Titanium Mesh With Competitive Price In China

Wstitanium manufacturing titanium mesh, which is a system involving multidisciplinary knowledge and multiple advanced technologies. With its excellent performance and diverse structural forms, titanium mesh has shown great application value in many fields such as medicine, aerospace, chemical industry, and construction.

- Gr.1

- Gr.2

- Gr.3

- Gr.4

- Gr.5

- Gr.7

- Gr.9

- Gr.10

- Gr.11

- Gr.12

- Gr.16

- Gr.17

- Gr.23

- Gr.27

- Gr.29

- ASTM F136 & ASTM B863

- Wire Coil, Wire Spool, Straight Rod

- Supply capacity: 5000 tons per month

- 0.3-2.0mm x 1000mm x L Customized

- Customization available upon request

Reputable Titanium Mesh Factory - Wstitanium

Titanium mesh inherits the advantages of titanium’s high strength, low density, excellent corrosion resistance and good biocompatibility, and has unique application value in many fields. Wstitanium manufactures titanium mesh, from strict screening of raw materials, to different types of titanium mesh manufacturing technology, to comprehensive and strict quality inspection, each link plays a vital role in the performance and quality of titanium mesh.

Gr1 Titanium Mesh

Gr1 Titanium Mesh is often used in scenarios with high requirements for formability but low strength, such as pipe linings of chemical equipment and filter screens of food machinery.

Gr2 Titanium Mesh

Gr2 Titanium Mesh can resist corrosion for a long time in heat exchangers and seawater desalination equipment. It is a titanium mesh material with a high frequency of use in the industrial field.

Gr5 Titanium Mesh

Gr5 Titanium Mesh is used in high-end aerospace, medical and other fields, and is often made into aircraft oil line filtration, orthopedic implants such as artificial joints, bone nails, etc.

Gr9 Titanium Mesh

Gr9 is a titanium mesh material with a balance between lightweight and corrosion resistance. It is often used in catheters, hydraulic pipelines, pipeline filters, linings, etc.

Gr12 Titanium Mesh

Gr12 has good resistance to crevice corrosion and stress corrosion cracking. It is mainly used to make filter components that resist corrosion from sulfur-containing and chlorine-containing media.

Gr23 Titanium Mesh

Gr23 titanium mesh is the preferred material for making artificial joints, heart stents, skull repair mesh and other implants. It can coexist safely with human tissue for a long time and reduce the risk of rejection.

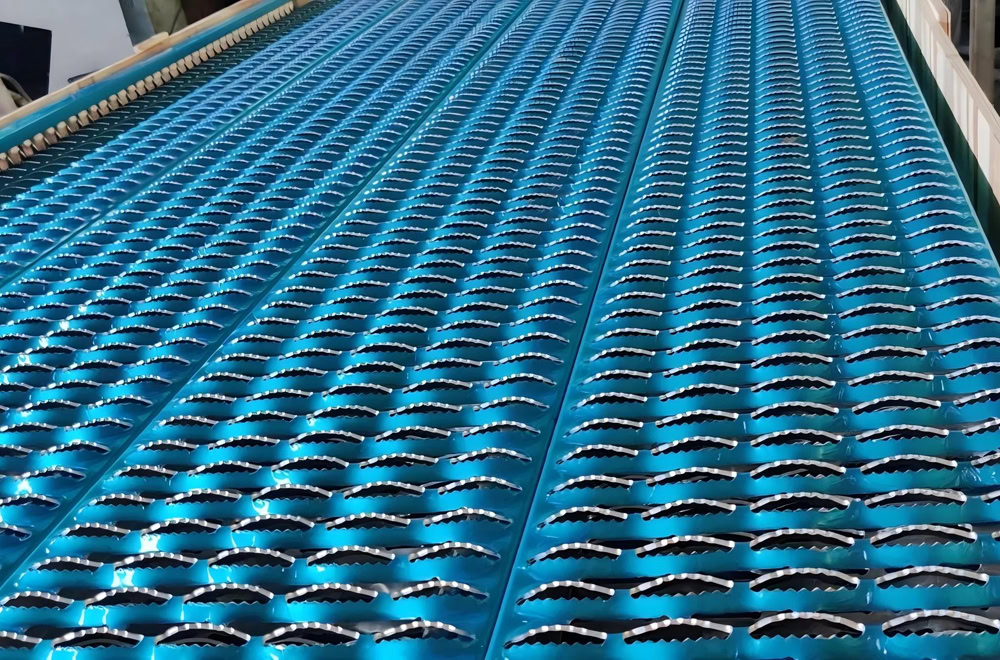

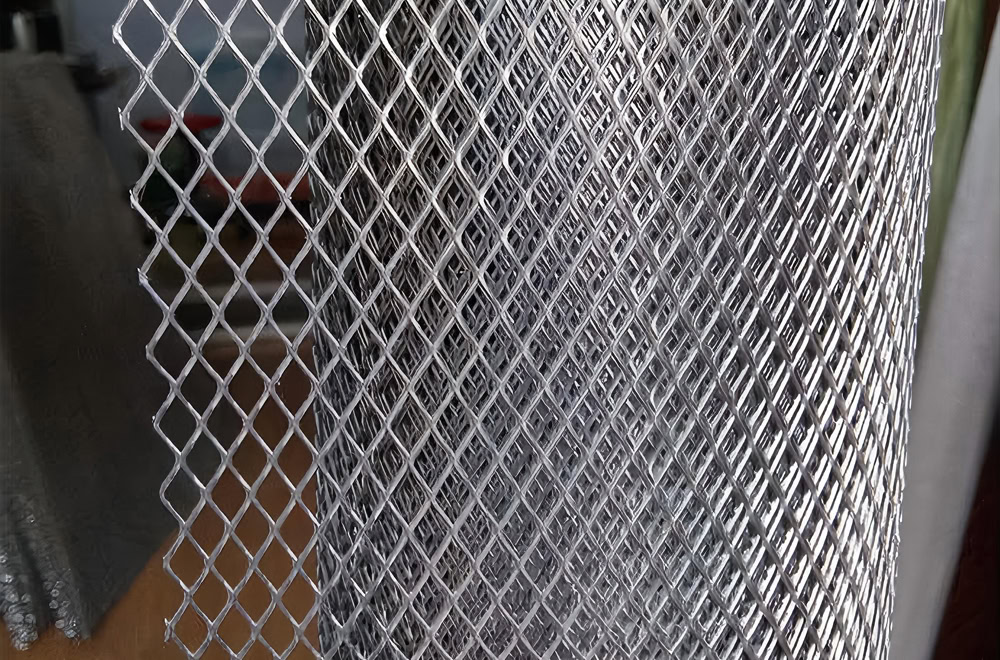

Braided Titanium Mesh

It is made of braided titanium wires, with good flexibility and air permeability, and is used in situations that require elasticity and filtration, such as chemical filtration.

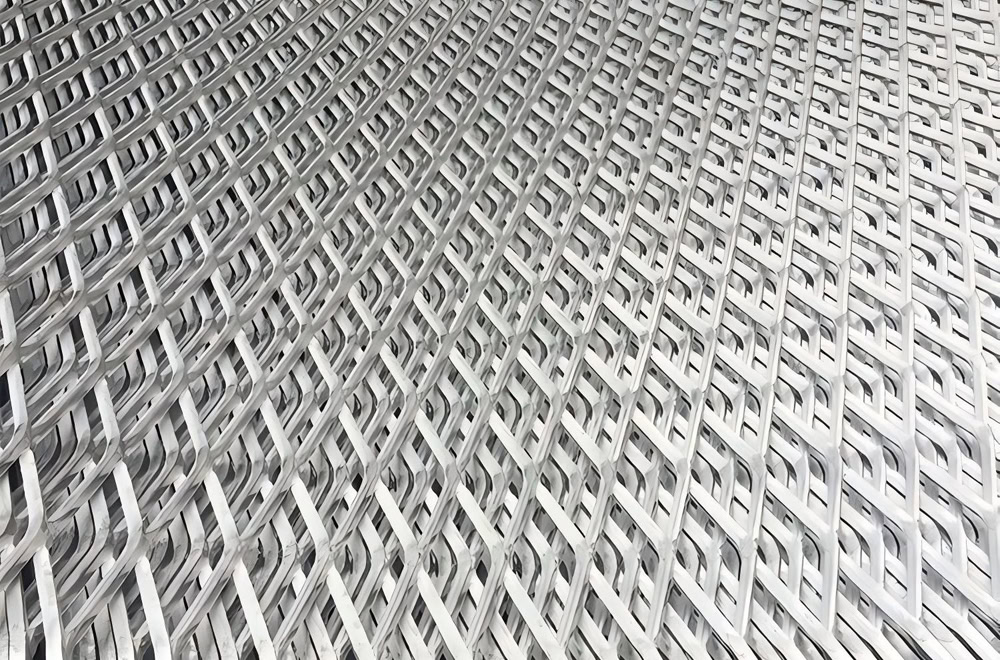

Welded Titanium Mesh

It is made of titanium plates or titanium wires connected by welding. It has a strong structure, high strength, and can withstand greater pressure and weight.

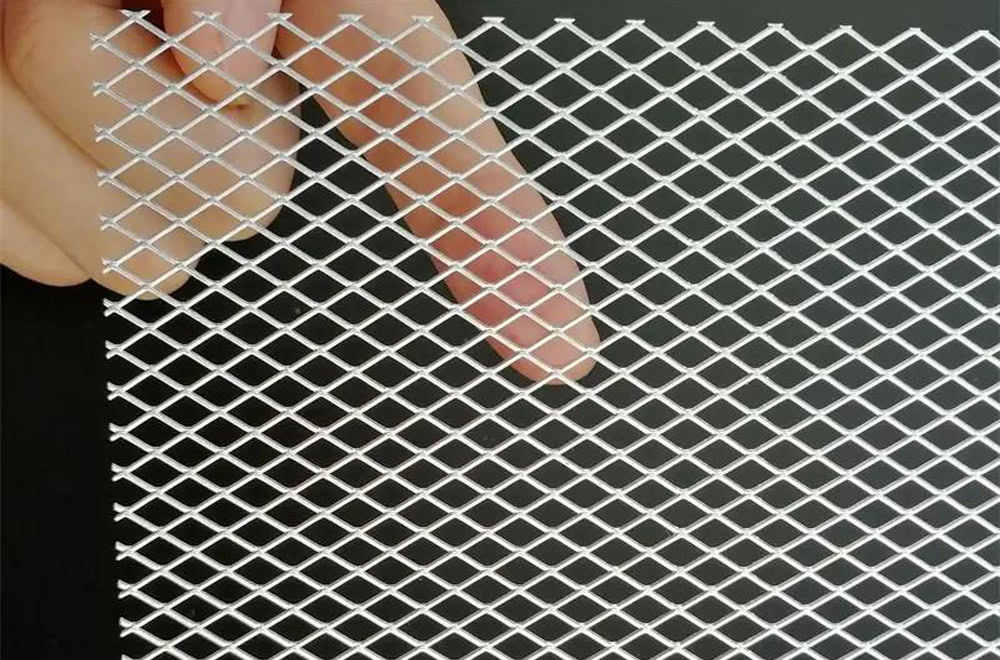

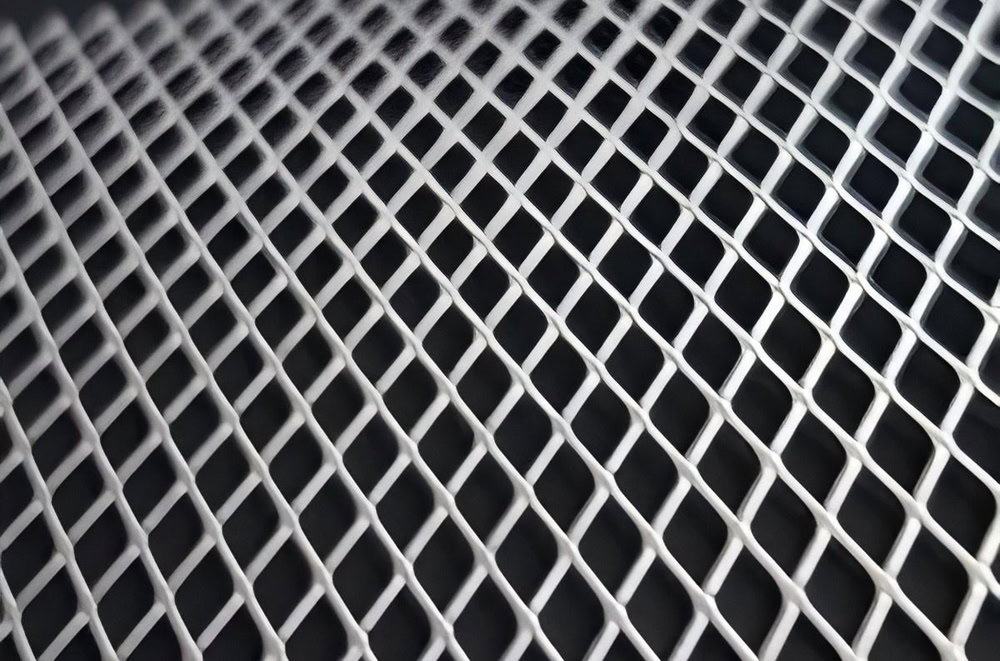

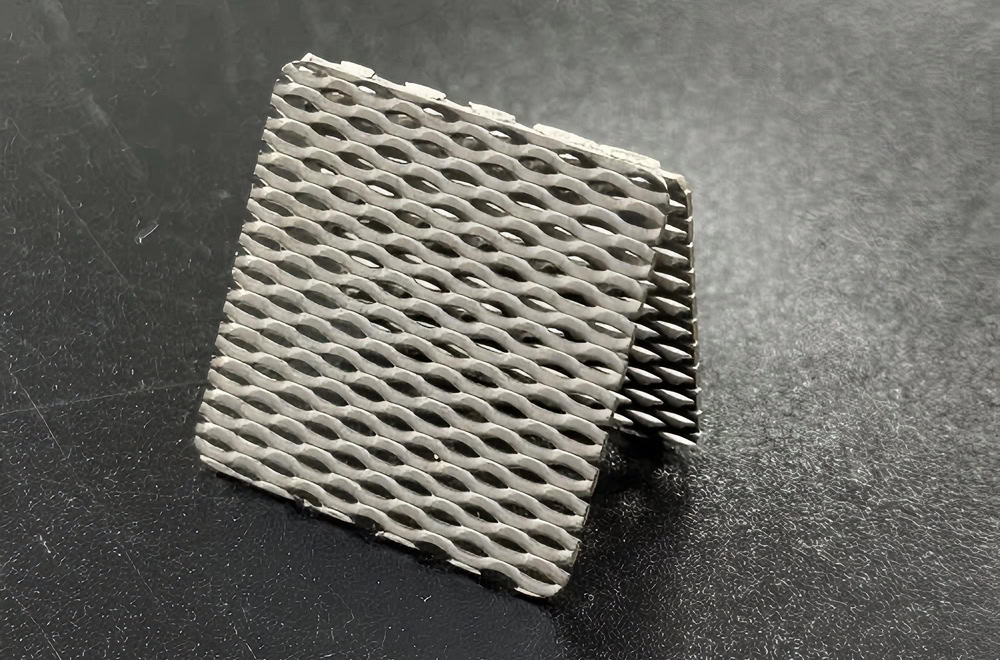

Stamped Titanium Mesh

The titanium plate is processed into meshes with specific shapes and sizes by stamping technology, such as round, square, diamond, etc.

Medical Titanium Mesh

It has good biocompatibility and corrosion resistance, and will not cause immune and allergic reactions in the human body. It is often used in skull repair, maxillofacial bone repair, spinal fusion, etc.

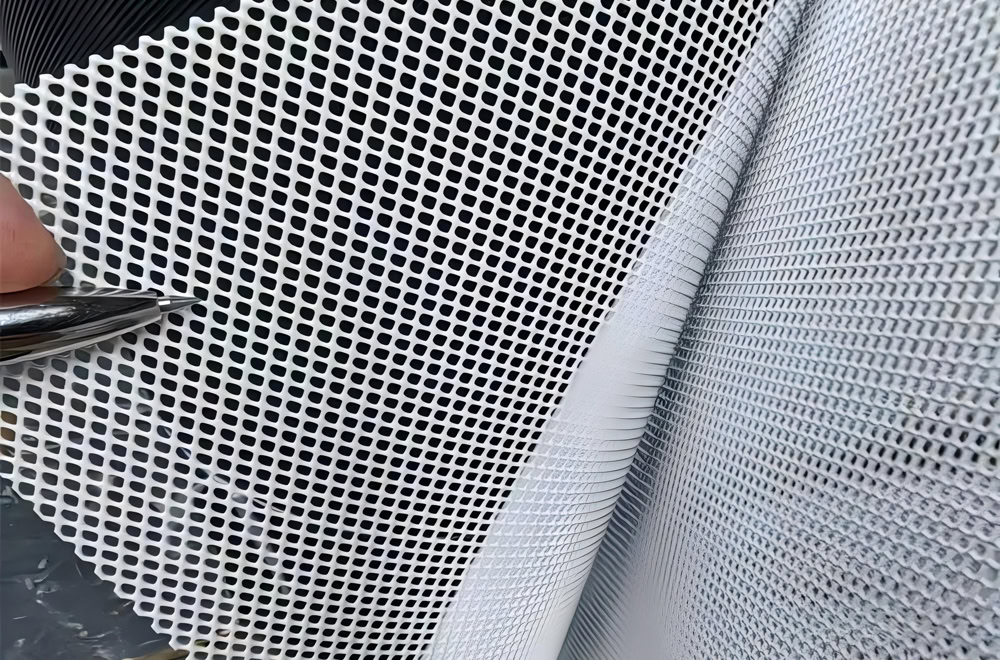

Industrial Titanium Mesh

It has a wide range of applications in industrial fields such as chemical, petroleum, electroplating, and sewage treatment. It is mainly used for filtration, screening, catalyst carriers, electrodes, etc.

Architectural Titanium Mesh

It has the characteristics of beauty, durability, and corrosion resistance. It is used for building facade decoration, roof shading, stair handrails, etc., adding a modern and artistic atmosphere to the building.

Titanium Mesh Manufacturing

Wstitanium conducts strict inspections on the purchased raw materials, including chemical composition analysis (using spectral analysis, etc.), metallographic structure detection, and mechanical property testing (tensile test, hardness test, etc.). The raw materials are pre-treated according to different manufacturing technologies. For example, for woven titanium mesh, the titanium ingot needs to be processed into titanium wire that meets the requirements. Through multiple wire drawing, the diameter of the titanium wire is gradually reduced to ensure the strength and flexibility of the titanium wire. For stamped titanium mesh, the titanium plate blank needs to be cut into a suitable size and shape.

Woven Titanium Mesh

Install the pretreated titanium wire on the braiding machine and set the braiding parameters according to the design requirements, such as braiding method, braiding density, mesh size, etc. Monitor the tension of the titanium wire and the operating status of the braiding machine in real time to ensure stable braiding quality. After the braiding is completed, the titanium mesh is initially shaped and cut to remove the excess parts at the edge. Common braiding methods include plain weave, twill weave, satin weave, etc. By adjusting the weaving parameters (such as wire diameter, weaving density, weaving angle, etc.), the porosity, strength and flexibility of the titanium mesh can be controlled.

Features: It has high flexibility and deformability, uniform and continuous pores, and a flat mesh surface. It is suitable for occasions that need to fit complex shapes or perform fine filtration.

Place the cut titanium plate on the die of the punching machine and adjust the parameters such as the pressure, stroke and speed of the punching machine. Through one or more punching of the die, the titanium plate is formed into the required mesh structure. The mesh shape is regular (such as square, rectangular, circular, etc.), the dimensional accuracy is high, the mesh surface strength is large, but the flexibility is relatively poor.

Application areas: exterior wall decoration mesh and ceiling mesh in the field of architectural decoration; protective mesh and isolation mesh in the field of industrial protection.

According to the designed mesh shape and structure, the titanium wire or titanium bar is cut and bent into shape, and then the nodes are welded together by welding technology such as argon arc welding or laser welding. During welding, the welding parameters such as welding current, welding speed, gas flow, etc. are strictly controlled to ensure the quality of the welded joints, without defects such as pores and cracks.

Application areas: reactor support mesh and catalyst carrier mesh in the petrochemical field; high-temperature furnace protection mesh and filter mesh in the metallurgical industry, etc.

The chemical industry uses the characteristics of titanium mesh being resistant to acid and alkali corrosion and high temperature to make it into filter mesh for reactors, heat exchangers and other equipment. In the field of petrochemicals, titanium mesh is made into barrier mesh for oil refining equipment. The medical field is also an important application direction of titanium mesh. Due to its good biocompatibility and corrosion resistance. In orthopedic surgery, the mesh structure of titanium mesh can avoid fracture separation, enhance the stress of fracture ends and promote healing during fracture repair. When repairing bone defects, it can be used as a support to fill the defect area, often combined with autologous bone or allogeneic bone transplantation to promote new bone formation and integration.