Custom Manufacturing Slip On Titanium Flanges

In modern industry, the reliability and safety of pipeline connections are crucial. As a high-performance connector, the titanium sleeve flange has demonstrated irreplaceable value in the fields of chemical industry, marine engineering, aerospace, etc., relying on the excellent properties of titanium alloy.

- ASME B16.5

- 24/7 Online Service

- OEM/ODM Support

- Gr1, Gr2, Gr5, Gr7, Gr9, Gr12

- M12 to M48

- Class 500- Class 2500

- Pickling + Passivation

- Forging + CNC Machining

Trusted Slip On Titanium Flanges Factory - Wstitanium

Slip-on titanium flanges have become an indispensable connection component in modern industry due to the excellent performance of titanium alloys. Its advantages such as corrosion resistance, light weight, and high strength have shown significant value in the fields of chemical industry, ocean, aerospace, etc. Wstitanium will continue to break through and provide customized manufacturing solutions for engineering challenges in extreme environments.

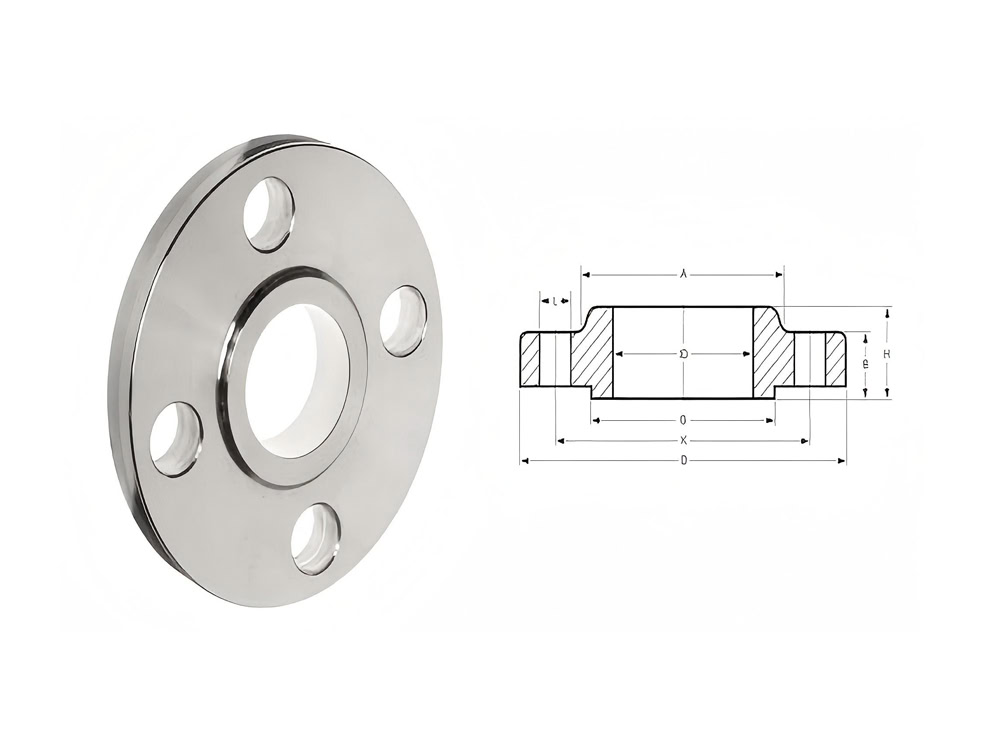

What is Slip On Titanium Flange?

Slip-On Titanium Flange is a connection device that is fixed by inserting the pipe into the flange neck and welding it. Its core structure includes flange, neck and bolt holes. According to ASME B16.5 standard, the inner diameter of the neck of the slip-on flange is slightly larger than the outer diameter of the pipe, allowing the pipe to slide freely and achieve sealing through fillet welds. Compared with butt-welded flanges, the manufacturing process of slip-on flanges is simpler and the cost is lower. It is especially suitable for low-pressure, non-high-temperature, large-diameter or frequently vibrating corrosive pipeline systems.

Advantages of Slip On Titanium Flanges

The slip-on structure of the slip-on titanium flange gives it unique installation convenience and adaptability. Compared with the traditional flange connection method, the slip-on structure does not require complicated centering operations, which can significantly shorten the on-site installation time, reduce construction difficulty and cost. Moreover, it can compensate for the processing error and thermal expansion and contraction deformation of the pipeline to a certain extent, and improve the reliability and stability of the entire pipeline system.

- Corrosion Resistance

itanium can resist 5% sulfuric acid corrosion and hypochlorite solution at room temperature, with a corrosion rate of <0.05mm/year. It is more than 90% higher than stainless steel.

- High Strength and Light Weight

Gr5 titanium has a tensile strength of ≥895MPa, a density of only 60% of steel, and a specific strength (strength/density) of 3 times that of stainless steel.

- Temperature Adaptability

Titanium maintains stable performance in the range of -250℃ to 550℃, and is suitable for extreme temperature scenarios such as liquid hydrogen storage tanks and high-temperature reactors.

Common Titanium Grades for Slip-On Flanges

Wstitanium has a rich inventory of titanium alloy materials, including industrial pure titanium (Gr1, Gr2), α+β titanium alloy (Gr5), and titanium-palladium alloy (Gr7). In response to special needs, Wstitanium introduces new titanium alloy materials or makes special adjustments to existing materials. In the chemical industry, when customers need to deal with highly corrosive media of specific concentrations and temperatures, if conventional Gr7 cannot fully meet the needs, Wstitanium develops customized materials with more targeted corrosion resistance by fine-tuning the palladium content or adding other trace elements.

Gr1

Gr1 purity is usually above 99.5%, with good plasticity and corrosion resistance, and tensile strength is generally between 240 and 345MPa. This grade of titanium alloy is suitable for some occasions that do not require high strength but have high corrosion resistance, such as food, medicine, chemical industry, etc.

Gr2

Gr2 has a slightly lower purity than Gr1, but its comprehensive performance is more balanced, with a tensile strength between 345-450MPa. It maintains good corrosion resistance and has improved strength, and is suitable for more industrial application scenarios, such as chemical pipeline connections, seawater desalination systems, etc.

Gr5

Gr5 is a typical α+β type titanium alloy, whose main alloying elements are 6% aluminum (Al) and 4% vanadium (V). Its tensile strength can reach more than 895MPa, and its yield strength is about 795MPa. Gr5 is widely used in aerospace, marine, medical, etc., and can withstand high pressure and harsh corrosive environments

Gr7

0.2% palladium significantly improves the corrosion resistance of titanium alloy in reducing acids, especially in media such as sulfuric acid and hydrochloric acid. The tensile strength of Gr7 is generally between 379 and 483MPa. It is mainly used in pipe connections involving sulfuric acid and electroplating in the chemical industry.

Custom Manufacturing Slip-On Titanium Flanges

Manufacturing slip-on titanium flanges is a combination of material science, precision forging, CNC machining, finishing and quality control. Wstitanium has established a complete manufacturing system with more than 20 years of experience in titanium alloys.During the startup phase, the Wstitanium team will communicate with you in depth to fully understand the application scenarios of your industry (such as chemical reactor connections, aviation fuel pipeline systems, etc.), operating conditions (pressure, temperature, medium characteristics, etc.), technical standards (American, European, Japanese standards) and special functional requirements (such as fire protection, explosion protection, radiation protection, etc.).

Titanium Ingot Melting

The melting of titanium ingots is the first step in the manufacture of Slip-On Titanium Tlanges. The commonly used melting methods for Wstitanium are vacuum consumable arc furnace melting (VAR). Vacuum consumable arc furnace melting is to make sponge titanium and alloy elements into consumable electrodes in a certain proportion, melt them by arc heating in a vacuum environment, and make the molten metal droplets fall into a water-cooled copper crucible and solidify into ingots. Strict quality inspection is required for the smelted titanium ingots.

Inspection items include chemical composition analysis, metallographic structure inspection, hardness test, etc. Chemical composition analysis uses spectral analysis and other methods to ensure that the alloy element content in the titanium ingot meets the design requirements; metallographic structure inspection observes the microstructure of the titanium ingot,

Forging is an important technology to improve the microstructure of titanium alloy and enhance the material performance. The forging temperature of titanium alloys of different grades is different. For example, the forging temperature of α+β type titanium alloy (such as Gr5) is generally between 850-950℃. During the heating process, the heating speed and holding time must be strictly controlled to ensure that the temperature of the billet is uniform and to avoid defects such as overheating and overburning. The heated billet is quickly transferred to the forging equipment for forging. By applying pressure, it is plastically deformed and gradually forms a billet close to the shape of the sliding titanium flange. During the forging process, the forging ratio must be reasonably controlled. Generally, the forging ratio is not less than 3 to ensure that the microstructure of the material is fully improved and its comprehensive performance is improved.

The main purpose of CNC Machining is to remove most of the excess on the blank to form the precise shape and size of the Slip-On Titanium Tlanges. CNC turning, CNC milling, CNC drilling, CNC grinding, etc. are usually used. CNC grinding is often used for the sealing surface of Slip-On Titanium Tlanges to obtain high-precision flatness and surface roughness. The flatness is within ±0.05mm, and the surface roughness Ra is below 3.2μm. For some occasions with extremely high requirements for sealing performance, honing can also be used to further improve the accuracy and surface quality of the sealing surface, so that the flatness is within ±0.02mm and the surface roughness Ra is below 0.8μm.

As a key component of industrial pipeline connection, Slip On Titanium Flanges have shown good performance in the transportation of corrosive media and reactor connection in the chemical industry, desalination and oil and gas extraction equipment in marine engineering, aircraft fuel systems and spacecraft propulsion systems in aerospace, and solved many problems that traditional materials and connection methods are difficult to deal with.