Titanium Parts For Bicycle

Wstitanium is a company that specializes in manufacturing titanium bicycle parts.

- ISO 9001:2016 Certified

- ISO 13485:2015 Certified

- 24/7 Engineering Support

- Full Size Quality Inspection Report

Titanium Bicycle Parts Manufacturer

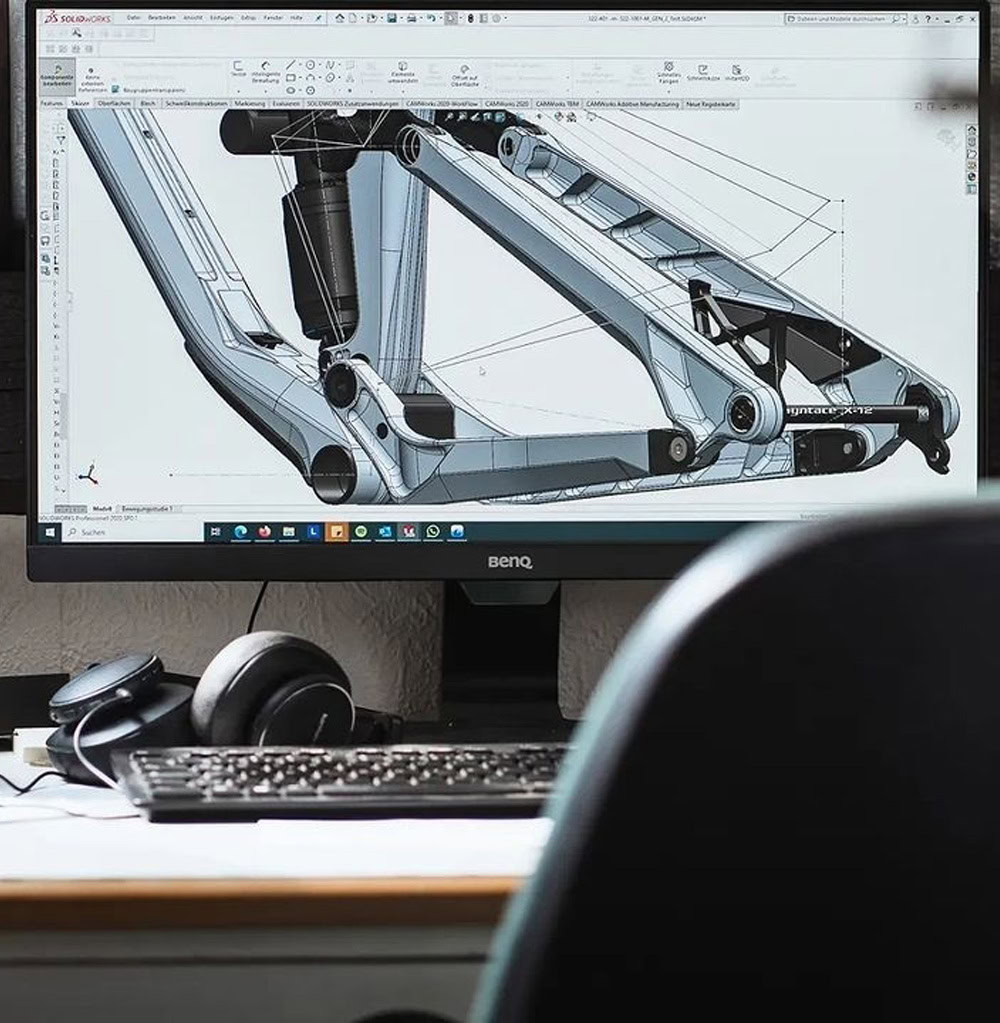

Titanium alloy parts stand out for their excellent performance and have become an ideal choice for bicycle manufacturers and cycling enthusiasts who pursue the ultimate riding experience. As a company specializing in the manufacture of titanium alloy bicycle parts, Wstitanium manufactures high-quality, high-performance titanium alloy bicycle parts with its profound attainments in core technologies such as CNC machining, sheet metal fabrication, and welding.

Titanium materials for bicycles

The density of titanium is about 4.51g/cm³, which is between aluminum (2.7g/cm³) and steel (7.85g/cm³). However, titanium alloys can reach or even exceed high-strength steel. For example, the commonly used Ti-6Al-4V titanium alloy has a yield strength of more than 880MPa, far exceeding the strength of aluminum alloys. This excellent strength-to-weight ratio allows titanium bicycles to be lightweight while having sufficient rigidity to cope with various riding conditions, whether it is high-speed sprints or bumps on rugged mountain roads, it can provide stable and reliable support.

The titanium alloys commonly used in bicycle manufacturing are mainly Ti-3Al-2.5V and Ti-6Al-4V. Ti-3Al-2.5V has good cold machining performance and is suitable for making pipes. Its welding performance is also relatively good, which can ensure the strength and quality of the frame welding parts. Ti-6Al-4V is a widely used titanium alloy that has a balanced performance in strength, toughness and corrosion resistance. It is often used to manufacture key parts of bicycles, such as front forks and handlebars.

Titanium Bicycle Parts

Titanium, with its high strength, light weight, corrosion resistance, fatigue resistance and other excellent properties, has shown unique advantages and great application value in various parts of bicycles. From the frame that provides stable support to the handlebars that achieve precise control; from the wheels that rotate efficiently to the brake system that ensures safety; from the speed change system that adjusts the power to the pedals that transmit the power, titanium plays an important role in every key part of the bicycle, bringing riders a more efficient, comfortable and safer riding experience.

Titanium Bicycle Wheel

The wheel needs to withstand various impact forces and friction. Titanium alloy rims have high strength characteristics and can maintain a stable structure when jumping and passing through rough roads. In addition to strength, lightweight is also an important performance indicator of the rim. Lighter rims require less energy when turning, which can improve the acceleration performance of the wheel and the overall smoothness of riding.

Titanium Bicycle Hub

The hub is the core component of the wheel, which directly affects the rotation efficiency of the wheel. Titanium alloy hubs have a low friction coefficient, which can reduce energy loss during rotation and improve transmission efficiency. Hubs are often eroded by rain, dust and mud, so corrosion resistance is crucial for hubs. The corrosion resistance of titanium alloys allows hubs to work normally in various harsh environments.

Titanium Bicycle Frame

As the core component of a bicycle, the frame is like the skeleton of a human body, playing a key role in supporting the weight of the entire bicycle and transmitting riding force. The frame made of titanium alloy significantly reduces its own weight while ensuring sufficient strength to cope with various riding conditions. A lighter frame means easier and more labor-saving riding.

In addition, titanium alloy also has unique elasticity. This elasticity allows the titanium alloy frame to absorb some of the vibration from the road during riding, providing you with a more comfortable riding experience.

Titanium Bicycle Handlebars

The handlebar is one of the important parts that the rider interacts directly with the bicycle, and it directly affects the handling performance of the bicycle. The handlebar needs to withstand frequent torque and pressure. Titanium alloy has excellent fatigue resistance and can maintain stable performance and is not easy to damage under the condition of long-term exposure to these complex stresses. In addition, titanium alloy handlebars effectively reduce weight and are more flexible when turning. For mountain bikes, flexible steering performance is the key to cope with complex terrain.

Titanium Bicycle Shift Lever

The shift lever is the operating part for the rider to control the speed change system. The titanium alloy shift lever allows the rider to accurately switch to the desired gear and achieve easy control. This precise speed change performance allows the rider to better utilize the performance of the bicycle and improve the efficiency and comfort of riding.

Titanium Bicycle Pedal

The pedal is the part that transmits the pedaling force between the rider and the bicycle. It needs to bear the rider’s weight and frequent pedaling force. Titanium alloy pedals are not prone to wear, deformation or damage. The lightweight characteristics of titanium alloy make the weight of the pedals greatly reduced while ensuring strength. During riding, lighter pedals can make the rider’s feet more relaxed and reduce fatigue.

Wstitanium Manufactures Titanium Bicycle Parts

Wstitanium has set extremely strict standards for the selection of titanium alloy raw materials. Not only does it conduct chemical composition analysis and use a spectrometer to accurately detect the content of each element, but it also conducts comprehensive tests on its mechanical properties, including key indicators such as tensile strength, yield strength, elongation, and impact toughness. Wstitanium is committed to creating top-level titanium bicycle parts with its deep understanding of titanium and advanced manufacturing processes (CNC Machining, sheet metal manufacturing, and welding techniques).

CNC Turning Titanium Bicycle Parts

Turning is one of the commonly used processes in CNC machining, mainly used to manufacture parts with circular features, such as shafts, pipes, etc. Among titanium bicycle parts, CNC turning is often used to manufacture seat tubes, hub axles, etc. Wstitanium ensures dimensional accuracy and surface roughness by precisely controlling parameters such as the lathe speed, feed rate and cutting depth.

CNC Milling Titanium Bicycle Parts

The 5-axis linkage CNC milling center invested by Wstitanium can realize multi-faceted machining and precise manufacturing of complex shapes of titanium parts. The tool is allowed to move simultaneously in five different directions, and the dimensional tolerance can be controlled within ±0.01mm. CNC machining has a high degree of automation and can achieve continuous and efficient production.

Drilling and Tapping

Drilling and tapping are important processes for making threaded holes for parts. In titanium bicycle parts, such as mounting holes and screw holes on the frame, drilling and tapping are required.

Grinding

Grinding is a process used to improve the surface accuracy and finish of parts. Wstitanium selects the appropriate grinding wheel type, grit and hardness, grinding speed, feed rate and depth, etc.

Sheet metal manufacturing

Sheet metal fabrication gives titanium bicycle parts unique performance and aesthetic values.Wstitanium selects the appropriate sheet thickness, strength grade and surface quality according to the performance requirements of different parts. A series of advanced sheet metal forming equipment in-house, such as CNC bending machines, laser cutting, etc., can realize the precise bending, stretching, stamping and other forming processes of titanium alloy sheets. Accurately control the bending angle and radius to ensure that the bending accuracy is within ±0.5°.

Welding

Welding directly affects the strength and reliability of parts. Wstitanium uses the internationally advanced inert gas shielded welding (TIG) technology to accurately control parameters such as welding current, voltage, welding speed and argon flow to ensure that the weld is uniform and firm, without defects such as pores, cracks, and unfused welds. After welding is completed, advanced non-destructive testing technologies such as ultrasonic flaw detection and radiographic flaw detection are used to conduct strict quality inspections on each welding part.

Finishing Services

Finishing services play an indispensable role. Various processes such as anodizing, sandblasting, Baked blue, electroplating, polishing, powder coating, etc. each have their own unique advantages. Through different combinations and applications, they can meet the performance, aesthetics and durability requirements of titanium bicycle parts.

Wstitanium manufactures key components of titanium bicycles, including frames, forks, handlebars, seat tubes, wheels, hubs, chains, pedals, brake systems, and shifting systems. Whether you need to build a new titanium bicycle or upgrade an existing one, you can find the right parts at Wstitanium. Wstitanium understands that every rider has unique needs and preferences, so it provides custom manufacturing solutions.