Powerful Titanium Heat Exchanger Manufacturer & Supplier

Titanium heat exchanger, as a highly efficient, energy-saving and environmentally friendly heat transfer equipment, will be widely used in more fields. Wstitanium will continue to uphold the concept of innovation, quality and service, continuously increase investment in technology research and development, equipment renewal and talent training, and continuously improve its core competitiveness.

- Gr.1

- Gr.2

- Gr.3

- Gr.4

- Gr.5

- Gr.7

- Gr.9

- Gr.10

- Gr.11

- Gr.12

- Gr.16

- Gr.17

- Gr.23

- Gr.27

- Gr.29

- Length: up to 16.5 m

- Surface:Polished/Pickling

- Wall Thickness: 0.89 - 5.52 mm

- Standard: ASTM B 338 & ASTM B 861

- Customization available upon request

Trustworthy Titanium Heat Exchanger Factory - Wstitanium

Titanium heat exchangers have an indispensable position in the chemical, petroleum, power, marine, food and pharmaceutical industries due to their excellent corrosion resistance, high strength-to-weight ratio, excellent heat transfer efficiency and good biocompatibility. As a titanium heat exchanger manufacturer and supplier, Wstitanium is committed to providing high-quality, customized and comprehensive technical solutions to global customers.

- Working temperature:-28.3-500°C

- Media type: oil, water, air, gas, stream

- Working pressure: maximum to 1.31Mpa

- Heat exchange area:1-800m

- Standard: ASME, ANSI, JIS, GB

- Color: based on customer requirements

Gr1 Titanium Heat Exchanger

Gr1 Titanium Heat Exchanger is suitable for applications with high corrosion resistance but relatively low strength requirements, such as heating or cooling of food liquids, heat exchange of pharmaceutical solutions, etc.

Gr2 Titanium Heat Exchanger

Gr2 is the most commonly used grade of industrial pure titanium. Gr2 Titanium Heat Exchanger is used for heating and cooling of seawater, as well as heat exchange equipment for acid and alkali solutions that are not too corrosive.

Gr7 Titanium Heat Exchanger

Gr7 Titanium Heat Exchanger is suitable for chemical industries such as contact with hot acids and chlorine, as well as heating or cooling of electroplating solutions to resist corrosive components in electroplating solutions.

Gr9 Titanium Heat Exchanger

Gr9 Titanium Heat Exchanger has good comprehensive performance, and is suitable for applications that require corrosion resistance and strength, but do not require high strength like Gr5, such as small chemical heat exchangers.

Gr5 Titanium Heat Exchanger

Gr5 is the best titanium alloy with high tensile strength, excellent corrosion resistance and good biocompatibility. It is commonly used to manufacture heat exchanger components in aircraft engines and heat exchange systems for aviation fuel.

TC11 Titanium Heat Exchanger

TC11 can work for a long time below 500 degrees and maintain good mechanical properties and corrosion resistance in high temperature environments. It is mainly used to manufacture heat exchangers that need to work at higher temperatures.

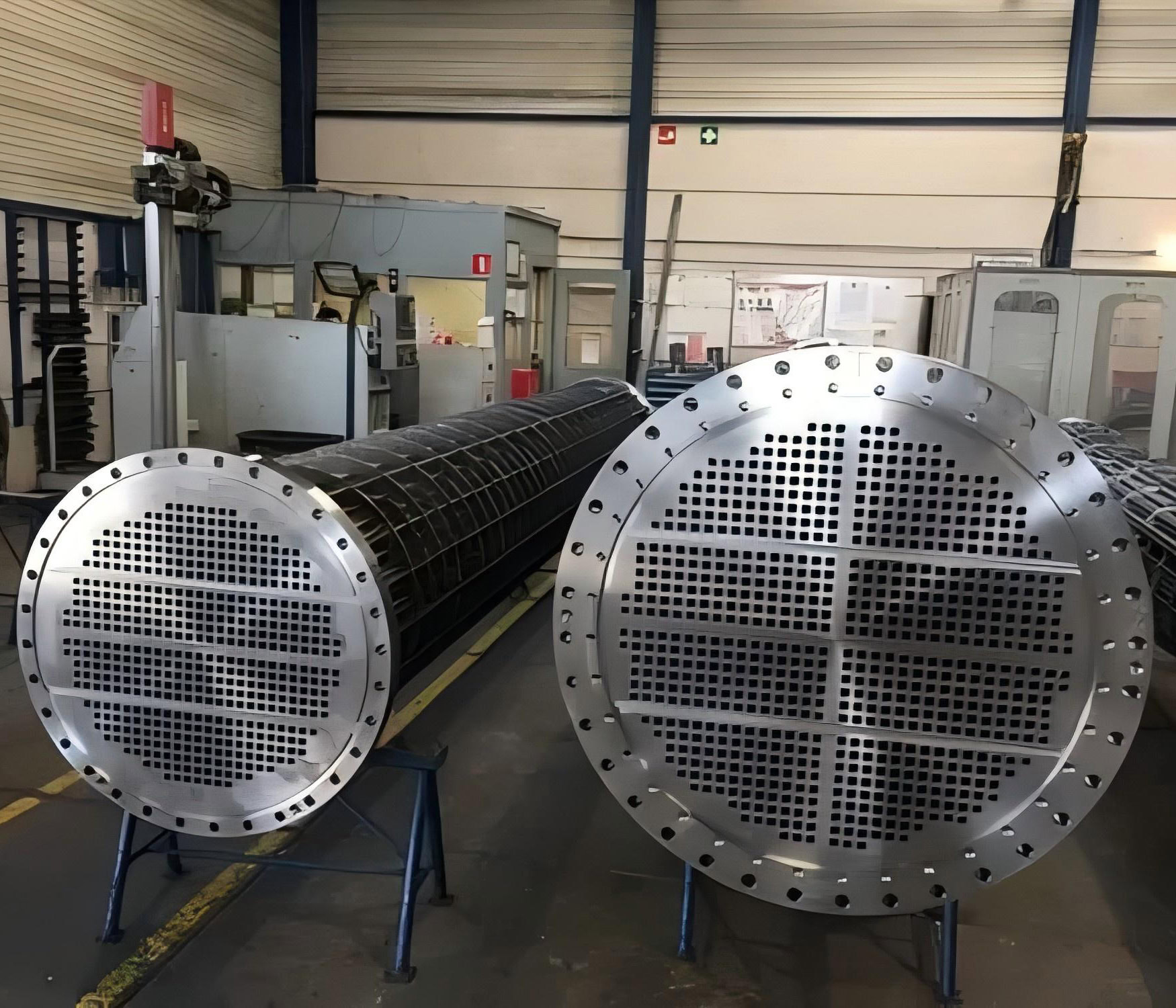

Tube Shell Titanium Heat Exchanger

The fixed tube sheet type has a simple structure and low cost. The floating head tube bundle is easy to clean and repair. The U-tube type can be freely expanded and contracted without temperature difference stress, which is suitable for high temperature, high pressure and clean fluid in the tube.

Plate Titanium Heat Exchanger

It is composed of a series of corrugated metal plates, and thin rectangular channels are formed between the plates. Its advantages are high heat transfer coefficient, compact structure, easy disassembly, easy cleaning and maintenance, and suitable for liquid-liquid heat exchange with small flow and low pressure.

Spiral Plate Titanium Heat Exchanger

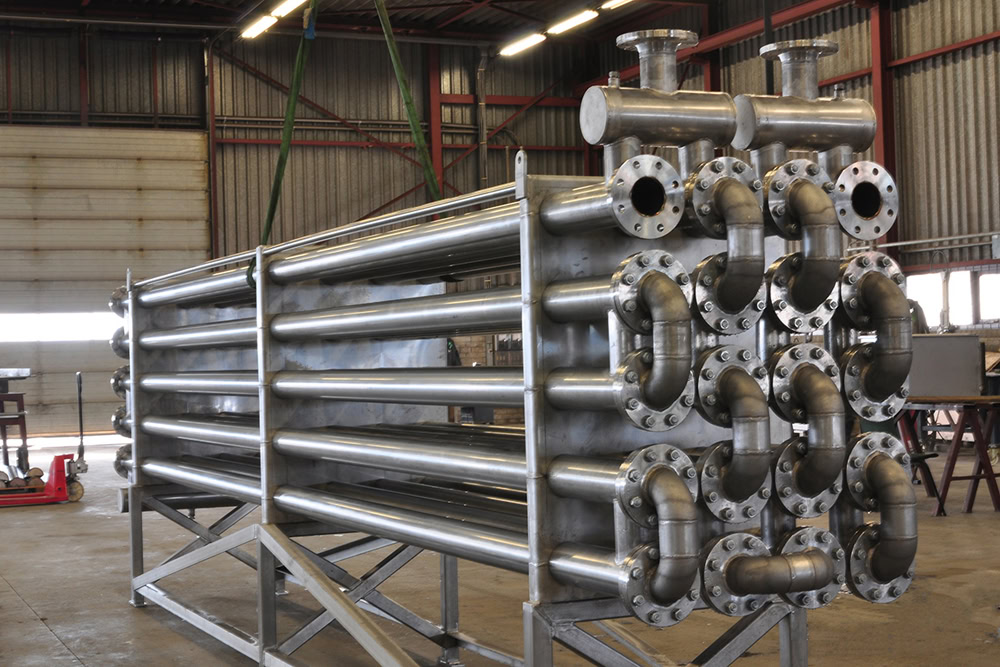

It is made of two parallel metal sheets rolled to form two spiral channels. The fluid flows in the spiral channel, which has the advantages of high heat transfer efficiency, not easy to scale, and can handle high viscosity fluids. It is suitable for heat exchange of corrosive media such as chemical and petroleum.

Manufacturing Titanium Heat Exchangers

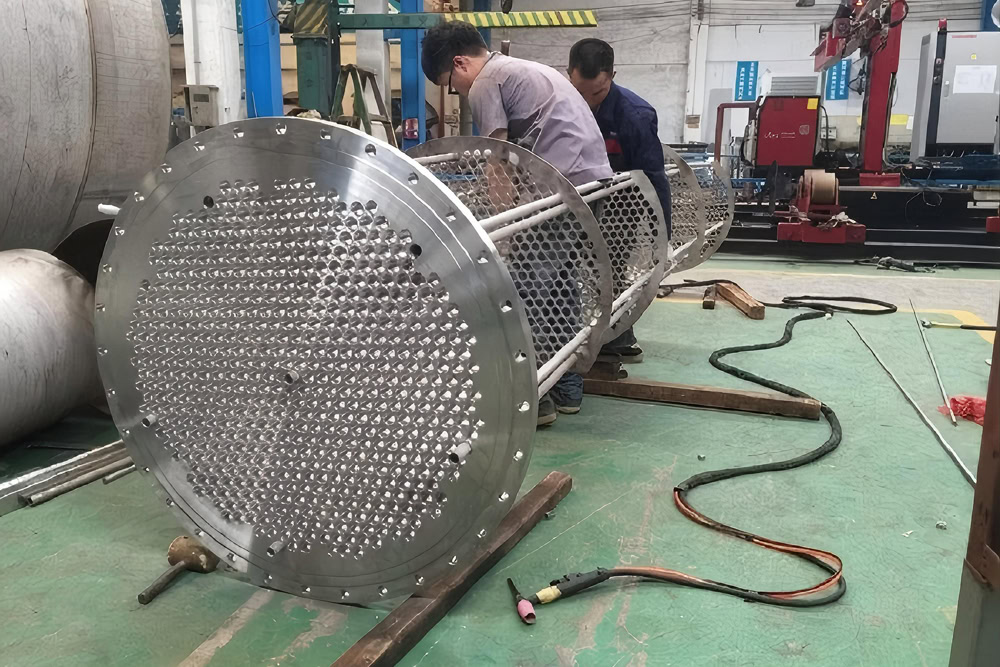

According to the design and application of the heat exchanger, choose the appropriate titanium grade and specification of titanium. For shell and tube heat exchangers, it is necessary to purchase raw materials such as titanium tubes and titanium plates. For plate heat exchangers, titanium plates are purchased for stamping plates. Wstitanium conducts strict inspections on the purchased titanium materials. The chemical composition of titanium materials is detected by spectral analysis to ensure that they meet the corresponding grade standards. Mechanical performance tests such as tensile tests and hardness tests verify the strength, plasticity and other performance indicators of titanium materials. Ultrasonic flaw detection and radiographic flaw detection are used to check whether there are defects such as cracks and pores inside the titanium materials.

Titanium Plate Machining

According to the design size of the heat exchanger, CNC cutting machines and other equipment are used to cut titanium plates. During cutting, Wstitanium strictly controls the dimensional accuracy to ensure the specifications of the plates. For some parts with complex shapes, high-precision equipment such as laser cutting machines are used for cutting.

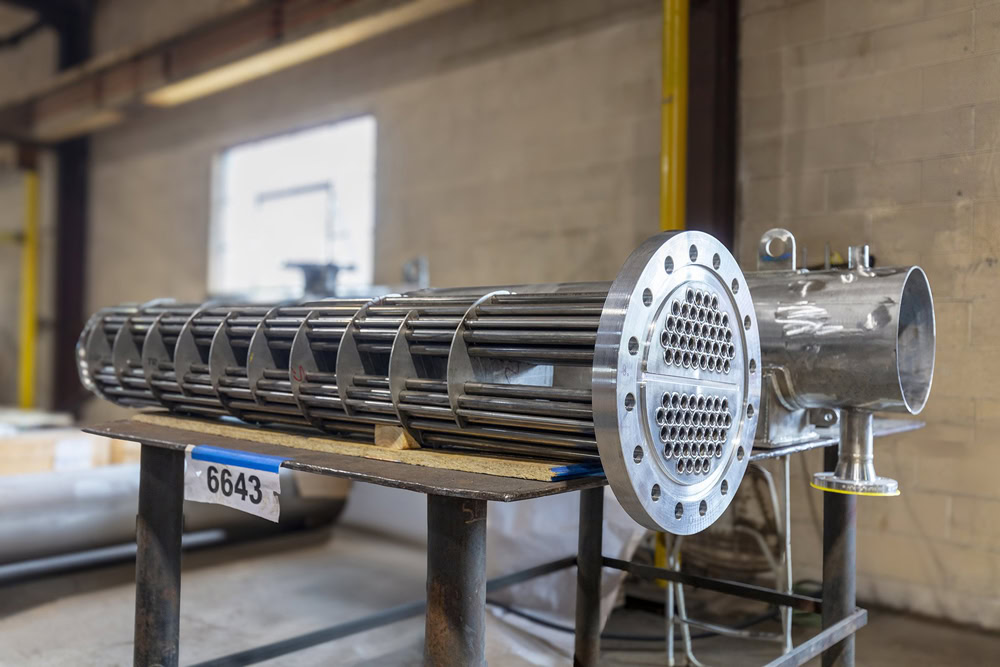

Tube Machining

The titanium tube is cut according to the designed length, and the cutting equipment can be a tube cutter. During the cutting process, attention should be paid to controlling the flatness and verticality of the cut end surface to avoid defects such as burrs. For the connection between the titanium tube and the tube sheet of the shell and tube heat exchanger, the titanium tube usually needs to be expanded or flanging. Flaring is to expand the end of the titanium tube so that it can be better connected to the tube sheet. Flanging is to fold the end of the titanium tube to increase the strength and sealing of the connection.

Titanium materials are usually welded by argon arc welding (TIG welding), plasma arc welding, etc. Argon arc welding has the advantages of stable arc, good protection effect, and high weld quality. It is one of the most widely used technologies in titanium heat exchanger welding.

In welding, high-purity argon gas is used as a shielding gas to prevent titanium materials from reacting with oxygen, nitrogen, etc. in the air at high temperatures to ensure the quality of the weld. Welding parameters have an important influence on the quality of the weld, including welding current, welding speed, arc voltage, argon gas flow, etc. Before welding, it is necessary to evaluate the welding process according to factors such as the grade and thickness of the titanium material to determine the appropriate welding process parameters. During welding, these parameters are strictly controlled to ensure that the weld depth and width are uniform, and there are no defects such as pores and cracks.

After welding is completed, the weld is fully inspected. In addition to the appearance inspection, observe whether the weld surface is flat, whether there are defects such as undercuts and pores, non-destructive testing is also required, such as ultrasonic testing and radiographic testing, to detect whether there are defects such as incomplete penetration and slag inclusions inside the weld. For some important welds, mechanical property tests such as tensile tests and bending tests may also be required to verify whether the strength and toughness of the weld meet the requirements.

Assembly

For shell and tube heat exchangers, install the tube bundle into the shell and fix the two ends on the tube sheet. Pay attention to the arrangement and spacing of the tube bundle to ensure that the fluid can flow evenly in the tube side and shell side. Then, install the baffles, heads, pipes, etc., and assemble the components together by welding or flange connection. During assembly, ensure that the installation position of each component is accurate and the seal is good to prevent leakage.

For plate heat exchangers, stack the stamped plates in the design order, install the sealing gaskets, and then clamp the plate group with clamping bolts. Pay attention to the direction of the plates and the installation position of the sealing gaskets to ensure a good seal. At the same time, control the size of the clamping force to avoid deformation of the plates due to excessive clamping force or poor sealing due to insufficient clamping force.

For spiral plate heat exchangers, roll the spiral plate into a spiral channel and install the inlet and outlet pipes and cover plates. During assembly, ensure that the size of the spiral channel is accurate, the connection between the components is firm, and the seal is reliable. When welding spiral plates, special attention should be paid to the quality of the weld to prevent leakage and problems affecting heat transfer performance.

Quality Inspection

After the heat exchanger is assembled, it needs to be pressure tested to check its sealing and strength. The pressure test usually adopts water pressure test or air pressure test, and the test pressure is generally 1.25-1.5 times the design pressure. In addition to the pressure test, the heat exchanger needs to be fully inspected for quality, including appearance inspection, dimension inspection, heat transfer performance test, etc. The appearance inspection mainly checks whether the surface of the heat exchanger is flat, scratched, deformed and other defects. The dimension inspection verifies whether the dimensions of the heat exchanger meet the design requirements. The heat transfer performance test simulates the actual situation and measures the performance indicators such as the heat transfer coefficient of the heat exchanger to ensure that it meets the use requirements.

Applications

Titanium heat exchangers cover almost all major industries such as chemical, energy, marine, food, and pharmaceuticals. They solve the problems that traditional heat exchangers are difficult to overcome under strong corrosion, high temperature, and high pressure conditions, improve efficiency, and reduce maintenance costs.

- Chemical Industry

In the chemical industry, many media are highly corrosive, such as sulfuric acid, hydrochloric acid, nitric acid, etc. Titanium heat exchangers, with their excellent corrosion resistance, can operate stably during the heat exchange process of these corrosive media. For example, in sulfuric acid production equipment, it is used to cool high-temperature sulfuric acid gas and reduce its temperature to a suitable range. At the same time, titanium heat exchangers also play an important role in hydrochloric acid desorption, nitric acid concentration, etc.

- Energy Industry

In petroleum refining and chemical industry, titanium heat exchangers are used for crude oil preheating, heat exchange of fractionation towers, cooling of oil products, etc. For example, in atmospheric and vacuum distillation units, they are used to heat crude oil to a suitable distillation temperature. In catalytic cracking units, they are used to cool the oil and gas after the reaction and separate different products. Titanium heat exchangers can operate stably under high temperature, high pressure and complex media environments.

- Marine Engineering

In the power system of a ship, the cooling water and lubricating oil of the engine need to be cooled and heated to ensure the normal operation of the engine. Titanium heat exchangers are very suitable for heat exchange in ships due to their good resistance to seawater corrosion. Various equipment on offshore platforms, such as oil and gas processing equipment and living facilities, require heat exchangers to achieve heat transfer and temperature control.

- Pharmaceutical Industry

Titanium heat exchangers play an important role in many aspects of drug production. In drug synthesis reactions, the reaction materials need to be heated or cooled to control the reaction rate and reaction process. Titanium heat exchangers can accurately achieve temperature control to ensure that the reaction is carried out under optimal conditions and improve the yield and quality of drugs.

Although titanium heat exchangers have many advantages, there are still some areas that need to be improved. For example, the relatively high cost of titanium materials has limited its wider application to a certain extent. Some types of titanium heat exchangers are still difficult to clean and repair. In the future, with the advancement of titanium smelting technology and the reduction of costs, as well as the continuous innovation of heat exchanger design and manufacturing technology, titanium heat exchangers are expected to be used in more fields and achieve further improvements in performance and economy.