The Ultimate Guide to Laser Thermal Evaporation Coatings

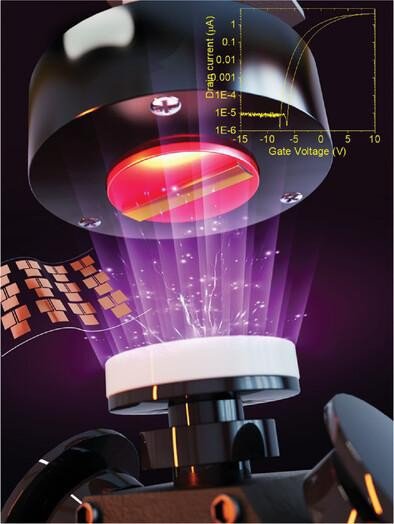

Laser thermal evaporation coating is a technology that uses a high-energy laser beam to irradiate the surface of a material, causing it to heat up and evaporate instantly. The evaporated atoms or molecules are deposited on the surface of the substrate to form a thin film.

- Low Cost

- Good Film Uniformity

- Higher Film Deposition Rate

- Strong Film-Substrate Bonding

Wstitanium Workshop

Our Powerful Facilities

Everything You Should Know About Laser Thermal Evaporation Coating

Laser evaporation coating, as a physical vapor deposition (PVD) technology with unique characteristics and advantages, has gradually emerged and become an indispensable key technology in many scientific research fields and industries. Laser evaporation coating not only accurately controls the growth and structure of thin films at the microscopic level, and achieves fine control of film composition, thickness, uniformity and crystal state, but also deposits high-quality and high-performance thin films on a variety of complex material substrates.

Laser evaporation coating is a type of physical vapor deposition (PVD) technology. It uses a high-energy pulsed laser beam to focus and irradiate the surface of the target material, causing the local area of the target material to instantly absorb extremely high energy, and the temperature rises sharply to the evaporation temperature or even higher, causing the target atoms or molecules to obtain enough kinetic energy to break away from the target surface and evaporate in gaseous form. These evaporated atoms, molecules or ions fly freely in a vacuum, and then deposit, adsorb, diffuse and gradually condense on the surface of the substrate. After continuous accumulation and interaction between atoms, a continuous film is finally formed. Compared with traditional evaporation coating methods, such as resistance heating evaporation and electron beam evaporation, laser evaporation coating has significant differences in energy input mode, evaporation mechanism and film growth. These differences give laser evaporation coating unique technical advantages and application potential.

Principle of Laser Evaporation Coating

When a high-energy-density pulsed laser beam irradiates the surface of the target, the absorption of laser energy by the target is the starting point of the whole process. The absorption efficiency of the target to the laser is closely related to the laser wavelength and the optical properties of the target (such as absorptivity, reflectivity, etc.). Generally speaking, most materials have a high absorptivity in the ultraviolet band, so the commonly used excimer lasers (such as KrF 248nm, XeCl 308nm, ArF 193nm, etc.) effectively transfer energy to the target. After the laser energy is absorbed by the target, it is quickly converted into the internal energy of the target atoms or molecules, causing the surface temperature of the target to rise sharply in a very short time (usually nanoseconds).

When the surface temperature of the target rises rapidly, the heat will diffuse into the interior of the target through heat conduction. The thermal motion of the target atoms or molecules intensifies, gradually obtaining enough energy to overcome the binding force between atoms, and begins to change from solid to gas, entering the evaporation stage. As the temperature of the target surface increases further, the evaporated atoms and molecules interact with the photons and electrons generated by the laser, ionization occurs, and a plasma composed of ions, electrons, and neutral atoms is formed.

When the evaporated atoms reach the surface of the substrate, they interact with the atoms on the substrate surface and begin to deposit. The evaporated atoms will be adsorbed on the substrate surface to form adsorbed atoms. They will diffuse on the substrate surface and find a suitable position to combine with other atoms. As the number of adsorbed atoms continues to increase, when the distance between atoms is small enough, they will be combined together through the interaction forces between atoms (such as van der Waals forces, chemical bonds, etc.) to form atomic clusters. When the size of the cluster reaches a critical value, a stable crystal nucleus will be formed. The crystal nucleus continues to adsorb the surrounding atoms and gradually grows, and finally forms a continuous film through the contact and merging of adjacent crystal nuclei. In the growth of thin films, factors such as the temperature of the substrate, the surface state, and the deposition rate of evaporated atoms will have a significant impact on the crystal quality, organizational structure, and performance of the film.

Materials For Laser Evaporation Coating

Aluminum (Al)

Aluminum is one of the most commonly used metal materials in laser evaporation coating. The laser source is mostly Nd:YAG pulse laser with a wavelength of 1064nm, a pulse width of 5-20ns, and an energy density of 1-5J/cm²; the vacuum degree needs to be maintained at 1×10⁻⁴ – 5×10⁻⁵ Pa. The deposition rate is generally 0.5-2nm/s, and the film thickness can be adjusted to 50-500nm according to demand. Aluminum film is widely used in reflectors, electrode layers, etc.

Copper (Cu)

Copper is often used to prepare conductive films due to its high electrical and thermal conductivity. Commonly used excimer lasers (such as KrF, wavelength 248nm) or Nd:YAG lasers, pulse width 10-30ns, energy density 2-6J/cm²; vacuum degree needs to be better than 5×10⁻⁵ Pa, a small amount of inert gas (such as Ar) can be introduced to control plasma diffusion, gas pressure 0.1-1Pa; substrate temperature 50-300℃. Deposition rate 1-3nm/s, film thickness 100-1000nm.

Silver (Ag)

Silver has the highest visible light reflectivity and is the core material for optical coating. Laser evaporation parameters: laser wavelength is mostly 532nm (Nd:YAG frequency doubling), energy density 1.5-4J/cm², pulse width 5-15ns; vacuum degree must reach 1×10⁻⁵ Pa; substrate temperature is controlled at room temperature to 100℃. Deposition rate 0.3-1.5nm/s, film thickness 50-200nm. Silver film is easy to sulfide and needs to be matched with a protective layer (such as SiO₂).

Gold (Au)

Gold has chemical stability and good conductivity. Laser evaporation parameters: 1064nm Nd:YAG laser, energy density 2-5J/cm², pulse width 10-20ns; vacuum degree 1×10⁻⁵ Pa, N₂ gas (0.05-0.5Pa) can be introduced to enhance film adhesion; substrate temperature 100-400℃. Deposition rate 0.5-2nm/s, film thickness 50-500nm.

Nickel (Ni)

Nickel film has high hardness and wear resistance and is often used for wear-resistant coatings. Laser evaporation parameters: laser wavelength 1064nm, energy density 3-7J/cm², pulse width 10-30ns; vacuum degree 5×10⁻⁵ Pa, Ar gas (0.1-2Pa) can be introduced to control plasma energy; substrate temperature 200-500℃. Deposition rate 1-3nm/s, film thickness 1-5μm.

Chromium (Cr)

Chromium is often used as a transition layer of thin films to improve the adhesion of subsequent film layers to the substrate. Laser evaporation parameters: laser wavelength 248nm (KrF excimer), energy density 2-6J/cm², pulse width 10-20ns; vacuum degree 1×10⁻⁴ Pa, substrate temperature 100-300℃; deposition rate 0.2-1nm/s, film thickness 10-50nm.

Titanium (Ti)

Titanium film has good corrosion resistance and biocompatibility. Laser evaporation parameters: laser wavelength 1064nm, energy density 3-8J/cm², pulse width 10-25ns; vacuum degree 5×10⁻⁵ Pa, O₂ gas (0.01-0.1Pa) can be introduced to prepare TiO₂ film; substrate temperature 200-600℃. Deposition rate 0.5-2nm/s, film thickness 50-500nm.

Silicon dioxide (SiO₂)

SiO₂ is the most commonly used dielectric material in optical coating. Laser wavelength 248nm or 193nm (excimer laser), energy density 2-6J/cm², pulse width 5-20ns; vacuum degree 1×10⁻⁴ Pa, O₂ gas (0.1-1Pa) is introduced to compensate for oxygen loss; substrate temperature 100-400℃. Deposition rate 0.1-0.5nm/s, film thickness 50-1000nm.

Titanium dioxide (TiO₂)

TiO₂ has a high refractive index and is often used in high-reflection films and optical filters. Laser wavelength 1064nm or 532nm, energy density 3-8J/cm², pulse width 10-30ns; vacuum degree 5×10⁻⁵ Pa, O₂ gas pressure 0.05-0.5Pa; substrate temperature 300-600℃. The deposition rate is 0.2-1nm/s, and the film thickness is 50-500nm.

Silicon nitride (Si₃N₄)

Si₃N₄ has high hardness and insulation, and is used for semiconductor passivation layers and wear-resistant coatings. Laser wavelength 1064nm, energy density 4-10J/cm², pulse width 10-25ns; vacuum degree 5×10⁻⁵ Pa, N₂ gas (0.1-2Pa); substrate temperature 400-800℃. Deposition rate 0.3-1.5nm/s, film thickness 100-1000nm.

Zinc oxide (ZnO)

ZnO is a wide bandgap semiconductor used for transparent conductive films and piezoelectric devices. Laser wavelength 248nm, energy density 2-6J/cm², pulse width 10-20ns; vacuum degree 1×10⁻⁴ Pa, can be fed with O₂ gas (0.01-0.1Pa); substrate temperature 200-500℃. Deposition rate 0.2-1nm/s, film thickness 100-1000nm.

Indium tin oxide (ITO)

ITO is a core material for transparent conductivity. Laser wavelength 1064nm, energy density 3-7J/cm², pulse width 10-30ns; vacuum degree 5×10⁻⁵ Pa, O₂ gas (0.005-0.05Pa) can be introduced; substrate temperature 150-300℃. Deposition rate 0.1-0.5nm/s, film thickness 50-200nm.

Titanium nitride (TiN)

TiN has a golden appearance and high hardness. Laser wavelength 1064nm, energy density 4-9J/cm², pulse width 10-25ns; vacuum degree 5×10⁻⁵ Pa, N₂ gas pressure 0.1-1Pa; substrate temperature 200-600℃. Deposition rate 0.5-2nm/s, film thickness 1-5μm. Control N/Ti ratio (≈1) to ensure hardness > 20GPa.

Silicon carbide (SiC)

SiC is a high-temperature semiconductor material. Laser wavelength 1064nm, energy density 5-12J/cm², pulse width 10-30ns; vacuum degree 1×10⁻⁵ Pa, CH₄ gas (0.05-0.5Pa) can be passed; substrate temperature 800-1200℃. Deposition rate 0.3-1nm/s, film thickness 500-5000nm. Control carbon content (Si/C≈1).

Yttrium-stabilized zirconia (YSZ)

YSZ is a high-temperature electrolyte used in solid oxide fuel cells (SOFCs). Laser wavelength 248nm, energy density 3-8J/cm², pulse width 10-20ns; vacuum 1×10⁻⁴ Pa, O₂ gas pressure 0.1-1Pa; substrate temperature 600-1000℃. Deposition rate 0.2-1nm/s, film thickness 1-10μm.

Magnesium fluoride (MgF₂)

MgF₂ is a low-refractive-index dielectric material used for antireflection coatings and optical prism coatings. Laser wavelength 1064nm, energy density 2-5J/cm², pulse width 10-20ns; vacuum 5×10⁻⁵ Pa, substrate temperature 100-300℃; deposition rate 0.1-0.4nm/s, film thickness 50-500nm. Parameters must ensure the refractive index (1.38±0.02).

Aluminum-doped zinc oxide (AZO)

AZO is a low-cost transparent conductive material that replaces ITO for flexible electronics. Laser wavelength 532nm, energy density 2-6J/cm², pulse width 10-25ns; vacuum 1×10⁻⁴ Pa, O₂ gas pressure 0.01-0.1Pa; substrate temperature room temperature to 200℃. Deposition rate 0.2-1nm/s, film thickness 100-500nm.

Lithium niobate (LiNbO₃)

LiNbO₃ is a piezoelectric and electro-optical material used in optical modulators and sensors. Laser wavelength 248nm, energy density 4-9J/cm², pulse width 10-20ns; vacuum degree 5×10⁻⁵ Pa, O₂ gas pressure 0.05-0.5Pa; substrate temperature 500-800℃. Deposition rate 0.1-0.5nm/s, film thickness 100-1000nm.

Neodymium iron boron (NdFeB)

NdFeB is a high magnetic energy product material used for micro magnets and magnetic recording. Laser wavelength 1064nm, energy density 5-10J/cm², pulse width 10-30ns; vacuum degree 1×10⁻⁵ Pa, Ar gas pressure 0.1-1Pa; substrate temperature 200-500℃. Deposition rate 0.5-2nm/s, film thickness 1-10μm.

CdSe

CdSe is a narrow bandgap semiconductor used for quantum dots and infrared detectors. Laser wavelength 532nm, energy density 3-7J/cm², pulse width 10-20ns; vacuum 5×10⁻⁵ Pa, Se atmosphere pressure 0.01-0.1Pa; substrate temperature 200-400℃. Deposition rate 0.1-0.5nm/s, film thickness 50-500nm. Parameters need to control the Cd/Se ratio (≈1).

Cadmium telluride (CdTe)

CdTe is used for thin-film solar cells. Laser wavelength 1064nm, energy density 4-8J/cm², pulse width 10-30ns; vacuum degree 1×10⁻⁵ Pa, Te gas pressure 0.05-0.5Pa; substrate temperature 300-500℃. Deposition rate 0.5-2nm/s, film thickness 1-5μm. Control grain size (1-5μm) and improve light absorption coefficient (>10⁴ cm⁻¹).

Gallium Nitride (GaN)

GaN is a wide bandgap semiconductor used in blue LEDs and power devices. Laser wavelength 248nm, energy density 5-12J/cm², pulse width 10-20ns; vacuum 5×10⁻⁶ Pa, N₂ gas pressure 0.1-1Pa; substrate temperature 800-1200℃. Deposition rate 0.1-0.5nm/s, film thickness 100-1000nm.

Gallium Arsenide (GaAs)

GaAs is a high-frequency semiconductor used in microwave devices and solar cells. Laser wavelength 1064nm, energy density 4-9J/cm², pulse width 10-25ns; vacuum 1×10⁻⁵ Pa, AsH₃ gas pressure 0.01-0.1Pa; substrate temperature 500-700℃. Deposition rate 0.2-1nm/s, film thickness 500-5000nm.

Lanthanum oxide (La₂O₃)

La₂O₃ is a high-k dielectric material used for semiconductor gate insulation. Laser wavelength 1064nm, energy density 3-7J/cm², pulse width 10-20ns; vacuum 5×10⁻⁵ Pa, O₂ gas pressure 0.05-0.5Pa; substrate temperature 300-600℃. Deposition rate 0.1-0.5nm/s, film thickness 10-50nm.

Tungsten carbide (WC)

WC has extremely high hardness and is used for superhard coatings and cutting tools. Laser wavelength 1064nm, energy density 6-12J/cm², pulse width 10-30ns; vacuum 1×10⁻⁵ Pa, CH₄ gas pressure 0.1-1Pa; substrate temperature 400-800℃. Deposition rate 0.5-2nm/s, film thickness 1-10μm.

Cerium oxide (CeO₂)

CeO₂ is a polishing material and fuel cell electrolyte. Laser evaporation parameters: laser wavelength 248nm, energy density 2-6J/cm², pulse width 10-20ns; vacuum 5×10⁻⁵ Pa, O₂ gas pressure 0.1-1Pa; substrate temperature 500-800℃. Deposition rate 0.2-1nm/s, film thickness 100-1000nm.

Zinc sulfide (ZnS)

ZnS is a medium refractive index optical material. Laser wavelength 1064nm, energy density 3-7J/cm², pulse width 10-25ns; vacuum degree 1×10⁻⁴ Pa, H₂S gas pressure 0.01-0.1Pa; substrate temperature 100-300℃. Deposition rate 0.2-1nm/s, film thickness 50-500nm. Ensure infrared band transmittance > 70% (8-12μm).

Barium titanate (BaTiO₃)

BaTiO₃ is a ferroelectric material used in capacitors and sensors. Laser evaporation parameters: laser wavelength 248nm, energy density 4-9J/cm², pulse width 10-20ns; vacuum degree 5×10⁻⁵ Pa, O₂ gas pressure 0.05-0.5Pa; substrate temperature 600-1000℃. Deposition rate 0.1-0.5nm/s, film thickness 100-1000nm.

Lithium tantalate (LiTaO₃)

LiTaO₃ is a piezoelectric and pyroelectric material used in infrared detectors and filters. Laser evaporation parameters: laser wavelength 1064nm, energy density 3-8J/cm², pulse width 10-30ns; vacuum degree 1×10⁻⁵ Pa, O₂ gas pressure 0.01-0.1Pa; substrate temperature 500-800℃. Deposition rate 0.1-0.5nm/s, film thickness 100-1000nm.

Yttrium oxide (Y₂O₃)

Y₂O₃ is a high-temperature protective coating material. Laser evaporation parameters: laser wavelength 1064nm, energy density 5-10J/cm², pulse width 10-25ns; vacuum degree 5×10⁻⁵ Pa, O₂ gas pressure 0.1-1Pa; substrate temperature 600-1000℃. Deposition rate 0.3-1.5nm/s, film thickness 5-50μm.

Advantages of Laser Evaporation Coating

Compatible with complex materials

For some materials with complex chemical composition and crystal structure, such as perovskite structure materials (ABO₃ type, where A and B are different metal ions). Laser evaporation coating accurately transfers various elements in the target material to the film in proportion.

Rapid evaporation

The laser beam has extremely high energy density, which can rapidly increase the temperature of the local area on the target surface to the evaporation temperature or even higher in a very short time, thus realizing rapid evaporation of the material.

Good film quality

The evaporated atoms have high kinetic energy and can be more densely stacked when deposited on the substrate surface, forming a dense film structure and improving the density and hardness of the film.

Excellent crystallization performance

The films prepared by laser evaporation coating usually have good crystallization performance, complete crystal structure and few defects.

Application of Laser Evaporation Coating

The application of laser evaporation coating in the fields of optics, electronics and semiconductors, biomedicine, aerospace, etc. has achieved remarkable results. From high-performance optical films, semiconductor devices to biocompatible coatings and aerospace protective coatings, they all rely on the support of this technology.

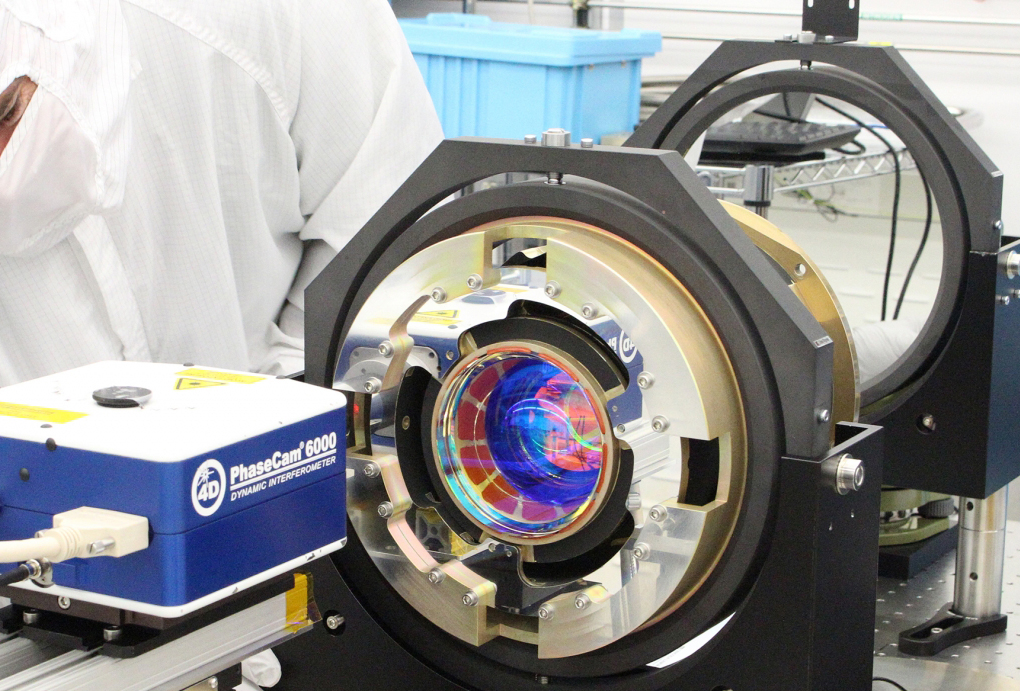

Optics

Laser evaporation coating can accurately control the thickness and refractive index of the film, which is suitable for the preparation of high-performance anti-reflection films. For example, coating magnesium fluoride (MgF₂) anti-reflection films on the surface of laser windows, optical lenses and other components can reduce the reflectivity of the visible light band from about 4% to less than 1%, significantly improving the imaging quality and light energy utilization of the optical system. For complex multi-layer anti-reflection film systems, such as anti-reflection films for wide bands, the composition control accuracy and film uniformity advantages of laser evaporation coating can ensure the stability of the film system performance.

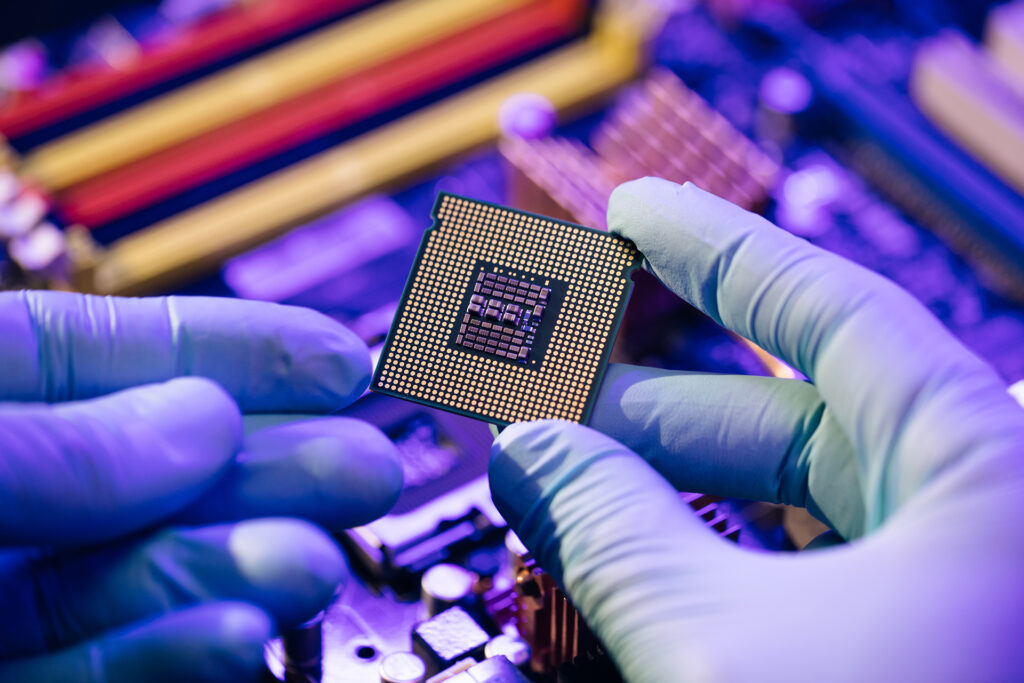

Semiconductor

In semiconductor devices, passivation films are used to protect the device surface to prevent impurity contamination and charge accumulation; insulating films are used to isolate different conductive areas. Laser evaporation coating is used to prepare passivation films and insulating films such as silicon nitride (Si₃N₄) and silicon dioxide (SiO₂). These films have good insulation properties, chemical stability and density, and can effectively improve the reliability and life of semiconductor devices. For example, coating Si₃N₄ passivation film on the surface of integrated circuit chips can prevent water vapor and ions from corroding the chip and improve the working stability of the chip.

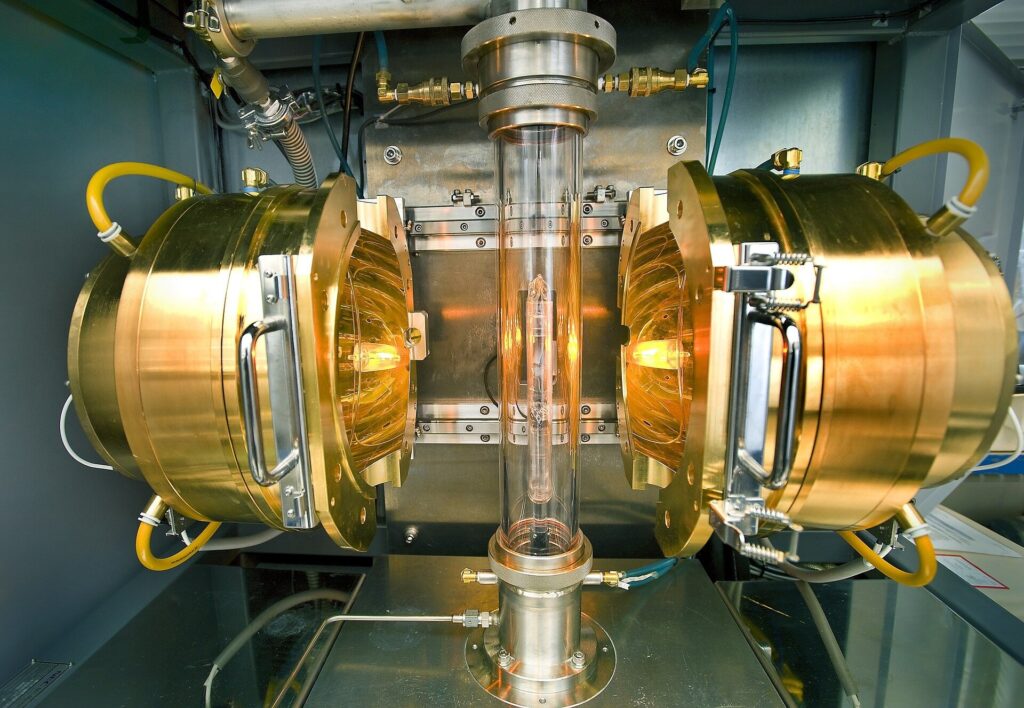

Superconducting

High-temperature superconducting materials (such as YBa₂Cu₃O₇₋ₓ, YBCO) have zero resistance and complete anti-magnetism at low temperatures, and have important applications in superconducting cables, superconducting magnets, superconducting quantum interference devices (SQUIDs), and other fields. Laser evaporation coating is one of the main methods for preparing high-temperature superconducting films, and can grow YBCO films with high critical temperature (Tc) and high critical current density (Jc). By optimizing process conditions such as laser parameters, substrate temperature, and oxygen atmosphere, high-quality YBCO superconducting films can be prepared on single crystal substrates (such as SrTiO₃), and their critical current density can reach more than 10⁶ A/cm², meeting the application requirements of superconducting devices.

Biomedicine

Laser evaporation coating is used to prepare inorganic thin films with antibacterial properties, such as silver (Ag) doped films, zinc oxide (ZnO) films, etc. Silver ions have broad-spectrum antibacterial properties and have strong inhibitory and killing effects on microorganisms such as bacteria and fungi; ZnO films will produce active oxygen species (such as hydroxyl radicals) under light, which have excellent antibacterial properties. These antibacterial films can be applied to the surfaces of medical equipment (such as surgical instruments, ward furniture), food packaging materials, etc., effectively inhibiting the growth and reproduction of microorganisms and reducing the risk of cross-infection and food spoilage.

Aerospace

The turbine blades, combustion chambers and other parts of aerospace engines work under high temperature, high-speed airflow scouring and friction environments, and need to have excellent high-temperature wear resistance and oxidation resistance. Laser evaporation coating can prepare ceramic coatings (such as zirconium oxide (ZrO₂), aluminum oxide (Al₂O₃), titanium nitride (TiN), etc.), which have the characteristics of high hardness, high temperature resistance, wear resistance and oxidation resistance. For example, ZrO₂-Y₂O₃ thermal barrier coating is plated on the surface of nickel-based high-temperature alloy turbine blades to reduce the operating temperature of the blades, improve their wear resistance and service life; TiN coating can be used for engine bearings, gears and other components to improve their wear resistance and fatigue resistance.

Conclusion

As an advanced physical vapor deposition technology, laser evaporation coating occupies an important position in the field of material surface engineering due to its unique principles and characteristics. From the technical principle point of view, it realizes the rapid evaporation of materials and the precise deposition of thin films through the interaction between high-energy laser and target material. In terms of material application, laser evaporation coating shows strong compatibility. Whether it is metal, compound (oxide, nitride, fluoride, etc.), this technology can be used to prepare thin films that meet specific needs, providing a rich material selection for applications in different fields.