Titanium Bolts Manufacturer and Supplier In China

In the field of custom titanium bolts, Wstitanium has become your trusted partner with its outstanding technical strength and strict quality standards, including key indicator inspections such as size, tensile strength, yield strength, and elongation.

- 24/7 Online Service

- OEM/ODM Support

- DIN、JIS、ASTM、ISO、GB

- SGS, BV and CE Certificates

- M2-M120

- 10+ Finishing Options

- Full thread / Half Thread

- 15+ Titanium Grade Options

Customized Titanium Bolting Solutions

Wstitanium’s professional design team provides you with a full range of customized titanium bolt design support. Fully understand your specific needs and applications. Whether it is a special connection requirement, a unique appearance requirement, or a special indicator of bolt performance, it can meet your requirements. Whether it is a prototype, a low-volume, multi-variety custom order, or a large-scale mass production order, it can rely on advanced manufacturing equipment and an efficient management system to ensure on-time and high-quality delivery.

Design

Through advanced 3D modeling software, the design team converts your needs into an intuitive three-dimensional model, which can clearly see the design effect of the customized titanium bolt. In the design process, the characteristics of titanium alloy materials and the feasibility of technology are fully considered, and the design scheme is optimized to ensure that the design not only meets functional requirements, but also can be efficiently implemented in the manufacturing process. For example, in order to customize a titanium bolt for high-performance engine connection for participating in the Melbourne F1 car, the design team designed a bolt with high strength, light weight and unique appearance according to the structure and working environment of the engine, and optimized the head shape and thread structure of the bolt to improve its fastening performance and anti-loosening performance.

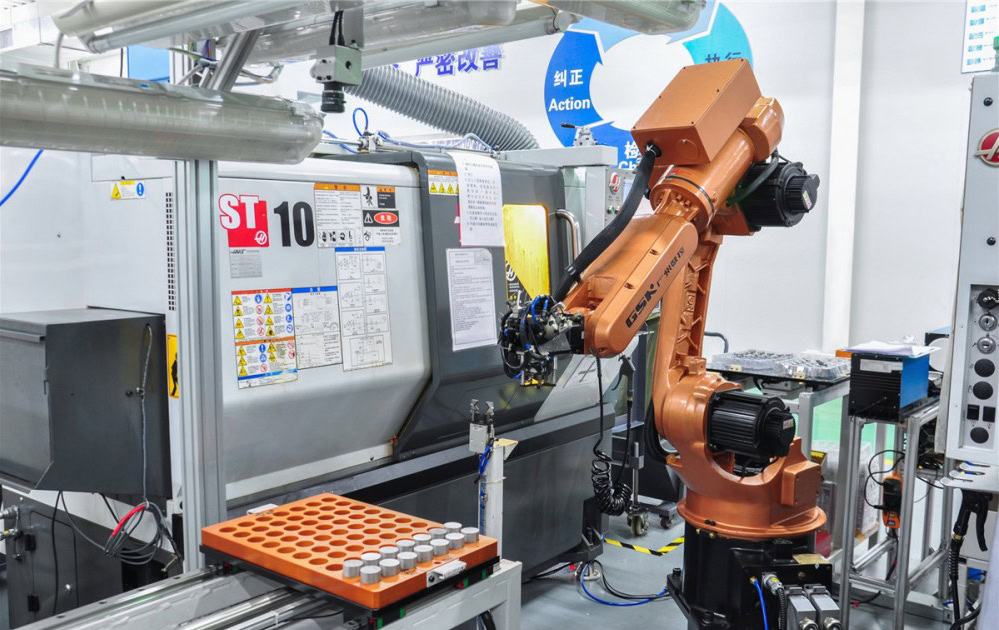

Wstitanium invested in several CNC turning centers, including DOOSAN, HARDINGE, NEF400, HAAS and TORNOS CNC Swiss machine tools, which is an important measure for its pursuit of excellent quality and efficiency in the field of titanium bolt custom manufacturing. These advanced equipment not only improves Wstitanium’s manufacturing quality and efficiency, but also provides strong technical support for its customized titanium bolt manufacturing.

Haas ST-10

Haas ST-10 is a high-performance compact CNC turning center with fast processing speed and excellent precision. It realizes multi-axis linkage control and can accurately control the tool path when manufacturing complex-shaped titanium bolts. It is mainly used to manufacture small-sized, high-precision titanium bolts to meet the needs of electronic equipment, medical equipment and other fields for micro titanium bolts.

Haas ST-20

ST-20 has improved manufacturing capabilities and precision, with a larger stroke and higher cutting power, suitable for manufacturing medium-sized titanium bolts. High-precision ball screws and linear guides ensure stability and precision. The automatic tool change system quickly changes tools to improve efficiency. It is mainly used to manufacture slightly larger titanium bolts in the automotive, aerospace and other fields.

DOOSAN CNC Turning Center

Wstitanium introduced 5 PUMA SMX2600S/ST to meet medium-sized needs and cope with complex titanium bolt manufacturing tasks. Doosan CNC turning centers can withstand large cutting forces. It can realize high-precision motion control and complex tool path planning, and can produce high-precision titanium bolt threads and complex shapes. The multi-axis linkage function can also complete multiple processes in one clamping.

HARDINGE CNC Turning Center

HARDINGE TALENT series CNC turning center is a leading product in ultra-precision machining and hard turning applications, capable of manufacturing the most challenging titanium bolts. The TALENT series is equipped with 8 axes, with ultimate flexibility, performance, functionality and maximum productivity, which helps Wstitanium quickly respond to market demand for titanium bolts of different specifications.

DMG NEF400

DMG NEF400 has high positioning accuracy and repeatability, which can ensure the dimensional accuracy of titanium bolt processing, such as the diameter tolerance can be controlled within +/0.001mm. The manufactured titanium bolt has high thread accuracy and good pitch uniformity, which improves the reliability of bolt connection.

The maximum torque is 340Nm, which can provide sufficient power for cutting titanium alloy materials.

The accuracy of TORNOS CNC Swiss machining center can usually be controlled within ±0.001mm. The diameter, pitch and other key dimensional errors of the manufactured titanium bolts are extremely small, and the roundness error can be as low as 0.002mm. The diameter range is usually 1mm – 50mm, and the length range is 5mm – 300mm. It meets the high-precision requirements of titanium bolts in the medical and aerospace fields.

Types of Titanium Bolts Manufactured

Wstitanium uses advanced CNC machining technology to accurately manufacture complex polyhedral shapes and fine thread structures. When machining high-precision countersunk titanium bolts, the taper angle accuracy of the bolt head can be controlled within ±0.001°, ensuring a perfect fit with the connector and seamless connection. For some special-shaped bolts, such as those with unique grooves or protrusions, the multi-axis linkage function of the CNC Swiss machine tool can complete the machining of complex shapes in one go, greatly improving efficiency and accuracy.

Hex Bolts

Carriage Bolts

Cap Screw

U Bolt

Countersunk Socket Head Screw

Button Head Screw

Square Head Bolt

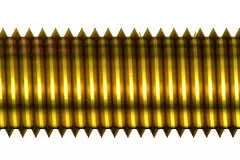

Threaded Rod

Socket Set Screws

Socket Set Screws

Socket Set Screws

Socket Set Screws

Bolts Titanium Grade

Titanium bolts are a solid bond between many precision equipment and key structures, and the cornerstone of their performance is different titanium grades. Each titanium grade is like a unique key that unlocks different application scenarios. From the ultimate challenge of aerospace to the life protection in the medical field; from the pursuit of efficiency in the automotive industry to the rigorous test of marine engineering, different titanium grades rely on their own characteristics to support titanium bolts to play a key role in various fields. Now, let us explore the secrets of these titanium grades and see how they create the excellent quality of Wstitanium titanium bolts.

Gr1

Industrial pure titanium, high purity, low impurity content. Its tensile strength is about 240-345MPa, elongation can reach 24%, and it has excellent corrosion resistance in neutral and oxidizing media. It is often used to manufacture titanium bolts that do not require high strength but high corrosion resistance, such as titanium fasteners in food processing equipment.

Gr2

Also industrial pure titanium, its tensile strength is 345-450MPa, yield strength is about 275MPa, and elongation is 18%. It has achieved a good balance between corrosion resistance, strength and processing performance, and is widely used, such as titanium bolts in ship seawater pipeline systems.

Ti-6Al-4V, an α-β two-phase titanium alloy containing 6% aluminum and 4% vanadium. The room temperature tensile strength can reach more than 895MPa, the yield strength is about 825MPa, and the tensile strength can still be maintained at more than 600MPa at 600℃. It has excellent comprehensive performance, high strength, good corrosion resistance, and good heat resistance. It is often used in aerospace engines, medical equipment, etc.

Gr7

0.12% – 0.25% palladium is added to industrial pure titanium. Its tensile strength is 345-450MPa. Its corrosion resistance in reducing media is significantly improved compared with industrial pure titanium. It is often used in chemical equipment in highly corrosive environments, such as reactor connection bolts for treating acidic solutions.

Gr9

Contains a small amount of aluminum, vanadium and other elements, its tensile strength is 620-795MPa, has good cold processing performance, moderate strength and corrosion resistance, and is often used in bicycle parts manufacturing, such as bicycle frame connection bolts.

Gr12

Contains 0.3% molybdenum and 0.8% nickel, with a tensile strength of 515-690MPa, good corrosion resistance and certain strength, used for parts with specific requirements for corrosion resistance and strength, such as some joints in petrochemical equipment.

Gr23

It is an ultra-low clearance element version of Gr5. Compared with Gr5, it has better toughness and fatigue resistance. It is often used to manufacture key parts in high-demand fields such as aerospace, such as bolts for aircraft landing gear.

Finishing For Titanium Bolts

To meet different application scenarios, Wstitanium provides a variety of surface treatment options. Anodizing can form a hard and dense oxide film on the surface of titanium bolts, which not only enhances its wear resistance, but also presents different colors according to needs, such as classic silver, deep black, etc. In the fields of electronic equipment, high-end furniture, etc., it not only ensures the functionality of titanium bolts, but also improves the overall aesthetics. For occasions where corrosion resistance needs to be further improved, such as outdoor equipment, medical equipment, etc., nickel plating, chrome plating and other surface treatment methods are used. The thickness of the nickel plating layer can reach 0.02-0.05mm, which effectively blocks the erosion of external corrosive media and extends the service life of titanium bolts.

Passivation

Anodizing

Chemical Plating

Hot Dip Galvanized

Nickel Plated

Micro-arc oxidation

Dacromet

Black Zinc Plated

Thermal Spraying

Titanium Bolt Application

In the medical field, customized titanium bolts are used for orthopedic implants. They have excellent biocompatibility, do not cause immune response in the human body, and have extremely high dimensional accuracy, ensuring that the implants are closely integrated with the human skeleton and promoting bone healing. In automobiles, lightweight titanium bolts are used in key parts such as engines and suspension systems, which not only reduce the weight of the vehicle body, but also improve the fatigue strength and reliability of the components, helping the car achieve high performance and low energy consumption. In high-end electronic products, small and exquisite customized titanium bolts, with their beautiful appearance and high-precision assembly performance, meet the design requirements of lightweight and miniaturized electronic products, and improve the overall quality of the product.

Choosing Wstitanium’s customized titanium bolt service means choosing excellent quality, precise customization and worry-free service. With professionalism and enthusiasm, we inject soul into each of your projects, making each titanium bolt a perfect crystallization of industrial aesthetics and practical value.