Titanium Anode Manufacturer and Supplier In China

As an innovative leader in the field of titanium anodes in China, Wstitanium manufactures MMO titanium anodes such as ruthenium-iridium coating, iridium-tantalum coating, platinum coating, and lead oxide coating for global customers.

- Ru+Ir Coated

- PEM Electrolyzer

- Iridium Ta-Coated

- Platinized Titanium Anodes

- ICCP Anodes

- Electroplating Anode

- Titanium Electrolyzer

- Water Treatment Anode

Good Reputation Titanium Anode Manufacturer In China

Wstitanium is committed to continuous innovation and improvement of titanium anodes, providing better, more efficient and more environmentally friendly electrochemical solutions for many fields such as chlor-alkali industry, electroplating, wastewater treatment, electrosynthesis, etc. Wstitanium has become a highly regarded supplier of titanium anodes in China with its outstanding R&D strength, advanced manufacturing technology and strict quality control system.

Customized Ruthenium-Iridium Coated Titanium Anodes For Chlor-Alkali to Wastewater Treatment, Swimming pool water disinfection, etc.

- Voltage<24V

- RuO2 +IRO2 +X

- Gr1 Titanium As Substrate

- Coating Thickness 8~15μm

- Current Density<5,000A/㎡

Iridium oxide coated titanium anode for non-ferrous metal electrolysis, electrolytic recovery of copper in etching solution, etc.

- PH Value:1-12

- Temperature <85 ℃

- Base: Gr1, Gr2 Titanium

- Current Density: 500-800A

- Fluoride Content: <50 mg / L

Platinum-coated titanium anode has excellent stability, catalytic efficiency and low consumption, making it a typical negative electrode.

- Temperature: <80 ℃

- Base: Gr1, Gr2 Titanium

- Fluoride Content: <50mg / L

- Current Density: ≤ 5000 A/m²

- Coating Thickness: 0.2-10μm

PEM Electrolyzer

Proton exchange membrane (PEM) electrolyzers are designed to electrolyze water to produce clean hydrogen efficiently and green.

- Hydrogen Purity: >99.99%

- Hydrogen Pressure: 3.5 MPa

- Water Consumption: 60kg/h

- Rated Hydrogen Volume: 50-300Nm3/h

- Rated Power Consumption: <4.5kW/Nm3

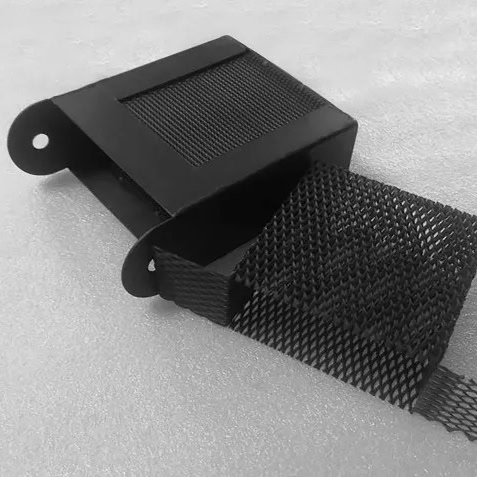

Cathodic protection anodes counteract corrosion of pipelines and equipment by sacrificing themselves through a controlled electric current.

- ICCP Anodes

- DSA MMO Anode

- Sacrificial Anodes

- Reference Electrodes

- Customized Terminal Connectors

MMO anode or mixed metal oxide titanium anode plays a pivotal role as an electrode in the field of electrochemical water treatment.

- For Sewage Treatment

- For Seawater Desalination

- For Swimming Pool Disinfection

- For Hospital Wastewater Treatment

- For Sodium Hypochlorite Production, etc.

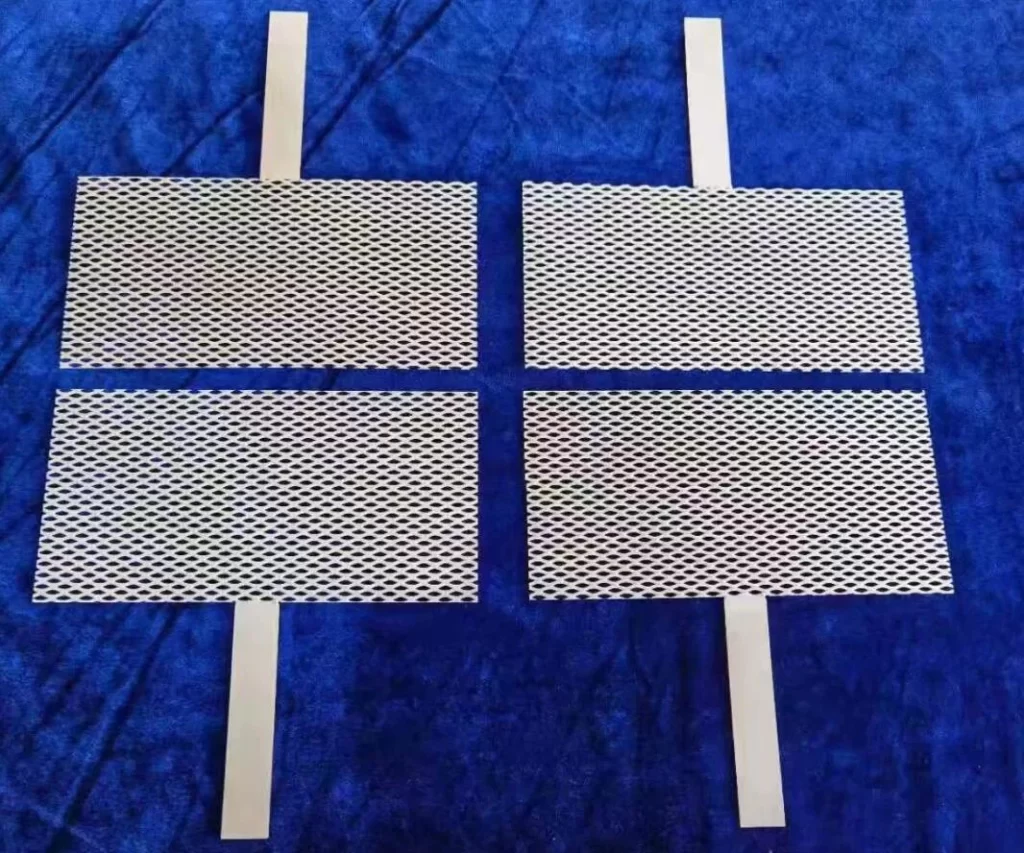

Electroplating Anode

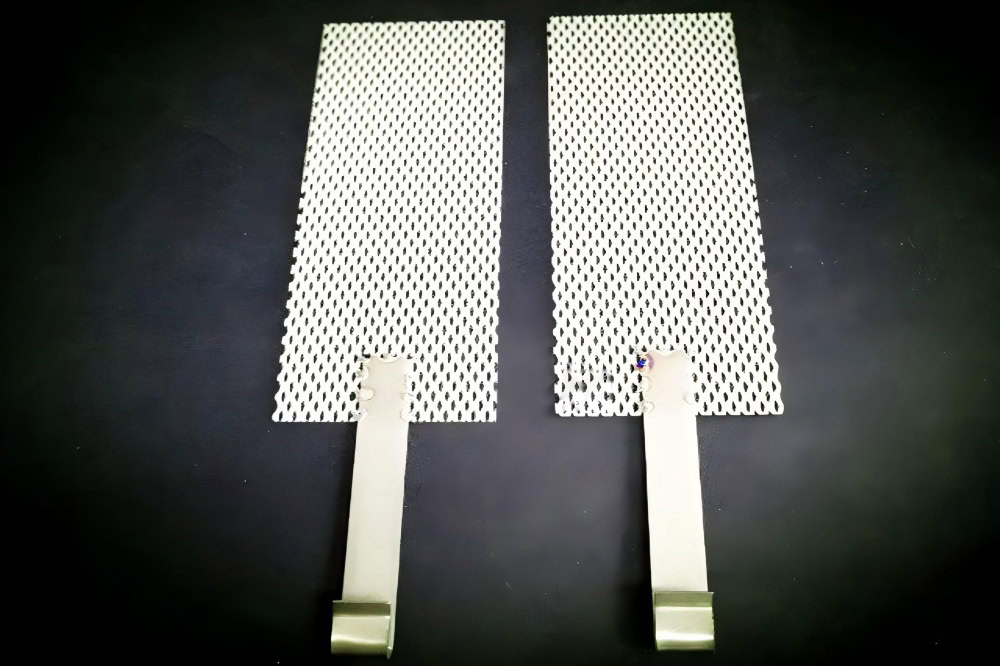

Electroplating anodes are made of titanium and coated with different metal oxides to increase the efficiency of producing metal ions.

- For Zinc Electroplating

- For Nickel Electroplating

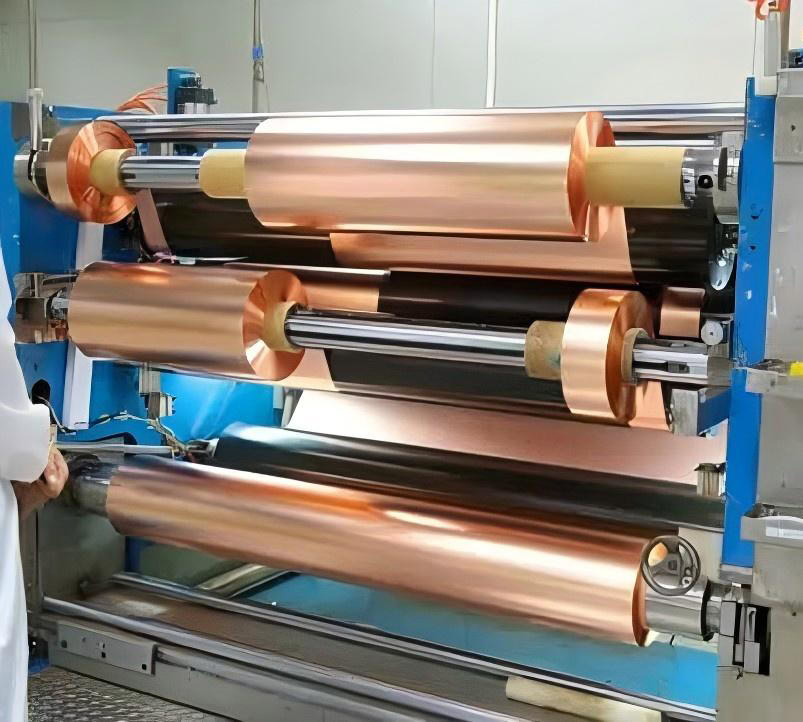

- For Copper Foil Production

- For Chromium Electroplating

- For Precious Metal Electroplating

Electrowinning Electrode

Electrowinning anode is placed in a liquid containing metal ions, resulting in the electrolytic deposition or extraction of the metal.

- Ti/Pt Anode

- Nb/Pt Anode

- Ti/Ir+Ta Anode

- Ti/PbO2 Anode

- Ti/MMO Anode

Impressed Current Cathodic Protection (ICCP) uses a controlled low voltage to actively prevent rust and effectively combat metal corrosion.

- Graphite Anode

- Mixed Metal Oxide Anode

- Precious Metal Oxide Anode

- High Silicon Cast Iron Anode

- Platinum-Coated Titanium Anode

Cathodic Protection Cable

Made of copper encased in corrosion and abrasion resistant plastic insulation, it provides long-lasting performance in harsh environments.

- Bending Radius: 20D

- Rated Voltage: DC 600V

- CPVV, CPY, CPFY, CPFY33

- Insulation: HMWPE, PVDF, or KYNAR

- Cross-Section:10,16,25,35,50,70

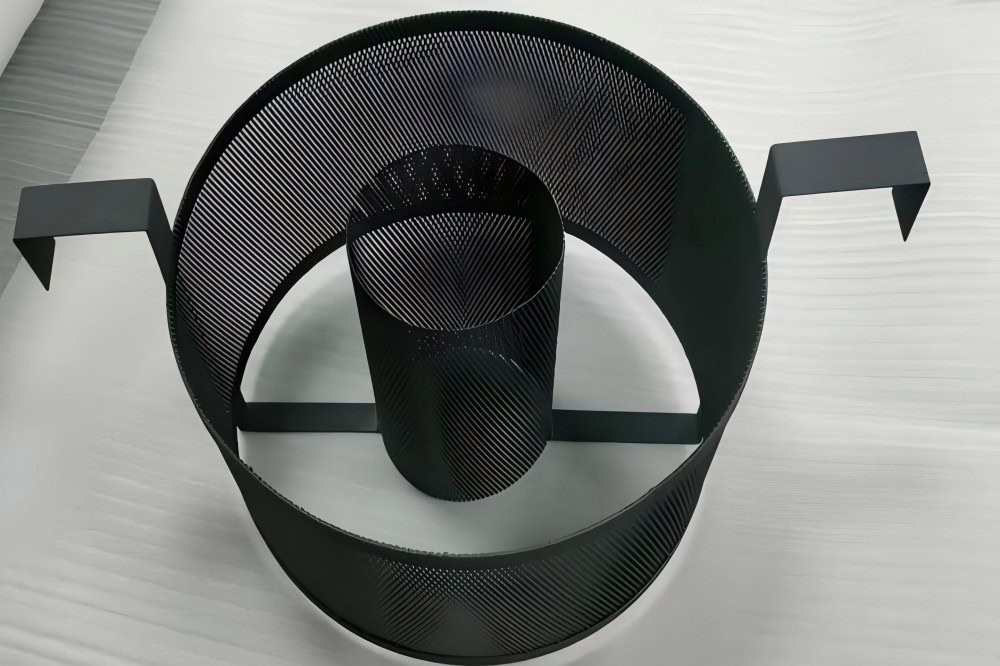

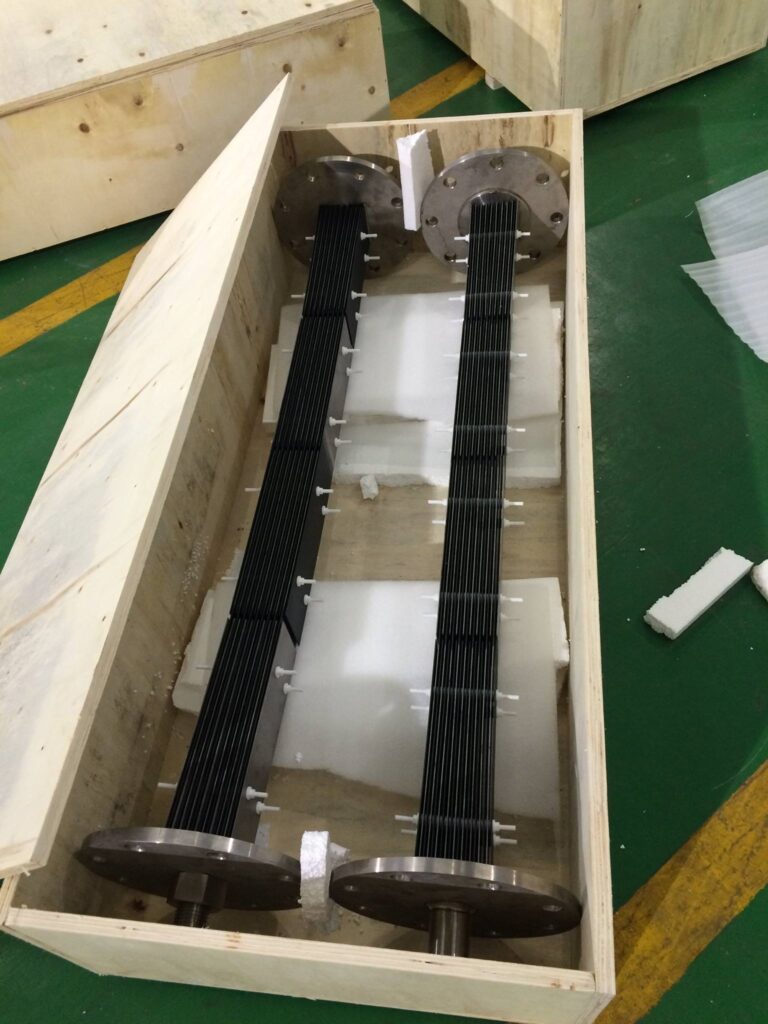

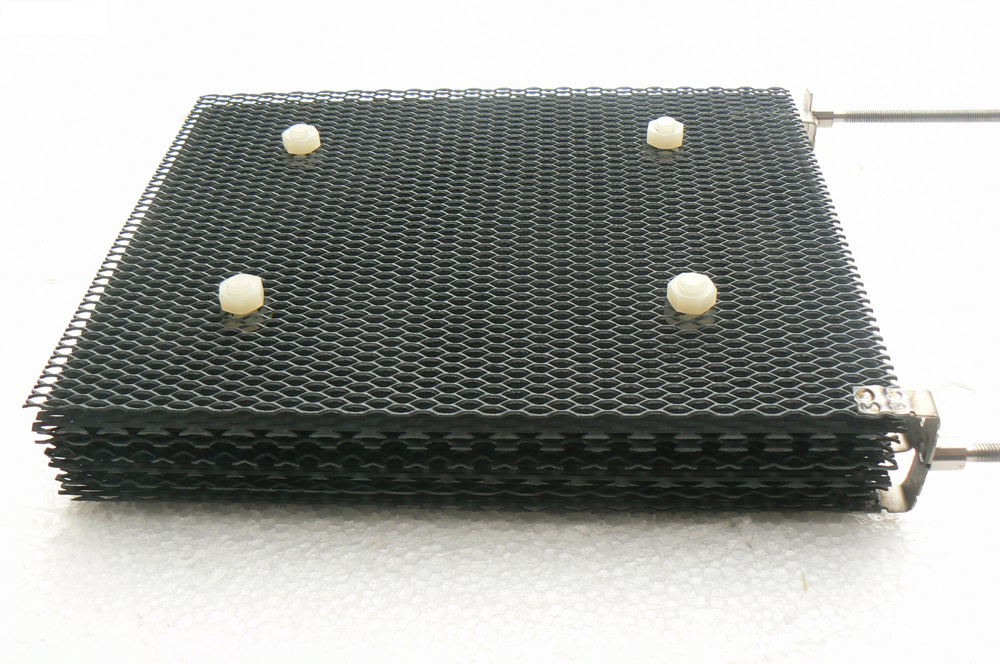

Titanium electrolyzers are specialized vessels for electrolytic chlorination, used to convert brine or seawater into sodium hypochlorite.

- Parallel Plate Electrolyzer (PPE)

- Concentric Tubular Electrolyzer

- Sodium Hypochlorite Electrolyzer

- Seawater Sodium Hypochlorite Generator

- Brine Water Sodium Hypochlorite Generator

Sacrificial anodes are used to protect pipelines, tanks, etc. from corrosion and are made of reactive metals such as zinc, aluminum or magnesium.

- Galvanic Anode

- Sacrificial Zinc Anode

- Aluminum Sacrificial Anode

- Magnesium Sacrificial Anode

- Customized In Various Sizes and Shapes

Custom Manufacturing Titanium Anode Services

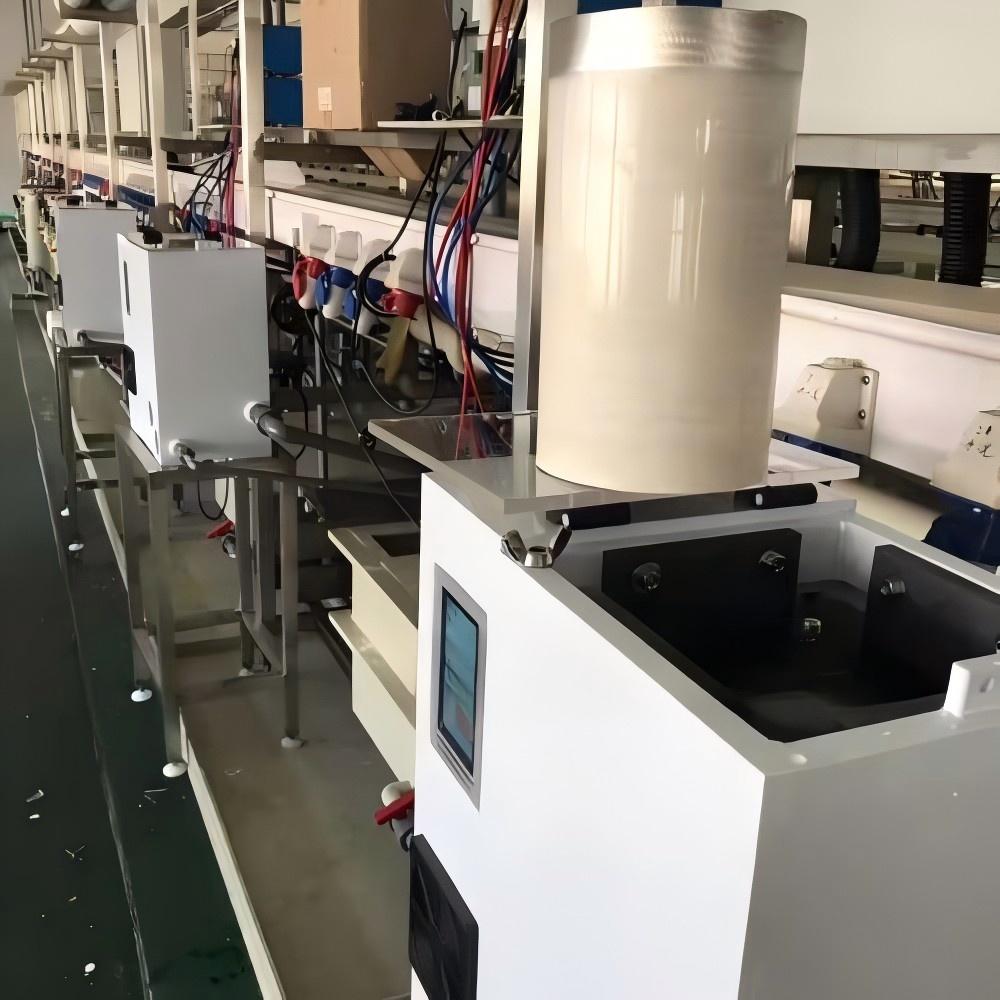

As an innovative leader in China’s titanium anode field, Wstitanium’s technical team includes professionals in multiple fields such as materials science, electrochemistry, surface treatment, and mechanical design. Investing in a series of internationally leading manufacturing facilities, such as high-precision laser cutting machines, automated coating production lines, and advanced thermal decomposition furnaces, ensures high-precision and stable manufacturing of titanium anodes. Advanced testing laboratories, including scanning electron microscopes (SEM), energy dispersive spectrometers (EDS), and X-ray diffractometers (XRD), are capable of full-scale testing of raw materials, semi-finished products, and finished products, providing a solid guarantee for quality.

Wstitanium fully understands the application field and grasps the information you need about the corrosion resistance and catalytic activity of the titanium anode, and then considers the composition, temperature, concentration, current density, voltage, time and other parameters of the electrolyte. Determine the customized products you need, such as ruthenium-based titanium anodes, iridium-tantalum titanium anodes, platinum-plated titanium anodes or other mixed metal oxide titanium anodes.

- Custom Specifications: Sizes, shapes and configurations to meet project requirements.

- Coating: Determine the coating material to achieve the best performance in a specific environment.

- Electrodes: Rod, mesh, plate or tubular electrodes designed to optimize electrochemical processes.

- Voltage and Current: Specify your exact needs for optimal electrochemical efficiency.

- Coatings: Determine ideal coating thickness to balance durability and performance.

- Specialty Connectors: Custom end connectors or terminals for integration into electrochemical systems.

Titanium Anode Manufacturing Process

Wstitanium has strict standards for the selection of raw materials for titanium anodes. Raw materials must undergo rigorous testing, including chemical composition analysis, mechanical properties testing (for titanium substrates), purity testing (coating materials), etc. Wstitanium determines the best coating solution formula, coating process parameters (such as coating times, coating speed, etc.), curing temperature and time, etc.

Select Titanium Substrate

Confirm the titanium anode base material Gr1, Gr2. It is required to be of high purity and free of defects such as deep pits and cracks on the surface.

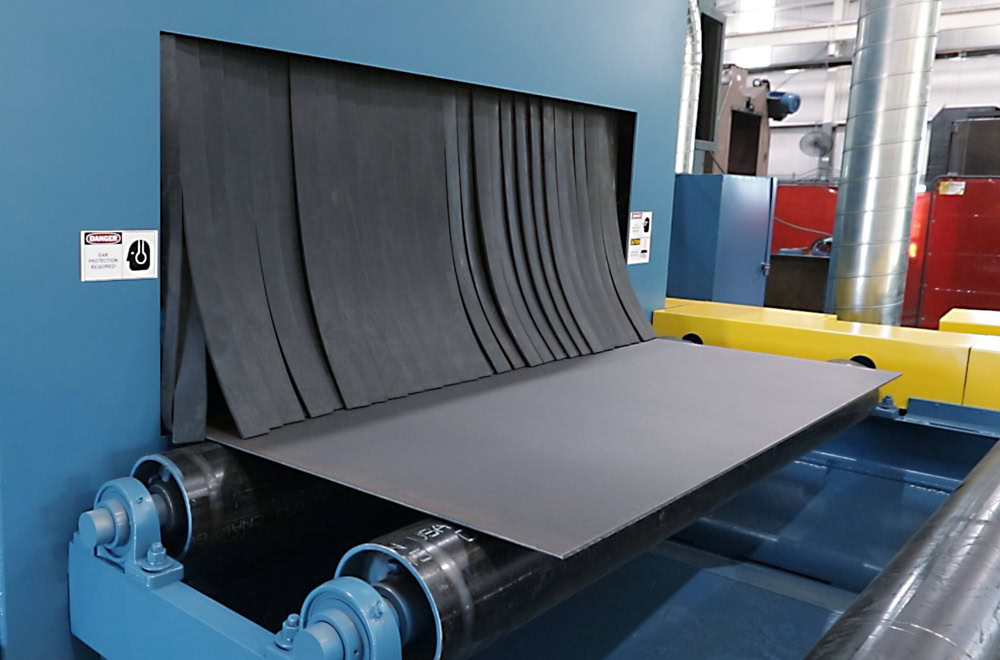

Forming

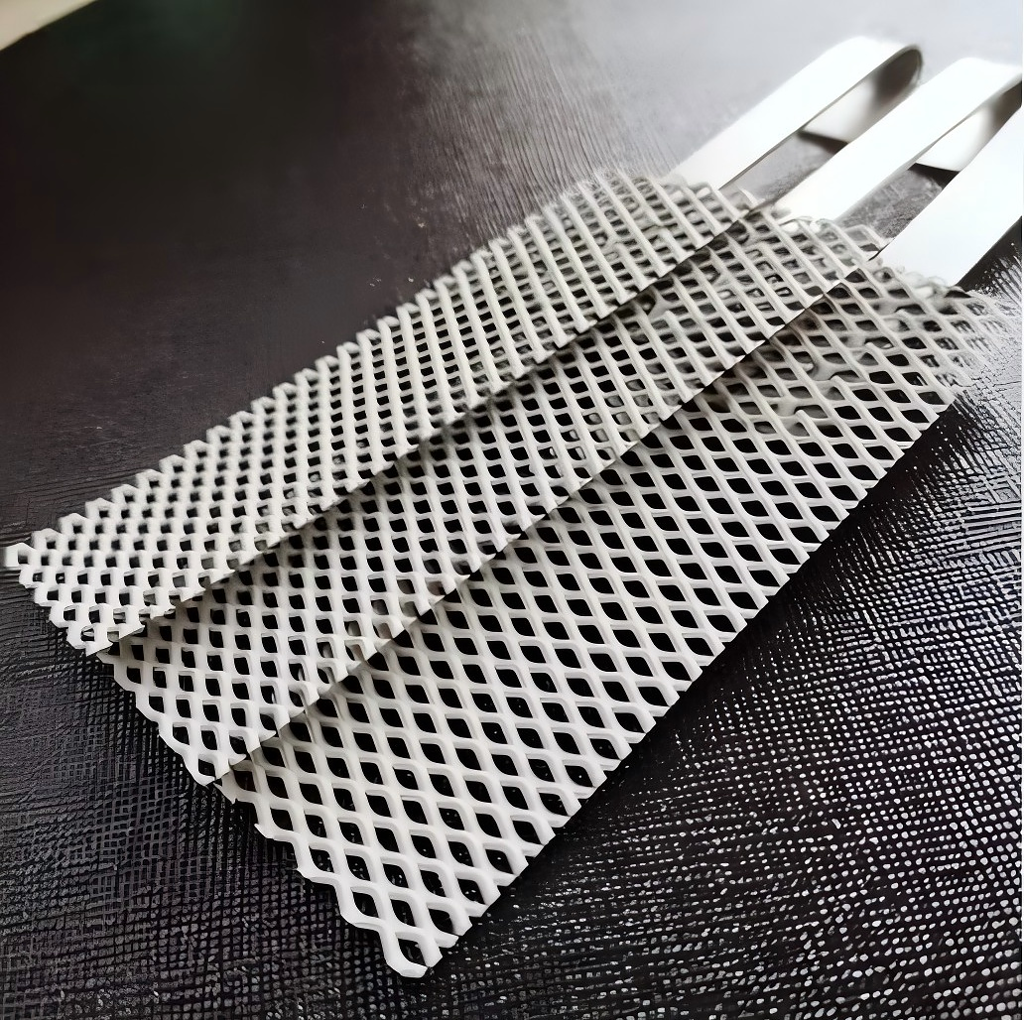

Shearing, laser cutting or welding, forming the titanium material into the required shape and size, such as plate, tube, rod, mesh, etc.

Leveling / Annealing

Leveling is to ensure the flatness of the plate. Annealing is to eliminate stress on the titanium substrate and improve performance.

Pickling

Puting titanium substrate in boiling oxalic acid to boil and soak, remove surface oxide, make the surface rough, and increase the adhesion of the coating.

Sand Blasting

Sand is sprayed onto the surface of the titanium substrate to remove impurities and oxide layer, make it rough, and improve the adhesion of the coating.

Liquid Preparation

Dissolve the metal salts in a selected solvent in a certain proportion to prepare the coating solution, and prevent precipitation.

Coating

Brush the coating solution evenly onto the surface of the titanium substrate. No impurities or dust should be contaminated.

Drying

Repeat the process of brushing, drying, heating and cooling. The coating liquid reacts fully with the substrate to form an active coating.

Quality Inspection

The size, appearance, coating adhesion, electrical properties, etc. of the titanium anode are inspected and accepted item by item.

Dimension

Length: Available from tens of millimeters to several meters to accommodate different electrolyzer sizes and application scenarios. For example, for small laboratory electrolyzers, shorter titanium anodes are recommended.

Width: The width is customized according to your requirements. Generally speaking, the choice of width will take into account factors such as the current distribution and electrolysis efficiency of the anode.

Thickness: The thickness of the titanium substrate follows the conditions of use. In some applications that need to withstand greater mechanical stress, a thicker titanium substrate is selected.

Coating Thickness

The coating thickness can be customized according to the requirements of the electrolysis process and the service life of the anode. Thicker coatings usually have longer service life, but the cost is also relatively high. Generally speaking, the coating thickness ranges from a few microns to tens of microns.

Shape

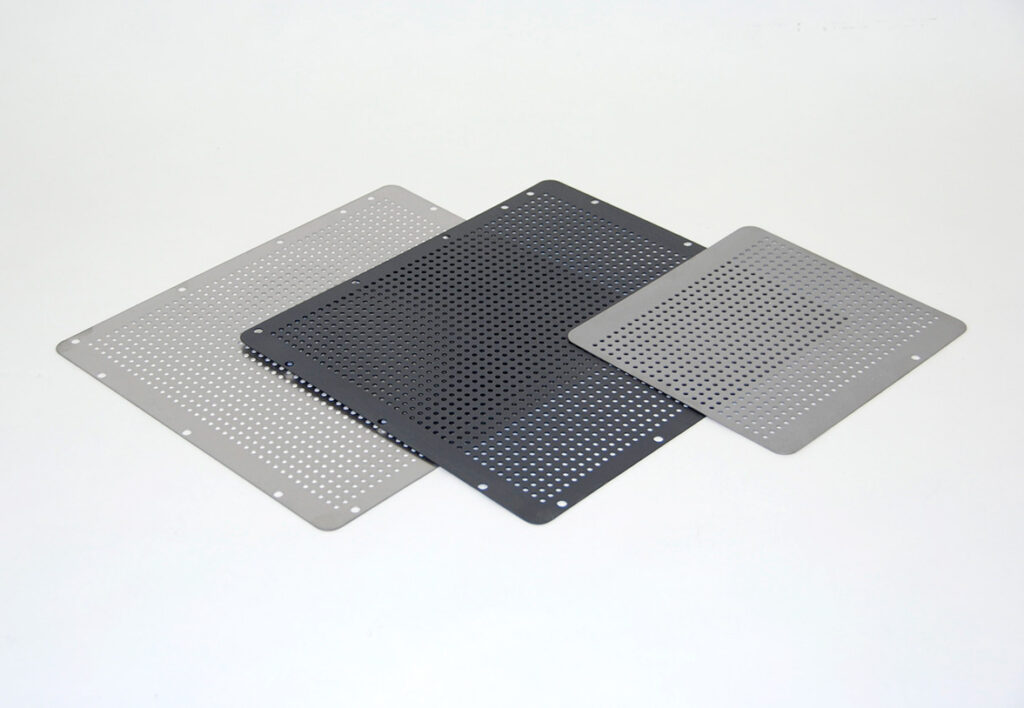

Wstitanium’s design of the titanium anode shape prioritizes the strong bonding of the titanium substrate with its active coating. By optimizing the surface area of the electrode, enhanced electrocatalytic efficiency and optimal current density are ensured. This focus on optimized design translates into high efficiency and cost savings for you.

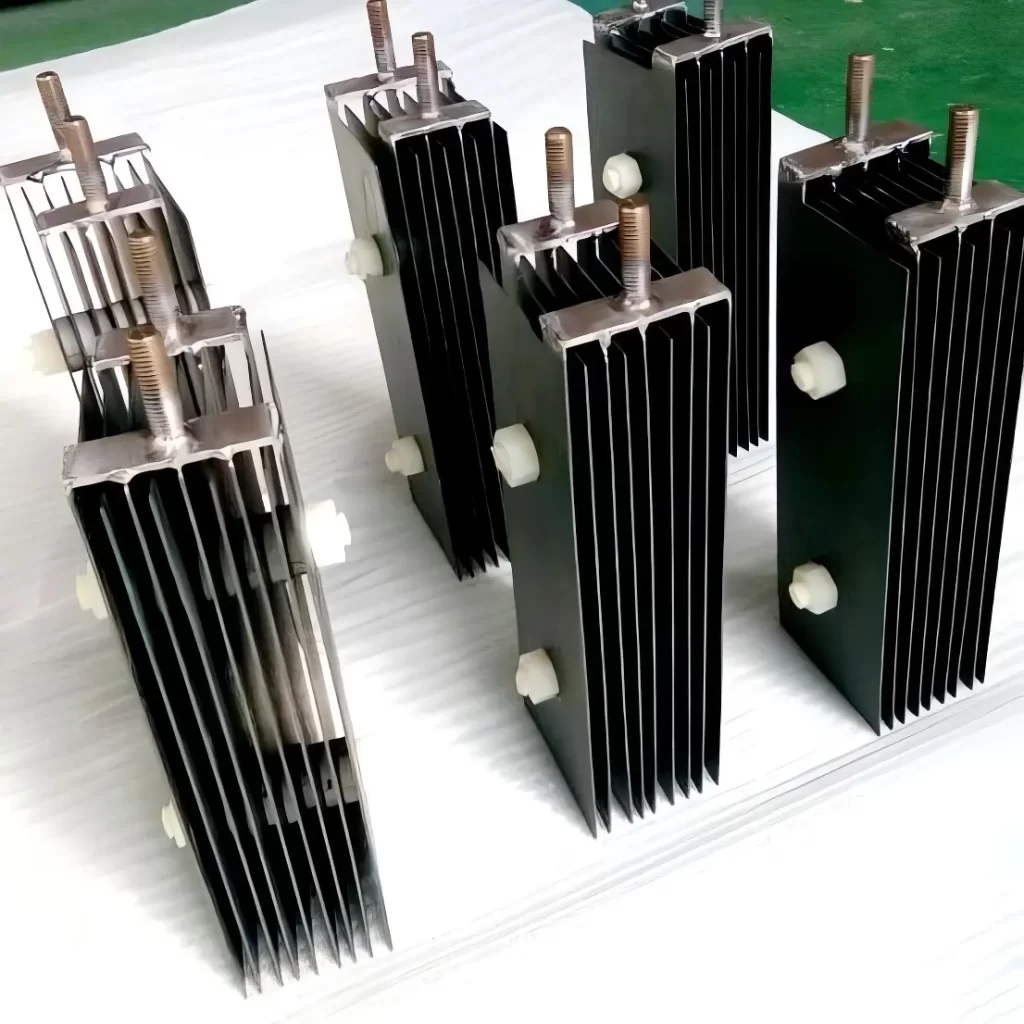

Plate: square and rectangular patterns are available. The structure is simple and easy to manufacture. Different electrolysis needs can be met by changing the size and thickness of the plate. It is often used in electrolysis systems that require large electrode areas and regular shapes, such as industrial wastewater treatment. However, at high current densities, there may be edge effects, resulting in uneven current distribution.

Mesh: Large surface area, can effectively improve electrode reaction rate and current efficiency, gas is easy to escape, can reduce the attachment of bubbles on the electrode surface, and is often used in chlor-alkali industry, etc. Its mechanical strength is relatively low, and external force impact should be avoided when using it.

Cylindrical: The electric field distribution is relatively uniform, suitable for occasions with high requirements for electric field uniformity, such as precision electroplating processes. It can be designed as solid or hollow as needed. Hollow cylindrical anodes can save materials, reduce weight, and can also pass cooling media.

Special shape: customized according to special electrolysis needs. For example, for electroplating of complex-shaped parts, the anode can be designed to match the shape of the plated part. It can accurately control the current distribution and improve the quality of electroplating, but it is difficult to manufacture and has high cost.

Titanium Anode Design

The design of titanium anode is a complex system project that requires comprehensive consideration of the electrolyte composition, temperature, concentration, current, voltage, electrolysis time, electrolytic cell structure, electrode spacing, installation method and other factors to meet different industrial needs and electrolytic process requirements.

Case 1: Titanium Anodes for Chlor-alkali Industry

In the chlor-alkali industry, titanium anodes have become standard configurations, and their performance directly affects the efficiency and cost of chlor-alkali manufacturing. Taking a large chlor-alkali production enterprise as an example, the ruthenium-iridium-titanium coated titanium anode designed by Wstitanium was used in the newly built production line, achieving significant economic and environmental benefits.

Parameters and conditions: The electrolyte of the production line is a saturated sodium chloride solution, the temperature is controlled at 85-95℃, and the electrolyte concentration is 300-320g/L. The anode adopts a plate structure, the current density is designed to be 1000-1500A/m², the electrolytic cell is a rectangular structure, the electrode spacing is 8-10mm, and the anode is installed in a suspended manner.

Anode performance and effect: After using ruthenium-iridium-titanium coated titanium anode, the purity of chlorine and hydrogen reached 99.5% and 99.9% respectively, and the service life of the anode increased from 2-3 years to 5-8 years. In addition, due to the improved catalytic activity of the anode, the energy consumption in the electrolysis process was also reduced by 10%-15%.

Experience and inspiration: In the chlor-alkali industry, ruthenium-iridium-titanium coated titanium anode has excellent catalytic activity and corrosion resistance under high current density and high temperature environment, which is the key to improving production efficiency and reducing costs. Electrode spacing helps to improve performance and life.

Case 2 Titanium Anode for Sewage Treatment

The titanium-based lead dioxide coated anode manufactured by Wstitanium has achieved good results in sewage treatment.

Design: The sewage is mainly a mixture of domestic sewage and industrial wastewater, the electrolyte is weakly acidic, and the pH value is between 6 and 7. The anode adopts a mesh structure to increase the surface area of the electrode. The current density is designed to be 500-800A/m², the electrolytic cell is a rectangular structure, the electrode spacing is 10-15mm, and the anode is fixedly installed.

Anode performance and effect: After titanium-based lead dioxide coated anode treatment, the removal rates of pollutants such as chemical oxygen demand (COD) and ammonia nitrogen in sewage reached 89%-94% and 80%-92% respectively.

Experience: Titanium-based lead dioxide coated anode has good electrocatalytic activity and stability, and can effectively degrade organic pollutants in sewage. In addition, the mesh structure of the anode can increase the contact area between the electrode and sewage, improve reaction efficiency, and reduce energy consumption.

Case 3: Titanium Anode For Electroplating

As an insoluble anode, titanium anode has been widely used in the electroplating industry. An electronic component electroplating company used platinum-titanium coated titanium anode for gold plating process and achieved excellent electroplating effect.

Design parameters: The electroplating solution of the company is potassium gold cyanide solution, the temperature is controlled at 40-50℃, and the electrolyte concentration is 10-15g/L. The anode adopts a mesh structure, the current density is designed to be 20-50A/dm², the electrolytic cell is a rectangular structure, and the electrode spacing is 15-20mm.

Performance and effect: After using platinum-titanium coated titanium anode, the yield rate has increased from the original 80% to more than 95%.

Experience: The conductivity and stability of the anode are key factors affecting the quality of the coating. Platinum-titanium coated titanium anode has good conductivity and corrosion resistance, which can ensure the stable transmission of current during the electroplating process, thereby obtaining a high-quality coating.

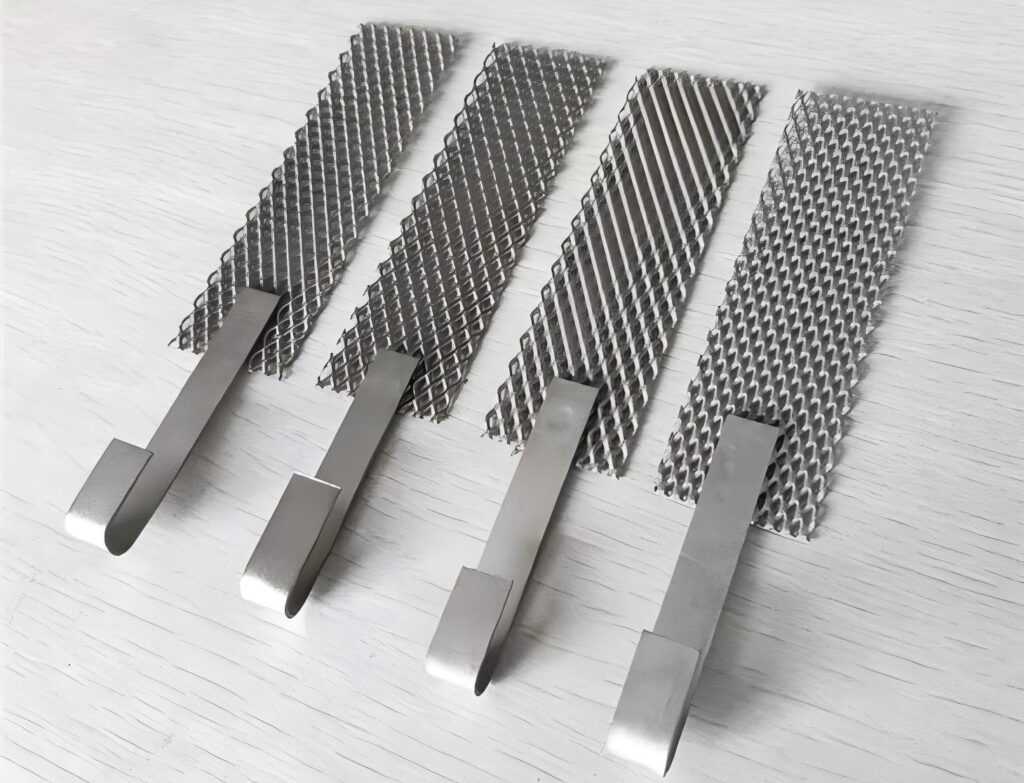

Case 4: Titanium Anode For Hydrometallurgy

The application of titanium anode effectively improves the extraction efficiency and quality of metals. A copper hydrometallurgical enterprise adopted a new type of comb-tooth titanium anode plate and achieved good economic benefits.

Design parameters: The electrolyte of the enterprise is an acidic solution containing copper sulfate, the temperature is controlled at 50-60℃, and the electrolyte concentration is 150-180g/L. The anode adopts a comb-tooth structure, which is cut into two parts by a whole titanium anode plate body. The width of the comb teeth is 15-20mm, and the spacing between adjacent comb teeth matches the width of the comb teeth. The current density is designed to be 300-500A/m², the electrolytic cell is a rectangular structure, the electrode spacing is 10-15mm, and the anode is installed in a suspended manner.

Anode performance and effect: The service life of the comb-tooth titanium anode is increased by 10%, the material cost is reduced by 30%, and the current density is increased by 40%. At the same time, due to the design of the comb-tooth structure, the current distribution on the anode surface is more uniform, which effectively reduces the shedding of the coating and the passivation of the anode, and improves the copper extraction efficiency and product quality.

Advantages of Titanium Anodes

Titanium anode plays an important role in many industrial fields with its unique material properties and excellent performance advantages. Its advantages such as high corrosion resistance, high electrochemical activity, long service life and low maintenance cost make it the preferred electrode material in the field of modern electrochemistry.

High Corrosion Resistance

One of the most prominent advantages of titanium anode is its excellent corrosion resistance. In seawater or chemical industry, electrolyte solution is highly corrosive, and titanium anode performs well in these highly corrosive media. For example, in the chlor-alkali industry, titanium anode operates stably for a long time in high concentration sodium chloride solution and chlorine environment.

High Electrochemical Activity

The coating of titanium anode has high electrochemical activity and can significantly increase the rate of electrode reaction. Taking the chlor-alkali industry as an example, the ruthenium oxide coating effectively catalyzes the oxidation reaction of chloride ions and reduces the overpotential of the reaction. This means that at the same current density, the consumption of electrical energy is reduced.

High Electrochemical Activity

The service life of titanium anode is usually much longer than that of traditional electrode materials. It can be used for more than ten years or even longer. For example, in the electrochemical oxidation process of sewage treatment, titanium anode effectively degrades organic matter and pollutants in sewage for a long time. The frequency and cost of electrode replacement are reduced.

The high corrosion resistance and long service life of titanium anodes make their maintenance costs relatively low. Frequent surface treatment and replacement are not required, reducing labor and material costs. For example, the cathodic protection system of offshore oil platforms can greatly reduce the maintenance workload and costs by using titanium anodes. Since titanium anodes can operate stably for a long time in harsh marine environments, they do not require frequent inspections and maintenance, which improves the operating efficiency and economic benefits of the equipment.

Titanium Anode Types

There are many types of titanium anodes, each with its own unique characteristics, performance and application scenarios. Ruthenium-based titanium anodes, iridium-based titanium anodes, titanium-based lead dioxide anodes, titanium-based platinum group metal anodes and titanium-based intermetallic compound anodes play an important role in different industrial fields.

Ruthenium Coated Titanium Anode

The coating is mainly composed of ruthenium and titanium oxides, which have high electrocatalytic activity, especially in the chlorine evolution reaction. Ruthenium titanium oxide coated anodes are widely used in the process of electrolyzing salt water to produce chlorine, hydrogen and sodium hydroxide. However, in certain strong oxidizing environments, such as high-concentration hypochlorite solutions, the coating of ruthenium titanium oxide coated anodes may dissolve, resulting in a decrease in anode performance. Therefore, when using this anode, it is necessary to make reasonable selection and maintenance according to the specific application environment.

Ruthenium Iridium Titanium Anode

Ruthenium Iridium Titanium Anode is based on Ruthenium Titanium Oxide Coating with Iridium. The addition of Iridium improves the corrosion resistance and stability of the coating, especially in strong oxidizing and acidic environments. Ruthenium Iridium Titanium Oxide Coated Anode has higher electrocatalytic activity and longer service life, and is suitable for more demanding electrolytic environments. For example, in chemical production, electrolysis is required in strongly acidic and oxidizing solutions, and Ruthenium Iridium Titanium Oxide Coated Anode can better meet these requirements. In the electroplating industry, Ruthenium Iridium Titanium Oxide Coated Anode can provide a stable current density to ensure the quality and uniformity of the coating.

Iridium Coated Titanium Anode

Pure iridium oxide coated titanium anode has attracted attention for its excellent corrosion resistance and electrocatalytic performance. Iridium is a precious metal whose oxide has extremely high chemical stability and electrocatalytic activity. This anode maintains high electrocatalytic activity in strong acidic and oxidizing environments, such as in solutions of sulfuric acid and nitric acid. However, the high cost of pure iridium oxide coated anodes limits its use in some cost-sensitive applications. Therefore, in practical applications, it is necessary to decide whether to use this anode based on specific needs and budget.

Iridium-Tantalum Coated Titanium Anode

Iridium-Tantalum coated titanium anode is based on iridium oxide coating with tantalum added. The addition of tantalum further improves the corrosion resistance and conductivity of the coating while reducing the cost. Working in a high concentration of sodium chloride solution and chloride ion environment, the iridium-Tantalum coated titanium anode can effectively resist the corrosion of chloride ions. Its high electrocatalytic activity and good corrosion resistance enable it to operate stably for a long time in a complex sewage environment.

Lead Dioxide Titanium Anode

Lead dioxide has good electrocatalytic properties and electrical conductivity, and performs well in some specific electrolytic processes. For example, in the electroplating industry, the lead dioxide coating can provide a stable anode potential, promote the deposition of chromium ions, and obtain a high-quality chrome plating layer. However, titanium-based lead dioxide anodes also have some disadvantages. The lead dioxide coating may fall off after long-term use, affecting the performance of the anode. At the same time, lead dioxide is a heavy metal, and attention should be paid to environmental protection during use and handling.

Platinum-Coated Titanium Anode

Platinum-coated titanium anode has extremely high chemical stability and electrocatalytic activity, and is used in high-end fields. Such as fuel cells, electrochemical sensors, etc. As a catalyst, the platinum anode can promote the oxidation reaction of the fuel and improve the efficiency of the fuel cell. However, the high price of platinum limits the large-scale application of titanium-based platinum anodes. Titanium-based platinum anodes are usually prepared by electrochemical deposition or physical vapor deposition. The electrochemical deposition method is to deposit platinum on the surface of the titanium substrate by electrochemical methods in a solution containing platinum salts. The physical vapor deposition method is to deposit platinum vapor on the surface of the titanium substrate to form a platinum coating.

Palladium-Coated Titanium Anode

Palladium is also a platinum group metal with good electrocatalytic properties and corrosion resistance. Titanium-based palladium anode can catalyze the oxidation or reduction reaction of organic compounds to achieve the synthesis and conversion of organic compounds. Such as organic electrosynthesis, electrocatalytic hydrogenation, etc. Compared with platinum, the price of palladium is relatively low. The preparation method of palladium-coated titanium anode is similar to that of titanium-based platinum anode, mainly electrochemical deposition method and physical vapor deposition method.

Titanium-Based Intermetallic Compound Anode

Intermetallic compounds are compounds composed of two or more metals with specific crystal structures and properties. For example, titanium-aluminum compound anodes, titanium-nickel compound anodes, etc. Titanium-based intermetallic compound anodes have potential application value in some high-temperature electrolysis processes, such as high-temperature molten salt electrolysis, solid oxide fuel cells, etc. However, the preparation process of titanium-based intermetallic compound anodes is relatively complex and the cost is high. The main methods for preparing titanium-based intermetallic compound anodes are powder metallurgy, thermal spraying, etc.

| Type | Composition | Advantages | Disadvantages | Applicable Scenarios | Price Range |

| Ruthenium-Titanium Oxide Coated Anode | Titanium substrate, and the coating is mainly composed of ruthenium and titanium oxides. | High electrocatalytic activity, especially outstanding performance in the chlorine evolution reaction; can reduce the overpotential of the chlorine evolution reaction, improve the current efficiency, and reduce the power consumption; relatively long service life. | In some strongly oxidizing environments (such as high-concentration hypochlorite solutions), the coating may dissolve, resulting in a decline in anode performance. | The electrolysis of brine in the chlor-alkali industry to produce chlorine, hydrogen, and sodium hydroxide. | Relatively low, with high cost-effectiveness. |

| Ruthenium-Iridium-Titanium Oxide Coated Anode | Titanium substrate, and the coating is composed of ruthenium, iridium, and titanium oxides. | Higher electrocatalytic activity and longer service life; better corrosion resistance and stability, especially excellent performance in strongly oxidizing and acidic environments. | The cost is relatively higher than that of the ruthenium-titanium oxide coated anode. | The electrolysis of strongly acidic and oxidizing solutions in the chemical production industry; ensuring the quality and uniformity of the coating in the electroplating industry. | Moderately high. |

| Pure Iridium Oxide Coated Anode | Titanium substrate, and the coating is pure iridium oxide. | Excellent corrosion resistance, and can operate stably for a long time in strongly acidic and oxidizing environments; high electrocatalytic performance. | The cost is relatively high, which limits its application in cost-sensitive fields. | Special electrolysis processes, such as the electrolysis of high-concentration sulfuric acid solutions to prepare persulfates. | High. |

| Iridium-Tantalum-Titanium Oxide Coated Anode | Titanium substrate, and the coating is composed of iridium, tantalum, and titanium oxides. | Good corrosion resistance and electrical conductivity; can effectively resist the corrosion of chloride ions in seawater; can operate stably in complex sewage environments. | The preparation process is relatively complex, and the proportion of elements needs to be precisely controlled. | Seawater desalination, electrochemical oxidation treatment of sewage in sewage treatment. | Moderately high. |

| Titanium-Based Lead Dioxide Anode | Titanium substrate, and the coating is lead dioxide. | Good electrocatalytic activity in electroplating processes such as chrome plating, which can promote the deposition of chromium ions; can be used in some electrolysis processes of organic synthesis. | The lead dioxide coating may fall off after long-term use, affecting the anode performance; lead dioxide is a heavy metal, and environmental protection issues need to be noted. | Chrome plating in the electroplating industry; some electrolysis processes of organic synthesis. | Relatively low. |

| Titanium-Based Platinum Anode | Titanium substrate, and the coating is platinum. | Extremely high chemical stability and electrocatalytic activity; can promote the fuel oxidation reaction in fuel cells and improve the efficiency. | The high price of platinum limits large-scale application. | High-end application fields such as fuel cells and electrochemical sensors. | Very high. |

| Titanium-Based Palladium Anode | Titanium substrate, and the coating is palladium. | Good electrocatalytic performance and corrosion resistance; can catalyze the oxidation or reduction reaction of organic compounds in organic electrosynthesis. | The cost is still higher compared with other non-platinum group metal anodes. | Specific electrolysis processes such as organic electrosynthesis and electrocatalytic hydrogenation. | High. |

| Titanium-Based Intermetallic Compound Anode | Titanium substrate, and common intermetallic compounds include titanium-aluminum compounds, titanium-nickel compounds, etc. | Good electrical conductivity, corrosion resistance, and high-temperature stability. | The preparation process is relatively complex, and the cost is high; it is currently in the research and development stage, and its performance needs further verification. | High-temperature electrolysis processes such as high-temperature molten salt electrolysis and solid oxide fuel cells. | High |

Titanium Anode Cost

The cost of titanium anode is affected by many factors, including type, custom specifications, coating composition and thickness. The cost of titanium substrate including plate, sheet, mesh and rod is related to the market price. Wstitanium adjusts the titanium substrate cost based on Shanghai Metal Market (SMM) accordingly.

Iridium-based titanium anodes are relatively expensive due to the scarcity and high cost of their main component iridium. Iridium is a precious metal with large price fluctuations, which also leads to unstable prices of iridium-based titanium anodes.

- Ruthenium-based titanium anodes are relatively cheap because the price of ruthenium is relatively stable, and its preparation process is relatively mature and cost control is better.

- The price of mixed metal oxide titanium anodes depends on their specific composition and preparation process. If the mixed metal oxide contains more precious metal components, the price will be relatively high; if the main component is a lower-priced metal oxide, the price will be relatively low.

Titanium Anode Application

As an electrode material with excellent performance, titanium anode has extensive and important applications in many fields such as chlor-alkali chemical industry, cathodic protection, electroplating industry, circuit board printing, sodium hypochlorite industry, wastewater treatment, PCB etching solution recovery, circulating water softening, electrolytic copper foil, swimming pool disinfection, etc.

In chlor-alkali chemical industry, sodium hydroxide, chlorine and hydrogen are mainly produced by electrolysis of saturated salt water. Titanium anode is used as an anode material. During the electrolysis process, chloride ions lose electrons on the anode surface and are oxidized to generate chlorine. The coating on the surface of the titanium anode can effectively promote this reaction and inhibit the occurrence of other side reactions.

High current efficiency: The catalytic activity of titanium anode is high, and it can carry out the oxidation reaction of chloride ions at a lower overpotential, thereby improving the current efficiency and reducing the power consumption.

Long service life: In the highly corrosive environment of chlor-alkali electrolysis, the corrosion resistance of titanium anode can ensure its long-term stable operation, reducing the frequency and cost of electrode replacement.

Low oxygen content in chlorine: High-quality titanium anode coating can effectively inhibit the precipitation of oxygen and reduce the oxygen content in chlorine.

Cathodic Protection

Cathode protection is to inhibit the corrosion of metal by applying cathodic current to the protected metal structure to shift its potential negatively below the corrosion potential of the metal. Titanium anode acts as an auxiliary anode to transmit current to the protected metal structure, playing the role of cathodic protection.

Good corrosion resistance: In various soil, seawater and other environments, titanium anode can work stably for a long time, providing reliable current output for cathodic protection.

High current output capacity: Titanium anode can provide a large current output according to the size of the protected structure and the requirements of the corrosive environment to meet different cathodic protection needs.

In marine projects such as offshore platforms, ships, submarine pipelines, and buried oil and natural gas pipelines, titanium anodes can provide good cathodic protection effects, reducing the occurrence of corrosion perforation and leakage accidents of pipelines.

As an insoluble anode, the titanium anode provides the necessary anode reaction for the electroplating tank and maintains the ion balance in the electroplating solution, thereby obtaining a uniform and high-quality coating.

High coating quality: The stability and uniform current distribution of the titanium anode can ensure the uniform thickness and fine crystallization of the coating, and improve the adhesion and corrosion resistance of the coating.

Long plating solution life: The insoluble titanium anode will not dissolve into the plating solution, which reduces the pollution of the plating solution, extends the service life of the plating solution, and reduces the manufacturing cost.

Titanium anode can be applied to various electroplating processes, such as zinc plating, nickel plating, chromium plating, etc.

Circuit Board Printing

In the manufacturing of high-density interconnect (HDI) circuit boards and flexible circuit boards (FPC), etching and electroplating processes are mainly involved. Titanium anodes act as anodes in the etching process to remove unnecessary copper foil through electrolysis; they provide the current required for electroplating to the copper foil or other metal layers on the circuit board to form the required circuit graphics and connection points.

High precision: Titanium anodes can provide stable current and precise etching control to achieve high precision of circuit boards and meet the requirements of the electronics industry for the fineness of circuit boards.

High efficiency: In the process of electroplating and etching, the high efficiency of titanium anodes can shorten the production cycle, improve production efficiency and reduce production costs.

Sodium hypochlorite industry

Sodium hypochlorite is produced by electrolyzing salt water solution. At the anode, chloride ions are oxidized to generate chlorine gas, which reacts with water to generate hypochlorous acid and hydrochloric acid, and hypochlorous acid is further ionized to generate hypochlorite ions, thereby obtaining sodium hypochlorite solution. The coating on the surface of the titanium anode can effectively promote the oxidation reaction of chloride ions and improve the efficiency of sodium hypochlorite generation.

High efficiency: The high catalytic activity of the titanium anode can quickly oxidize chloride ions into chlorine gas, increasing the generation rate and yield of sodium hypochlorite.

High quality: The stability of the titanium anode ensures the stability of the electrolysis process, making the concentration and quality of the sodium hypochlorite solution more stable, which is conducive to the storage and use of the product.

Long life: In the highly corrosive environment of sodium hypochlorite preparation, the corrosion resistance of the titanium anode can extend the service life of the equipment and reduce the maintenance cost of the equipment.

Wastewater Treatment

In wastewater treatment, titanium anode mainly degrades pollutants such as organic matter and heavy metal ions in wastewater through electrochemical reactions. At the anode, organic matter is oxidized and decomposed into harmless substances such as carbon dioxide and water, and heavy metal ions are oxidized to high valence states, making it easier to precipitate or be adsorbed and removed.

Good effect: Titanium anode also has a good treatment effect on some organic matter that is difficult to biodegrade, improving the treatment efficiency and water quality of wastewater.

Strong adaptability: The electrolysis parameters such as current density and electrolysis time can be adjusted according to different wastewater quality and treatment requirements, and it has strong adaptability.

No secondary pollution: No new chemical agents are introduced during the electrochemical treatment process, reducing secondary pollution.

PCB etching solution recovery

PCB etching solution will gradually accumulate impurities such as copper ions during use, affecting the etching effect. Through electrolysis, the copper ions in the etching solution are oxidized to copper element using a titanium anode to achieve copper recovery and etching solution regeneration. At the anode, the copper ions lose electrons and are oxidized to copper ions, and then get electrons at the cathode to be reduced to copper element and deposited.

Resource recycling: It can effectively recycle copper resources in the etching solution, reduce production costs, and reduce the waste of copper resources and pollution to the environment.

Etching solution regeneration: Through electrolysis treatment, the copper ion concentration in the etching solution is reduced, the etching ability of the etching solution is restored, and the service life of the etching solution is extended.

Simple process: Compared with traditional etching solution treatment methods, the electrolysis process is simple, easy to operate, and easy to realize automatic control.

Circulating Water Softening

In the circulating water system, calcium, magnesium and other ions in the water will cause scale to form, affecting the normal operation of the system. Titanium anodes use electrochemical reactions to precipitate calcium, magnesium and other ions in the water or convert them into a form that is not easy to scale, thereby softening the circulating water.

Good softening effect: It can effectively reduce the concentration of calcium and magnesium ions in the circulating water, reduce the formation of scale, and improve the operating efficiency and equipment life of the circulating water system.

Environmental protection and energy saving: The electrochemical softening method does not use chemical agents, which reduces pollution to the environment and also reduces operating costs.

Electrolytic Copper Foil

Electrolytic copper foil is prepared by electrolyzing copper sulfate solution. The coating on the surface of the titanium anode promotes the oxidation reaction of water, produces oxygen, and maintains the ion balance in the electrolyte; at the cathode, the copper ions get electrons and are deposited on the cathode plate to form copper foil.

High quality copper foil: The stability and uniform current distribution of the titanium anode can ensure the uniform thickness, smooth surface, and fine crystallization of the copper foil, improving the quality and performance of the copper foil.

High production efficiency: The high catalytic activity and good conductivity of the titanium anode can increase the electrolysis speed, shorten the production cycle, and improve production efficiency.

Swimming pool disinfection

During the electrolysis process, the titanium anode promotes the oxidation reaction of chloride ions to generate chlorine gas, which reacts with water to generate hypochlorous acid and hypochlorite ions, which play a disinfecting role.

High-efficiency disinfection: It can quickly and effectively kill bacteria, viruses, algae and other microorganisms in swimming pool water to ensure the hygiene and safety of swimming pool water.

Environmental protection and safety: Compared with traditional chemical disinfectants, disinfectants such as sodium hypochlorite produced by electrolysis have no residue and no odor, and are harmless to the human body and the environment.

Automated control: It can realize the automated control of the swimming pool disinfection system, automatically adjust the electrolysis parameters according to the water quality and flow of people in the swimming pool, and ensure the stability of the disinfection effect.

Wstitanium is committed to continuous innovation and improvement of titanium anode technology, always at the forefront of titanium anode manufacturing, contributing to the success of many projects around the world. With more than ten years of excellent experience, we promise high-quality materials, coatings and specifications to meet the growing needs of different industries, providing you with better, more efficient and more environmentally friendly electrochemical solutions.