Customized Titanium Ball Valve Manufacturer and Supplier

Titanium ball valves, with their excellent corrosion resistance and high strength, ensure reliable operation in various complex working conditions such as chemical industry, aerospace, marine engineering, and pharmaceuticals.

- 24/7 Online Service

- OEM/ODM Support

- ASTMB367 / JIS 5801 / DIN

- SGS, BV and CE Certificated

- ISO 9001:2015

- ISO 13485:2016

- Gr1, Gr2, Gr5, Gr7, Gr12

- Forging, CNC Machining, Casting

Reputable Titanium Ball Valve Factory - Wstitanium

Wstitanium relies on its advanced internal manufacturing equipment and technology, strict quality control system, professional team and strong R&D capabilities to ensure the high precision and excellent performance of titanium ball valves. It is your trusted one-stop customized titanium ball valve partner.

What is titanium ball valve?

The titanium ball valve is a valve made of titanium as the main material, and its core component is a sphere with a circular through hole. The valve is opened and closed by rotating the sphere, thereby controlling the flow of the fluid. When the through hole of the sphere is aligned with the axis of the pipeline, the valve is in an open state and the fluid can pass freely. When the sphere rotates 90 degrees so that the through hole is perpendicular to the axis of the pipeline, the valve is closed to prevent the flow of fluid. This simple and efficient working principle makes titanium ball valves widely used in various industrial fluid control scenarios.

- Valve Body

As the outer shell of the valve, it is the basic support structure of the entire valve. It is connected to the pipeline to guide the fluid in and out of the valve. The valve body affects the strength, sealing and corrosion resistance of the valve.

- Ball

It is a key component of the titanium ball valve. Its surface accuracy and the dimensional accuracy of the through hole are crucial to the performance of the valve. The ball ensures stable performance during frequent opening and closing operations.

- Valve Seat

Located between the ball and the valve body, it plays a sealing role to prevent fluid leakage. The valve seat material is usually selected from materials with good elasticity and corrosion resistance, such as polytetrafluoroethylene (PTFE).

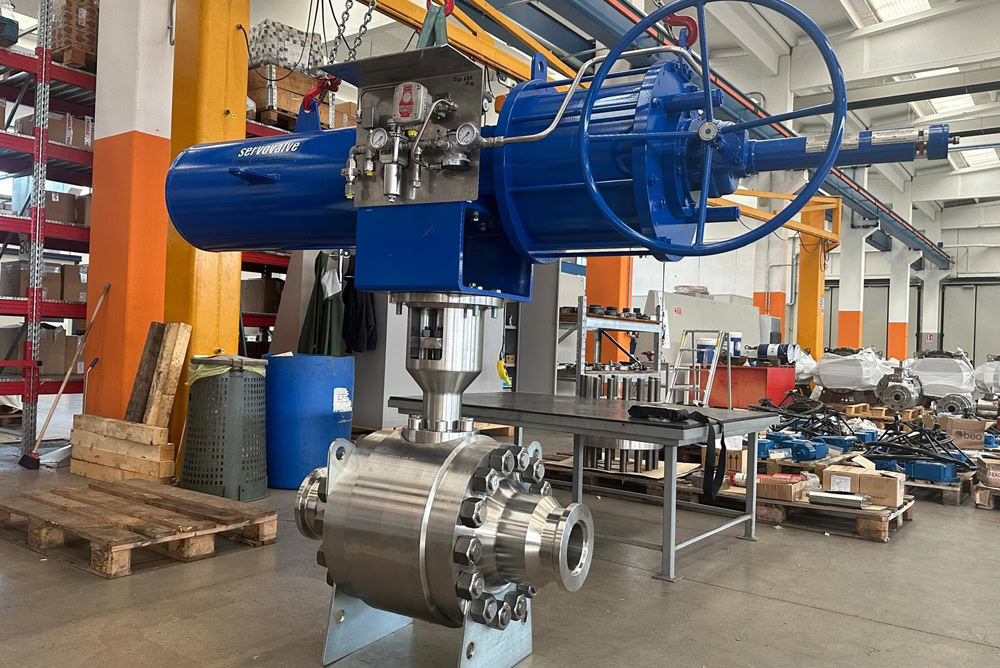

- Operating Mechanism

Driving the valve stem to open and close the valve. The operating mechanism can be a manual handle, worm gear, or electric, pneumatic or hydraulic actuator, which can be selected according to different application scenarios.

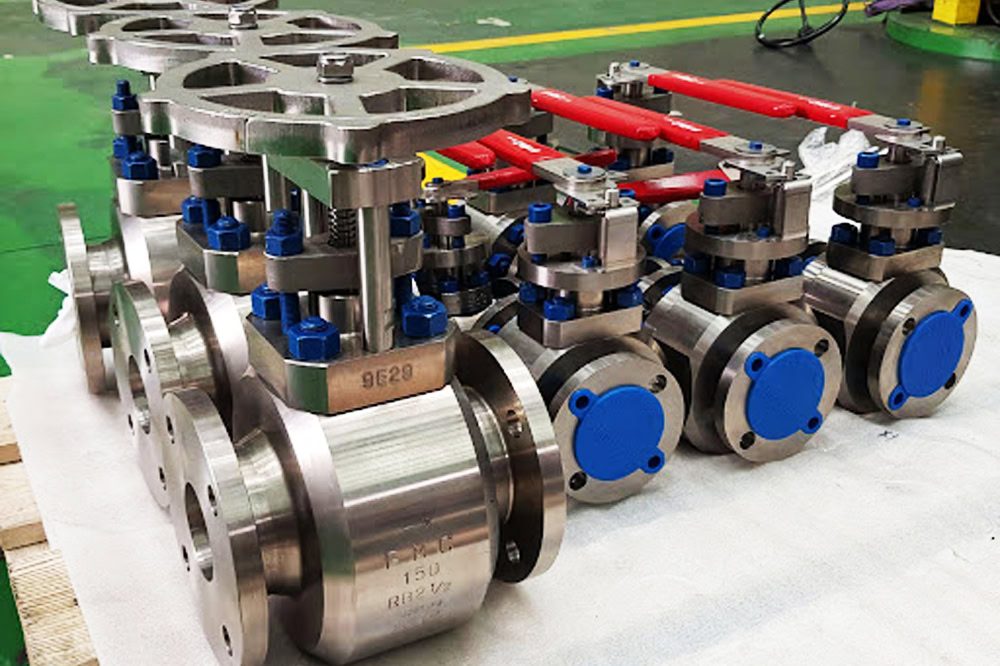

Forging Titanium Ball Valves

Forging is one of the important technologies for manufacturing key components of titanium ball valves (such as valve bodies, balls, etc.). Forging causes titanium billets to undergo plastic deformation under high temperature and pressure, thereby improving the material’s organizational structure, strength, toughness and density.

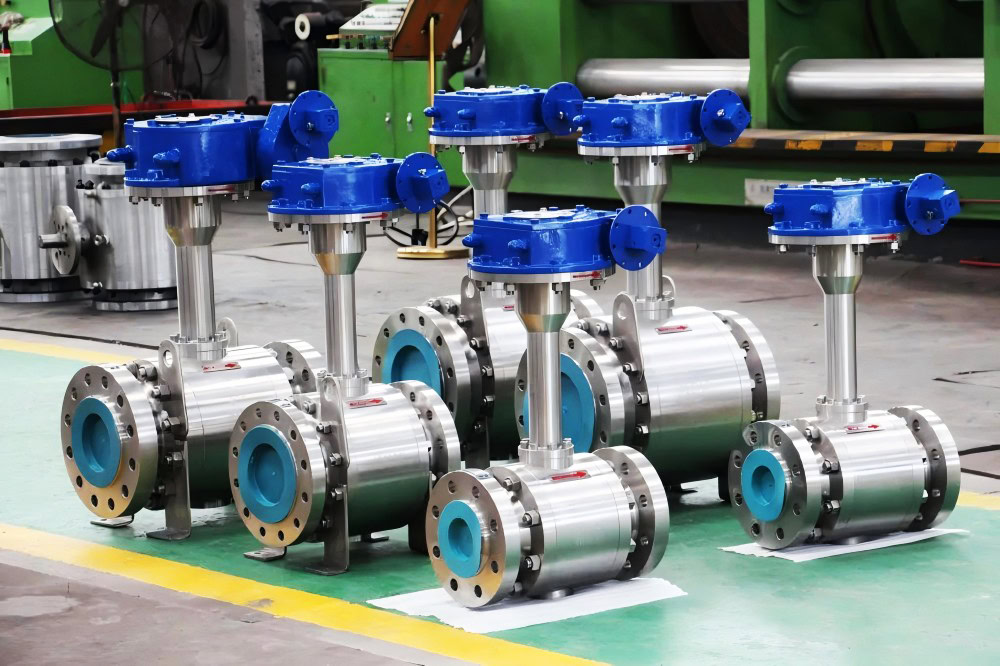

Casting Titanium Ball Valves

Casting is suitable for manufacturing titanium ball valve parts with complex shapes, such as valve bodies. Liquid titanium is cast into a mold, and the shape of the titanium ball valve is created after cooling and solidification. Investment casting accurately controls the size and surface quality of titanium ball valves.

CNC Machining Titanium Ball Valves

CNC machining is a key link in manufacturing forged or cast billets to meet design requirements. Including turning, milling, drilling, grinding, etc., accurately create the size, shape and surface accuracy of each valve component. Titanium has poor cutting performance, and it is necessary to select appropriate tool materials and cutting parameters.

Advantages of Wstitanium In Manufacturing Titanium Ball Balves

Wstitanium has invested in a series of internationally advanced high-precision 5-axis linkage CNC machining centers, CNC lathes, CNC grinders, etc., which can meet the design requirements of complex shapes and high-precision dimensions of titanium ball valves. Advanced hot isostatic pressing technology (HIP) eliminates defects such as pores and shrinkage inside castings, and improves the density and performance uniformity of materials.

Strict Quality Control System

Wstitanium conducts comprehensive inspections on each batch of titanium raw materials. The inspection content includes chemical composition analysis, mechanical property testing, metallographic structure inspection, etc., to ensure that the quality of raw materials meets the design requirements and relevant standards. Only raw materials that have passed the inspection can enter the manufacturing process, which guarantees product quality from the source.

In addition to non-destructive testing and pressure testing of titanium ball valves, targeted performance tests are also carried out. For example, for titanium ball valves used in the aerospace field, strict fatigue tests and high and low temperature cycle tests will be carried out to ensure the reliability and stability of the valves under extreme working conditions.

Professional Technical Team

Wstitanium has a professional technical team composed of senior material engineers, mechanical engineers and technical engineers. These engineers have many years of experience in the research and development and production of titanium ball valves, are familiar with the performance characteristics and manufacturing technology of titanium alloy materials, and provide customized solutions according to your needs and application scenarios.

In recent years, a series of important research and development results have been achieved in the lightweight design and intelligent control of titanium ball valves, providing customers with more efficient and reliable titanium ball valves and services.

Titanium Ball Valve Gallery