Die Casting Titanium Services

Wstitanium is a one-stop solution die-casting titanium manufacturer in China, ISO9001 & ISO 13485 certified, including mold design and development, die-casting services, CNC machining and Finishing.

- 100% Quality Inspection Report

- 20+ Surface Treatment Options

- Tolerances Up to ± 0.05mm

- 30-Day Global Delivery

- Competitive Price

WSTITANIUM Factory

Our Powerful Facilities

Die Casting Titanium Manufacturer

As one of the key supports of modern industry, die-casting titanium service is reshaping the pattern of various fields with its unique charm. With its unique performance advantages, it occupies an important position in key fields such as the lofty ambitions of aerospace, life protection in the medical field, deep blue exploration in marine engineering, and green innovation in the automotive industry.

What is Die Casting Titanium?

Die-casting titanium refers to a casting method in which liquid or semi-liquid titanium is quickly filled into the die-casting mold cavity under high pressure under vacuum or inert gas protection, and solidified under pressure. The process of titanium die casting mainly includes the steps of mold closing, injection, pressure holding, cooling, mold opening and taking out parts. High pressure helps to overcome the high viscosity of titanium liquid, so that it can quickly fill the complex mold cavity. At the same time, solidification under pressure can reduce shrinkage and shrinkage defects inside the parts and improve the density and mechanical properties of the parts.

Wstitanium Casting Titanium Capabilities

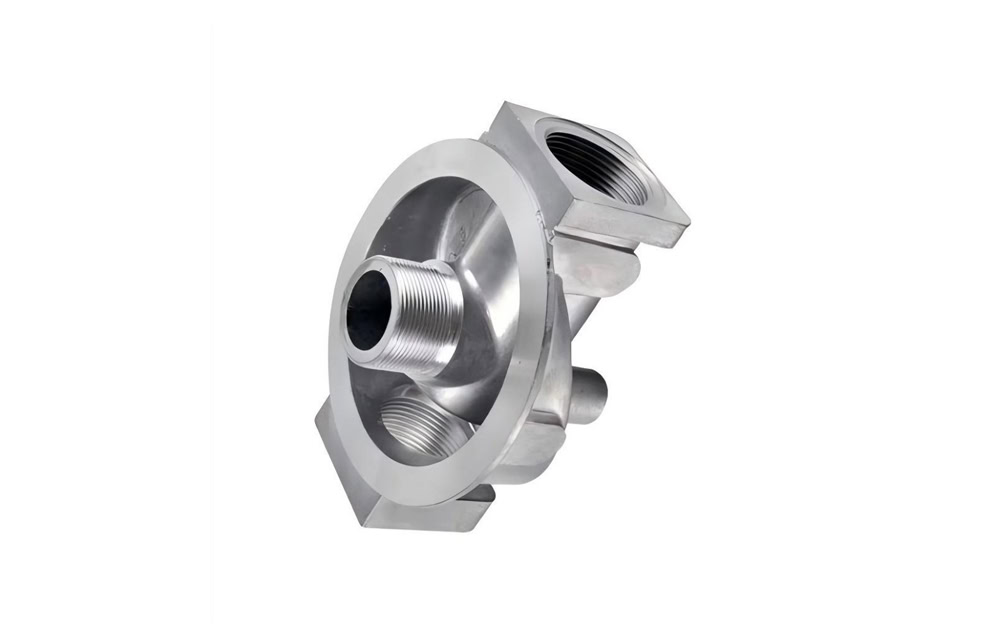

Wstitanium’s state-of-the-art titanium and titanium alloy foundry is located in Baoji, China, with a full range of multi-level capabilities to meet your stringent requirements for titanium die castings. Continuous investment in training of internal teams, such as material engineers, die casting engineers, mold designers, quality engineers, etc. Equipped with advanced manufacturing equipment, including 1000T, 2000T, 5000T die casting machines, and vacuum die casting technology. VAR furnaces can manufacture titanium castings weighing from a few grams to 100 kg. The container can accommodate parts up to 500 mm long and 250 mm high. We have extensive experience in manufacturing valves, pumps, impellers and a range of complex aerospace components.

Vacuum Consumable Electrode Shell Furnace

When die-casting titanium parts, the vacuum consumable electrode shell furnace plays a key refining role. Titanium has active chemical properties and is easy to react with gases such as oxygen, nitrogen, hydrogen and crucible materials at high temperatures, resulting in performance degradation. The vacuum consumable electrode shell furnace melts in a vacuum environment, which can greatly reduce the gas content and avoid impurities. The shell formed between the water-cooled copper crucible and the molten metal is like a protective barrier to prevent the crucible material from contacting the titanium liquid, thus eliminating the crucible from polluting the titanium liquid and ensuring the high purity of the die-cast titanium parts. In addition, the electromagnetic stirring effect is used to make the titanium liquid composition more uniform, further improving the purity of the material.

The vacuum consumable electrode shell furnace achieves precise control of the cooling rate of the titanium liquid, promotes grain refinement, improves the ingot structure, and improves the ingot quality. High-quality ingots lay a good foundation for the subsequent processing of die-cast titanium parts, ensuring that the parts have good mechanical properties and processing technology.

Design and Manufacturing Titanium Die Casting Molds

The manufacturing of die-cast titanium parts molds usually adopts CNC machining, EDM and other processes. Since mold materials such as nickel-based alloys and molybdenum-based alloys have high hardness and are difficult to process, it is necessary to select appropriate tools and processing parameters during the processing. For example, when milling nickel-based alloys, carbide tools can be used, and the cutting speed is generally controlled at 20-50m/min and the feed rate is 0.1-0.3mm/r. EDM can be used to process complex cavities and fine structures of molds.

After mold manufacturing, heat treatment is usually required to improve hardness, strength and thermal fatigue resistance. Through heat treatment, the mold structure can be made more uniform and the overall performance of the mold can be improved.

Titanium Parts Die-Casting Machine

Die-casting titanium parts need to select a die-casting machine that can provide sufficient injection pressure and injection speed. Due to the high melting point and high viscosity of titanium, a cold chamber die-casting machine should generally be selected, and the parameters of the die-casting machine such as the clamping force and injection system should be reasonably selected according to the size, shape and die-casting process requirements of the parts.For example, for the production of large titanium alloy parts, it is necessary to select a die-casting machine with a large clamping force (such as 2000-4000t) to ensure the tight closure of the mold during the die-casting process and prevent the generation of defects such as flash.

Before die-casting, the die-casting machine must be fully debugged. The debugging content includes checking whether the pressure and speed of the injection system are normal, whether the clamping force of the clamping system is uniform, and whether the cooling system and lubrication system are working well. Through debugging, ensure that the various parameters of the die-casting machine can meet the process requirements of die-casting titanium parts. At the same time, it is also necessary to debug the control system of the die-casting machine, set appropriate die-casting process parameters, and conduct simulated die-casting tests to observe the changes in various parameters during the die-casting process and optimize the parameters.

Quality inspection of die-cast titanium parts

The complexity of casting makes the quality of titanium parts susceptible to many factors. Titanium has active chemical properties and is prone to react with gases such as oxygen and nitrogen during high-temperature casting, resulting in performance degradation; slight fluctuations in casting process parameters such as temperature, time, cooling rate, etc. may also cause defects such as pores, cracks, shrinkage, etc., which seriously affect the quality and reliability of parts. In the aerospace field, a tiny casting defect may lead to a flight accident; in the field of medical devices, titanium implants that do not meet quality standards may cause serious medical problems. Therefore, Wstitanium strictly follows comprehensive quality inspections, which is essential for casting titanium parts.

Appearance inspection

Visual inspection or use a low-power magnifying glass to check whether there are pores, sand holes, cracks, flash, lack of meat, etc. on the surface of the parts. Pores are like small pits on the surface, sand holes contain impurities and are irregular in shape, and cracks are linear lines.

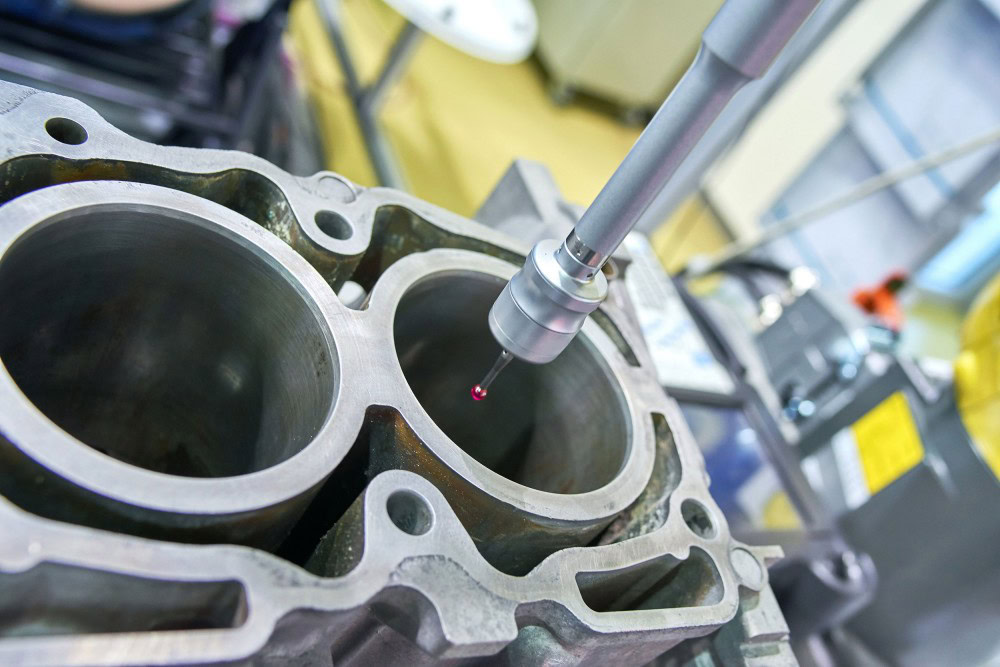

Dimension inspection

Use calipers, micrometers, three-coordinate measuring instruments and other measuring tools to compare the dimensions according to the design drawings to ensure that they are within the tolerance. Key dimensional deviations affect assembly and performance.

Chemical Analysis

Use spectral analysis, chemical titration, etc. to measure the content of titanium and alloy elements to ensure compliance with standards. Improper element ratios affect mechanical and corrosion resistance.

Metallographic Inspection

After grinding and etching the sample, observe it with a metallographic microscope to evaluate the grain size, morphology and distribution, and judge the casting process and heat treatment effect. Abnormal structure affects performance.

Mechanical properties

Tensile test measures tensile strength, yield strength and elongation; hardness test measures the hardness of the surface or specific parts of the parts; impact test measures impact toughness, reflecting the ability to resist impact.

Internal defect detection

X-ray flaw detection finds internal pores, shrinkage holes, cracks and other volume defects; ultrasonic flaw detection is sensitive to internal defects and detects small cracks and delamination.

Finishing Services

There are natural deficiencies in the surface of die-cast titanium parts. On the one hand, the die-casting process may cause microscopic defects on the surface, such as pores, micro-cracks, etc., affecting the appearance and structural integrity of the part. On the other hand, although titanium itself has certain corrosion resistance, its corrosion resistance still needs to be further improved under certain environments. In addition, some application scenarios have special requirements for the hardness, wear resistance, lubricity, etc. of the part surface. Through appropriate surface treatment technology, not only can surface defects be repaired and appearance quality improved, but also parts can be given special properties and their application scope can be broadened.

Powder coating

High-speed projectiles are sprayed onto the surface of die-cast titanium parts to cause plastic deformation and form a residual compressive stress layer. This not only improves the surface hardness and fatigue life of the parts, but also closes the surface microcracks and improves the overall structural strength.

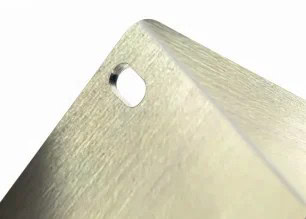

Grinding and polishing

By using abrasives and polishing tools, burrs, oxide scales, etc. on the surface of parts are removed, the surface roughness is reduced, and the surface flatness and finish are improved. For titanium implants in medical devices, grinding and polishing can reduce irritation to human tissues.

Pickling

Use acid solution to react chemically with oxides on the surface of die-cast titanium parts to remove the oxide layer and make the surface clean. For example, a mixed acid solution of hydrofluoric acid and nitric acid is often used for pickling titanium parts, which can effectively dissolve titanium oxides and restore the metallic luster.

In a high-temperature vacuum environment, titanium or other metals are evaporated and deposited on the surface of the part to form a coating. For example, depositing titanium nitride coating can significantly improve the surface hardness, wear resistance and corrosion resistance of parts.

Bead-blasting

Sandblasting the surface of titanium parts. Remove impurities and oxide scales, change the surface roughness and morphology. Sandblasting causes residual compressive stress on the surface of titanium parts, offsets some of the tensile stress during work, and improves the fatigue life of titanium parts.

Anodizing

Die-cast titanium parts are placed in the electrolyte as an anode, and an oxide film is formed on the surface by applying an electric current. This oxide film can not only improve corrosion resistance, but also obtain different colors by adjusting process parameters, and can be used for products with high decorative requirements.

Die Cast Titanium Parts Gallery