Titanium Fasteners Supplier & Manufacturer in China

As a well-known supplier of titanium fasteners, Wstitanium manufactures a variety of types, specifications, and finishes, including standard, customized, and special titanium screws, nuts, bolts, pins, and rivets to meet the needs of aerospace, automotive, marine, medical, marine, and chemical industries.

- Titanium Screws

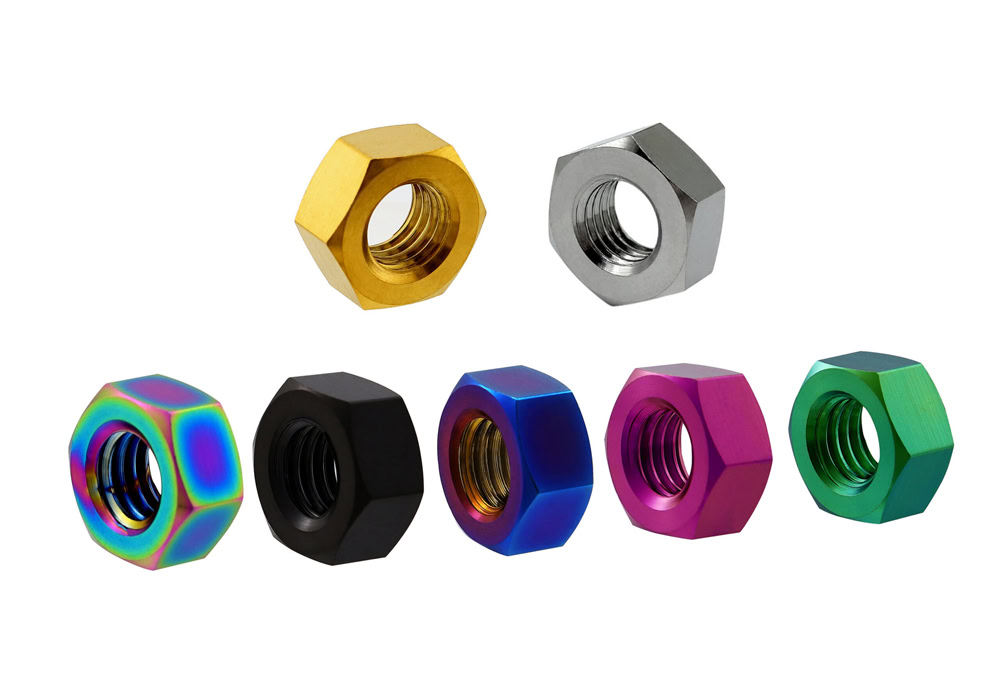

- Titanium Nuts

- Titanium Washers

- M1-M72

- Titanium Bolts

- Titanium Rivets

- Titanium Pins

- 15+ Titanium Grade Options

Trusted Custom Titanium Fastener Factory - Wstitanium

Titanium fasteners occupy an important position in many industries due to their excellent properties such as high strength, low density, excellent corrosion resistance and good biocompatibility. As a well-known titanium fastener manufacturer and supplier in China, Wstitanium is committed to providing high-quality and diversified titanium fastener customized solutions to global customers, including titanium screws, titanium bolts, titanium nuts, titanium pins, titanium washers, titanium screws and titanium rivets, etc., with a variety of titanium grades, styles, sizes and finishes.

Advantages of Titanium Fasteners

Titanium is extremely active, flexible/highly ductile, and offers an excellent combination of strength and resistance to corrosion, oxidation, heat, and cold. It is non-magnetic, non-toxic, and lightweight, has a low coefficient of thermal expansion, and is not susceptible to brittleness at very low temperatures.

Corrosion Resistance

The most notable property of titanium fasteners is their superior corrosion resistance to saltwater/seawater. The unique ability of titanium fasteners to rapidly regenerate their protective passivation layer in the presence of oxygen gives them unparalleled resistance to saltwater. Resistant to seawater temperatures up to 500°F (260°C)

Chlorides, Chlorine, and Other Media

Similar to saltwater, the strong protective oxide film that titanium regenerates makes it extremely resistant to oxidizing environments and chloride solutions, including hypochlorites, chlorates, perchlorates, sodium chlorite, and chlorine dioxide. This protection applies as long as moisture is present – which can be as low as 50ppm.

Lightweight Strength

Not only are titanium fasteners extremely strong, they are also very lightweight. Titanium Grade 5 screws are 4 times stronger than 316 stainless steel, but are nearly half the weight. Titanium fasteners are ideal for applications that require light weight and exceptional strength, such as medical, military, and more.

Titanium Fastener Category

- Cross slot Screw

- Hexagon Screws

- Plum Blossom Slot

- T-shaped Screw

- Hex Socket Screw

- Machine Screw

- Self Drilling Screw

- Thread Forming

- Chipboard Screw

- Drywall Screw

- Hex Bolt

- Flange Bolt

- Stud Bolt

- Screw Bolt

- Hex Socket Bolt

- U Bolt

- Carriage Bolt

- Counterhead Bolt

- Semi-round Bolts

- Foundation Anchor

- Hex Nut

- Lock Nut

- Rivet Nut

- Flange Nut

- Hex Dome Cap Nut

- Castle Nut

- Wing Nut

- Welding Nut

- Furniture Nut

Titanium Pins

- Cylindrical Pin

- Counterfeit Pin

- Elastic Titanium Pin

- Type R Titanium Pin

- Headless Titanium Pin

- Spline Pin

- Knurled Pin

- Slotted Pin

- Straight Slot Pin

- Square Head Pin

- Flat Washer

- Lock Washer

- Spring Washer

- Square Washer

- Wave Washer

- Cone washer

- Wrap-around

- Spherical washer

- Internal tooth lock

- External tooth lock

- Half round head rivets

- Flat cone head rivets

- Countersunk head

- Flat head rivets

- Hollow rivets

- Tubular rivets

- Blind rivets

- Driving rivets

- R-type rivets

- Tree rivets

Customize Manufacturing Titanium Alloy Fasteners For You

Wstitanium is composed of experts in materials science, mechanical engineering, surface treatment and other fields. Whether it is material selection, structural design or manufacturing process, we provide you with a full range of technical support. As a professional titanium fastener manufacturer, our customized services include:

- Material Selection: A range of titanium grades meet your specific application requirements.

- Design: The in-house design team is proficient in CAD drawings and prototype development.

- Dimension Customization: Whether it is micro or large, it can adapt to the precise specifications of your project.

- Threading Options: A variety of thread options, including UNC, UNF and metric, to meet your needs.

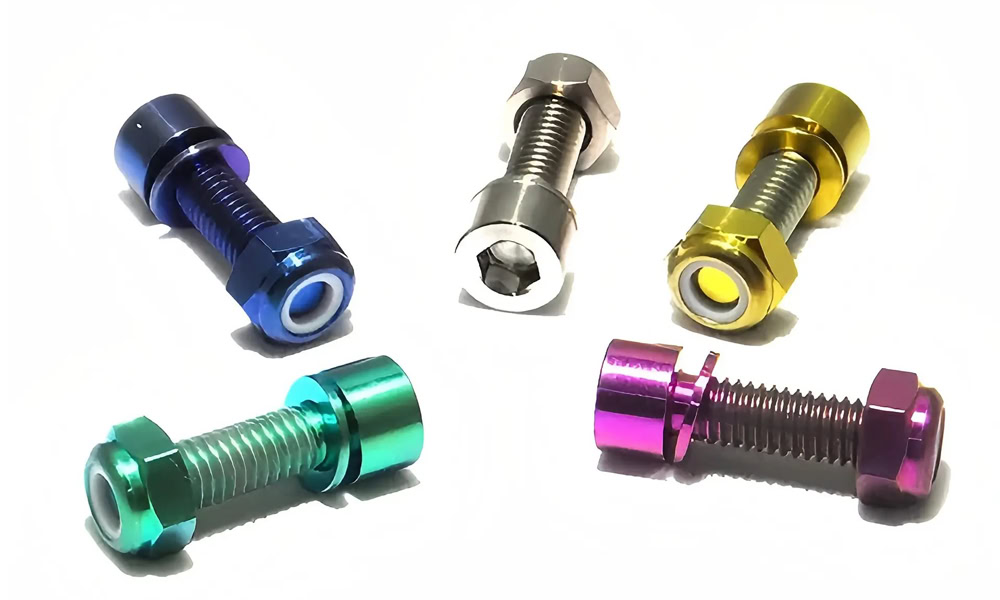

- Surface Finishing: Explore different surface treatments, such as anodizing, polishing or coating, to enhance aesthetics and functionality.

Raw Material

Forging

Precision CNC Machining

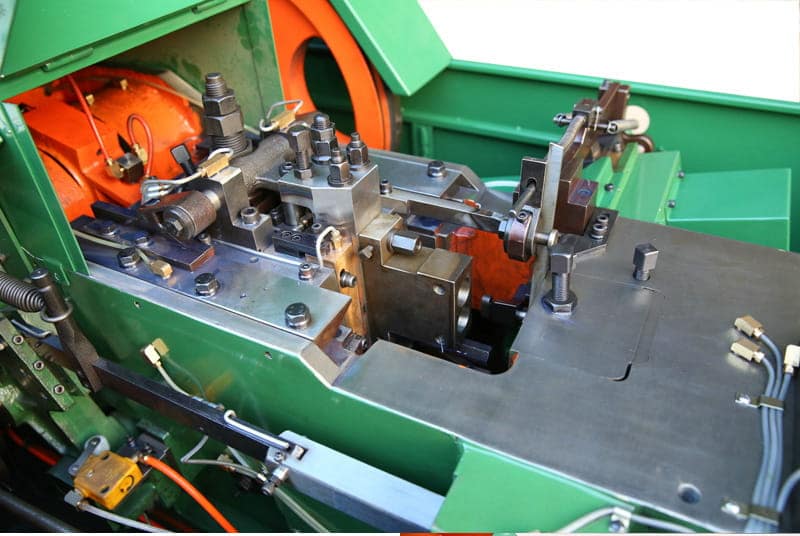

Thread Rolling

Finishing

Quality Inspection

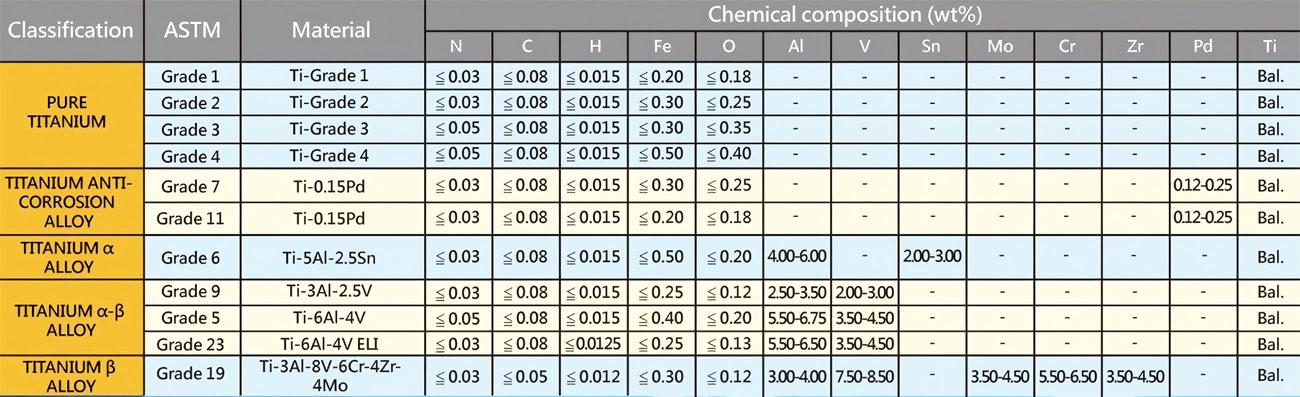

Titanium Fastener Materials

Wstitanium offers a range of titanium alloys to manufacture connection solutions for your applications, including Gr 1, Gr 2, Gr 3, Gr 4, Gr 5, Gr 6, Gr 7, Gr 9, Gr 11, Gr 12, Gr 19, Gr 23, as well as Ti6-2-4-2, 6AI-6V-2Sn, 15V-3-3-3, 8Al-1Mo-1V, 10V-2Fe-3Al. In addition to standard titanium alloy grades, Wstitanium can customize the mechanical properties of titanium alloys according to your specific needs, such as tensile strength, yield strength, elongation, etc. For example, in some applications with stringent requirements for high temperature performance, the aluminum content is appropriately increased to improve the oxidation resistance and thermal stability of the alloy. In situations where better low-temperature toughness is required, the proportion of elements such as vanadium is adjusted to optimize the performance of the material in a low-temperature environment. Precisely control the heat treatment process, including the temperature, time and cooling rate of annealing, solution treatment and aging treatment to meet the requirements of different application scenarios.

| Grade | Features | Applications |

| Grade 1 | – Purest form- Excellent weldability and corrosion resistance. | – Medical implants- Marine equipment. |

| Grade 2 | – Good strength, weldability, formability, and corrosion resistance. | – Aerospace, automotive, and industrial components. |

| Grade 3 | – Enhanced strength over Grades 1 and 2. | – Industrial and aerospace structures. |

| Grade 5 (Ti-6Al-4V) | – High strength and lightweight. | – Aerospace parts, marine applications, medical implants. |

| Grade 7 | – Enhanced corrosion resistance due to palladium. | – Chemical processes, and production equipment. |

| Grade 9 (Ti-3Al-2.5V) | – Moderate strength and good ductility. | – Aircraft tubes, marine pipelines. |

| Grade 12 | – Enhanced corrosion resistance with nickel and molybdenum. | – Chemical processing, marine, oil & gas industries. |

| Grade 23 (Ti-6Al-4V ELI) | – Higher fracture toughness and better ductility. | – Medical and dental implants. |

Titanium Fastener Specifications

Wstitanium custom manufactured titanium fasteners cover all basic types and a wide range of sizes.

| Form | Description | Production Specifications |

| Bolts & Screws | Threaded fasteners joining components; require nuts or counterparts. | Types: hex head, countersunk, cap. Diameter: M1.6 – M48. Length: 3mm – 300mm. Threads: UNC, UNF, Metric. |

| Nuts | Internally threaded counterparts for bolts/screws. | Types: hex, lock, wing. Diameter: M1.6 – M48. Threads: UNC, UNF, Metric. |

| Washers | Flat pieces under a nut or bolt head; spread load & prevent loosening. | ID: starts 1mm. OD: up to 100mm. Thickness: 0.3mm – 12mm. |

| Studs | Threaded rods for flanges or frequent disassembly. | Diameter: M1.6 – M48. Length: 10mm – 500mm. Threads: UNC, UNF, Metric. |

| Pins | Unthreaded for aligning/assembling parts; held by friction. | Types: dowel, clevis. Diameter: starts 1mm. Length: 5mm – 300mm. |

| Threaded Rods | Long, threaded for construction, plumbing, manufacturing. | Diameter: M2 – M52. Length: up to 3m. Threads: UNC, UNF, Metric. |

| Anchors | Secure/fasten materials in concrete/masonry. | Diameter: M3 – M24. Length: 10mm – 200mm. Types: wedge, drop-in, sleeve. |

| Retaining Rings | Hold components on shafts/bores; prevent movement. | Diameter: starts 3mm. Thickness: 0.5mm – 5mm. Styles: internal, external. |

| Rivets | Permanent fasteners with a head and tail. | Diameter: 1mm – 8mm. Length: 5mm – 100mm. Head types: flat, round, countersunk. |

| Spacers & Standoffs | Unthreaded/threaded separators for PCBs/assemblies. | Diameter: starts 2mm. Length: 2mm – 250mm. Threads (if applicable): UNC, UNF, Metric. |

Wstitanium Titanium Fasteners Stock List

| Bolts | Hex head bolts, hex head cap screws, heavy hex bolts, carriage bolts, custom bolts |

| Socket Cap Products | Socket cap screws, flat socket cap screws, button socket cap screws, socket head shoulder screws, custom socket cap screws |

| Machine Screws | Hex head machine screws, flat slotted machine screws, fillister phillips machine screws, flat phillips machine screws, pan slotted machine screws, pan phillips machine screws, fillister slotted machine screws, binding slotted machine screws, truss slotted machine screws, custom machine screws |

| Nuts | Hex nuts, heavy hex nuts, hex jam nuts, machine screw nuts, hex slotted nuts, hex thick nuts, hex nuts-all-metal lock, hex nuts-delf-locking, custom nuts |

| Pipe Plugs | Solid hex pipe plugs, solid square pipe plugs, socket pipe plugs |

| Wahsers | Flat type narrow washers, lock washers, custom washers |

| U-bolts | U bolts, other bolts |

| Set Screws | Hex socket cup point set screws, square head cup point set screws, slotted cup point set screws, customs set screws |

| Threaded Rods | Threaded rods |

| Threaded Studs | Full thread studs, full thread stud bolts, double end studs, custom studs |

| Sheet Metal Screws | Flat slotted sheet metal screws, flat phillips sheet metal screws, pan slotted sheet metal screws, pan phillips sheet metal screws, hex head sheet metal screws, flat socket sheet metal screws, custom sheet metal screws |

| Custom Fasteners | According to your drawing requirements |

Wstitanium Manufacturing Titanium Fastener Technology

Manufacturing titanium screws is a complex and delicate process, covering a variety of forming technologies from cold heading, hot heading, CNC turning, CNC tapping to heat treatment, surface treatment and strict quality inspection and control.

For small diameter, high precision titanium screws, Wstitanium usually chooses CNC Swiss machine tools. For large diameter, mass-produced titanium screws, HAAS milling machine tools (ST20) are selected. Due to the poor machinability of titanium alloys, the commonly used tool materials for turning titanium alloys are cemented carbide, ceramics, and cubic boron nitride (CBN). In CNC turning, strict quality control is required. Regularly measure the dimensions of the workpiece and check the quality of the machined surface, such as whether there are defects such as cracks, scratches, and chatter marks. If quality problems are found, analyze the causes in a timely manner and take appropriate measures to adjust, such as adjusting cutting parameters, replacing tools, or re-calibrating tools.

Cold Heading

The titanium alloy forged bars used for cold heading usually need to be surface treated. Common treatment methods include pickling, phosphating and saponification. The purpose is to remove the oxide scale, oil stains and other impurities on the surface of the wire to make the surface clean. The quality and precision of the cold heading die play a decisive role in the forming quality of titanium screws. The cold heading machine applies pressure to the blank through the die, causing the blank to undergo plastic deformation in the die cavity, gradually forming the shape of the head and rod of the screw.

Hot Upsetting

Hot upsetting requires heating the titanium alloy blank to a certain temperature to reduce its deformation resistance and improve plasticity. Commonly used heating equipment includes resistance furnaces, induction furnaces, etc. For different titanium alloys, the heating temperature range is also different. Taking Ti-6Al-4V alloy as an example, the heating temperature during hot upsetting is usually between 900℃ and 1000℃. The heated blank needs to be quickly transferred to the mold of the hot upsetting machine and accurately positioned. The hot upsetting machine applies pressure to the blank, causing it to undergo plastic deformation in the mold cavity to complete the forming of the screw.

Heat treatment can significantly improve the mechanical properties of titanium screws. The reasonable application of annealing, solution treatment and aging treatment can make titanium fasteners have good strength, hardness, plasticity and toughness. Eliminate the residual stress generated by cold upsetting, hot upsetting, CNC turning, etc. of titanium screws, improve the plasticity and toughness of the material, and make the structure of the material more uniform. Taking Ti-6Al-4V alloy as an example, the temperature of full annealing is generally between 700℃-800℃, usually for 1-3 hours. The solution treatment temperature is generally between 920℃-950℃, usually for 1-2 hours. The aging temperature is generally between 500℃-600℃, and the holding time is 2-8 hours.

Custom Surface Finishing Options

In order to further improve the performance of titanium fasteners, such as enhancing corrosion resistance, improving wear resistance, improving appearance and meeting special functional requirements, surface treatment has become an indispensable and important link. Wstitanium understands that different applications require different surface finishes for titanium fasteners. Therefore, we offer a range of customizable surface treatment options to meet your specific needs.

Anodizing

The oxide film formed on the surface of anodized titanium fasteners is firmly bonded to the substrate and has good corrosion resistance and wear resistance. By adjusting the parameters, the thickness and color of the oxide film can be controlled to meet different appearance and performance requirements. The oxide film has good insulation properties and is suitable for some application scenarios that require insulation performance.

Electroplating

Electroplating can form a uniform and dense metal coating on the surface of titanium fasteners, significantly improving its corrosion resistance and wear resistance. Different plating metals are selected according to different needs to achieve different functions, such as zinc plating can improve corrosion resistance. Nickel plating can improve wear resistance and conductivity. Chromium plating can improve hardness and aesthetics.

Nitriding

Titanium fasteners coated with titanium nitride coating on the surface. Its Vickers hardness can usually reach more than 2000HV. This enables the fasteners to effectively resist friction, wear, reduce thread damage, etc., and can also resist erosion by acids, alkalis, salts, and humid air. Titanium nitride has a high melting point (2930℃) and good thermal stability. The titanium nitride coating is golden yellow, and the metallic luster plays a decorative role.

Titanium Fastener Applications

Titanium fasteners play an indispensable role in many fields such as aerospace, automobile, medical, and marine engineering due to their unique performance advantages.

Aerospace

Titanium fasteners are widely used to connect aircraft frames, skins and other parts. For example, Boeing 787 and Airbus A350 use a large number of titanium fasteners, which significantly reduces the weight of the fuselage. The high temperature resistance and good mechanical properties of titanium fasteners make them an ideal choice for connecting engine parts. For example, the connection of engine compressor blades, turbine disks and other parts cannot be separated from the application of titanium fasteners.

Ocean

The excellent corrosion resistance of titanium fasteners makes it an ideal choice for hull structure connections, deck equipment fixation and other parts. Offshore platforms are exposed to the marine environment for a long time and face problems such as seawater corrosion. The application of titanium fasteners can improve the structural stability and durability of offshore platforms. The corrosion resistance and high strength of titanium fasteners can ensure the safe operation of submarine pipelines in complex marine environments.

Automobile

In automobile engines and transmissions, titanium fasteners can reduce component weight, improve engine response speed and fuel economy. At the same time, their corrosion resistance can also ensure long-term stable operation in harsh working environments. The lightweight characteristics of titanium fasteners can reduce the unsprung mass of the suspension system and improve the vehicle's handling performance and driving comfort.

Electrical

In the assembly of electronic products such as mobile phones and computers, titanium fasteners are used to fix circuit boards, housings and other components because of their light weight, corrosion resistance and good conductivity. Its small size and high precision also meet the requirements of miniaturization and precision of electronic products. In electrical equipment, such as transformers and generators, titanium fasteners can maintain good performance in harsh environments such as high temperature and humidity to ensure the normal operation of electrical equipment.

Medical

Titanium and titanium alloys have become the preferred materials for orthopedic implants due to their good biocompatibility. Titanium fasteners such as screws and bolts are widely used to fix fracture sites, artificial joints, etc. Their low elastic modulus characteristics help reduce stress shielding effects and promote bone growth and healing. Titanium fasteners are used to fix implants so that they are tightly combined with alveolar bones. In addition, titanium fasteners are also used in the assembly of medical devices, such as surgical instruments and medical equipment housings.

Sports

The application of titanium fasteners in the field of sports equipment is also increasing. For example, titanium fasteners are used to connect bicycle parts, and they can maintain reliable connections even in the face of bumps, vibrations and shocks, reducing the risk of frame damage. The connection between the head and shaft of a golf club needs to be firm and precise, and titanium fasteners can meet this requirement. Titanium fasteners are used to connect the various segments of trekking poles, as well as to fix handles, wrist straps and other components.

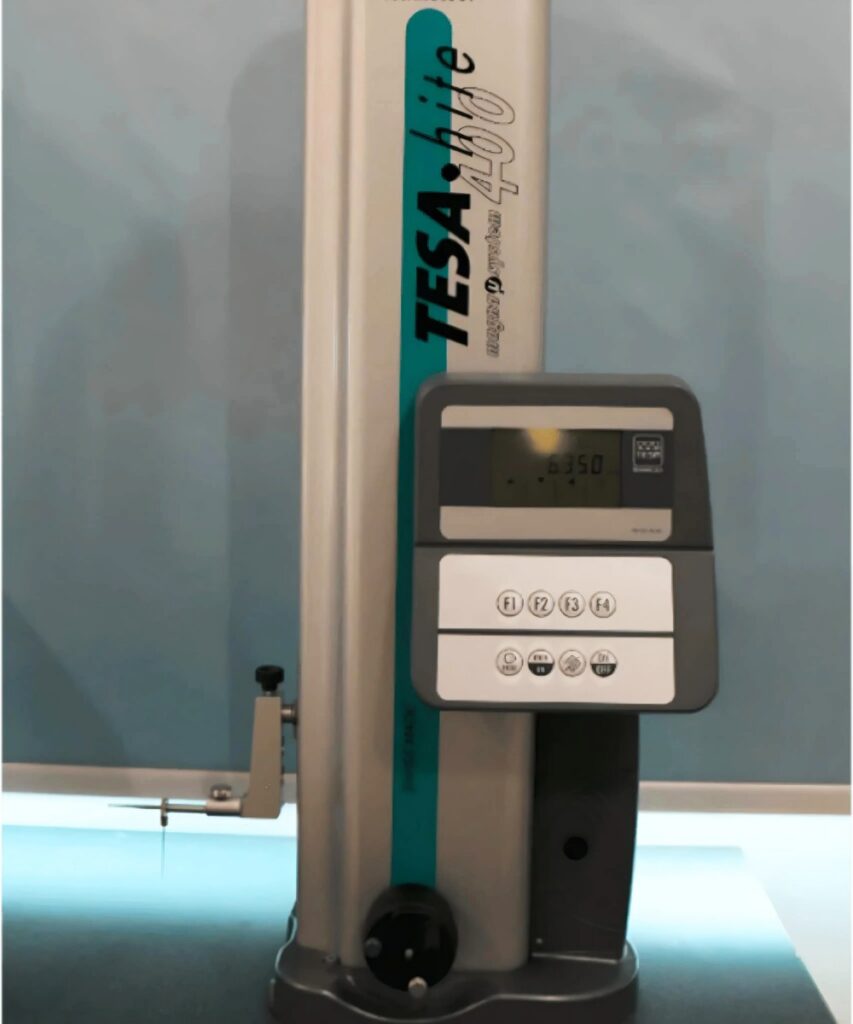

Quality Inspection

Quality inspection is a key link to ensure the quality and reliability of titanium fasteners, and is of great significance for ensuring product safety, improving product quality and competitiveness. Wstitanium follows ASTM\DIN\JIS\KS standards to conduct comprehensive quality inspections on titanium fasteners, including size, mechanical properties, hardness, torque, metallographic structure, spectral analysis, salt spray test, corrosive medium immersion, etc.

Quality Inspection Laboratory

3D Measuring Instrument

Salt Spray Tester

Density Detector

Height Instrument

Push-pull Gauge

Vickers Hardness Tester