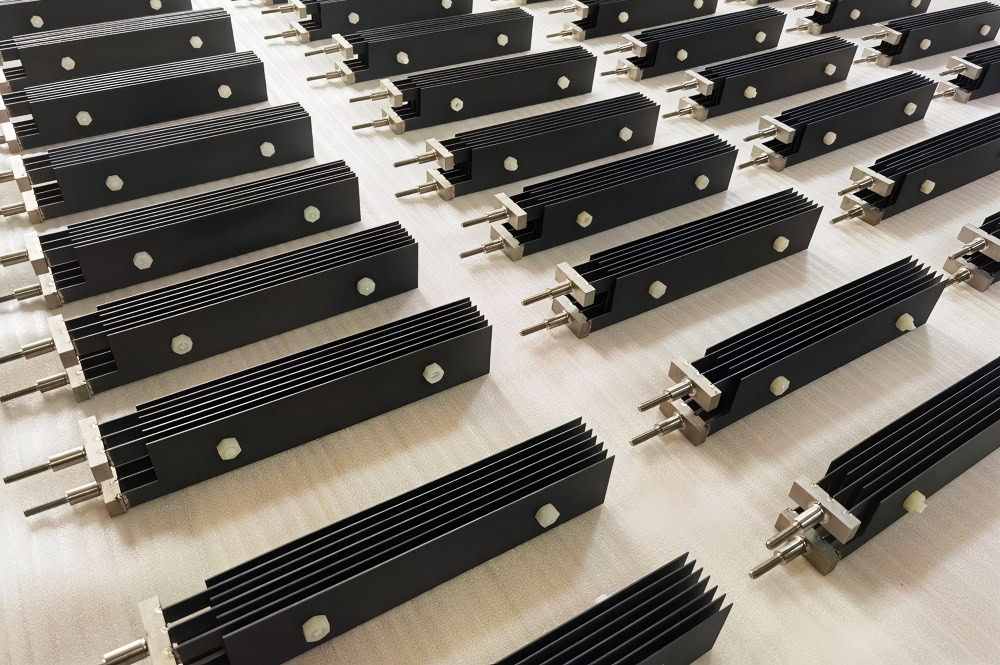

Titanium Anode For Fruit and Vegetable Sterilizer

The application of titanium anodes in the field of fruit disinfection provides a new and effective way to solve these problems. Titanium anodes have many excellent properties, which make them show unique advantages in fruit disinfection, providing more efficient, safer and more environmentally friendly disinfection for fruits and vegetables.

- Iridium-coated titanium anode

- Platinum-coated titanium anode

- Ruthenium-coated titanium anode

- Mixed oxide-coated titanium anode

- Titanium electrolytic cell

- Palladium-coated titanium anode

- Carbon-titanium composite anode

- Metal-metal oxide composite anode

Titanium Anode Application In Fruit Vegetable Sterilizer

As a new type of fruit disinfection technology, titanium anode has shown great application potential in the field of fruit disinfection with its many advantages such as high efficiency disinfection, safety and environmental protection, economic energy saving, and strong applicability. Food safety is of vital importance. However, fruits are extremely susceptible to contamination by microorganisms and pesticide residues during growth, picking, transportation and storage. Traditional fruit disinfection methods have many limitations. For example, chemical disinfectants may leave harmful chemicals on the surface of fruits, affecting the quality and safety of fruits. Simple water washing is difficult to completely remove stubborn pollutants.

Titanium Anode Type for Sterilizer

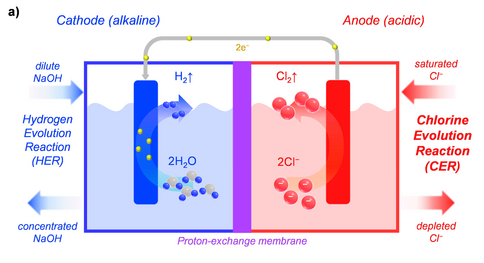

According to the different surface catalytic coatings, titanium anodes can be divided into chlorine-evolving titanium anodes, oxygen-evolving titanium anodes, and titanium anodes with both chlorine and oxygen-evolving functions.

Chlorine-evolving titanium anode

The coating is mainly composed of ruthenium oxide, which has a low chlorine-evolving overpotential in the electrolyte, efficiently produces chlorine gas, and then generates hypochlorous acid for disinfection. Its characteristics are suitable for occasions where a large amount of hypochlorous acid needs to be produced for disinfection.

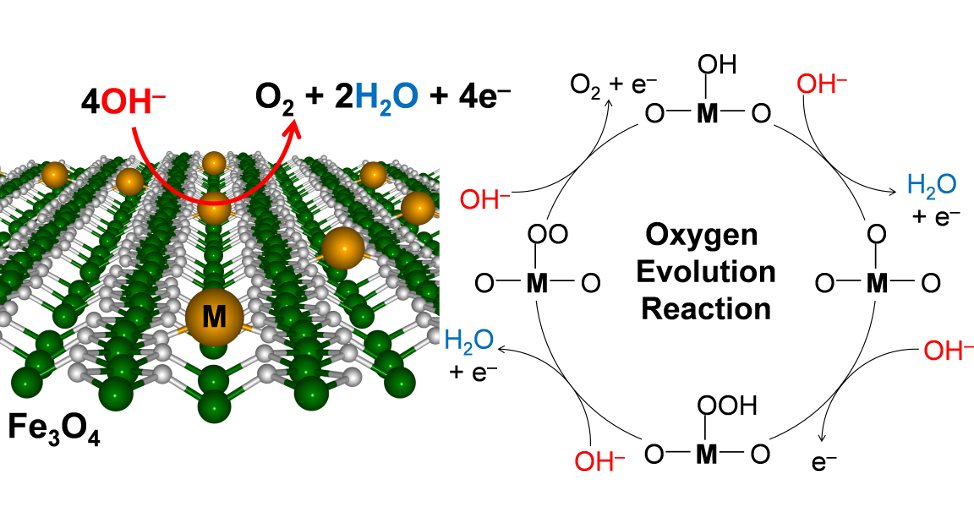

Oxygen-evolving titanium anode

The coating mainly contains iridium oxide, etc. In electrolytes without chloride ions or with low chloride ion concentrations, the oxygen evolution overpotential is low, and the main oxygen evolution reaction produces hydroxyl radicals. Its advantage is that it has a significant effect on removing organic pollutants and pesticide residues.

Chlorine and oxygen-evolving anodes

The titanium anode has the performance of chlorine and oxygen evolution. Under different electrolyte conditions, it can produce appropriate amounts of chlorine and oxygen, as well as corresponding strong oxidizing substances as needed. It has strong adaptability and can meet the needs of various fruit disinfection scenarios.

Ruthenium-iridium-coated titanium anode has high catalytic activity for both chlorine and oxygen evolution reactions. It quickly produces a large amount of chlorine and oxygen at a low voltage, and then generates hypochlorous acid and hydroxyl radicals. It is suitable for disinfecting fruits such as citrus with strong acidity and persimmon with high alkalinity. The disadvantage is that the cost is high.

Iridium-tantalum-coated titanium anode shows excellent catalytic performance in oxygen evolution reaction and efficiently produces hydroxyl radicals. It has obvious advantages in removing organic pollutants and pesticide residues on the surface of fruits. Compared with traditional graphite anodes, its energy consumption is reduced by 20% – 30%. Disadvantages: Its manufacturing cost is high.

The platinum-plated titanium anode reduces the resistance of the electrode and improves the current efficiency, thereby accelerating the electrolysis reaction. The efficiency is 15% – 20%. Its hydrogen evolution overpotential is low, which reduces the production of hydrogen and avoids the interference of hydrogen in the disinfection process. It also improves the effective utilization rate of the anode.

How Does Titanium Anode Work in Sterilizer?

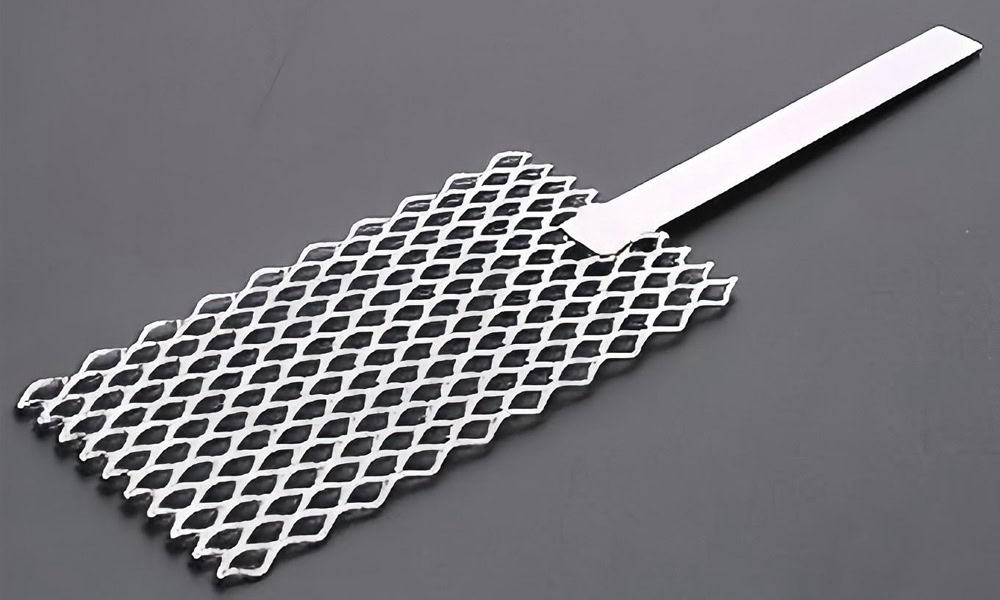

Titanium anode, full name titanium-based metal oxide coated electrode (MMO). It is based on titanium, and a layer of metal oxide coating with specific functions is coated on its surface. Titanium has good mechanical strength and corrosion resistance, and provides a stable support structure for the coating. The metal oxide coating on the surface gives the titanium anode good conductivity, electrocatalytic performance and chemical stability. The coating usually contains precious metal oxides, such as ruthenium (Ru), iridium (Ir), platinum (Pt), etc. These precious metal oxides have low resistivity and high electrocatalytic activity, which effectively reduce the overpotential of the electrode reaction and improve the electrolysis efficiency. For example, in the ruthenium-iridium coated titanium anode, the synergistic effect of ruthenium and iridium oxides makes the anode show excellent performance in both chlorine evolution and oxygen evolution reactions.

In the field of fruit disinfection, titanium anodes mainly achieve disinfection by electrolyzing water to produce strong oxidizing substances. When the titanium anode is connected to the positive electrode of the power supply, as the anode of the electrolytic cell, under the action of the electric field, water electrolysis produces a series of reactions. On the surface of the anode, water molecules are oxidized, and oxygen evolution reaction or chlorine evolution reaction occurs (depending on whether the electrolyte contains chloride ions).

- Oxygen Evolution Reaction

In an electrolyte without chloride ions, the main oxygen evolution reaction occurs: 2H2O – 4e^- = O2↑ + 4H^+). Oxygen escapes in the form of bubbles, and at the same time forms hydroxyl radicals (・OH) with strong oxidizing properties near the anode. Hydroxyl radicals are very active oxidants with an oxidation potential of up to 2.8V, which can quickly oxidize and decompose organic pollutants, pesticide residues and microorganisms on the surface of fruits. For example, hydroxyl radicals can break chemical bonds such as P-O bonds and P-S bonds in organophosphorus pesticide molecules, decomposing them into harmless small molecules.

- Chlorine Evolution Reaction

When the electrolyte contains chloride ions (Cl^-), a chlorine evolution reaction occurs: 2Cl^- – 2e^- = Cl_2↑ . Chlorine (Cl₂) partially dissolves in water and reacts with water: Cl_2 + H_2O = HClO + HCl , generating hypochlorous acid (HClO) . Hypochlorous acid is a weakly acidic strong oxidant with good bactericidal and disinfecting capabilities . It can penetrate the cell walls of microorganisms, destroy the enzyme system and genetic material in their cells, and thus achieve the purpose of killing microorganisms . In addition, hypochlorous acid can also react with some organic pollutants on the surface of fruits to decompose and remove them .

Advantages of Titanium Anodes

Titanium anodes quickly produce a large amount of strong oxidizing substances such as hypochlorous acid and hydroxyl radicals. They quickly destroy the cell structure, protein and nucleic acid of microorganisms, making them inactive, thereby achieving high-efficiency sterilization and disinfection. Studies have shown that the strong oxidizing substances produced by the electrolysis of water using titanium anodes can shorten the killing time of common bacteria such as Escherichia coli and Staphylococcus aureus to 1-2 minutes, which is much faster than traditional disinfection methods.

- Comprehensive Removal of Pollutants

Not only effectively kills microorganisms such as bacteria, molds and yeasts, but also decomposes and removes pollutants such as pesticide residues, hormones, heavy metals, etc. on the surface of fruits.

- Safety and Environmental Protection

Titanium anode disinfection is a strong oxidizing substance produced by the electrolysis of water. It will gradually decompose during disinfection without leaving any harmful residues.

- Strong Applicability

Based on the automatic control of titanium anodes in the disinfection machine, suitable disinfection solutions can be found for acidic, alkaline fruits, and easily damaged fruits.

Application Cases

The application of titanium anodes in sterilizers has shown great potential and advantages, bringing new changes and development opportunities to the field of sterilization. Next, we will use actual cases to deeply explore the specific application of titanium anodes in different types of sterilizers, the actual effects, and the economic and social benefits they bring.

Large Fruit Factory

In the past, chlorine-containing disinfectants were used to disinfect apples. Not only was there a problem of chlorine residue, which affected the quality and taste of apple juice, but the disinfection effect was unstable and microorganisms often exceeded the standard. After the introduction of the electrolytic water disinfection system based on ruthenium-iridium-coated titanium anode, the disinfection efficiency was greatly improved. The system electrolyzes an aqueous solution containing a certain concentration of sodium chloride to produce hypochlorous acid to disinfect apples. The disinfection process only takes 3-5 minutes to increase the killing rate of microorganisms such as Escherichia coli and mold on the surface of apples to more than 99.9%, and effectively removes 60%-70% of pesticide residues on the surface of apples.

Fruit and Vegetable Wholesale Market

In order to ensure the safety and hygiene of fruits, a disinfection machine based on iridium-tantalum-coated titanium anodes was introduced. The disinfection effect is significant for fruits that are easily contaminated, such as strawberries and blueberries. After testing, the pesticide residue on the surface of the disinfected strawberries was reduced by more than 85%, and the number of microorganisms was reduced by more than 90%. Moreover, since this disinfection method has little impact on the quality of fruits, the shelf life of fruits has also been extended to a certain extent, which has been well received by merchants and consumers.

Home Application

There are many household fruit and vegetable disinfection machines based on titanium anode technology on the market. Take a certain brand of household fruit and vegetable disinfection machine as an example. It uses a titanium anode with both chlorine and oxygen evolution functions. Just put the fruit in the water tank of the disinfection machine, add an appropriate amount of water and a small amount of salt (to enhance conductivity). The disinfection machine produces hypochlorous acid and hydroxyl free radicals through electrolysis, and completes the disinfection of fruits within 10-15 minutes. According to tests, the microbial killing rate of fruits disinfected by this disinfection machine reached more than 95%, and it can effectively remove pesticide residues on the surface of fruits.

Different types of titanium anodes, such as ruthenium-iridium coated titanium anodes, iridium-tantalum coated titanium anodes, platinum-plated titanium anodes, etc., each have unique performance characteristics and are suitable for different fruit disinfection scenarios. From large fruit factories to home applications, from fruit and vegetable wholesale markets to fruit planting, titanium anode technology has had successful application cases and achieved good results. However, the application of titanium anodes in the field of fruit disinfection also faces some challenges, such as high cost and other problems. With the continuous advancement of science and technology, titanium anode technology is expected to achieve new breakthroughs and developments in cost reduction, intelligent precision, coordinated application with other technologies, and expanded application scope in the future.