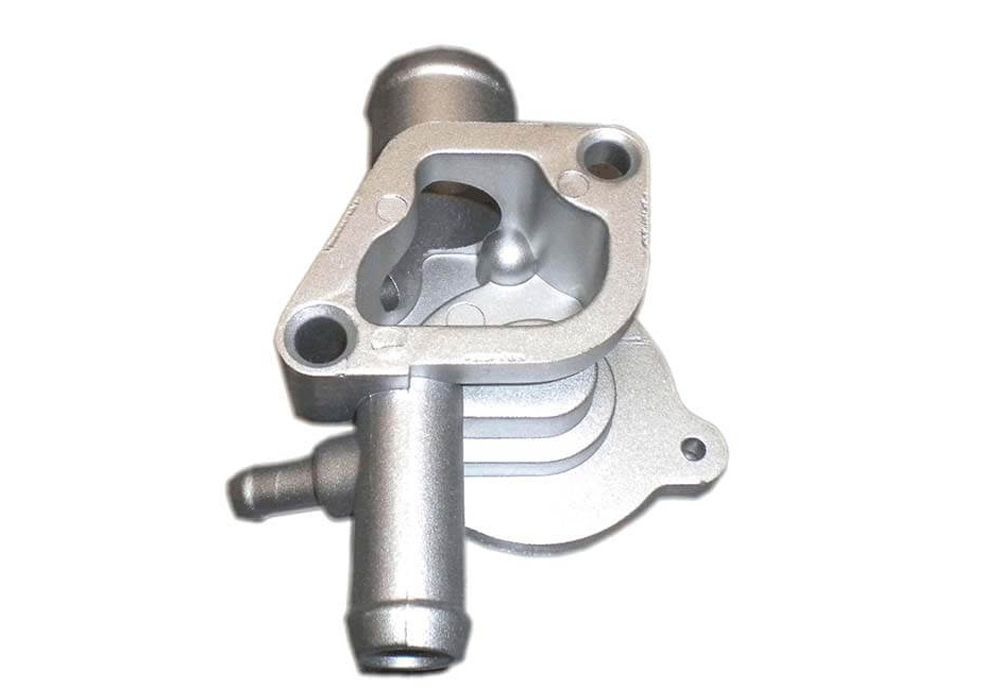

Titanium Investment Casting Services

Wstitanium is an ISO13485 & ISO9001 certified casting manufacturer in China. Tailor-made solutions for precision investment casting titanium parts that meet your needs. Diverse material selection and reliable expertise to meet all your casting requirements.

- Size: 10mm - 1000 mm

- Tight tolerance: +/- 0.1mm

- Surface Finish Ra.1.6~3.2μm

- 20+ Finishing Services Options

- From 1 to 100+ Parts Within 7 Days

- All uploads are secure and confidential.

Investment Casting Manufacturers for Titanium Parts

Investment casting achieves an ideal balance between precision and cost. Investment casting has the ability to manufacture complex shapes, high flexibility in material selection, high repeatability, and obvious environmental advantages at a lower cost. It has become one of the first choices for mass production of various aerospace, medical, and industrial parts. Investment casting technology has high geometric accuracy and can faithfully reproduce fine and smooth surface details. Undercuts, thin walls, and recessed features can be achieved.

What is investment casting?

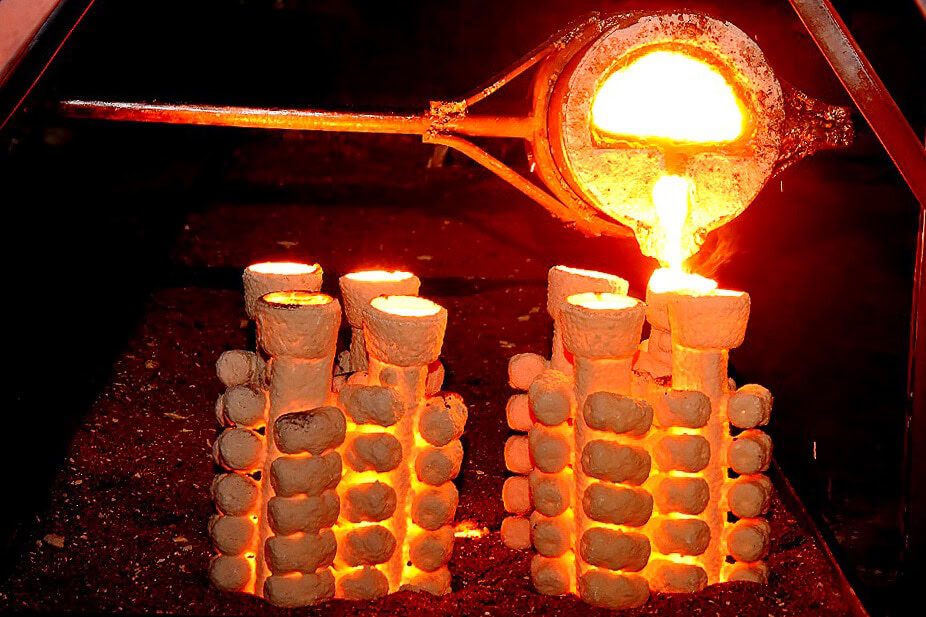

Investment casting begins with a wax replica of the part to be cast. The wax is coated with a refractory slurry, which is then placed in an oven to bake. After drying, it forms a mold. As the wax pattern is melted and drained, a cavity is left behind. Next, the mold is filled with molten titanium, usually by pouring a melted titanium ingot into the mold in a vacuum or argon atmosphere. After the titanium cools and solidifies, the mold is torn apart to reveal the casting. The casting is then subjected to a variety of finishing operations, including CNC machining, sandblasting, and heat treatment, to eliminate any surface defects and improve its mechanical quality. Investment casting is suitable for manufacturing titanium components with precise tolerances, fine details, and micro features. It also avoids the need for welding and brazing, which can affect the strength and integrity of the part. Due to its excellent strength, durability, and corrosion resistance, investment cast titanium parts are commonly used in aerospace, medical, defense, and industrial applications.

Wstitanium Custom Investment Casting Service Capabilities

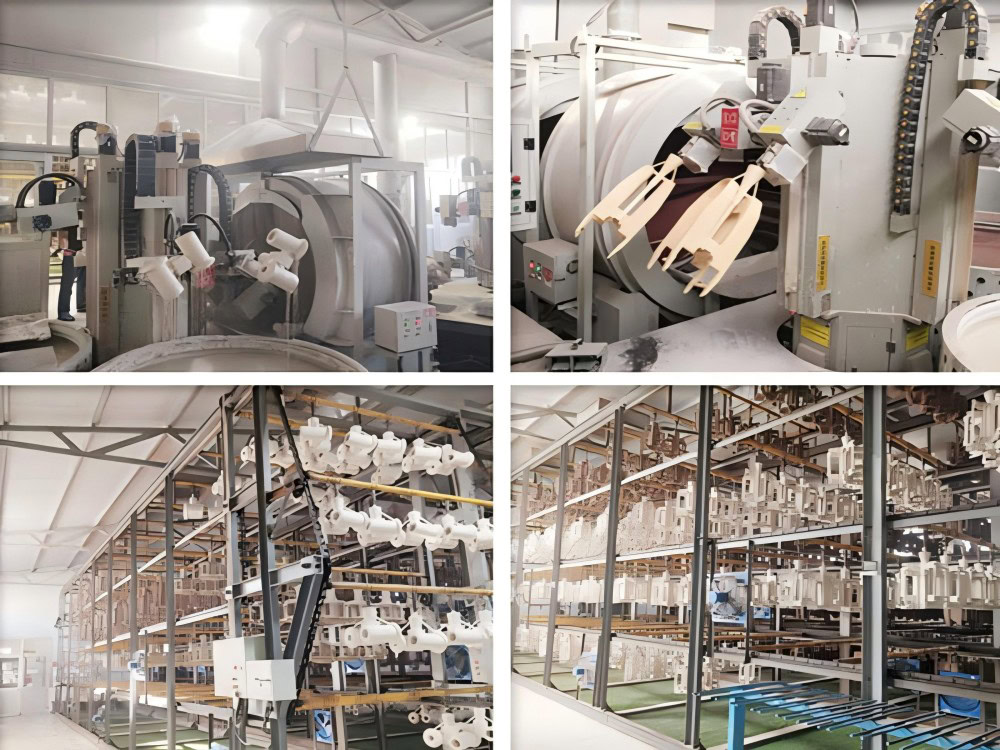

Wstitanium specializes in manufacturing net-shape titanium parts for the production of commercial and industrial applications through the investment casting process. Investment casting is a very detailed process and every step must be carefully controlled. The process variables are endless and include temperature, humidity, viscosity, pressure, speed, flow, etc. Wstitanium monitors and controls the process variables through PLC and various control instruments. Daily data analysis is essential to achieve high quality castings of titanium precision parts on a consistent basis.

| Standard | Capabilities |

| Casting Size (mm) | 10-1000 |

| Maximum Casting Weight (kg) | 10 |

| Minimum Wall Thickness (mm) | 0.5 |

| Tolerance (mm) | +/- 0.1 |

| Surface Finish | Ra 1.6 |

| Tolerance | CT4-CT7 |

| MOQ | 500 |

| Additional Services | CNC machining, |

| Heat treatment, | |

| Finishing Services | |

| Assembly, | |

| Packaging, etc. |

Wstitanium Investment Casting Process

Titanium castings have been successfully used as a cost-effective alternative to forging for high-performance and increasingly cost-sensitive applications such as military and commercial aircraft fuselage structures. In some cases, these castings can be manufactured at half the cost of comparable forged and machined parts. For much of the past two decades, investment casting has been one of the preferred methods of manufacturing complex titanium castings. Below is a detailed process of Wstitanium investment casting.

- Mold Development And Design

- Lost Wax Workshop

- Lost Wax Inspection

- Wax Group Tree

- Silica Sol Shell

- Water Glass Reinforcement

- Steam Dewaxing

- Roasting-Pouring

- Remove Gate Sanding

- Blank Positive

- Steam Dewaxing

- Complete Precision Castings

Investment Casting Titanium Grades

Different applications have different requirements for the performance of titanium alloys, which has led to the emergence of a variety of investment casting titanium grades. For example, in the manufacture of aircraft engines, it is necessary to withstand high temperature, high pressure and high stress, requiring titanium alloys to have good high temperature strength, thermal stability and fatigue resistance, and specific titanium grades have come into being; in the field of medical devices, biocompatibility and corrosion resistance are extremely high, and there are titanium grades that match them.

- Grade 2 Ti

- Grade 5 Ti

- Grade 19 Ti

- Grade 23 Ti

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (Brinell) | Shear Strength (MPa) | Impact Strength (J) | Fatigue Strength (MPa) |

| Grade 2 Ti | 345 | 275 | 120 | 205 | 60 | 215 |

| Grade 5 Ti | 895 | 830 | 330 | 550 | 85 | 330 |

| Grade 19 Ti | 485 | 345 | 135 | 295 | 70 | 230 |

| Grade 23 Ti | 828 | 759 | 320 | 545 | 110 | 315 |

Finishing Services

The surface treatment options for investment casting titanium parts are not only a key means to improve part performance and extend service life, but also an important driving force for the development of related industries towards higher performance, more reliability and longer durability.

- Anodizing

- Brushing

- Polishing

- Sandblasting

- Electroplating

- Powder Coating

- Mirror Finishing

- Pickling

- Passivation

- Alkaline Washing

- Boriding Treatment

- Electrolytic Polishing

- Physical Vapor Deposition (PVD)

- Chemical Vapor Deposition (CVD)