Trustworthy Titanium Product Manufacturer

Wstitanium is an ISO9001 Certified titanium product manufacturer in China, serving the global aerospace, medical, robotics, chemical, marine, electronics, bicycle and many other fields.

- Titanium Bar

- Titanium Rod

- Titanium Pipe

- Titanium Tube

- Titanium Flange

- Titanium Foil

- Titanium Wire

- Titanium Plate

- Titanium Ingot

- Titanium Sheet

One-stop Titanium Product Manufacturer in China - Wstitanium

As a metal with excellent performance, titanium plays an increasingly important role in modern industry. Its unique physical and chemical properties, such as low density, high strength, excellent corrosion resistance, good high temperature performance and biocompatibility, make it widely used in many fields such as aerospace, navigation, medical, chemical, energy, robotics and bicycles. As a one-stop titanium product manufacturing company in China, Wstitanium manufactures various titanium products, including titanium anodes, titanium fasteners, titanium flanges, titanium blocks, titanium rods/bars, titanium ingots, titanium plates/sheets, titanium tubes/pipes, titanium wires, titanium foils and titanium heat exchangers, etc.

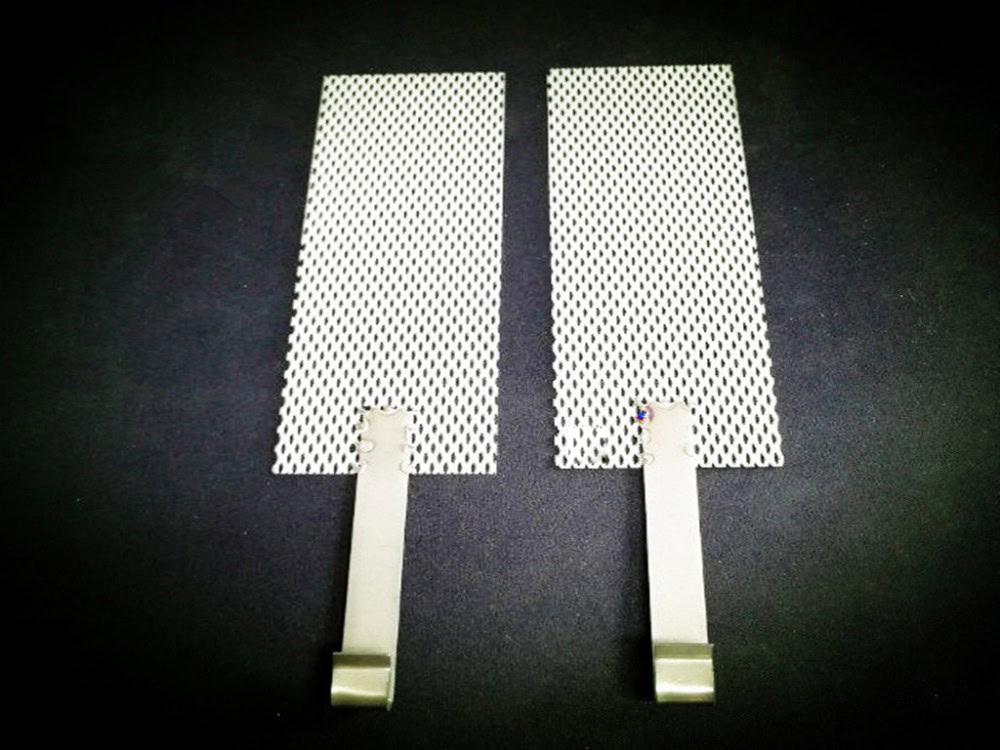

Wstitanium is a high-quality MMO titanium anode manufacturer and supplier, providing customized solutions with ruthenium, iridium and platinum coatings, ensuring quality and affordability. Titanium anodes are essential to industries that prioritize durability and efficiency, such as wastewater treatment and electroplating. Titanium anodes manufactured by Wstitanium are known for their corrosion resistance and long-lasting performance, ensuring your operations are both reliable and cost-effective. These titanium anodes can be customized to specific needs, optimizing functionality and extending the life of your system.

Ruthenium-iridium coated titanium anodes utilize the catalytic efficiency of ruthenium and the exceptional antioxidant capabilities of iridium. They excel in a variety of applications such as chlorine production, electroplating, and wastewater treatment.

Iridium-tantalum coated titanium anode has high electrocatalytic activity, strong corrosion resistance, long service life and good dimensional stability. It is used in electrochemical fields such as chlor-alkali, electroplating, and water treatment.

Platinum-coated titanium anodes have a platinum layer with a thickness of 0.2 to 5 microns. It has high catalytic activity, strong corrosion resistance, and excellent conductivity. It is typically used in the chlor-alkali industry, sewage treatment, metallurgy, etc.

Titanium fasteners are known for their high strength, light weight, and corrosion resistance. They are essential to many industries, including chlor-alkali, marine, energy, desalination, medical, and pulp and paper. GR2, Ti-6AL-4V (GR5), GR7 are the most popular grades of titanium fasteners. Wstitanium manufactures titanium nuts, washers, screws, nuts, bolts, etc., with a variety of sizes and surface treatments to choose from (sandblasting, pickling, polishing, anodizing, blueing, PVD coating, etc.). Of course, custom manufacturing solutions can be provided according to your drawings. Follow US, Metric (M0.8-M24 or larger) and Imperial standards.

Wstitanium manufactures Ti6AL4V titanium screw series, including M3, M4, M5, M6, M8, M10, M12, M14 and M15, etc., with flat head, round head, cap head, cone head, 12 point head and flange head, etc.

Wstitanium manufactures imperial and metric titanium bolts in various styles and threads. Sizes are M3*3-M3*32. Common materials are grade 2 titanium, grade 5 titanium, grade 7 titanium.

Nuts are typically used with bolts, threaded rods or parallel thread screws and are often right-handed. Available in grade 2 and grade 5 titanium as standard, with thread sizes from M1.6 to M56.

Titanium Pins

Titanium Pin is a high performance connector made from Ti6Al4V (Grade 5) titanium alloy designed to meet the demanding needs of industry, aerospace, medical devices and offshore engineering. Diameter: 1mm to 20mm. Length: 10mm to 200mm

Ti 6AI-4V (Grade 5) and Ti 6AI-4v ELI (Grade 23) Titanium washers are designed to reduce surface wear and have a yield strength three times higher than stainless steel. This means loads will be more evenly distributed. Custom Options Metric and Imperial.

Rivets can handle shear loads and tensile loads. Head forms such as Round, Pan, Hex, Flat, Button, Truss, Oval, Binding, Chese, Fillister etc. Specification: M3-M36. Heat Treatment: Tempering, Hardening, Spheroidizing, Stress Relieving

Titanium flanges are components used to connect pipes, valves, pumps or other equipment. Grade 2 titanium flanges are the most popular type in the pipe valve and fittings industry, with high strength and corrosion resistance. Sizes range from 12.7mm-203.2mm. Including: threaded, slip-on, reducer, blind hole, weld neck, socket weld and lap joints. Follow standards: ASA/ANSI/ASME (US), PN/DIN (Europe), BS10 (UK/Australia) and JIS/KS (Japan/Korea). Used in medical, space, robotics and other high-strength applications. Wstitanium manufactures titanium flanges with multiple technologies in-house, including CNC Machining, casting, forging, etc.

CNC machining titanium flanges pay attention to every detail to ensure dimensional accuracy and surface quality. After turning, drilling, milling, etc., the flange is given the required shape and structure. The surface roughness of CNC machined titanium flanges is Ra=0.1–0.8. The tight tolerance is +/-0.005mm.

Forged titanium flanges are produced by applying pressure to titanium blanks to produce plastic deformation to obtain the desired shape, size and performance. The forged titanium flanges have dense and uniform internal structure and high dimensional accuracy, which can meet more demanding applications.

Cast titanium flanges are pipe connectors made by melting titanium and injecting it into a specific mold, cooling and solidifying it. Its advantage is that it is suitable for large-scale production and is cost-effective. Cast titanium flanges are widely used in connection structures that do not require high strength and toughness.

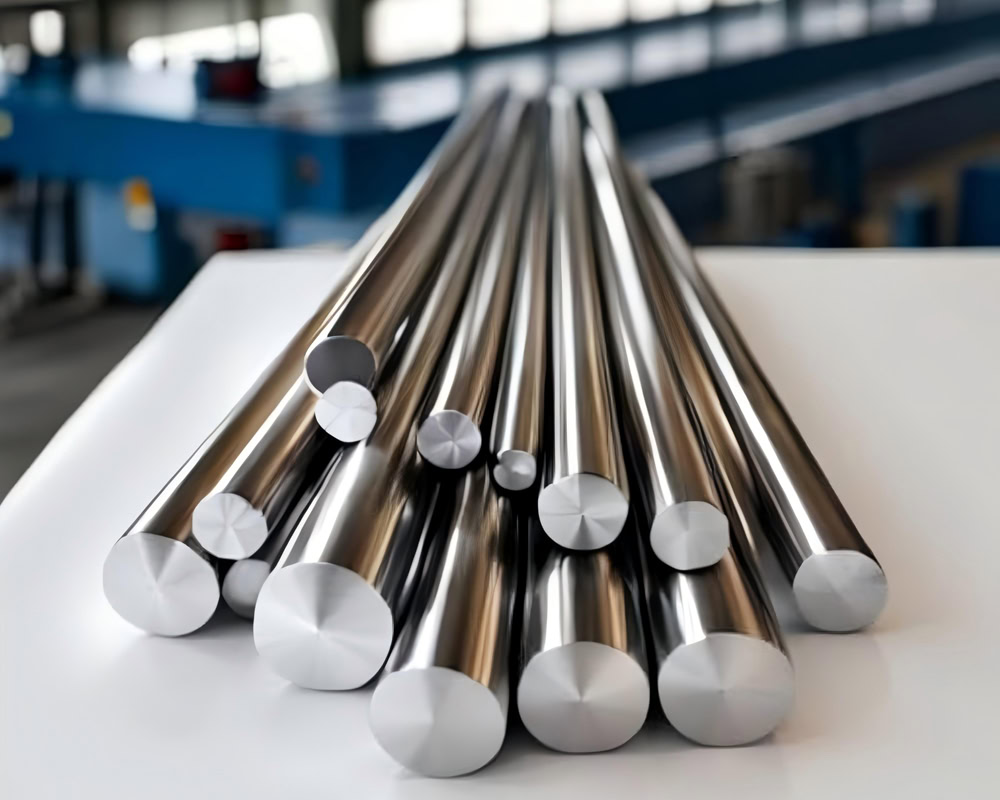

The titanium bars produced by Wstitanium can be divided into pure titanium bars and titanium alloy bars. Pure titanium bars: TA1, TA2, TA10, Gr1, Gr2, Gr4 and other grades. Titanium alloy bars: TC4, TC10, Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 and other grades. Surface treatment: black, pickling, sandblasting, polishing. Shape: square bar, round bar, hexagonal bar, etc. Condition: cold rolled (Y), hot rolled (R), annealed (M), quenched (C). Round bars with diameters from 4 mm to 400 mm, and square bars with dimensions of 410 x 410 mm. The design and tolerance of titanium bars vary: For small diameters in ground form, h7 tolerance is provided, etc. Titanium bars with larger diameters are delivered in rolled form with tolerances of h9 or h11. Forged titanium bar material has been peeled or CNC turned.

Pure Titanium Rod

Pure titanium rod refers to a rod with a titanium content of more than 99%. Wstitanium’s technology for manufacturing pure titanium rods: forging, rolling, drawing, etc. Gr1, Gr2, G3, Gr4 pure titanium rod diameter: 3-~800mm.

Titanium Alloy Rod

Titanium alloy rod material options are GR5, GR7, GR12, GR23, etc. Its shape is round, square, flat, hexagonal, etc. The diameter is 3-1200mm. The maximum length is 6000 mm. The annealed titanium alloy rod is polished and pickled.

Medical Titanium Rod

Two types of medical grade titanium alloy rods are commonly used: Ti-6AL4V and Ti-6AL4VELI, also known as Gr. 5 and Gr. 23. There are clear labels on the outside to ensure effective identification and quality control.

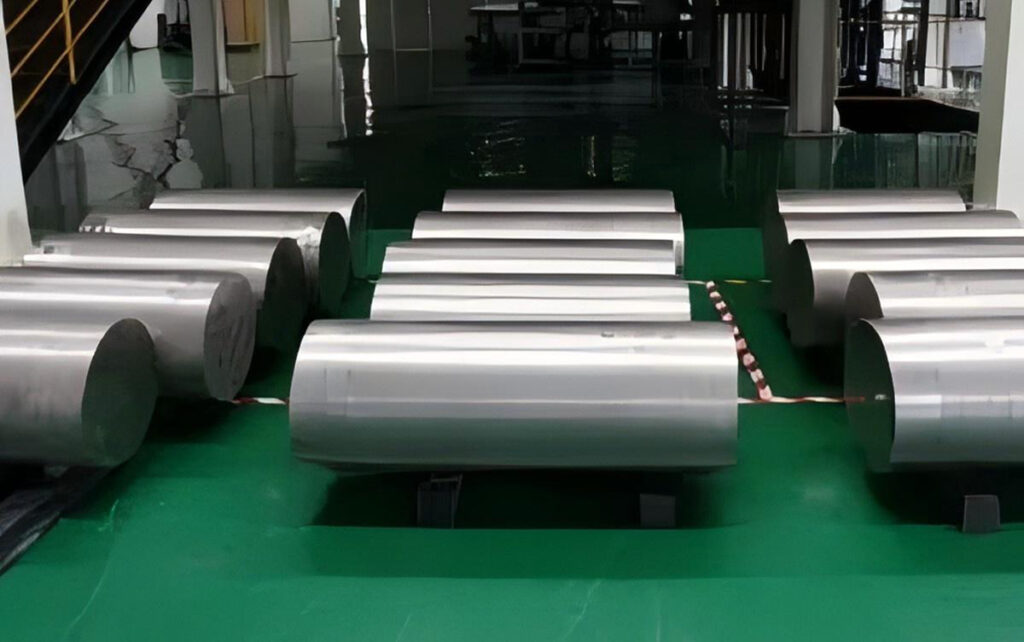

Titanium ingot is a large piece of solid titanium metal. There are two types of titanium ingots available: pure titanium ingot and titanium alloy ingot, such as Ti 6AI-4V. Wstitanium is a large pure titanium ingot manufactured by electron beam melting. Pure titanium or titanium alloy ingots are made by melting titanium sponge and adding alloying elements. Since titanium reacts easily with oxygen, nitrogen and carbon, the melting process is carried out in vacuum or inert atmosphere. Titanium Grade Options: Gr 1- Gr4, Gr 5, 6, 7, 9, 12, 24, 26, 29, TA1, TA2, TA3, TA4, TA9, TA10, TC4, etc. Sizes: Diameter 380 – 960 mm.

Pure Titanium Ingot

As an important basic raw material for the titanium and titanium alloy industry chain, pure titanium ingots are widely used in many fields such as aerospace, medical equipment, and chemical industry. Diameter: 380mm-960mm (15″-37.8″), length: 2000mm-3000mm (78.7″-118″). Purity after polishing to 99.95%-99.999%.

Titanium Alloy Ingot

Material options of titanium alloy ingots GR5, GR5ELI, GR7, GR9, GR12, GR23, Ti-4Al-2V, Ti-4Al-1.5Mn, etc. Titanium alloy ingots manufactured by Wstitanium through vacuum consumables arc furnace, with diameter 200mm-800mm or as per your requirements, following GB/T-26060-2010, ASTM B977/B977M-19 standards.

Medical Titanium Ingot

Wstitanium produces titanium ingots with diameters of 30 inches (762 mm) and 33 inches (838 mm) through multiple vacuum melting using EBCH (Electron Beam Cold Furnace) and VAR (Vacuum Arc Remelting) furnaces. Titanium 6AL4V (Gr. 5) and 6AL4V ELI (Gr. 23) are the most commonly used types of titanium in medicine.

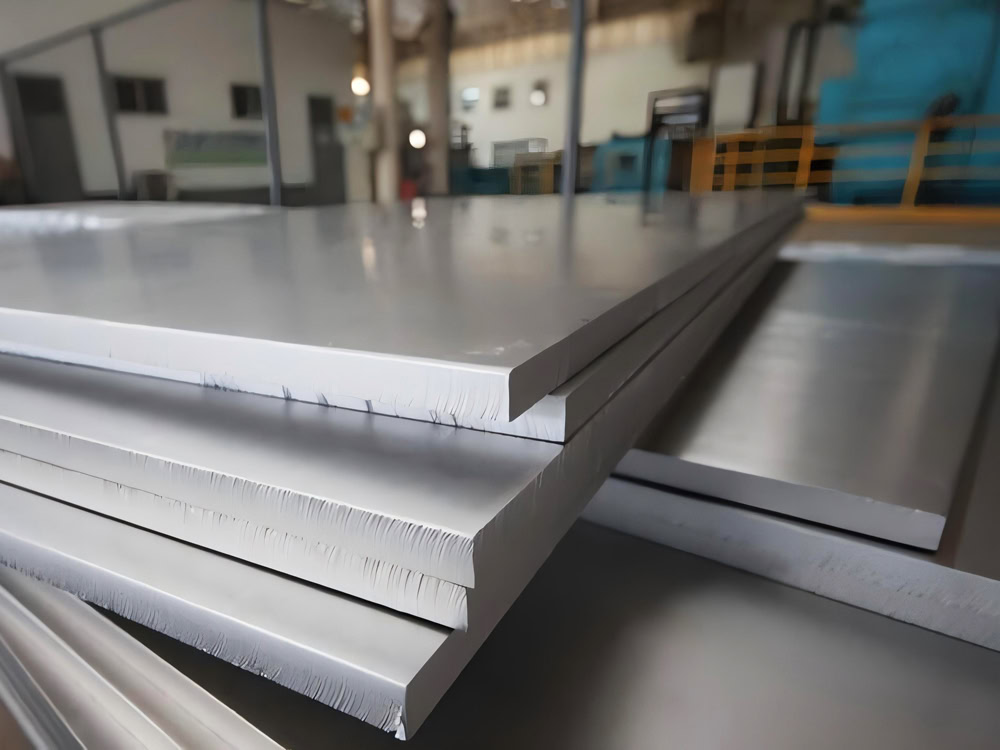

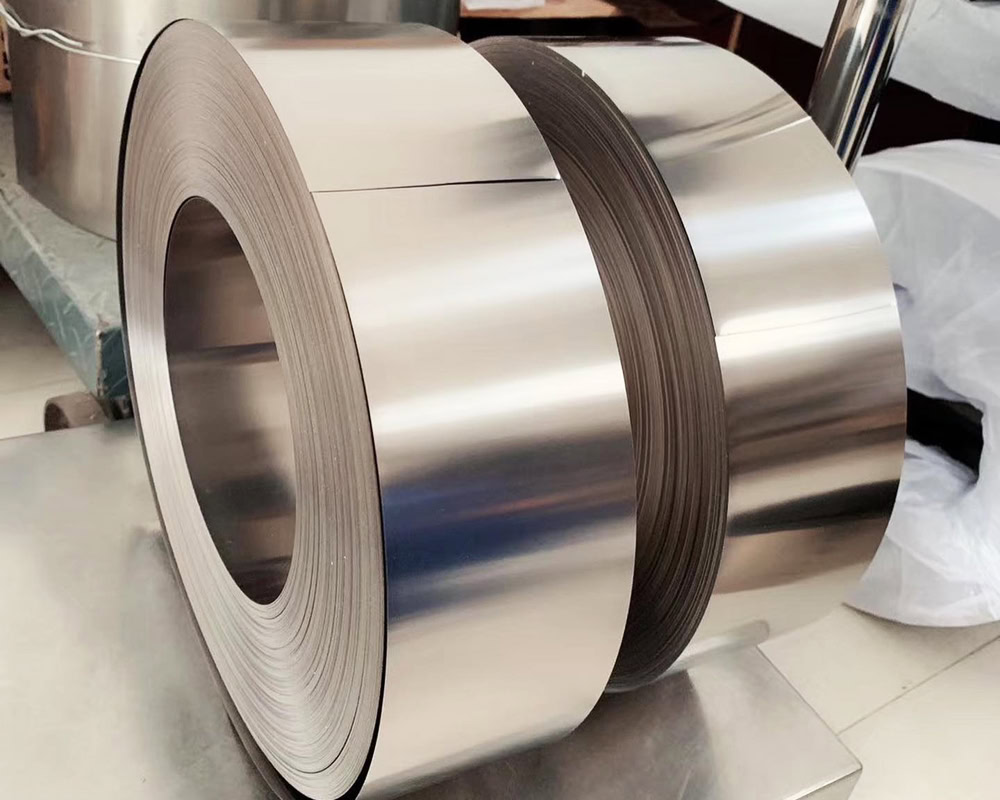

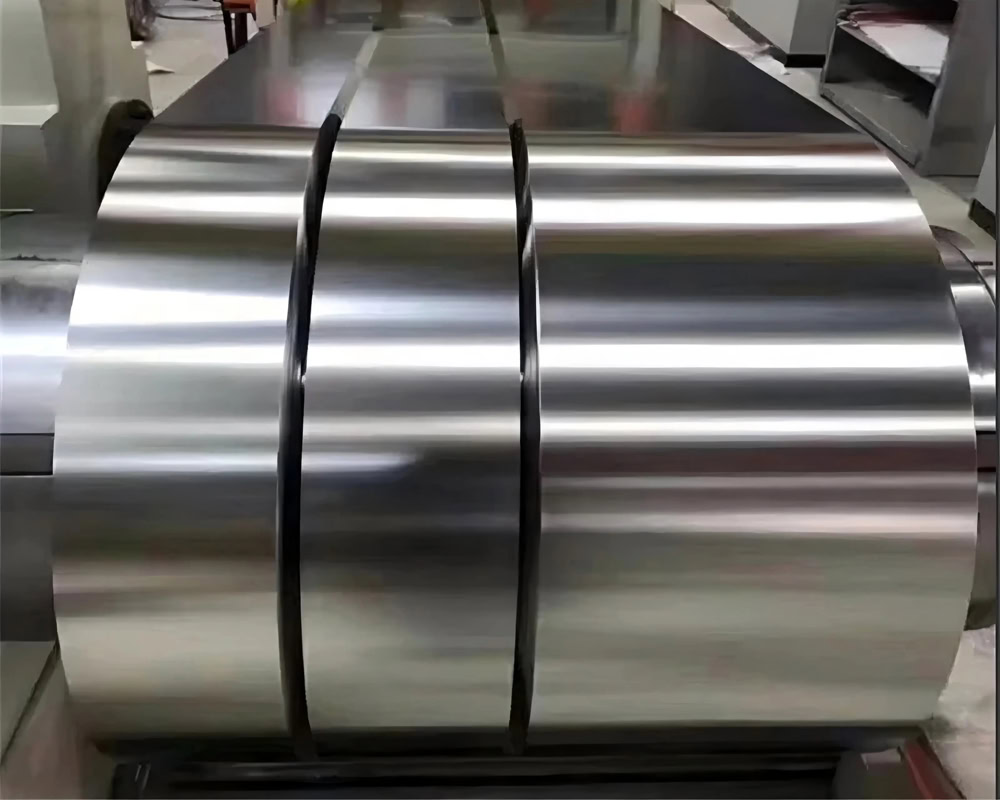

Wstitanium manufactures titanium plates/sheets in grades of GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR12, GR16, GR17, GR23, Ti-6Al-4V ELI, Ti-6-2-4-2, Ti-15-3-3-3. The thickness of titanium plates ranges from 0.3-250 mm. Width 100-1000 mm, length 200-1500 mm. Surface options: polished, milled, pickled, painted, brushed or sandblasted finishes. Follow ASTM B265, ASTM SB265, AMS 4902, ASME SB265 and DIN 17860 standards.

Titanium Plates

Wstitanium uses sponge titanium with a purity of more than 99.5% as the main raw material to ensure the quality of titanium plates. After vacuum furnace melting, forging, hot rolling or cold rolling, heat treatment and surface treatment technology. The thickness ranges from extremely thin 0.1mm to extremely thick 35mm or even thicker. Width 300mm, 400mm, 1000mm, etc. Length: 800mm, 1000mm, etc.

Titanium Sheet

Wstitanium selects high-purity sponge titanium or titanium ingots as starting materials to manufacture titanium sheets. After smelting in a vacuum consumable arc furnace or electron beam melting furnace, cold rolling or hot rolling, pickling, a sheet with a thickness of 0.03-8mm is obtained. Common titanium sheet thickness is 0.05mm-4.76mm. The maximum length is up to 6000mm.

Cold Rolled Titanium Plate

Cold-rolled titanium plate refers to the annealed plate being sent to the cold rolling mill for rolling. The cold rolling mill generally uses a four-roll or six-roll mill. For titanium plates with high precision requirements, consider a twenty-roll Sendzimir mill. Common cold-rolled titanium plate thickness: 0.1mm-4.0mm, etc. Thickness tolerance ±0.02mm to ±0.05mm. Width: 100-2000mm. Length: 100-8000mm.

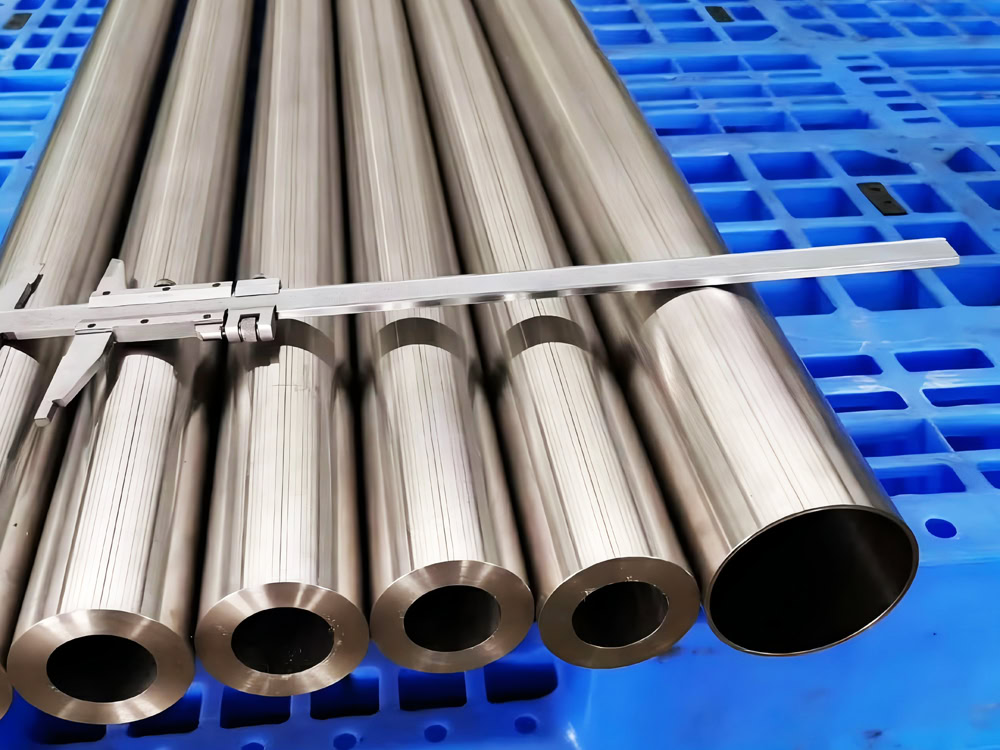

Wstitanium manufactures titanium tubes with a wide range of outer diameters, from capillaries to larger diameter industrial tubes. Common outer diameter specifications range from 0.5mm to 610mm. For some special needs, we also provide you with customized manufacturing solutions. Titanium tubes with smaller outer diameters (such as 3-20mm) are often used in the medical field, such as catheters and stents for medical devices; titanium tubes with medium outer diameters (20-200mm) are widely used in the chemical, petroleum, power and other industries for conveying various media; titanium tubes with larger outer diameters (200-610mm) are mostly used in marine engineering, construction and other fields, such as pipelines for seawater desalination equipment, support pipes in building structures, etc.

Pure Titanium Tube

Wstitanium manufactures pure titanium tubes with an outer diameter of 6-210 mm, a wall thickness of 3mm ~ 30mm, and a length of 500mm ~ 15000mm. Titanium tubes are delivered in straight or U-bend form. The most commonly used pure titanium tube is Gr2, which is used in heat exchangers, reaction and pressure vessels in the chemical, aerospace and marine industries.

Titanium Alloy Tube

Wstitanium manufactures titanium alloy tubes with grade options of GR5, GR7, GR9, GR12, GR23, etc. After smelting, forging, rolling, heat treatment, and surface treatment, the tolerance of titanium alloy tubes less than 6000mm is 0 to + 6mm; the tolerance of lengths greater than or equal to 6000mm is 0 to + 10mm.

Medical Titanium Tube

Wstitanium provides you with competitively priced medical grade titanium tubes and titanium capillaries. Titanium capillaries are micro hollow tubes made of pure titanium or titanium alloys. Follow standards: ASTM B337/ASME SB337, ASTM B338/ASME SB338, ASTM B861/ASME SB861. Material: Gr.1, Gr.2, Gr.9. Outer diameter: 0.2 – 8 mm Wall thickness: 0.05 -2 mm.

Titanium Pipe

Wstitanium provides seamless and welded titanium pipes for chemical plants, pulp mills, energy, marine, with material options of GR1, GR2, GR3, GR4, GR7, GR9, GR12, GR16, GR17, etc. Seamless titanium pipes are available in lengths up to 18 meters with diameters ranging from 0.4 mm to 340 mm. Welded titanium pipes are available in lengths of 15 meters with diameters ranging from 90 mm to 5,000 mm. Titanium welded pipes are welded in a single continuous welding line and are 100% X-ray tested and liquid penetrant tested!

Seamless Titanium Pipe

Titanium seamless pipes are made through processes such as titanium rod oblique rolling and perforation, hot rolling or cold rolling, CNC turning, etc. They have the advantages of no welds, high strength, good pressure resistance, uniform internal structure, and strong fatigue resistance.

Chemical Titanium Pipe

Chemical titanium pipes generally use Gr2 and Gr7. Gr2 has a relatively low price and good comprehensive corrosion resistance, and is suitable for conventional chemical environments. Gr7 has more advantages in some highly corrosive chemical media due to the palladium element.

Welded Titanium Pipe

Titanium welded pipes are made by rolling titanium coils or wide sheets into tubes. The main titanium alloy grades are Gr.1, Gr.2 and Gr.12. The strength of titanium welded pipes is lower than that of seamless titanium pipes, and they are widely used in chemical industry and seawater desalination.

Wstitanium offers various diameters of grade 2, grade 4, grade 5, grade 7 and grade 23 titanium wires with tight tolerances and α values (conductive resistance). Titanium wire size: minimum diameter: 1.60 mm | maximum diameter 4.78 mm. Wstitanium manufactures high-purity uniform-shaped titanium wires with the highest density. Generally divided into: pure titanium wire, titanium alloy wire, eyeglass wire, straight line, welding wire, hanging wire, coil wire, medical wire, titanium-nickel alloy wire, etc. Each titanium wire has different uses. For example, pure titanium eyeglass wire is mainly used to make eyeglass brackets. Titanium hanging wire is used to hang heavy objects. Titanium-nickel alloy wire is often used as memory alloy material.

Pure Titanium Wire

- Diameter: +0mm-5.0mm

- Grade: Gr1, Gr2, Gr3, Gr4

- Length: coil or as required

- Surface: black, pickled, polished

- Technology: hot rolling, cold rolling

Titanium Alloy Wire

- Length: 500-3000mm

- Diameter: Ø0.1mm - Ø8 mm

- Grade: Gr5,Gr7, Gr9, Gr12, Gr23

- Standard: ASTM B863 ASTM F136

- Allowable Deviation: -0.125mm~ -0.14mm

Welding Titanium Wire

- Length: Customized

- Diameter: Ø0.05mm - Ø10 mm

- Application: MIG or TIG welding

- Allowable Deviation: -0.1mm~ -0.14mm

- Grade: Pure Titanium and Titanium Alloys

Wstitanium’s technology for manufacturing titanium foil: ingot melting—coating—heating—forging slab—planing and cleaning—grinding—inspection—surface spraying or coating—heating—hot rolling and heat setting—interruption and sizing—surface grinding—quenching—heating—hot rolling—alkali washing —- surface grinding—intermediate annealing—alkali washing—cold rolling—degreasing and deoiling—finished product annealing—alkali washing—sampling—finished product cutting—inspection, flaw detection (thin plate)–finished product correction–packaging–storage.

Pure Titanium Foil

- Length (mm):Customized

- Width (mm):10-200

- Grade: Gr 1, Gr 2, Gr 3

- Standard:ASTM B265

Titanium Alloy Foil

- Grade: Gr 5, Gr 7, Gr 9, Gr 12, G23

- Thickness: 0.01 mm to 0.100 mm

- Surface: smooth mirror or matte

- Width: up to 650 mm.

Cold Rolled Titanium Foil

- Multi-roll mill

- Titanium or titanium alloy

- Foil rolled to 0.05-0.003 mm thickness

- Width: up to 650 mm.

Wstitanium is a Titanium Heat Exchanger manufacturer in Titanium Grade 1, Titanium Grade 2, Titanium Grade 5 and Titanium Grade 7. Straight Tube, U-Tube, Kettle, Coil Type Titanium Heat Exchangers are used in Chemical, Oil, Gas, Aquaculture, Swimming Pools etc. Before shipment, they will go through NDT, pressure, X-ray, DP, UT, MT, PMI, helium leak inspection, etc. These are done under the observation and guidance of quality experts.

Pure Titanium Heat Exchanger

- Grade: Gr1, Gr2

- Diameter: 4~1140mm

- Length: less than 15m

- Wall thickness: 0.2 ~ 4.5 mm

Titanium Alloy Heat Exchanger

- Grade: Titanium 7, 9 and 12

- Diameter: Up to 120 inches

- Length: Up to 300 inches

- Weight: Up to 200 tons

Titanium Condenser

- Grade: Gr2/Gr12

- Diameter: OD12--OD89mm

- Wall thickness: 0.6mm-2mm

- Application: seawater, metallurgy, chlor-alkali