Sheet Metal Fabrication

Wstitanium is a leading titanium sheet metal parts manufacturer in China. The investment in advanced facilities supports comprehensive one-stop services, including laser cutting, bending, welding, stamping, threading, riveting.

- Fast In-house Manufacturing

- ISO9001 & ISO13485 Certified

- Prototype, Low-Volume Manufacturing

- ROSH Certified Materials Available.

- Full-Size Quality Inspection Report.

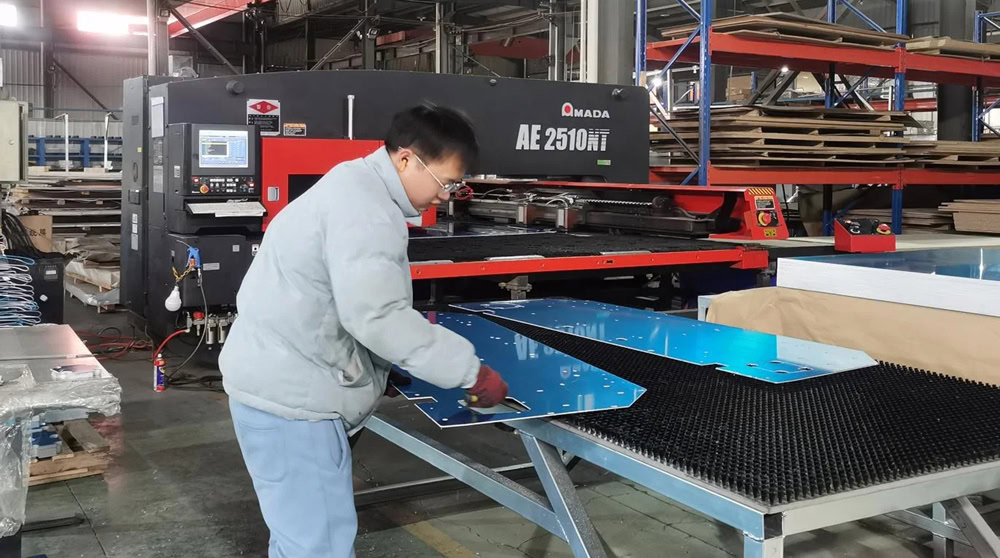

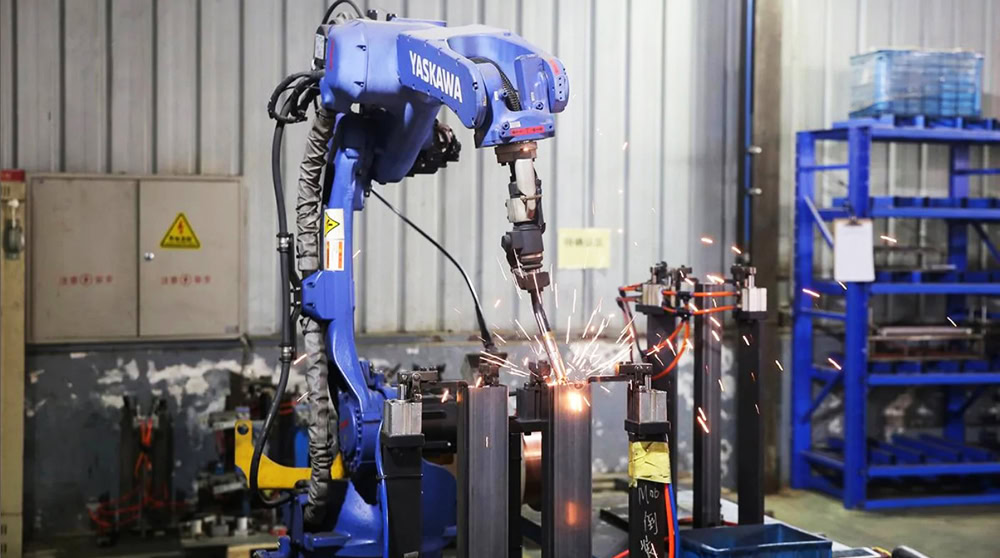

WSTITANIUM FACTORY

Our Powerful Facilities

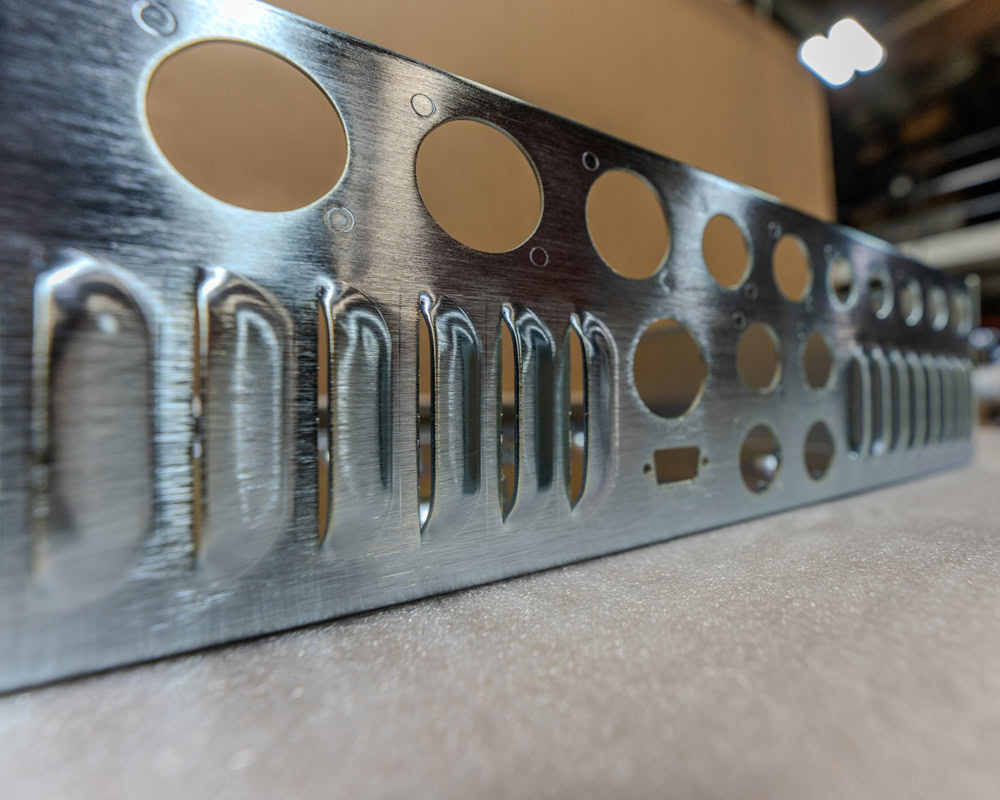

Sheet Metal Fabrication for Titanium

Titanium sheet metal manufacturing is the process of producing various forms, shapes and components using titanium flat sheets. Titanium has superior strength, weight and rigidity. In addition, it also has excellent resistance to salt water, salt corrosion, oxidation, rust, acid, chloride and scratches without coating or galvanizing. Other properties of titanium sheet metal include low thermal conductivity, flexibility, non-magnetic, high melting point, excellent high temperature strength, etc. It is often favored by many industries such as chemical processing, automotive, medical, marine, aerospace, military, etc.

Wstitanium Titanium Sheet Metal Manufacturing Capabilities

Wstitanium provides professional solutions to manufacture precision titanium sheet metal parts. We produce millions of assembled sheet metal titanium parts every year, helping many world-renowned companies. Mainly including Tesla, Olympus, Areva, Mitsubishi Heavy Industries, Fuji, etc.

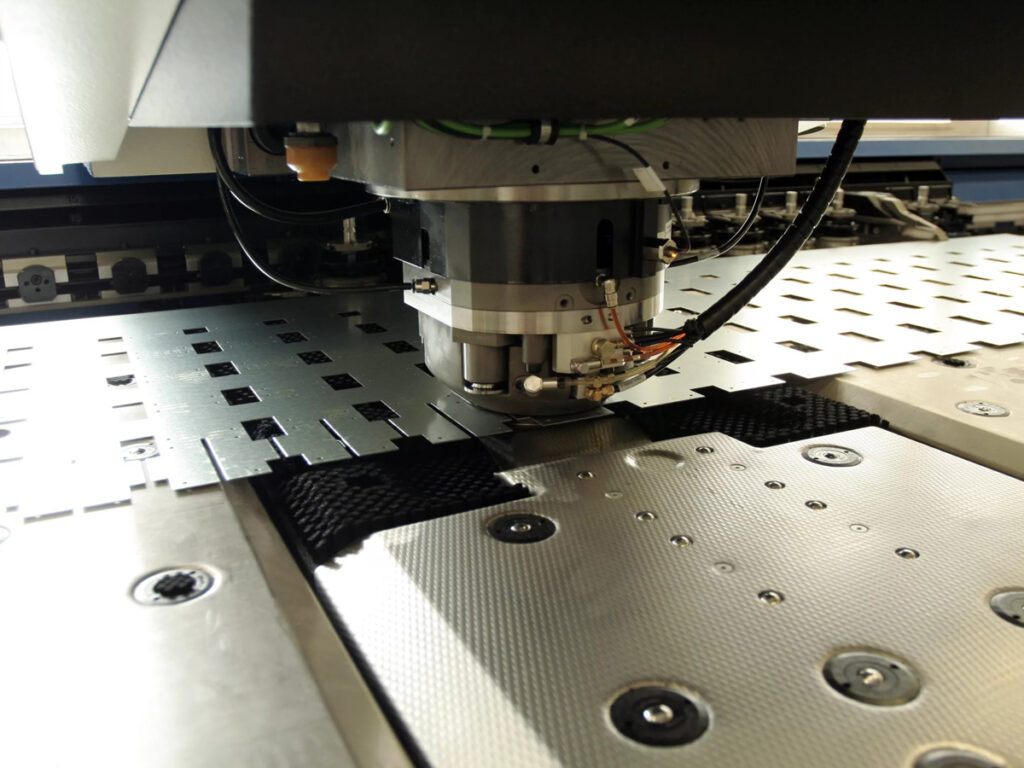

Sheet Metal Fabrication Machines

- Chamfering Machines

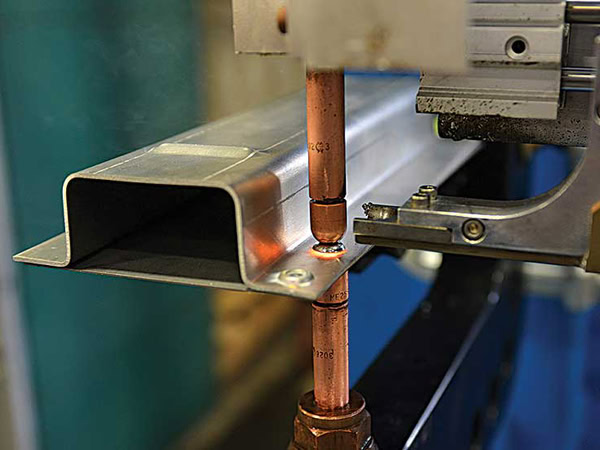

- TIG Welding Machines

- NCT Turret Punch (AMADA)

- Precision Grinding Machines

- Drilling and Tapping CNC Machines

- HSG 3000W/6000W Laser Cutting Machine

- Yaskawa/Fanuc/Panasonic Welding Robots

- Yawei Press Brake 110T 3+1 Axis/ 63T 3 Axis

Other Finishing

- Riveting

- Spot Welding

- Nut Insertion

- Laser Welding

- Laser Etching

- PEM and Rivets

- Assembly Services

- TIG and MIG Welding

Surface Freatment

- Anodizing

- Passivation

- Phosphating

- PVD Coating

- Sandblasting

- Electroplating

- Powder Coating

- Heat Treatment

- Silk Screen Printing

| General Tolerances | Metals : ISO 2768-c |

| Cutting Feature | ± .00787” 0.2mm |

| Bend Angle | ± 1.0° |

| Bend to Edge | ±0.010″ 0.254mm |

| Bend to Hole | ±0.2 mm |

Wstitanium Internal Facilities Showing

Wstitanium’s factory has invested in advanced machines and technologies, not limited to NCT turret punch presses (AMADA), laser cutting machines, bending machines, and automatic welding robots, etc. In addition, the sheet metal term is staffed by skilled designers, engineers, and machinists. They ensure the manufacture of high-quality and high-precision custom titanium sheet metal parts.

Sheet Metal Fabrication Services for Custom Titanium Parts

Wstitanium invested 3000 square meters of factory and expert engineers, 3000W optical laser cutting machine, 3D flexible welding platform, inspection machine, high-speed PU foaming machine and other advanced manufacturing equipment, which enables us to provide customized manufacturing of titanium metal sheets. We have been manufacturing titanium metal sheet products for various industries such as chemical processing, medical, automotive, marine, etc. Wstitanium processing capabilities include heat treatment, welding, forming, drilling, shearing, stamping, tempering, surface finishing, etc. You can provide us with the specifications you need or design and manufacture parts with the specifications you need. Titanium metal sheets are inspected, tested, and passed international standards such as ISO, ASTM, JIS and other quality standards.

Laser cutting is designed to cut, etch or engrave titanium using a focused laser beam, vaporizing or melting it to achieve precise edges and intricate patterns according to the designer’s specifications.

Bending involves applying force to thin sheets of titanium to shape them into various geometric shapes, such as a U, V, or channel. The thickness of the titanium can vary.

Welding is the process of joining two or more metal pieces using heat, pressure, or a combination of both to form a strong bond, creating a durable, strong metal structure.

Stamping refers to the use of dies and presses to form flat sheets of titanium into different shapes, creating complex three-dimensional designs through cold forming techniques.

Punching

Punching uses a punching tool to press a hole or shape through a die, cutting the metal through a shearing action to achieve a precise, clean manufactured part.

Riveting

Riveting is a semi-permanent joining method that uses mechanical fasteners (rivets) to connect sheet metal parts. It is faster and more cost-effective than welding.

Grades of Titanium for Sheet Metal Fabrication

ASTM International Material Specification Standard provides detailed standards for commercial titanium grades. Different sheet metal fabricators use different grades of titanium to create custom parts. The intended use of the titanium component often influences the selection of a specific grade. Some of the most popular pure titanium grades on the market today include:

Commercially Pure Grade 1: A soft, ductile titanium with excellent corrosion resistance.

Commercially Pure Grade 2: A stronger grade of titanium with high strength and good weldability, corrosion resistance, making it ideal for cryogenic vessels, airframe components, heat exchangers, pickling baskets, construction, and medical applications.

Commercially Pure Grade 3: One of the strongest and most widely used types of pure titanium. Grade 3 titanium has higher strength than grades 2 and 1. They have similar ductility and slightly worse formability. Commercially Pure Grade 3 titanium is well suited for medical devices, aerospace structures, and chemical processing applications.

Commercially Pure Grade 4: Of the 4 commercially pure titanium grades, Grade 4 is the strongest, but has low ductility. . It has good weldability, good formability, and excellent corrosion resistance. In addition, it is also ideal for surgical hardware, airframe components, etc.

Ti-6AL-4V Grade 5 – Grade 5 is the most commonly used titanium alloy. It has better high temperature resistance than Grade 2. In addition, it is commonly used in industries such as chemical processing, marine, medical, and aerospace.

Commercially Pure Grade 7: The pure form of titanium, widely used in desalination plants (similar to Grade 2). It has sought-after corrosion resistance.

Other grades of titanium include Grades 9, 12, 16, 17, etc.

Titanium (Grade 2) Properties

| Tensile Strength, Yield (MPa) | 275-410 |

| Fatigue Strength (MPa) | 300 |

| Elongation at Break (%) | 20 |

| Hardness (Brinell) | 149 |

| Density (g/cm^3) | 4.51 |

Titanium (Grade 5) Properties

| Tensile Strength, Yield (MPa) | 88 |

| Fatigue Strength (MPa) | 240 |

| Elongation at Break (%) | 14 |

| Hardness (Brinell) | 334 |

| Density (g/cm^3) | 4.43 |

Applications of Titanium Sheet Metal Fabrication

Titanium has become a popular metal that has been gaining traction in recent years, and is favored by manufacturers around the world. While titanium may not be as widely used as stainless steel and aluminum, it can still be used for a variety of purposes. Titanium sheet metal fabrication is a highly versatile and efficient manufacturing process, ranging from prototyping and low-volume manufacturing to high-volume production. Titanium sheet metal fabrication produces a wide variety of parts and assemblies, each designed for specific functional and aesthetic needs. These include housings, brackets, supports, panels and chassis, ductwork, and more. Next, we discuss some of the most popular applications for titanium sheet metal fabrication.

Aerospace

In aerospace applications, titanium sheet metal is often preferred over aluminum sheet metal. Titanium sheet metal’s corrosion and heat resistance make it an ideal material for aircraft, fuselages, engine components, and landing gear. Pure titanium has a low density but high strength, has greater formability, and is lighter in weight than steel. Of course, applications may be limited due to the higher cost of titanium, but it remains an irreplaceable material that is becoming increasingly popular due to its reliability and superior quality.

Automotive

Titanium has a special use in the automotive industry. Titanium is often used in the manufacture of racing and sports bike parts. Today, some luxury car manufacturers use titanium in automotive parts. It helps in significantly reducing part weight, resists heat and corrosion, reduces fuel consumption, and improves engine efficiency. The metal is mainly used in manufacturing valve springs, rocker arms, retainers, connecting rods, gear brackets, bumper brackets, exhaust systems, automotive fasteners, etc. Undoubtedly, the future of titanium in the automotive industry is bright.

Medical

Since titanium plates are so versatile, they have several uses in the medical field. Their durability, corrosion resistance, and lightweight properties make them an ideal material for devices such as surgical equipment and pacemaker housings. Its unique properties promote better adhesion, promote bone cell regeneration, and mimic human bones when used in trauma plates and joint replacements. This enhances the biochemical fixation of bone implants and helps in several other related processes. In short, titanium is cost-effective, requires minimal maintenance, and is a biocompatible metal that is non-toxic, making it the best choice for the medical industry.

Quality Inspection

Quality assurance is critical. This requires regular inspection and evaluation of the adequacy of high-quality titanium sheet metal parts production. It is essential to ensure that the quality of service and goods is up to standard to increase customer loyalty. Wstitanium focuses on quality at every step to provide precise sheet metal parts from design to manufacturing. Following the principles of Design for Manufacturability (DFM), we understand your needs and provide the best solution for your project. Advanced inspection tools such as CMM, 2D measuring instruments, XRF analyzers, gauges, micrometers and calipers ensure that all titanium parts meet stringent requirements. Choose Wstitanium to get precise, custom sheet metal parts manufactured to your specifications.

- 10+ quality engineers

- 20+ inspection equipment

- ISO 9001:2015, ISO 13485

- Tight tolerances 0.01 inches or less

In the absence of detailed requirements, follow this sheet metal quality control checklist:

| Plate Size | Allow Tolerance | Plate Size | Allow Tolerance |

| W/H(width or height)≤1000mm | ±0.5mm | Location of angle protector | ±0.5mm |

| 1000mm<W/H≤3000mm | ±1.0mm | Height of angle protector | ±1.0mm |

| W/H>3000mm | ±1.5mm | hole/gap dimension | ±0.2mm |

| Diagonal≤1000mm | ±0.5mm | hole/gap dimension≤200mm | ±0.5mm |

| 1000mm<Diagonal≤3000mm | ±1.0mm | hole/gap dimension>200mm | ±1.0mm |

| Diagonal>3000mm | ±1.5mm | location of stiffeners | ±2.0mm |

| R dimension | Thickness of the panelδ×1.5(According to design drawings or technical note) | quantity of stiffeners | According to design drawings or technical note |

| Plate direction | According to the drawings | accessories location≤1000mm | ±0.5mm |

| Angle | ±0.50 | accessories location>1000mm | ±1.0mm |

| hem dimension | ±0.2mm |

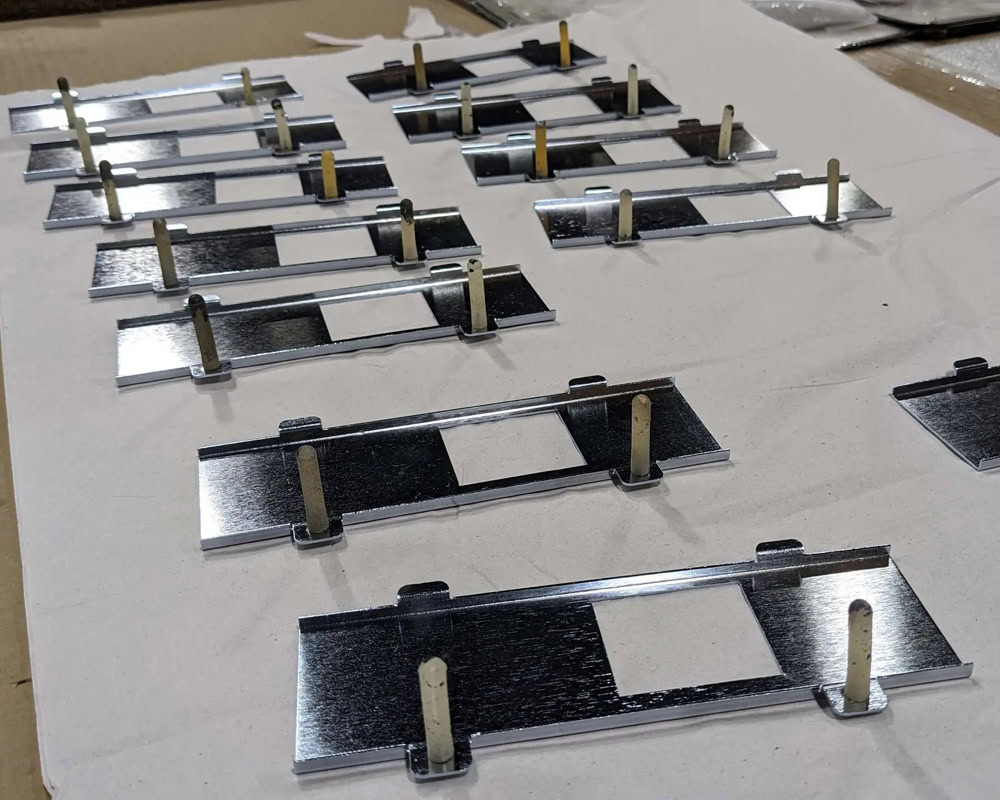

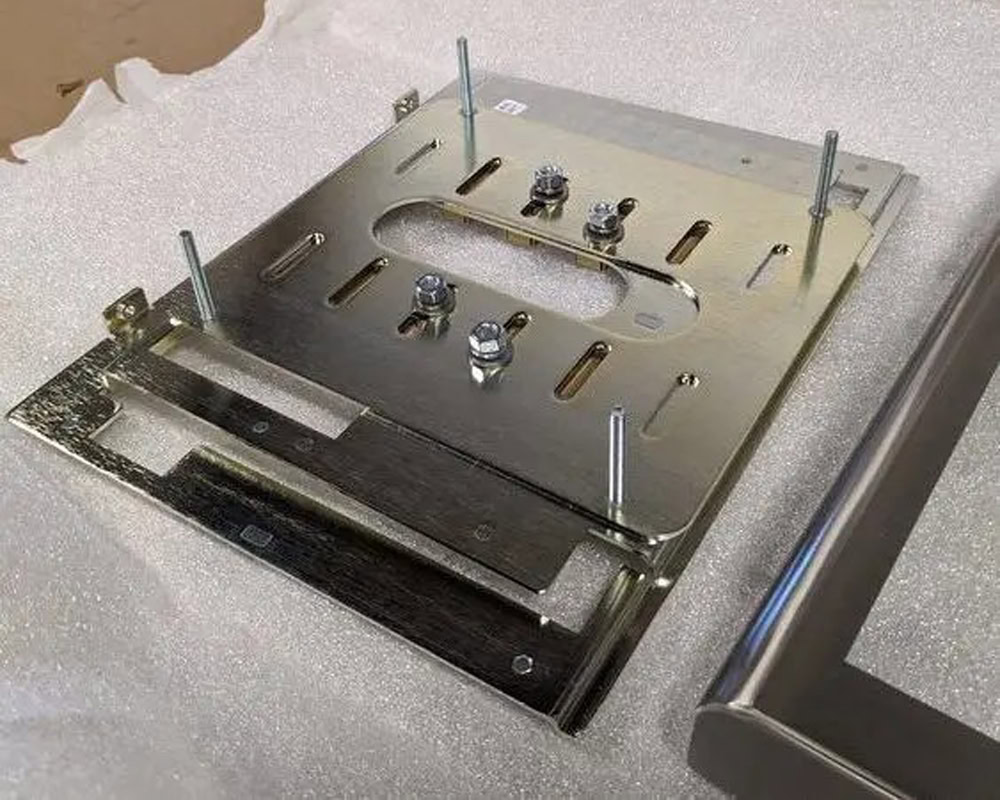

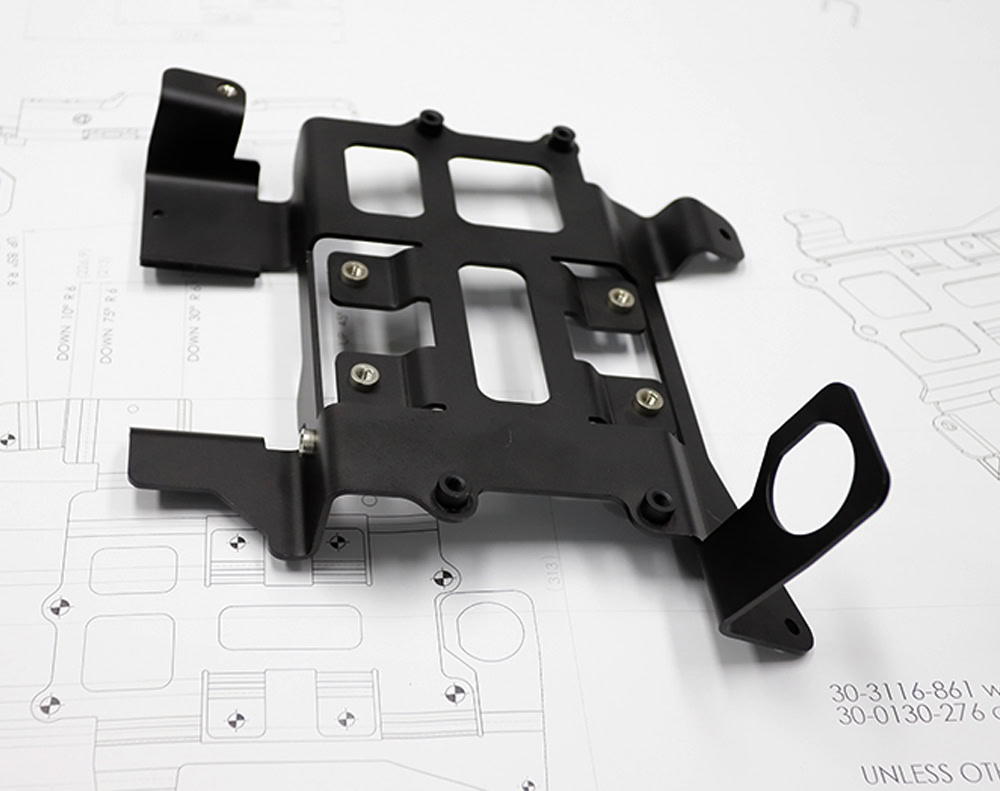

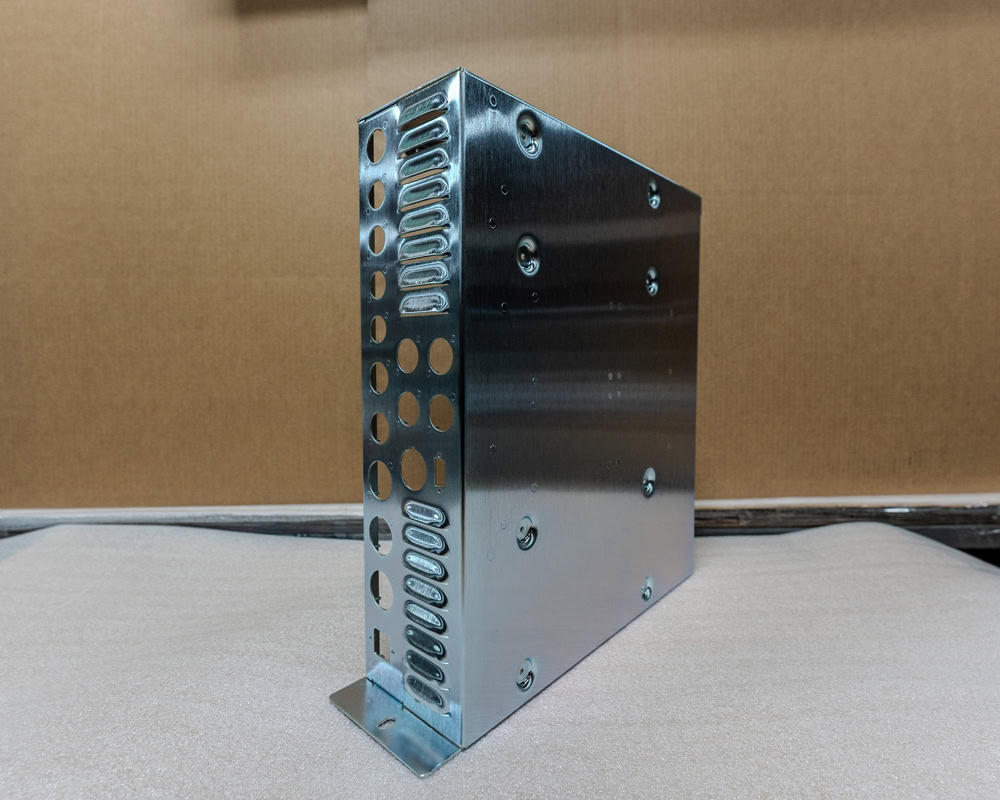

Titanium Sheet Metal Gallery