Iridium Tantalum Titanium Anode Manufacturer and Supplier In China

As a respected manufacturer of iridium-tantalum coated titanium anodes in China, Wstitanium provides customized solutions for many fields such as chlor-alkali industry, sewage treatment, electroplating industry, etc. with its advanced technology, high-quality products and perfect services.

- High Iridium Content

- Medium Iridium Content

- Low Iridium Content

- Plate, Mesh, Tube, Customized

- For Electroplating

- For Sewage Treatment

- For Electrolysis of Water

- For Chlor-alkali Industry

Iridium Tantalum Coated Titanium Anode Factory - Wstitanium

Iridium (Ir) and tantalum (Ta) both have good chemical stability and catalytic activity. Iridium-tantalum coatings are usually composed of iridium and tantalum oxides, such as IrO₂ and Ta₂O₅. These oxide coatings give the electrode high oxygen evolution overpotential and chlorine evolution overpotential, allowing the electrode to efficiently carry out redox reactions in electrochemical reactions. At the same time, the presence of the coating also enhances the corrosion resistance of the electrode, protects the titanium matrix, and extends the service life of the electrode.

High Iridium Content

Iridium content is around 60% – 90%, which has higher catalytic activity and stability, and is particularly suitable for applications requiring high current density and high oxygen or chlorine evolution efficiency, such as electrolytic cell anodes in the chlor-alkali industry.

Medium Iridium Content

The iridium content is usually between 30% and 60%. The performance is relatively balanced, with certain catalytic activity and stability, and it is more cost-effective than high-iridium types. It is used in cost-sensitive fields, such as certain electroplating.

Low Iridium Content

The iridium content is 10% – 30%. It mainly uses the characteristics of tantalum to reduce costs, while still maintaining certain electrochemical properties. It is suitable for scenarios with strict cost control, such as simple electrolysis processes in sewage treatment.

For Electroplating

It is used in various electroplating processes, such as copper plating, nickel plating, gold plating, etc. The anode needs to be able to dissolve evenly and provide a stable source of metal ions.

For Chlor-alkali Industry

It is specially designed for the electrolysis of salt water in chlor-alkali production, requiring the anode to have high chlorine evolution efficiency, low overpotential and good corrosion resistance.

For Electrolysis of Water

When used in the process of electrolyzing water to produce hydrogen or oxygen, the anode has high oxygen evolution catalytic activity and can reduce the oxygen evolution overpotential.

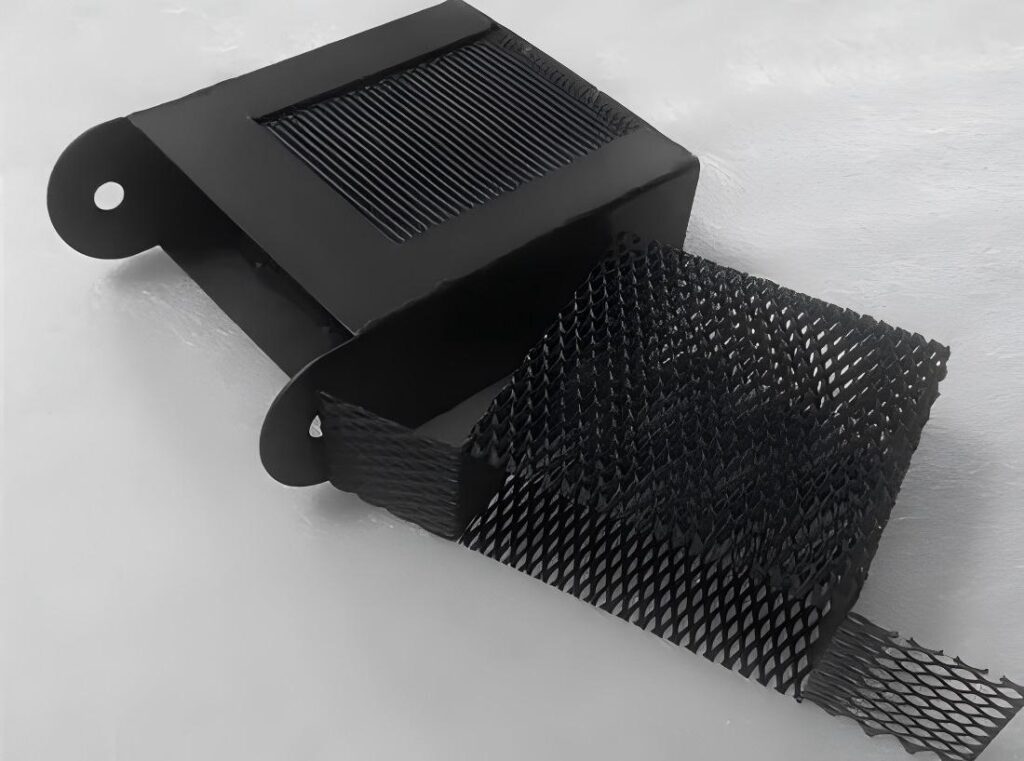

The shape is a flat plate with a simple structure and easy production. It is suitable for applications with low requirements for electrodes, large reaction area requirements and relatively smooth electrolyte flow.

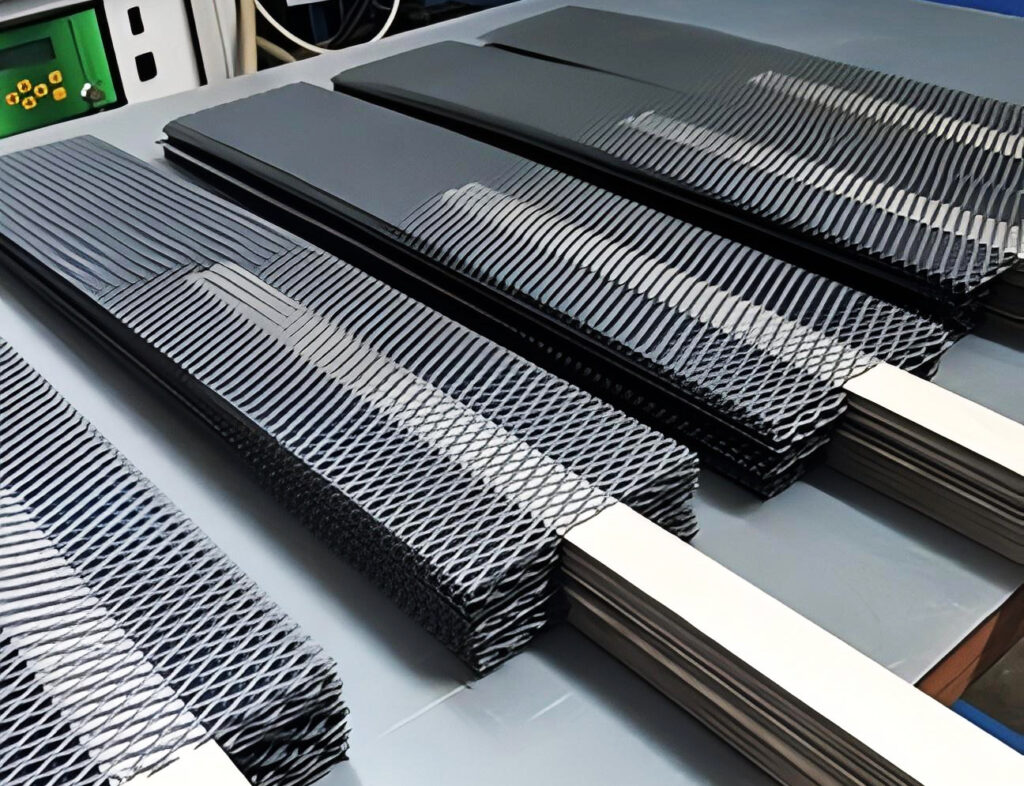

It has a mesh structure, which can increase the contact area between the electrode and the electrolyte, improve the reaction efficiency, and facilitate the circulation of the electrolyte and the escape of the gas.

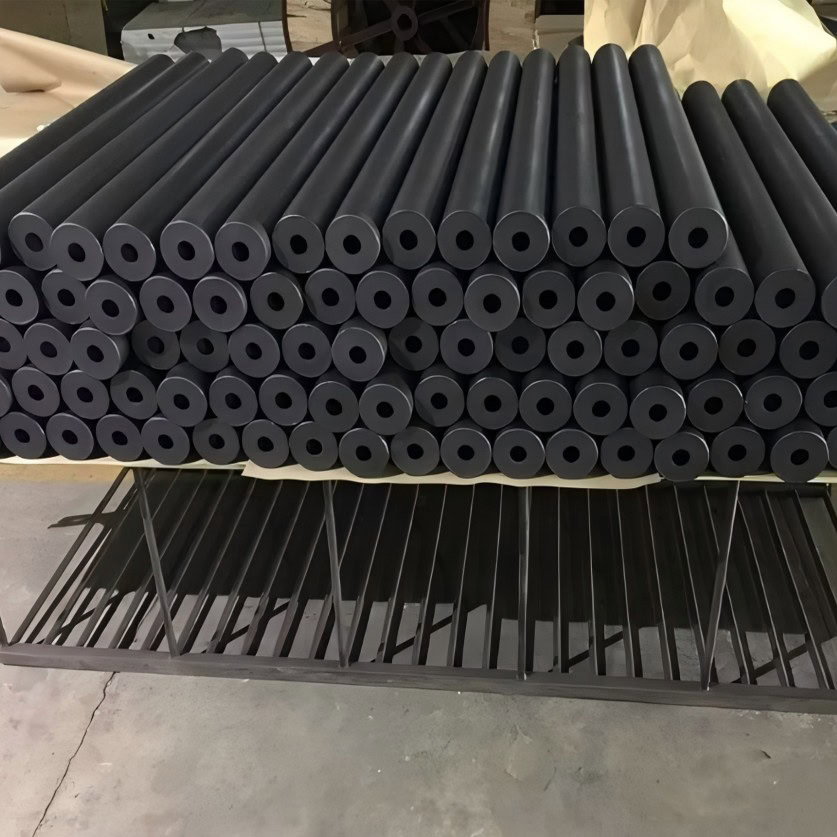

It is usually a tubular structure, and different diameters and lengths can be designed according to specific needs. Tubular anodes can better adapt to space and reaction conditions.

Basic principles of iridium-tantalum coated titanium anode

Iridium-tantalum coated titanium anode acts as an anode in an electrochemical system, and its main function is to undergo oxidation reaction under the action of current. Taking the common electrolysis of water as an example, the anode undergoes oxygen evolution reaction (4OH⁻ – 4e⁻ = 2H₂O + O₂↑), and in the chlor-alkali industry, the reaction of chloride ion oxidation to generate chlorine gas (2Cl⁻ – 2e⁻ = Cl₂↑) occurs. The presence of iridium-tantalum coating can reduce the overpotential of these oxidation reactions and increase the reaction rate and efficiency. Overpotential refers to the difference between the potential at which the electrode reaction actually occurs and the reversible electrode potential. The lower the overpotential, the less energy is required for the reaction, thereby saving electricity consumption.

The key role of iridium-tantalum coating is to protect the titanium substrate and optimize the electrochemical performance of the anode. Iridium is a precious metal with excellent electrochemical activity and corrosion resistance, and tantalum also has good chemical stability and corrosion resistance. The coating formed by the combination of the two can effectively prevent the electrolyte from corroding the titanium substrate and extend the service life of the anode. On the other hand, by adjusting the ratio of iridium and tantalum and the microstructure of the coating, the electrochemical activity of the anode can be precisely controlled to make it more suitable for different application requirements. For example, a higher content of iridium can further reduce the oxygen evolution overpotential and improve the performance of the anode in the oxygen evolution reaction.

Advantages of Iridium-Tantalum Coated Titanium Anode

The unique structure and working principle of the iridium-tantalum coated titanium anode give it many advantages such as excellent electrochemical properties, outstanding corrosion resistance, and good conductivity, which improves production efficiency, reduces costs, and promotes technological progress and sustainable development in related industries.

High performance

Iridium-tantalum coating can effectively increase the oxygen evolution overpotential of the anode and reduce the corrosion rate of the anode.

Good conductivity

Iridium-tantalum coated titanium anodes conduct current quickly and evenly during electrolysis, reducing power loss.

Titanium substrate

Titanium has good corrosion resistance, strength and plasticity. Maintain good physical properties in complex working environments.

Strong corrosion resistance

With the excellent corrosion resistance of iridium-tantalum coating, it can work stably in a variety of harsh chemical environments.

Custom Manufacturing Iridium Tantalum Coated Titanium Anodes

Wstitanium is a custom manufacturer with an excellent reputation in the field of iridium-tantalum coated titanium anode manufacturing. We use unique formulas and advanced coating technology to provide comprehensive customization services. Including titanium anode shape, size, coating thickness, composition ratio, precise adjustment according to specific needs, to ensure that the product can perfectly adapt to equipment and process flow.

Specifications of Iridium Oxide Coated Titanium Electrode

| Coating material | Iridium Oxides (IrO2), Tantalum Oxides (Ta2O5) | Precious metal content | 8-13g / m2 |

| Base metal | Gr1, Gr2 titanium | Coating thickness | 8-15μm |

| Temperature range | <85 ℃ | PH value | 1-12 |

| Current density | 500-800A | Enhanced life | 300 H-400H |

| Oxygen evolution potential | <1.45V | Fluoride content | <50mg / L |

Optimization of the Ratio of Iridium and Tantalum

The ratio of iridium and tantalum is one of the key factors affecting the performance of the coating. Different ratios will result in different electrochemical activities and corrosion resistance of the coating. Generally speaking, increasing the iridium content can improve the electrochemical activity of the coating and reduce the oxygen evolution overpotential, but it will also increase the cost. Therefore, it is necessary to determine the optimal iridium-tantalum ratio through experiments and theoretical calculations based on specific application requirements and cost budgets. For example, in the chlor-alkali industry, after a large number of experimental verifications, the iridium-tantalum ratio is 1:1 to 3:1, achieving a good balance between electrocatalytic activity and corrosion resistance. .

Anode shape

Wstitanium customizes various shapes of iridium-tantalum coated titanium anodes for your needs, such as flat plate, mesh, tubular, rod, etc. Different shapes are suitable for different application scenarios. For example, flat plate electrodes are suitable for some applications that require large area electrodes, while mesh electrodes are suitable for some applications that require higher mass transfer efficiency.

- Rods: Available from 10mm to 50mm in diameter

- Wires: Ranging from 0.5mm to 10mm in diameter

- Tubes: From 10mm to 200mm in diameter

- Plates: Thicknesses from 0.5mm to 5mm

- Meshes: 0.5mm to 2.0mm thick

Size

The size of the electrode can be customized according to the requirements of the drawing, including parameters such as length, width, thickness, etc. Wstitanium has advanced laser cutting machines, CNC machining centers, etc., which can ensure the accuracy and consistency of the electrode size. The size of the anode needs to take into account factors such as current density, electrolyte flow, and electrode spacing. Larger anode size can increase the surface area of the electrode and reduce current density, thereby reducing electrode loss and improving reaction efficiency. However, too large a size may cause uneven electrolyte flow and affect the uniformity of the reaction. Therefore, it is necessary to determine the optimal anode size through methods such as fluid mechanics and electrochemical simulation.

Coating Thickness

Coating thickness is one of the important parameters that affect the performance of iridium-tantalum coated titanium anodes. Wstitanium can control the coating thickness according to demand. Generally speaking, the coating thickness is between a few microns and tens of microns. Different coating thicknesses are suitable for different application scenarios, which requires selecting the appropriate coating thickness according to actual needs.

Support Structure

In order to ensure the stability of the anode during use, the support structure should have sufficient strength and corrosion resistance, while not affecting the flow of electrolyte and the conduction of current. Common support structures include frame type, mesh type, etc. The frame type support structure provides better mechanical support, while the mesh type support structure increases the surface area of the electrode and improves the reaction efficiency.

Connection method

A good connection method should ensure the reliability and conductivity of the electrical connection. Common connection methods include welding, bolt connection, etc. Welding connection can provide higher conductivity and mechanical strength, but attention should be paid to the impact on the titanium substrate and coating during welding. Bolt connection is easy to install and disassemble, but appropriate anti-corrosion measures need to be taken.

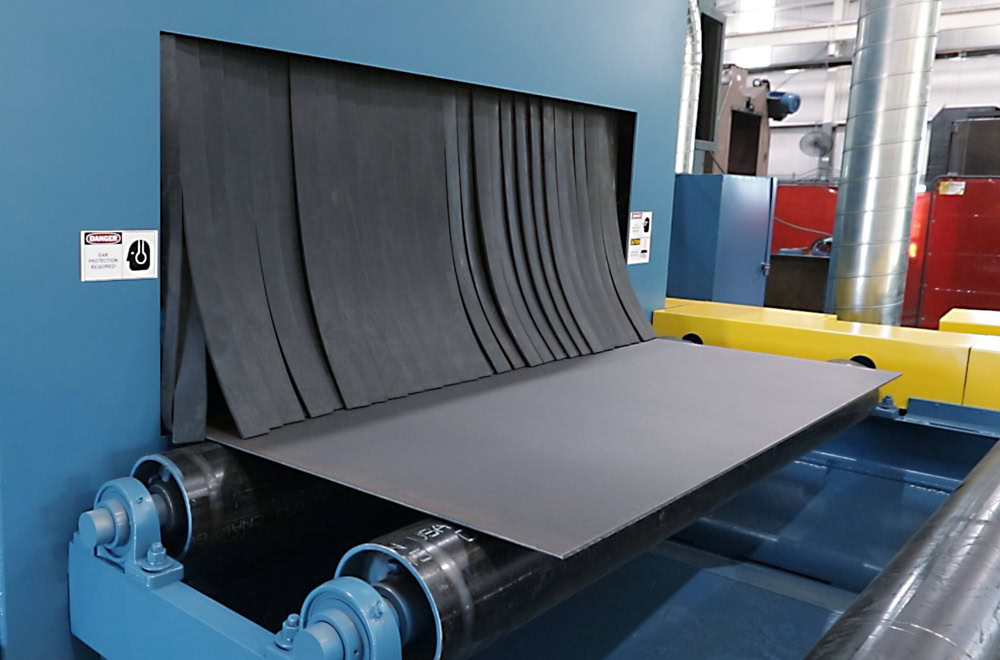

Manufacturing Process

Mechanically polish the titanium substrate to remove the titanium substrate oxide layer, oil and other impurities to make the surface smooth and clean. Next, use acid etching to further clean and increase the roughness to improve the adhesion of the coating. Prepare the coating liquid, dissolve the iridium and tantalum compounds in an organic solvent in proportion, add additives and stir evenly. Then apply the coating liquid evenly on the surface of the substrate by brushing, spraying, etc., and dry each layer after application. After thermal decomposition and curing, put the coated substrate in a high-temperature furnace to convert the compound into an iridium tantalum oxide coating at 500°C and a specific atmosphere. To ensure thickness and performance, the coating and curing steps need to be repeated many times.

Select Titanium Substrate

Confirm the titanium anode base material Gr1, Gr2. It is required to be of high purity and free of defects such as deep pits and cracks on the surface.

Forming

Shearing, laser cutting or welding, forming the titanium material into the required shape and size, such as plate, tube, rod, mesh, etc.

Sand Blasting

Sand is sprayed onto the surface of the titanium substrate to remove impurities and oxide layer, make it rough, and improve the adhesion of the coating.

Leveling / Annealing

Heat and shape the titanium material in a furnace at about 500°C, keep it warm for about 2 hours, eliminate the stress inside the material, and improve the material’s organizational structure.

Pickling

Soak the titanium material in the pickling solution to further remove the oxide scale and impurities on the surface, make the surface cleaner and rougher, and improve the adhesion of the coating.

Liquid Preparation

Mix compounds of precious metals such as iridium and tantalum with specific solvents, additives, etc. in a certain proportion to prepare a uniform coating solution.

Coating

Brush the coating solution evenly onto the surface of the titanium substrate. No impurities or dust should be contaminated.

Drying

Repeat the process of brushing, drying, heating and cooling. The coating liquid reacts fully with the substrate to form an active coating.

Quality Inspection

The size, appearance, coating adhesion, electrical properties, etc. of the titanium anode are inspected and accepted item by item.

Quality Inspection

After completing the customized design, samples are made and rigorously tested. The sample manufacturing technology and quality are strictly controlled to ensure that the performance of the sample meets the design requirements. Quality testing includes electrochemical performance testing, corrosion resistance testing, mechanical performance testing, etc. After the sample passes the quality inspection, mass production will be carried out. Manufacturers also need to record and analyze the data during the production process in order to promptly discover and solve quality problems and ensure the consistency and stability of product quality.

| Test Items | Test Conditions | Qualification |

| Combining Power | 3M adhesive tape | No black marks on the tape |

| Bend 180° on Φ12mm round shaft | No peeling at the bend | |

| Uniformity test | X-Ray Fluorescence Spectrometer | ≤15% |

| Coating thickness | X-Ray Fluorescence Spectrometer | 8-12μm |

| Chlorination potential | 2000A/m2, Saturation NaCl,25±2℃ | ≤1.13V |

| Analytical chlorine polarization rate | 200/2000A/m2, Saturation NaCl,25±2℃ | ≤40mV |

| Enhanced Lifespan | 20000A/m2,1mol/L H2SO4,40±2℃ | ≥700h(Ir+Ta 15g) |

| Intensive weightlessness | 20000A/m2,8mol/L NaOH,95±2℃, electrolysis 4h | ≤10mg |

Application of Iridium Tantalum Coated Titanium Anode

Iridium-tantalum coated titanium anodes have broad application prospects in many fields, such as electroplating, electrolytic aluminum, electrolytic copper, galvanized steel plate manufacturing, water treatment, and cathodic protection, due to their excellent electrochemical properties and corrosion resistance. By rationally designing the anode structure, optimizing manufacturing parameters and maintenance, the advantages of iridium-tantalum coated titanium anodes can be fully utilized, production efficiency can be improved, production costs can be reduced, and the goal of energy conservation and environmental protection can be achieved.

Electroplating

In electroplating, the iridium-tantalum-coated titanium anode acts as an insoluble anode and mainly conducts current. When current passes through the electroplating solution, an oxidation reaction occurs at the anode and a reduction reaction occurs at the cathode, and metal ions are deposited on the cathode surface to form a coating. The high catalytic activity of the iridium-tantalum-coated titanium anode can promote the anodic reaction and improve the electroplating efficiency and coating quality.

In a nickel plating process, the iridium-tantalum-coated titanium anode replaces the traditional lead anode. After a period of use, it was found that the coating quality was significantly improved, and defects such as pinholes and pitting were reduced by more than 80%. At the same time, the service life of the anode was extended by more than 3 times, and the power consumption was reduced by 20%.

Aluminum Electrolysis

In electrolytic aluminum, iridium-tantalum-coated titanium anodes are used to replace traditional graphite anodes, which can effectively reduce anode consumption and improve electrolysis efficiency. A large electrolytic aluminum plant tried iridium-tantalum-coated titanium anodes in some electrolytic cells. After one year of operation, anode consumption was reduced by 30%, and current efficiency was increased by 5%, saving millions of yuan in production costs each year. At the same time, due to the reduction of waste slag and waste gas emissions, the impact on the surrounding environment is also significantly reduced.

Electrolytic Copper

In electrolytic copper, iridium-tantalum-coated titanium anodes are used as insoluble anodes to oxidize and dissolve impurities in crude copper, thereby achieving copper refining. The main reaction on the anode is the oxidation reaction of copper and impurities. After an electrolytic copper plant used iridium-tantalum-coated titanium anodes in the refining process, the purity of refined copper increased from 99.5% to more than 99.9%, the service life of the anode was extended from the original 3 months to more than 1 year, and the production cost was reduced by about 15%.

Galvanized Steel Sheet

Iridium-tantalum-coated titanium anodes are used in the electrogalvanizing process. The anode undergoes an oxidation reaction under the action of electric current, providing the electrons required for zinc ions to deposit on the surface of the steel sheet. After a galvanized steel sheet manufacturer adopted iridium-tantalum-coated titanium anodes, the thickness uniformity of the zinc coating increased by 30%, the surface quality was significantly improved, and the market competitiveness of the product was enhanced. At the same time, the power consumption was reduced by 10%, and the frequency of anode replacement was reduced by 50%.

In water treatment, iridium-tantalum-coated titanium anodes are mainly used in electrocatalytic oxidation, electrolytic disinfection and other processes. Through the electrocatalytic action of the anode, pollutants such as organic matter and microorganisms in the water can be oxidized and decomposed to achieve the purpose of purifying water quality. A sewage treatment plant uses iridium-tantalum-coated titanium anode electrocatalytic oxidation process to treat industrial wastewater. After treatment, the removal rate of organic matter in the wastewater reached more than 90%, and the effluent water quality met the discharge standards.

In cathodic protection, the iridium-tantalum coated titanium anode acts as an auxiliary anode, polarizing the surface of the protected metal by providing cathodic current to the protected metal, thereby achieving the purpose of preventing corrosion. The anode undergoes an oxidation reaction, consuming its own chemical energy to provide a protective current. A certain oil pipeline uses iridium-tantalum coated titanium anode for cathodic protection. After years of operation, the corrosion rate of the pipeline has been significantly reduced, extending the service life of the pipeline, reducing leakage accidents caused by corrosion, and ensuring the safety of oil transportation.

Wstitanium will continue to be committed to the research and development and innovation of iridium-tantalum coated titanium anodes, provide you with better quality and more efficient products and services, and promote the development and application of electrochemical technology. With the continuous advancement and innovation of technology, it is believed that iridium-tantalum coated titanium anodes will play a more important role in future industrial applications. At the same time, the application research in new fields will continue to deepen, providing effective solutions to solve more industrial problems.