Custom Titanium Globe Valve Manufacturing In China

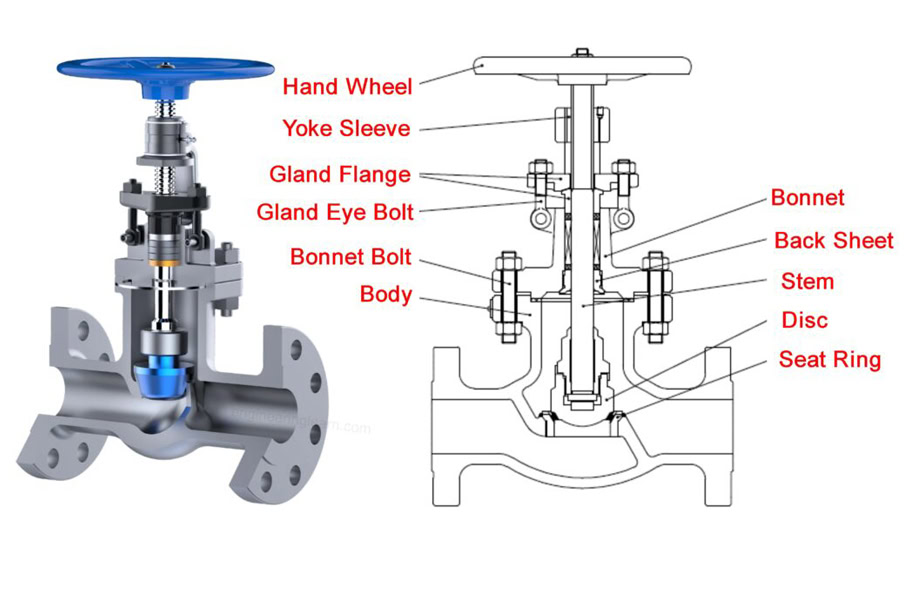

Titanium globe valve is a valve that uses the disc to move up and down along the center line of the valve seat to achieve the cutoff or throttling control of the fluid medium. It is mainly composed of valve body, valve cover, valve stem, valve disc, seal and other parts.

- 24/7 Online Service

- OEM/ODM Support

- ASTMB367 / JIS 5801 / DIN

- SGS, BV and CE Certificated

- ISO 9001:2015

- ISO 13485:2016

- Gr1, Gr2, Gr5, Gr7, Gr12

- Casting, Forging, CNC Machining

One-Stop Titanium Globe Valve Manufacturer & Supplier

Wstitanium strictly controls the quality from the careful selection of raw materials to casting, forging, CNC machining, heat treatment, surface treatment, assembly and commissioning to ensure that the titanium globe valves manufactured have the characteristics of high precision, high reliability and long life. They are widely used in chemical, marine engineering, aerospace, medicine, electric power and other industries.

Working Principle

The working principle of the titanium stop valve is based on forced sealing. When the fluid needs to be cut off, the valve stem is caused to move axially by operating the driving components such as the handwheel, gearbox, electric device or pneumatic device. The valve stem drives the valve disc to move downward, so that the valve disc sealing surface fits tightly with the valve seat sealing surface, thereby preventing the fluid from passing through the valve and realizing the cut-off function. When the stop valve is opened, as the valve disc rises, the flow area between the valve disc and the valve seat gradually increases, and the flow rate of the fluid also increases accordingly. By controlling the opening height of the valve disc, the flow rate of the fluid can be accurately adjusted to achieve the purpose of throttling control.

Titanium Globe Valve Type

Threaded Titanium Globe Valve

The valve is connected to the pipeline using threads, which is suitable for small-diameter, low-pressure pipeline systems. Threaded connection has the advantages of simple structure and easy installation.

Flanged Titanium Globe Valve

The flange connects the valve to the pipeline. It has high connection strength, good sealing, convenient installation and disassembly, etc., and is suitable for pipeline systems of various pressure and temperature levels.

Y-Type Globe Valve

Y-type globe valve has small fluid resistance and is suitable for large flow and high pressure conditions. Its structure is relatively complex, difficult to manufacture, and relatively high cost.

Custom Manufacturing Titanium Globe Valves

Titanium alloys can be divided into three categories: α titanium alloy, β titanium alloy and α+β titanium alloy. Different types of titanium alloys have different performance characteristics. When manufacturing titanium stop valves, it is necessary to select suitable titanium and titanium grades according to the valve’s use environment, working pressure, temperature, medium and other factors. For example, for valves working in highly corrosive media, titanium alloys with good corrosion resistance, such as Gr2 and Gr7, are usually selected; for valves working in high temperature environments, titanium alloys with stable high temperature performance, such as Gr5, are required. At the same time, factors such as material machining performance and cost need to be considered to ensure that the manufactured valves can meet performance requirements and have good economy.

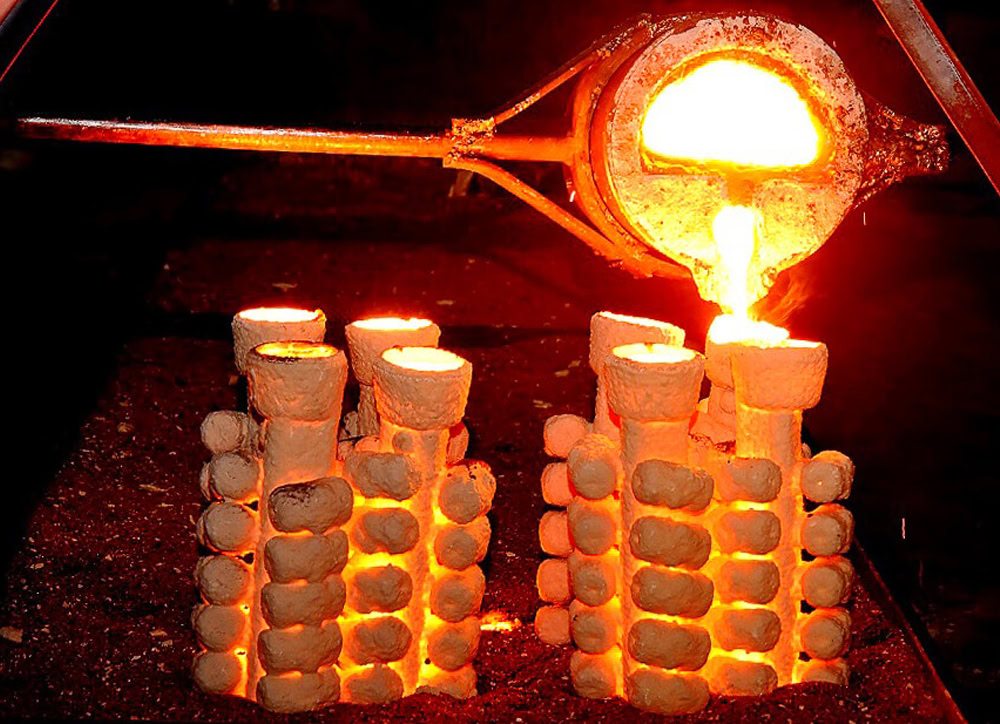

Casting

Investment casting is suitable for manufacturing titanium globe valve parts with complex shapes, high dimensional accuracy requirements and good surface quality, such as valve discs and valve seats. However, its production process is complex, the cost is high, and the production cycle is long. Control casting parameters, such as pouring temperature and cooling rate, to avoid casting defects.

Forging

Forging significantly improves the material properties of titanium and titanium alloys. Forging can refine the metal grains and make the structure more uniform, thereby improving the strength, toughness, plasticity and corrosion resistance of the material. At the same time, forging can also eliminate defects inside the metal, such as pores and shrinkage, and improve the density of titanium.

CNC Machining

Turning is to create the outer circle, inner hole, thread, etc. of the titanium globe valve. Milling realizes machining of various shapes, creating planes, grooves, gears, etc. Drilling is a method of machining holes on the parts of the titanium globe valve using a drill. Grinding is often used in precision machining to obtain extremely high dimensional accuracy and surface finish.

Titanium Globe Valves Application

Titanium globe valves are widely used in chemical, marine engineering, aerospace, medicine, power and other industries. With its corrosion resistance, high strength, lightweight, good biocompatibility and other characteristics, it has solved many fluid control problems. Whether in the transportation of highly corrosive media or in the fields of aerospace and nuclear power plants with extremely high reliability requirements, titanium globe valves have shown irreplaceable advantages.

Chemical Industry

Chemical industry often involves the transportation of various highly corrosive media, such as sulfuric acid, hydrochloric acid, nitric acid, sodium hydroxide, etc. Titanium globe valves, with their excellent corrosion resistance, can operate stably and for a long time in these highly corrosive media, effectively preventing valves from leaking due to corrosion. For example, in sulfuric acid production enterprises, titanium globe valves play a key role in ensuring the smooth transportation and precise control of sulfuric acid throughout the production.

Offshore Oil Platform

On offshore oil extraction platforms, whether it is the offshore crude oil pipeline or the various systems on the platform, a large number of valves are needed to control the flow of fluids. The marine environment is harsh, and the corrosive components in seawater, sea breeze and oil and gas seriously corrode the equipment. Titanium stop valves can work reliably in such an environment, prevent leakage accidents caused by corrosion, and ensure the safety of oil extraction operations. At the same time, its good strength and erosion resistance can also adapt to the working conditions of high-pressure and high-speed fluids in the process of offshore oil extraction.

Aerospace

In the field of aerospace, the safety and reliability of the fuel delivery system are of vital importance. Titanium globe valves, due to their light weight and high strength, can not only meet the requirements of lightweight parts of aerospace vehicles, but also withstand the high pressure and high-speed impact during fuel delivery. In the aircraft’s fuel system, titanium stop valves are used to control the flow direction and flow of fuel to ensure that the engine can obtain a stable fuel supply under various flight conditions. In the rocket’s propellant delivery system, titanium stop valves play a key role. Their rapid response and reliable sealing performance ensure the precise delivery of propellants during rocket launch and flight.

Medicine

In the production of drugs, the material and cleanliness of the equipment are extremely high to prevent the drugs from being contaminated. Titanium globe valves have good chemical stability and biocompatibility, will not react chemically with drugs, and will not release harmful substances to contaminate drugs. At the same time, its surface is smooth, easy to clean and disinfect, and can meet the strict hygiene requirements in the drug production process. In the synthesis, purification, filling and other links of drugs, titanium stop valves are used to control the delivery of various raw materials, intermediates and finished products to ensure the quality and safety of drug production.

Electricity

In thermal power plants, titanium globe valves can be used in some occasions that require high valve performance, such as steam systems of steam turbines, circulating water systems, etc. In steam systems, titanium stop valves need to withstand the erosion of high-temperature, high-pressure steam. Their good high-temperature performance and sealing performance can ensure the normal transportation and regulation of steam. In circulating water systems, titanium stop valves can resist the erosion of impurities and corrosive substances in circulating water, ensure the smooth flow of circulating water, and improve the operating efficiency and reliability of thermal power generation equipment.

As a high-performance valve product, titanium globe valve plays an important role in many industrial fields with its unique material properties and excellent performance advantages. From its definition, structural composition to working principle, each link contains advanced technology and design concepts to meet the strict requirements of fluid control under different working conditions.