy and surface quality required by the design. Wstitanium is equipped with advanced 5-axis CNC machining centers, such as CNC lathes, CNC milling machines, etc., to perform turning, milling, drilling, grinding and other processing operations on valve parts. Since the cutting performance of titanium materials has the characteristics of small elastic modulus, high cutting temperature, and severe work hardening, it is necessary to select appropriate tool materials (such as carbide tools, ceramic tools, etc.) and cutting parameters (such as cutting speed, feed rate, cutting depth, etc.) to ensure processing quality and efficiency.

Surface Treatment

In order to further improve the performance of titanium butterfly valves, Wstitanium performs a variety of surface treatment processes on valve components. For the sealing surface, precision grinding and polishing processes are used to make its surface roughness meet extremely high requirements, ensuring that the valve can achieve good sealing performance when closed and effectively prevent medium leakage. For the outer surface of the valve body and other components, passivation, spraying anti-corrosion coating, etc. can be selected according to different use environments and needs. Passivation can remove impurities and oxides on the surface of titanium materials and enhance their chemical stability. Spraying anti-corrosion coating can provide an additional protective layer for the valve, which is suitable for extremely corrosive environments.

Wstitanium strictly follows internationally recognized standards when custom manufacturing titanium butterfly valves to ensure the universality and interchangeability of valves worldwide. Refer to ASME (American Society of Mechanical Engineers) B16.10 standard and ISO (International Organization for Standardization) 5752 standard. Follow standards such as ASME B16.34 and EN (European Standard) 1759. ASME B16.34 specifies the pressure-temperature rating of the valve in detail, and determines the maximum allowable working pressure of the valve according to different materials and temperature ranges.

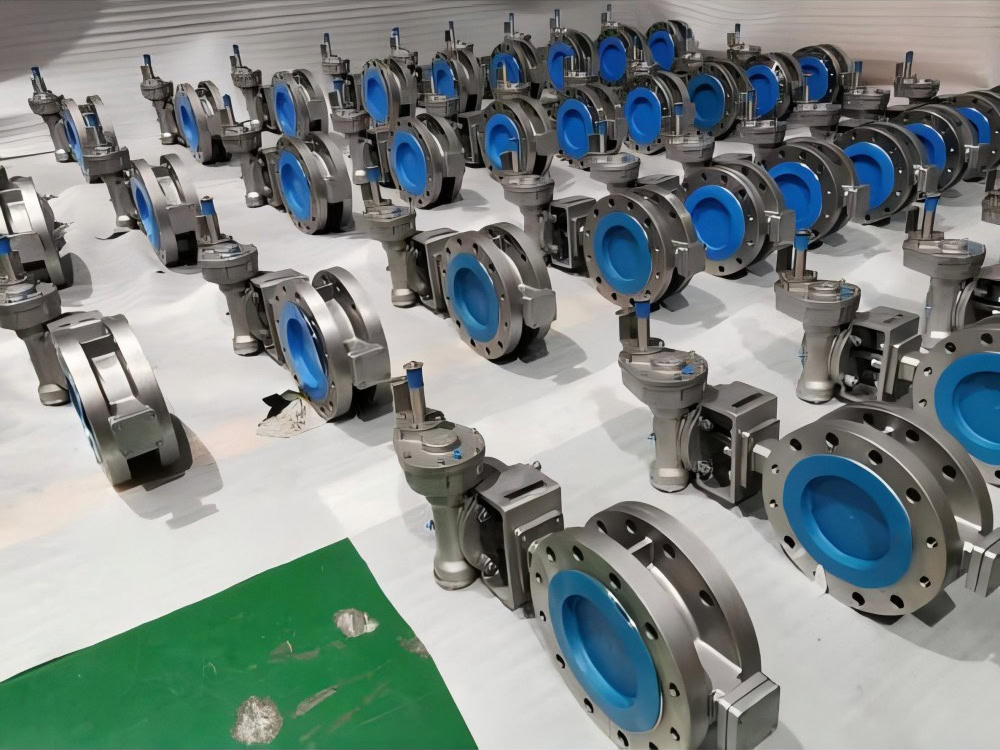

Custom Titanium Butterfly Valves Gallery