Remarkable Capability For Manufacturing Custom Titanium Parts

Wstitanium integrates the entire industry chain for manufacturing titanium products, and its processes include: CNC Machining, 3D Printing, Casting, Forging, Laser Cutting, Welding, Heat Treatment and Finishing Services.

- From Prototyping to on-demand Production

- 620,000 + Unique Parts Manufacturered

- Custom Parts Manufacturing & MOQ 1

- 3000 + companies served

- 20+ Finishing Options

Manufacturing Capability

Wstitanium integrates the entire industrial chain from raw materials to final products. The one-stop custom manufacturing model of titanium parts not only improves production efficiency, but also ensures quality control at every link, so that the final product can reach higher standards. Wstitanium uses a variety of advanced manufacturing technologies, including CNC machining, 3D printing, casting, forging, heat treatment and laser cutting. These technologies can ensure the manufacture of complex shapes and high-precision titanium parts.

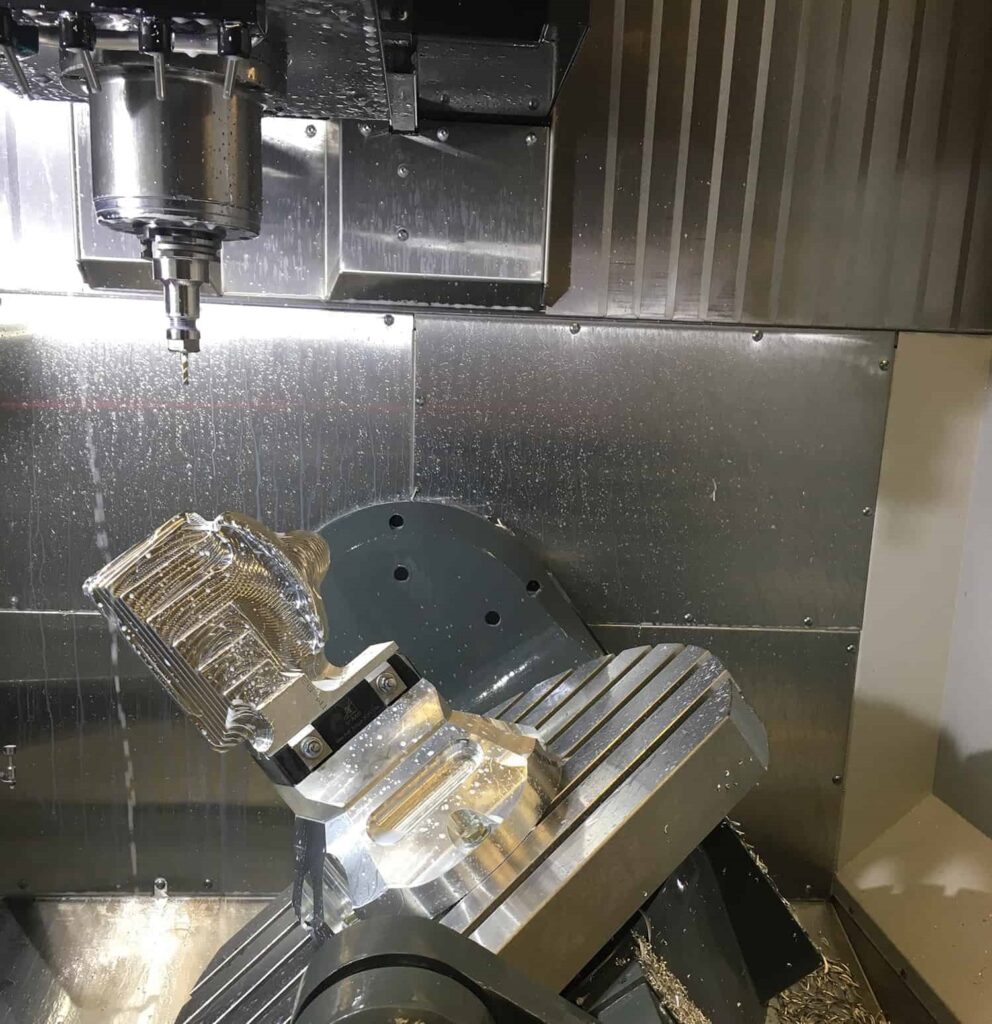

Wstitanium has invested over $5 million in 45 ultra-high precision CNC machines of well-known brands (HAAS, DMG), including: 3-axis, 4-axis, 5-axis CNC machining centers, EDM/WEDM, CNC grinding, CNC turning. Ensure the completion of complex projects and guarantee the close tolerances of manufactured custom parts. Regular internal training of engineers and programmers, as well as external training twice a year, provide you with solutions for manufacturing custom titanium parts.

- Maximum Part Size: 4000×1500×600 mm

- Threads and Tapped Holes: Φ 1.5-5 mm

- Minimum Feature Size: Φ 0.05 mm

- Linear Dimension: +/- 0.005 mm

- Minimum Part Size: 4×4 mm

- Hole Diameters:+/- 0.005 mm

- Shaft Diameters: +/- 0.025 mm

- Maximum Part Size: 200×500 mm

- Threads and Tapped Holes: Φ 1.5-5 mm

- Minimum Feature Size: Φ 0.05 mm

- Linear Dimension:+/- 0.001 mm

- Minimum Part Size: 1×1 mm

- Hole Diameters: +/- 0.005 mm

- Shaft Diameters: +/- 0.025 mm

- Minimum 0.5 mm, depth 0.1 mm

- Surface Finish Ra <3.2

Wstitanium purchased 3 metal 3D printers in 2018, providing you with direct metal laser sintering (DMLS) and selective laser melting (SLM) services. SLM is a laser-based technology that uses powdered metal. Similar to laser sintering, a high-powered laser selectively bonds titanium powder together to create parts. The most common 3D printed titanium material is Ti6Al4V.

- Accuracy: ±0.2%

- Surface Roughness: 150

- Minimum Details: 0.25mm

- Minimum Wall Thickness: 1mm

- Maximum Size: 245 x 245 x 330mm

- Elongation: 15

- Yield Stress: 138

- Hardness: 35 HRC

- Resolution: 20 μm

- Ultimate Tensile Strength: 153

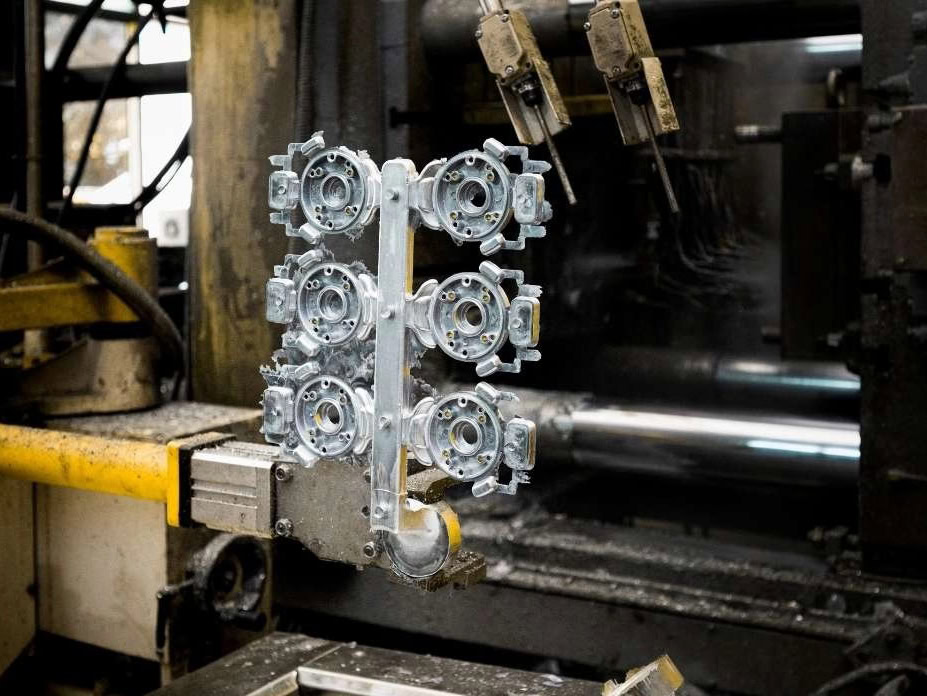

Wstitanium’s prototypes and models, complete design and manufacturing tools, and other modern production machines ensure high-quality and cost-effective titanium die casting parts with real-time X-ray inspection systems. The die casting process is carried out in a climate-controlled inspection room to meet your needs for non-toxic and precision titanium parts. The most popular titanium materials are: Ti6AL-4V, Ti6AL-4V ELI, Ti3AL 2.5, Ti5AL-2.5Sn.

- Standard: ASME SB367

- Min Wall Thickness: 0.5mm

- Casting Parts Weight: 0.001~100kg

- Surface Roughness: Ra3.2 ~ 6.3 µm

- Max Casting Size: Ф1200mm x 800mm

- Density: 4.5-4.51 g/cc

- Yield Strength: 800-1000MPa

- Tensile Strength: 1000-1200MPa

- Hardness: 200-400HBW

- Certified: ISO 9001:2015

Titanium forging is a specialized manufacturing process used to create titanium alloy components. Wstitanium has invested in 3 ring mills, 2 2,000 ton presses, and 5 drop hammers weighing 2,000-4,000 tons. The production of close tolerance, precision titanium alloy forgings has been successfully practiced. The facility is continuously updated to expand the forging capabilities and ensure that the needs of the aerospace, medical, marine, chemical and other industries continue to be met.

- Round Shafts: Ф400mm

- Flat Bar / Blocks: Ф600mm

- Cylinders / Sleeves: Ф900mm

- Seamless Rolled RingsD: Ф650mm

- Disks / Hubs / Special Shapes: Ф500mm

- 4000 ton presses: 3 units

- Custom Die Press: 400mm

- FLAT BAR / BLOCKS: 600mm

- Popular materials: α & α-β & β

- Standard: AMS 4928 or AMS 6931

Wstitanium’s machinists are skilled in many welding processes, such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), gas tungsten arc welding (TIG), etc., and are skilled in welding commercially pure titanium and most titanium alloys. To achieve good welding of titanium alloys, the first emphasis is on surface cleanliness and the proper use of inert gas shielding. Molten titanium reacts easily with oxygen, nitrogen and hydrogen, and exposure to these elements in the air or surface contaminants can have an adverse effect on the properties of titanium weld metal.

- TIG

- GTAW

- GMAW

- Clean laboratory

- Alpha Alloys

- Beta Alloys

- Alpha-Beta Alloys

- AWS A5.16/A5.16M:2007

Wstitanium provides a full range of custom titanium sheet metal services, including bending, forming, stamping, rolling, shearing, welding and assembly, etc. A one-stop solution from prototype to low-volume manufacturing, with tight tolerances up to ±0.005mm.

- Bending

- Forming

- Punching

- Rolling

- Edge Conditioning

- Shearing

- Assembly

- ASTM B265

- Adherence to DFM

- 0.5-4.75mm x 1000mm x L

The purposes of heat treating titanium and titanium alloys are to: reduce residual stresses induced during manufacturing (stress relieving), produce an optimal combination of better ductility, machinability, and dimensional and structural stability (annealing), increase strength (solution treating and aging), and optimize specific properties such as fracture toughness, fatigue strength, and high temperature creep strength.

- Fully Annealed

- Double Annealing

- Isothermal Annealing

- Solid Solution Treatment

- Aging Treatment

- α & α+β & β

- Age Hardening

- Stress Relieving

- Forging preheat Furnaces

- Slab or Bar Pre-heat For Rolling Mill

When exposed to high temperatures, titanium reacts with elements in the air, such as oxygen (O), hydrogen (H), nitrogen (N), and other elements embedded in the material, such as silicon (Si), aluminum (Al), and magnesium (Mg). This reaction forms a surface contamination layer on titanium parts that degrades their performance, resulting in increased hardness, reduced elasticity, and increased brittleness. Surface treatments can improve the aesthetics and corrosion resistance of titanium alloys. Wstitanium may offer 20+ finishing services options for titanium parts.

- Anodizing

- Passivation

- Acid Washing

- Electroplating

- Chemical Polishing

- Sandblasting

- PVD Coating

- Micro-arc Oxidation

- Mechanical Grinding

- Ultrasonic Grinding

Conclusion

Wstitanium has established a supply chain for titanium and has been doing business with international customers since its inception, and has established strategic partnerships with well-known companies in the global titanium industry. Wstitanium’s investment in advanced facilities and superb technical advantages ensure that you receive high-quality titanium products suitable to meet the specifications of their given projects. Wstitanium is very flexible and can customize any specific titanium product, and attaches importance to every step of the process. This may include planning, budgeting, raw material preparation, inspection and final delivery of the finished product. Wstitanium regards customer service as an important part of the business. We provide customers with transparent information and complete quotations covering the entire production process, answering any technical questions about our products. When you buy from us, you buy more than just raw material products. You buy from us is excellent service and technical support.