Titanium Anode Application In Electrodialysis

We discuss in depth the application of titanium anodes in electrodialysis, covering the types, working principles, advantages and key issues in practical applications of titanium anodes, aiming to provide a systematic reference for those engaged in the research, development and application of electrodialysis technology.

- Iridium-titanium anode

- Ir - Ta - Ti titanium anode

- Ru - Ir - Ti titanium anode

- Ruthenium-titanium anode (RuO₂-TiO₂)

- Graphite titanium anode

- Customized titanium anode

- Transition metal titanium anode

- Rare earth element titanium anode

The Ultimate Guide to Titanium Anodes in Electrodialysis

In the electrodialysis system, the electrode is a key component, and its performance directly affects the operating efficiency, energy consumption and life. Traditional electrode materials, such as graphite and lead, have problems such as low electrochemical activity, easy corrosion and short life, which make it difficult to meet the growing demand for electrodialysis technology. Titanium anodes have gradually become the first choice for electrodialysis electrodes due to their excellent electrochemical properties, good stability and long life, injecting new vitality into the development of electrodialysis technology and promoting the expansion and application of electrodialysis technology in more fields.

What is electrodialysis?

As an efficient membrane separation technology, electrodialysis (ED) has received extensive attention and rapid development in recent years due to its outstanding performance in ion separation, water desalination, wastewater treatment and industrial solution concentration. The electrodialysis process is to use the selective permeability of ion exchange membranes to anions and cations in the solution under the action of a DC electric field to achieve directional migration of ions in the solution, thereby achieving the purpose of concentrating, desalinating, refining or purifying the solution.

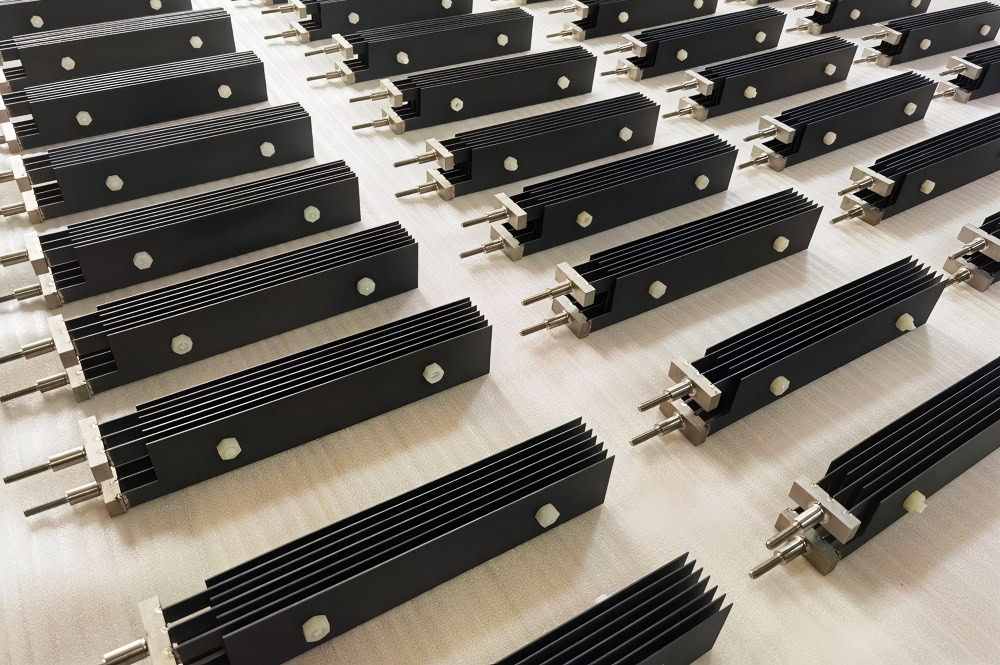

Titanium Anode Types for Electrodialysis

Titanium-based metal oxide anode is one of the most widely used titanium anode types in the field of electrodialysis. It is formed by preparing one or more layers of metal oxide coating on the surface of the titanium substrate by thermal oxidation, thermal decomposition, electrochemical deposition and other methods. Common coating materials include oxides of metals such as iridium (Ir), ruthenium (Ru) and tin (Sn). Different oxide combinations and coating structures give the anode different performance characteristics.

Ruthenium-titanium anode has good electrochemical activity and low chlorine evolution overpotential. It shows excellent electrocatalytic performance in solutions containing chloride ions and is often used in electrodialysis seawater desalination, brackish water desalination and other fields. RuO₂ plays the main electrocatalytic role and effectively promotes the generation of chlorine.

Iridium-titanium anode has higher chemical stability and corrosion resistance, especially in acidic and strongly oxidizing environments. It is suitable for the concentration of wastewater containing heavy metal ions and acidic solutions. IrO₂ can efficiently catalyze the oxidation and decomposition of water to produce oxygen, and its stable chemical structure makes it not easily corroded in harsh environments.

Composite titanium anode

Wstitanium has developed multi-component composite metal oxide anodes, such as Ru-Ir-Ti, Ir-Ta-Ti and other systems. For example, RuO₂ has good chlorine evolution activity, IrO₂ ensures the chemical stability of the anode, and TiO₂ provides structural support and enhances the adhesion of the coating, enabling the anode to perform excellent performance in a variety of electrodialysis applications.

In addition to traditional metal oxide coatings, anode materials with special properties can also be prepared by modifying the surface of titanium anodes to meet the specific needs of the electrodialysis process.

Doped modified anodes

Introducing appropriate amounts of rare earth elements (La, Ce, etc.) and transition metal elements (Mn, Co, etc.) into metal oxide coatings can change the electronic structure and crystal structure of the coatings, thereby improving the electrocatalytic activity and stability of the anodes. For example, the La element promotes the formation of active sites in the coating, reduces the charge transfer resistance of the anode, and improves its electrocatalytic efficiency.

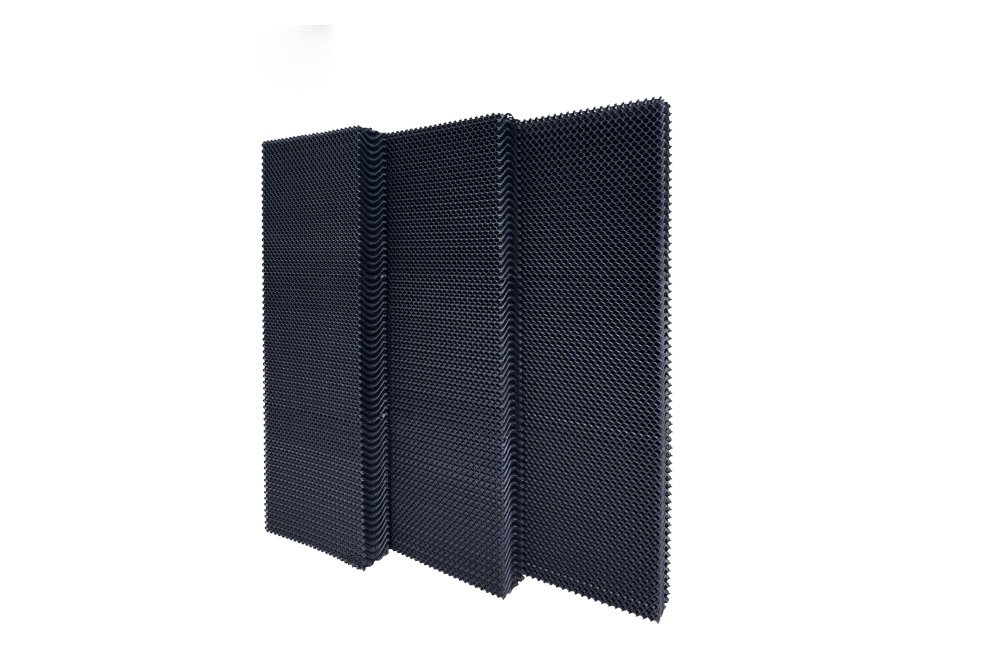

Nanostructured coated anodes

Nanostructured titanium anode coatings, such as nanoporous structures and nanofiber structures, can significantly increase the specific surface area of the anode, increase the number of electrocatalytic active sites, reduce the ion diffusion resistance in the solution, and improve the electrodialysis efficiency. For example, nanoporous IrO₂-TiO₂ anodes show higher treatment efficiency and lower energy consumption when treating high-concentration wastewater by electrodialysis.

Composite materials with high catalytic activity with titanium matrix to prepare new titanium-based composite anodes is also one of the research hotspots in the field of electrodialysis in recent years.

Loading precious metals (such as Pt, Pd, etc.) on the surface of titanium matrix or composite with metal oxide coating can significantly improve the electrocatalytic performance of the anode. Precious metals have excellent catalytic activity, can reduce the activation energy of the reaction, and promote the electrochemical reaction. For example, in the process of electrodialysis desalination, the presence of Pt in the Pt-RuO₂-TiO₂ composite anode can improve the oxidation ability of the anode to trace organic matter in water, while enhancing the catalytic activity of hydrogen and oxygen evolution of the anode, and improving the treatment effect and operation stability of the entire electrodialysis system.

Carbon-titanium composite anode

Carbon materials (such as graphene, carbon nanotubes, etc.) have high conductivity, large specific surface area and good chemical stability. Composite them with titanium anodes can improve the electrical properties and mass transfer properties of the anode. For example, the addition of graphene to the graphene-IrO₂-TiO₂ composite anode not only improves the conductivity of the anode, reduces the electrode resistance, but also enhances the mechanical strength and stability of the coating. At the same time, the high specific surface area of graphene provides more active sites for electrochemical reactions, improving the electrocatalytic efficiency of the anode during electrodialysis.

Advantages of titanium anode in electrodialysis

Titanium anode has shown great application potential and broad development prospects in the field of electrodialysis due to its significant advantages such as excellent electrochemical properties, good chemical stability, long service life, environmental friendliness and performance adjustability.

- High electrocatalytic activity

The metal oxide coating or composite material has abundant active sites, which effectively reduces the overpotential and increases the reaction rate. Whether it is anode reactions such as chlorine evolution and oxygen evolution, or cathode hydrogen evolution reaction, the titanium anode can show good electrocatalytic performance.

- Low electrode resistance

The metal oxide coating of the titanium anode has good conductivity. The low resistance characteristic enables the current to be evenly distributed on the electrode surface, reduces the occurrence of local overheating, and improves the stability and service life of the electrode. In addition, low resistance also means reduced energy consumption.

- Corrosion resistance

The metal oxide coating or composite coating on the surface of the titanium anode further enhances its stability in various chemical environments. For example, the IrO₂ coating effectively resists the corrosion of hydrochloric acid and sulfuric acid even in high-concentration salt solutions and strong oxidizing solutions. .

- Antioxidation ability

In electrodialysis, a large amount of strong oxidizing substances such as oxygen and chlorine are produced. The coating on the surface of the titanium anode can withstand the effects of these strong oxidizing substances. For example, the ruthenium-titanium oxide coating can remain relatively stable in chlorine evolution.

- Long life

The life of titanium anodes has been significantly improved compared to traditional electrode materials, reaching 5-10 years or even longer. For desalination plants, industrial wastewater treatment plants, etc., the long life advantage of titanium anodes is particularly important, effectively reducing overall costs.

- Environmentally friendly

Titanium anodes do not release heavy metal ions and do not pollute the environment. This feature is particularly important in applications such as electrodialysis wastewater treatment and drinking water purification, which can ensure that the treated water quality meets environmental standards.

With the continuous development of electrodialysis technology, higher requirements are placed on the performance of titanium anodes. In the future, Wstitanium’s research on titanium anodes will be directed towards further improving electrocatalytic activity, reducing energy consumption, enhancing stability under extreme conditions, and achieving more efficient resource recovery. With continuous technological innovation and optimization, titanium anodes will play a more important role in the field of electrodialysis.