3D Printing Titanium Services - DMLS

Direct Metal Laser Sintering (DMLS) enables the creation of strong and durable 3D printed titanium prototypes and high-volume manufacturing. DMLS enables unparalleled manufacturing freedom, enabling them to create mechanically consistent end-use parts from a wide range of titanium alloy grades.

- Low volume manufacturing of titanium parts

- High performance engineering applications

- Complex designs and geometries

- Tight Tolerances +/- 0.0002”

- Medical bio-implants

Wstitanium Workshop

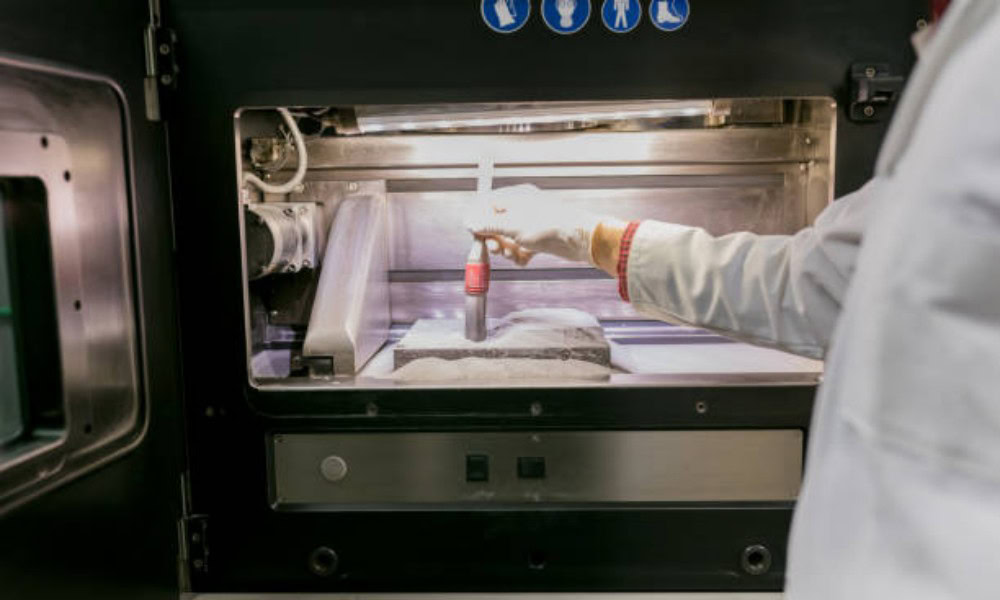

Our Powerful Facilities

DMLS For 3D Printing Titanium Parts

Direct Metal Laser Sintering, or DMLS for short, is a game changer for direct metal 3D printing. DMLS (Direct Metal Laser Sintering) ultra-high-end 3D printing technology is one of the world’s newest and most advanced manufacturing technologies, and is now in the hands of consumers, inventors, and designers like you. Wstitanium is proud to announce that starting today, everyone can use our online 3D printed titanium service – creating lightweight parts with excellent mechanical properties. Yes, custom 3D printed titanium parts!

Wstitanium DMLS Capabilities

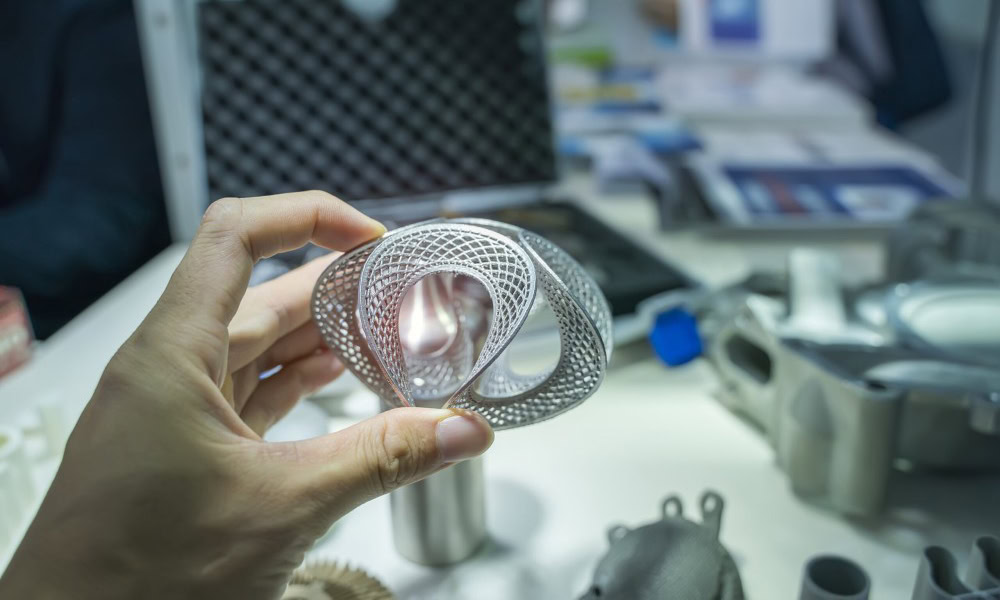

Direct Metal Laser Sintering (DMLS) is a metal 3D printing technology used to create titanium parts with exceptional mechanical properties and precision. Wstitanium’s network of manufacturing suppliers and in-house variety of DMLS machines and high-performance materials provide you with high-volume on-demand production capabilities. Designers often choose DMLS to create titanium parts because of its ability to create one-piece components and high-precision titanium parts with complex features such as internal supports and lattices. DMLS has no upfront setup or tooling costs, making it an economical choice for fully dense titanium parts with the design freedom of additive manufacturing. With the affordability, speed, and exceptional design freedom of DMLS, companies and creators can build titanium designs they never thought possible and manufacture precise titanium parts.

| Feature | Description | Feature | Description |

| Build Size | 10″ x 10″ x 10″ (250 x 250 x 250 mm) | Density | 4.42 g/cm3 |

| General Tolerances | +/- 0.0005” for the first inch is typical, plus +/- 0.0002” for every inch thereafter | Young Modulus | 105-120 GPa |

| Layer Height | .0012” – .0016″ depending on material | Yield Strength | 1085 MPa |

| Surface Roughness | 150-400 µin Ra, depending on build orientation and material used for the build | Elongation at Break | 0.09 |

| Infill | 100% | Hardness | HB 40 |

| Biocompatible | yes | Watertight | yes |

| Food Safe | yes | Recyclable | yes |

This table describes general tolerances for Direct Metal Laser Sintering (DMLS). Stress during the build process and other geometric considerations may cause deviations in tolerances and flatness. Part designs with thicker geometries, flat or wide parts, and parts with uneven wall thickness may be susceptible to significant deviation or warpage. Tolerances may be improved through manual quote review after successful prototype builds and must be approved on a case-by-case basis. Unless otherwise noted, general tolerances apply prior to secondary finishing or post-processing. Please review Xometry’s Manufacturing Standards for more information on tolerances for each process.

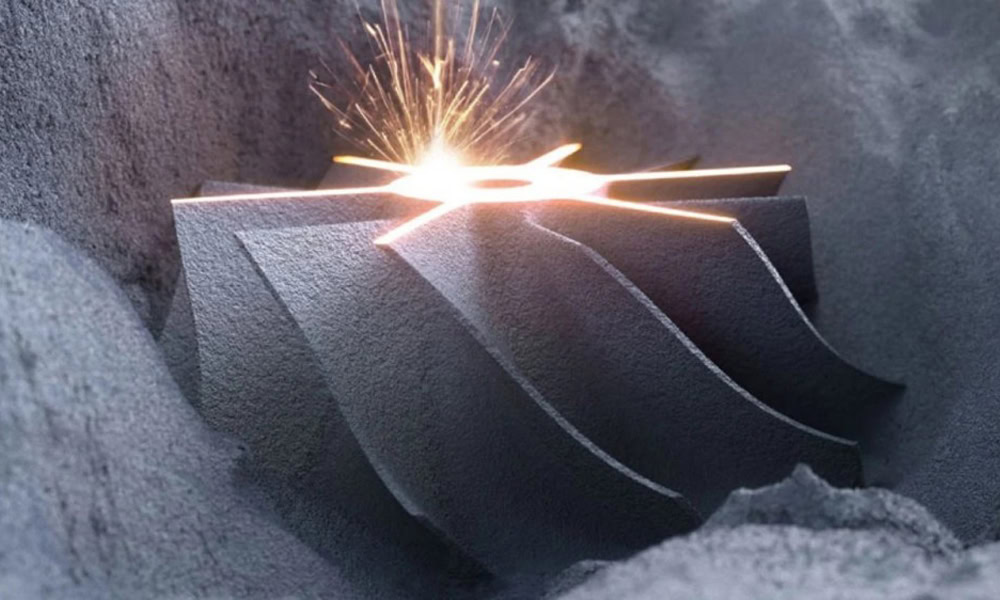

How does DMLS work?

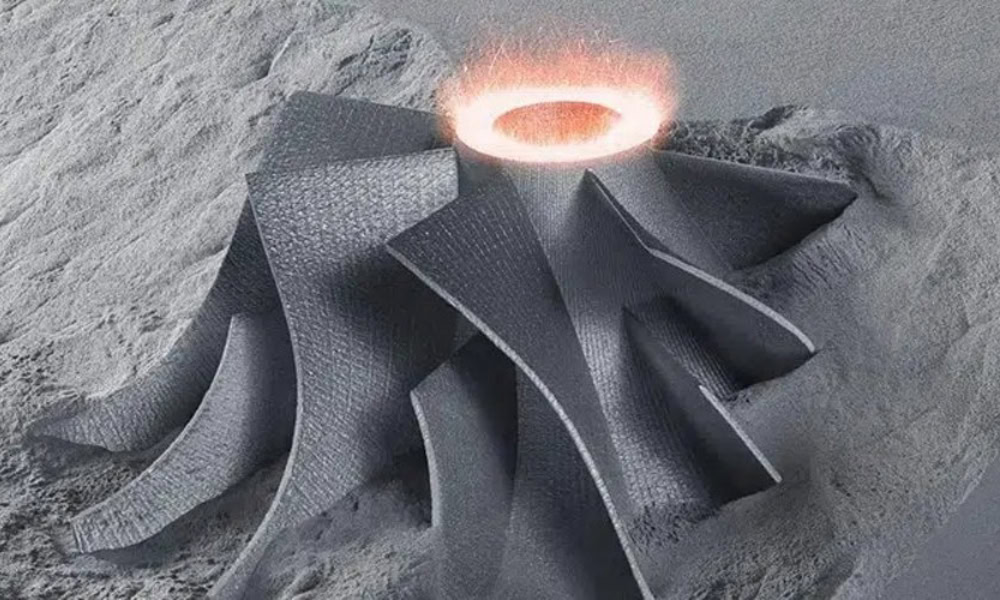

Direct Metal Laser Sintering (DMLS) is an additive metal printing technology that builds metal parts according to CAD files by selectively fusing titanium powder layer by layer using a high-power laser. This allows DMLS to produce complex parts that cannot be manufactured by traditional methods. Manufacturing metal parts using direct metal laser sintering is ideal for quickly manufacturing precision and complex titanium parts with lattice structures and cavities. This additive manufacturing technology gives designers the freedom to create lightweight, high-performance parts for a variety of end-use applications without compromising part strength. The density of structural parts can reach more than 99%, close to that of forging blanks. This additive manufacturing technology enables companies to unleash the potential of 3D printing in a variety of applications, ensuring high strength and durability of the final product. It has a wide range of applications in industries such as aerospace, automotive, and medical devices.

- A thin bed of titanium powder (20 to 60 microns) is laid down in the 3D printer.

- This layer is then sintered by a very powerful laser and will become the bottom layer of the part.

- A new layer of titanium powder is applied and the process is repeated.

- Remove your part from the 3D printer and clean off any loose, unsintered titanium powder.

- Typically, there will be 3D printed support structures made of titanium on and around your part.

- These supports must be removed manually using very powerful circular saws and other tools.

- Once the supports are removed, they need to be polished manually to remove any traces of the supports.

- Finishing such as polishing, painting, sandblasting may then be required.

Features of Direct Metal Laser Sintering (DMLS)

| Advantages | Considerations |

| The laser cladding layer and the base are metallurgically bonded, and the bonding strength is not less than 95% of the original base material | Surface roughness is higher than with CNC machining |

| The thermal effect on the material is small, and the deformation caused is also small | Higher costs than other manufacturing technologies |

| A wide range of materials, such as nickel-based, cobalt-based, iron-based alloys, cemented carbide composite materials, etc., can meet the requirements of different uses of the workpiece, and take into account the core performance and surface characteristics | Limited volume size |

| The cladding layer and its interface have a dense structure, fine grains, no porosity, no inclusions, cracks, and other defects | Structure Limits: Hollowed structure is difficult to be printed well since the supports can’t be removed clearly |

| The cladding process has good controllability and is easy to realize automatic control | Printed objects sometimes require additional heat treatment to reduce internal pressure |

Typical DMLS Titanium Grades

Titanium (Ti6Al4V) is a workhorse DMLS alloy. The mechanical properties of Ti6Al4V are comparable to wrought titanium in terms of tensile strength, elongation and hardness compared to Ti 23 grade after annealing. Titanium (Ti64) allows for parts that are lightweight but have high tensile strength, extraordinary corrosion resistance and extreme temperature tolerance. 3D objects printed with Wstitanium’s Titanium 6AI-4V are made from a fine metal powder consisting primarily of titanium (88-90%), aluminum (5.50-6.5%) and vanadium (3.50-4.50%). 3D printed titanium from Wstitanium is ideal for precision parts that require very thin walls.

| Properties | As Built | Heat Treated (at 800 °C) |

| Ultimate Tensile Strength | 1230±50 MPa (XY) | 1050±20 MPa (XY) |

| 1200±50 MPa (Z) | 1060±20 MPa (Z) | |

| Yield Strength (Rp 0.2%) | 1060±50 MPa (XY) | 1000±20 MPa (XY) |

| 1070±50 MPa (Z) | 1000±20 MPa (Z) | |

| Elongation at Break | (10±2)% (XY) | 14±1% (XY) |

| (11±3)% (Z) | 15±1% (Z) | |

| Hardness | 320±12 HV5 |

Grade 5 6Al-4V titanium is suitable for prototypes and functional parts in the aerospace and automotive sectors, as well as military applications. 3D printed titanium (unpolished) does not look like traditional shiny milled titanium. Instead, it has a matte grey finish, with a slightly rougher and less defined surface, or a slightly reflective satin finish. Parts manufactured from this alloy can be machined, spark eroded, welded, micro-peened, polished and coated if desired.

- Non-toxic

- Lightweight

- Biocompatible

- High temperature and corrosion resistance

- High stiffness and strength relative to weight

3D printed titanium part finishing is much more complex and technical than plastic 3D printed finishing. Parts made on DMLS machines have an original rough surface comparable to fine investment castings. The surface roughness is about 350 Ra-μ inches or Ra-μm 8.75, or a medium turned surface. This surface roughness can be improved all the way to 1 Ra a-μ inch or Ra a-μm 0.025, which meets the requirements of a super mirror finish. Wstitanium’s team of metal 3D printing engineers is committed to working with you to evaluate your project and ensure that your 3D model is perfect for your needs. They will help you choose the best post-processing strategy.

- Milling

- Drilling

- Turning

- Grinding

- Polishing

- Threading

- Heat Treatment

- Painting

- Shot peen

- Passivation

- Sandblasting

- Electroplating

- Screen Printing

- Powder Coating

DMLS Titanium Part Gallery