Titanium Parts for Robotics

Wstitanium is a Chinese manufacturer specializing in titanium alloy robot parts. CNC machining, 3D printing, sheet metal fabrication, welding, powder metallurgy.

- ISO 9001:2016 Certified

- ISO 13485:2015 Certified

- 24/7 Engineering Support

- Production-Grade Products

Titanium Parts Manufacturer For Robots

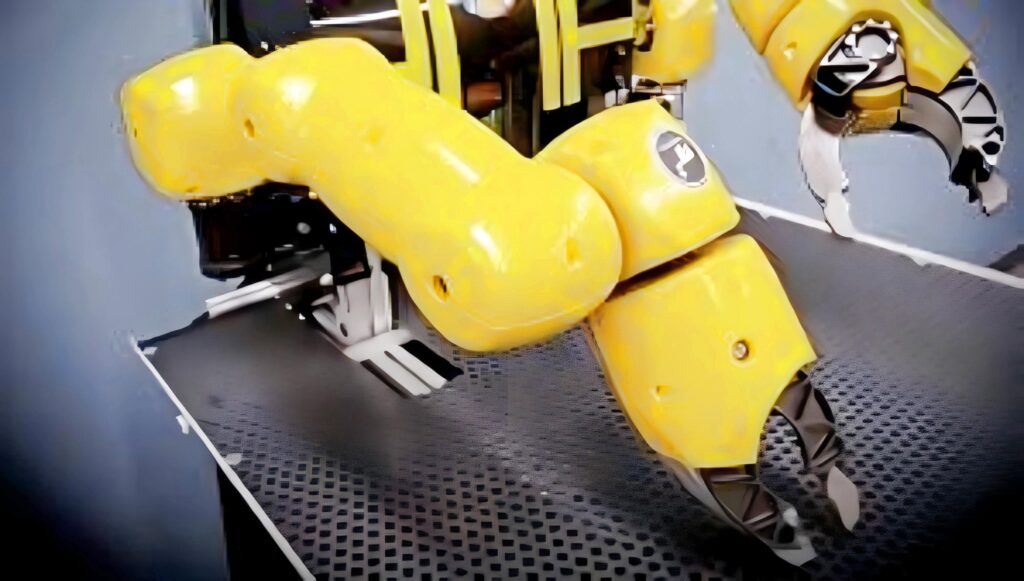

In the rapid development of modern robotics, titanium plays a vital role in the performance, function expansion and application field expansion of robots. Titanium alloy parts have excellent comprehensive performance and are gradually becoming more and more popular in the field of robotics. Their unique physical and mechanical properties have brought new opportunities and breakthroughs to the design and manufacture of robots.

Advantages of titanium alloy parts

The density of titanium alloy is about 4.5g/cm³, which is significantly lower than that of steel (about 7.8g/cm³). Although it is slightly higher than that of aluminum alloy (about 2.7g/cm³), it has significant advantages in strength. This low-density property enables robots to reduce their own weight while maintaining structural strength. For robots that need to move frequently and have high mobility, such as mobile robots and drones, reducing weight can reduce energy consumption and improve operating efficiency and endurance. For example, in robots and drones in the aerospace field, the use of titanium alloy parts can reduce the weight of the body and improve flight performance and payload capacity.

High Strength

Titanium alloy parts have excellent strength, especially in terms of specific strength (ratio of strength to density). Its tensile strength can reach more than 1000MPa, and some high-strength titanium alloys can even reach about 1400MPa. Due to the high strength and good rigidity of titanium alloys, the robot structural frame made of titanium alloy parts can withstand greater loads and torques, reduce deformation and vibration during movement, and thus improve the robot’s movement accuracy and stability.

Strong corrosion resistance

A dense oxide film can be formed on the surface of titanium alloy parts. This oxide film has good chemical stability and can effectively resist the erosion of various chemical media, including acid, alkali, salt, etc. In some harsh working environments, such as robots in the fields of ocean and chemical industry, corrosion resistance is one of the key factors in material selection. For example, underwater robot parts made of titanium alloy can work in seawater for a long time to ensure the normal operation of the robot.

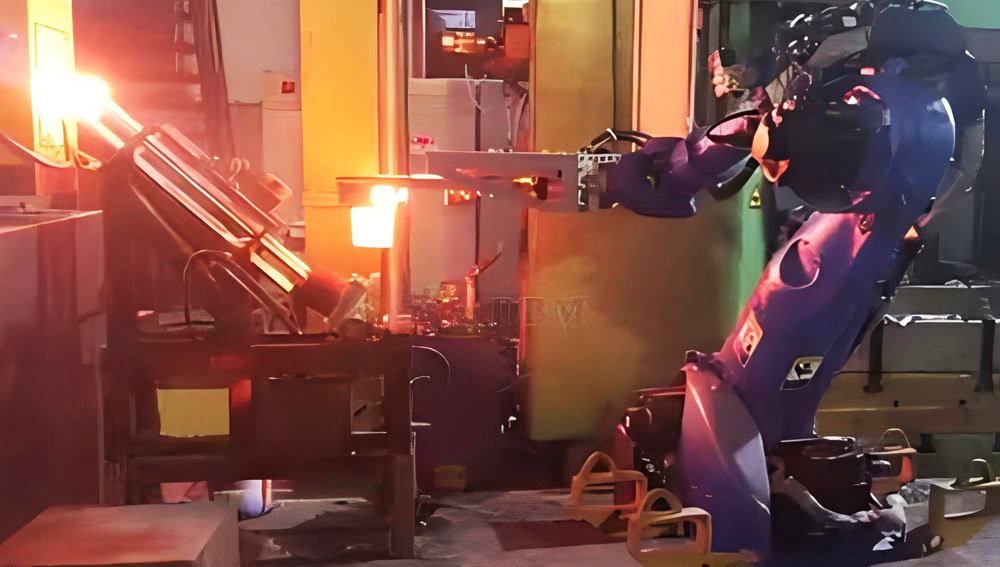

Good high temperature performance

Some titanium alloy parts can still maintain good mechanical properties in high temperature environments. For example, in the temperature range of 300-500℃, their strength and oxidation resistance can still meet the needs of many industrial applications. This allows robots to work normally in high temperature environments, such as robots on high-temperature industrial production lines such as metallurgy and glass manufacturing, which can adapt to harsh high-temperature working conditions.

Good biocompatibility

Titanium alloy parts have good compatibility with human tissues and will not cause immune and toxic reactions in the human body. This opens up a broad space for the application of robots in the medical field. Medical robots can use titanium alloys to manufacture parts that are in direct contact with human tissue, such as the joints of prosthetic limbs and the operating instruments of surgical robots, etc., to reduce adverse effects on the human body and improve the safety and reliability of medical robots.

Wstitanium manufactures robot parts

Wstitanium has a deep insight into the huge potential of titanium alloys in the field of robot parts manufacturing. Since its establishment, it has always been committed to combining advanced technology with exquisite craftsmanship to provide you with high-quality, customized titanium alloy robot parts.

CNC Machining

Wstitanium has invested in a series of internationally leading high-precision CNC machining centers, including 5-axis linkage CNC machining centers, high-speed milling machining centers, etc. These devices have the characteristics of high speed, high torque and high precision, and can achieve the dimensional accuracy and surface quality of complex-shaped titanium alloy parts. For example, the 5-axis linkage machining center can complete the machining of multiple faces and complex curved surfaces of parts in one clamping, effectively reducing clamping errors and improving machining accuracy and production efficiency. The accuracy can be controlled within ±0.001mm, and the surface roughness reaches Ra0.1-0.2μm, providing reliable guarantee for the high-precision movement of the robot.

In view of the characteristics of titanium alloy, Wstitanium has developed a set of advanced CNC machining processes. By precisely controlling cutting parameters such as cutting speed, feed rate and cutting depth, the impact of cutting force and cutting heat on parts is effectively reduced, and part deformation and surface quality degradation are avoided. At the same time, high-performance carbide tools and ceramic tools are selected. These tools have good wear resistance and heat resistance, and can maintain stable cutting performance under high-speed cutting conditions, ensuring machining accuracy and tool life.

3D printing

Wstitanium has introduced advanced metal 3D printing technologies such as electron beam melting (EBM) technology. This can directly melt and accumulate titanium alloy powder layer by layer to produce robot parts with complex internal structures and personalized appearance. Compared with traditional processing methods, 3D printing technology does not require molds, which greatly shortens the product R&D cycle and production cycle, and can optimize the use of materials and reduce manufacturing costs.

Titanium parts after 3D printing need to undergo a series of post-processing to further improve the performance and accuracy of the parts. Wstitanium uses hot isostatic pressing (HIP), heat treatment, surface polishing, etc. to eliminate the residual stress inside the parts and improve the organizational structure and mechanical properties of the parts.

Welding

Welding is a key link in the manufacturing of titanium alloy parts. Wstitanium has introduced advanced welding equipment, such as digitally controlled TIG welders, MIG welders and high-power laser welders. These equipment have precise current control, gas protection and welding process monitoring functions, which can achieve high-quality titanium alloy welding. In terms of welding technology, according to different part structures and welding requirements, personalized welding process plans have been formulated. By optimizing welding parameters such as welding current, voltage, welding speed and gas flow, welding defects are effectively reduced and the strength and sealing of welded joints are improved.

Powder Metallurgy

Wstitanium uses advanced powder metallurgy processes, such as metal injection molding (MIM) technology, to make titanium alloy powder into parts with high precision and good mechanical properties. In the powder preparation link, advanced gas atomization powder making technology is used to prepare titanium alloy powder with uniform particle size and good sphericity. In the molding process, the molding accuracy and density of the parts are improved by optimizing the mold design and molding process parameters. During the sintering process, advanced sintering processes such as vacuum sintering and hot isostatic pressing sintering were used to effectively improve the organizational structure and mechanical properties of the parts.

Robot Part Type

With the continuous expansion of robot application fields and the increasing diversification of customer needs, more and more customers need unique robot parts. Wstitanium provides professional customized titanium parts manufacturing solutions.

- Motors

- Sensors

- Prototypes

- Nano systems

- Actuators

- Robotic medical devices

- Casings, housings, tubing

- Automatic control equipment

- Clamps

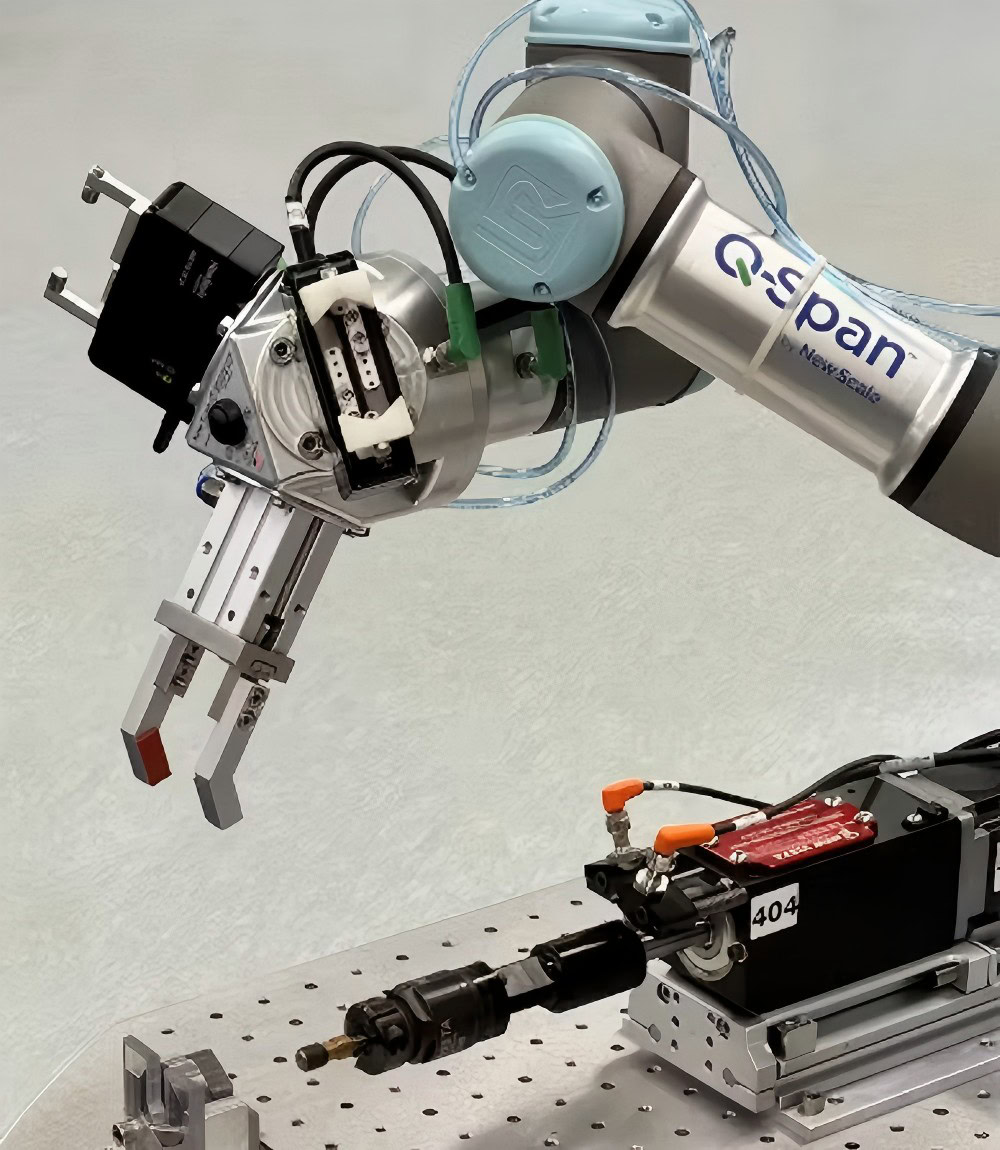

- End effectors

- Micro systems

- Manipulator parts

Wstitanium has established a complete quality inspection system, and has carried out strict quality inspection and control in every link from raw material procurement to product delivery. A series of advanced inspection equipment has been introduced, such as three-coordinate measuring machine, spectrum analyzer, metallographic microscope, hardness tester, etc. These equipment can conduct comprehensive inspection on the dimensional accuracy, chemical composition, mechanical properties, metallographic structure, etc. of titanium alloy parts.