Custom Manufacturing Titanium Check Valve In China

Titanium check valve is a valve made of titanium material. It is mainly used in pipelines that need to prevent fluid backflow. Its core function is to automatically open and close the valve disc by the thrust generated by the flow of the medium to achieve one-way flow control.

- 24/7 Online Service

- OEM/ODM Support

- DIN、GB、ANSI、ISO、JIS

- SGS, BV and CE Certificates

- For Marine

- For Chemicals

- For Aerospace

- For Pharmaceuticals

Reputable Titanium Check Valve Factory - Wstitanium

Titanium check valves play an irreplaceable role in many industrial fields due to their unique material advantages and reliable one-way flow control functions. Wstitanium manufactures high-quality titanium check valves through advanced material selection and technology, precision casting and CNC machining, and a strict quality inspection system.

Lifting Titanium Check Valve

The lifting titanium check valve is machined with guide sleeves on the upper part of the valve disc and the lower part of the valve cover. This structural design makes the movement trajectory of the valve disc precise, and can accurately fit and separate with the valve seat, ensuring good sealing performance.

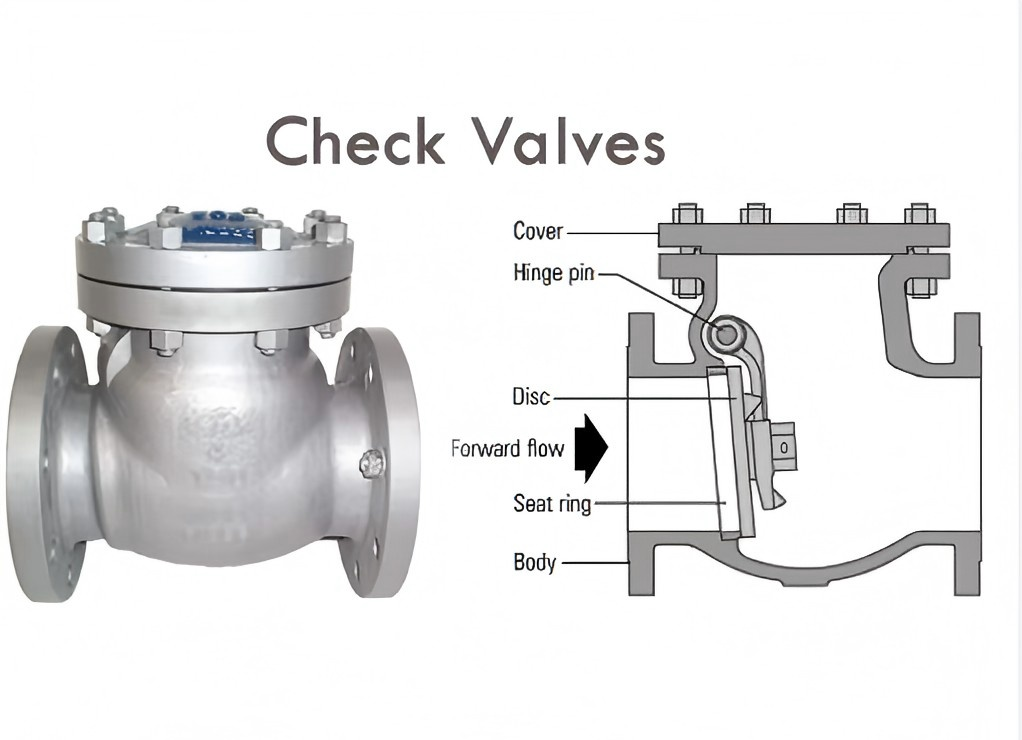

Swing Titanium Check Valve

The valve disc of the swing titanium check valve is disc-shaped and connected to the valve body through a pin shaft. The valve disc can rotate around the rotating shaft of the valve seat channel. Swing titanium check valves can be divided into single-flap type, double-flap type and multi-flap type.

Butterfly Titanium Check Valve

The butterfly titanium check valve is a special form of butterfly valve, whose valve disc rotates around the pin in the valve seat. The valve is mainly composed of a valve body, a valve disc, a pin, a seal, etc. The seal is installed between the valve disc and the valve body to ensure the sealing performance of the valve.

Working Principle of Titanium Check Valve

The operation of the titanium check valve is based on a simple and effective principle: using the force generated by the flow of the medium to control the opening and closing of the valve disc, thereby achieving unidirectional flow of the fluid. When the medium flows into the valve in the forward direction (the allowed flow direction), the pressure of the medium will generate a thrust on the valve disc. This thrust overcomes the weight of the valve disc itself (for some types that rely on gravity to close) or the preload of the spring (if the valve is equipped with a spring device), so that the valve disc moves from the closed position to the open position, and the medium can smoothly pass through the valve and enter the downstream pipeline system.

When the flow of the medium stops or there is a reverse flow trend, the situation changes. At this time, the valve disc moves rapidly to the closed position under the action of its own gravity (without spring assistance) or the elastic force of the spring (valves with springs), as well as the pressure of the reverse flow medium. The valve disc gradually approaches the valve seat until it fits tightly, thereby blocking the reverse flow path of the medium and preventing the occurrence of backflow. This working mode that automatically responds to changes in the flow state of the medium enables the titanium check valve to operate reliably in the pipeline system without external power drive.

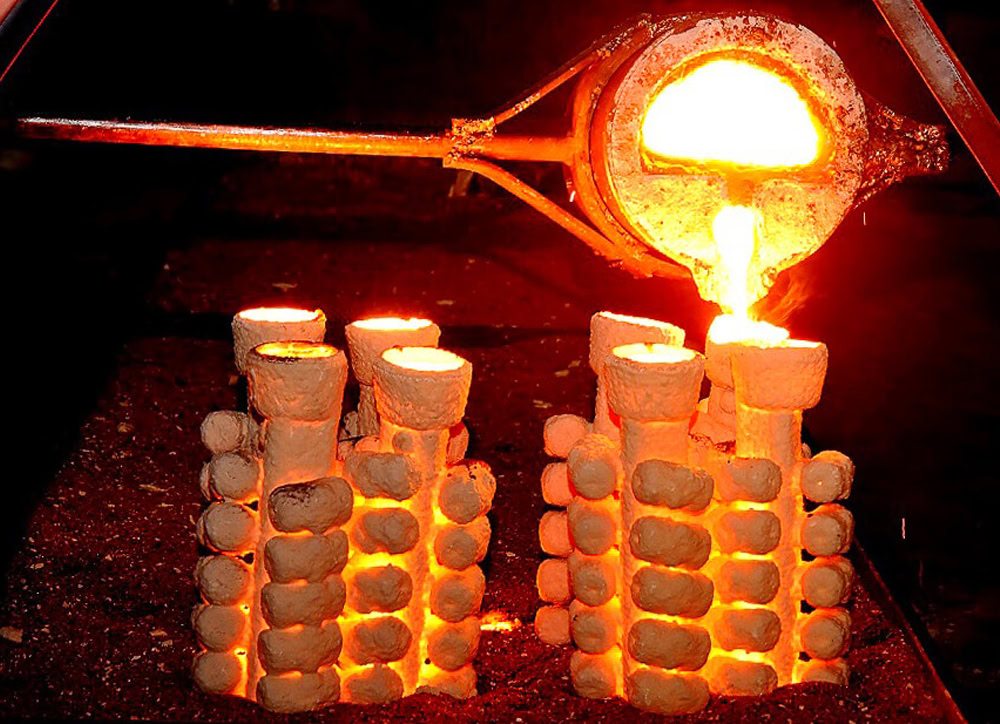

Manufacturing Titanium Check Valve

Wstitanium strictly selects titanium and titanium alloy materials when manufacturing titanium check valves. According to different application scenarios and working conditions, suitable titanium alloy grades are selected, such as Gr1, Gr2, Gr5, Gr7, Gr9, etc. These titaniums have their own advantages in strength, corrosion resistance, high temperature resistance, etc., and can meet the performance requirements of titanium check valves in various complex industrial environments.

Wstitanium uses advanced investment casting technology to manufacture key components such as the valve body of titanium check valves. The investment casting process can accurately replicate the shape of the mold and produce castings with high dimensional accuracy and good surface quality. During the casting process, the casting temperature, pouring speed and other process parameters are strictly controlled to ensure the internal quality of the casting and avoid defects such as pores and shrinkage.

For the cast titanium check valve components, Wstitanium uses high-precision CNC machining centers for machining. Through advanced manufacturing technology and programming, the size and shape of key parts such as valve seats and valve discs can be accurately created to ensure the sealing performance and overall performance of the valve. At the same time, special tools and cutting parameters are used to adapt to the characteristics of titanium to improve efficiency and quality.

Quality Inspection

Wstitanium has established a complete quality inspection system and uses a variety of advanced inspection methods to conduct comprehensive inspections on titanium check valves. In the material stage, spectral analysis, metallographic inspection and other methods are used to detect whether the chemical composition and organizational structure of the material meet the requirements. In machining, the dimensional accuracy of the parts is monitored in real time using equipment such as a three-coordinate measuring instrument. After the valve is assembled, pressure tests and sealing performance tests are carried out to ensure that the various performance indicators of the valve meet the design requirements.

- Pressure test

Install the valve on a special test device, inject liquid or gas into the valve, gradually increase the pressure according to relevant standards, test the pressure resistance of the valve under different pressure conditions, and check whether there are leakage, deformation and other abnormal conditions in the valve body, valve cover, joints and other parts.

- Sealing performance test

Apply a certain pressure medium in the forward and reverse directions to observe the seal between the valve disc and the valve seat. Simulate the water hammer pressure generated by the rapid opening and closing of the valve and the rapid change of the fluid flow rate to test whether the valve can withstand the impact without damage.

- Appearance inspection

The appearance inspection mainly checks whether the valve surface is smooth and whether there are defects such as pores, sand holes, cracks, etc. Dimension inspection uses measuring tools to accurately measure the dimensions of each part and compare them with the design drawings to ensure that they are within the tolerance range.

Wstitanium carefully controls every manufacturing process from raw material preparation to final packaging and labeling to ensure that the products meet strict performance and quality standards. This not only ensures the stable operation of the valve under various complex working conditions, prolongs its service life, but also reduces maintenance costs and safety risks for you.