Titanium Rolling Forging Services

Wstitanium focuses on titanium rolling manufacturing. With its persistent pursuit of technology and strict control of quality. It has gradually grown from a small machining enterprise to a leading titanium rolling company in China.

- Competitive Price

- ISO 9001 & ISO 13485

- Cold Rolling, Hot Rolling

- Full-Size Quality Inspection Report.

- Titanium Plates, Rods, Tubes, Wires, Foils

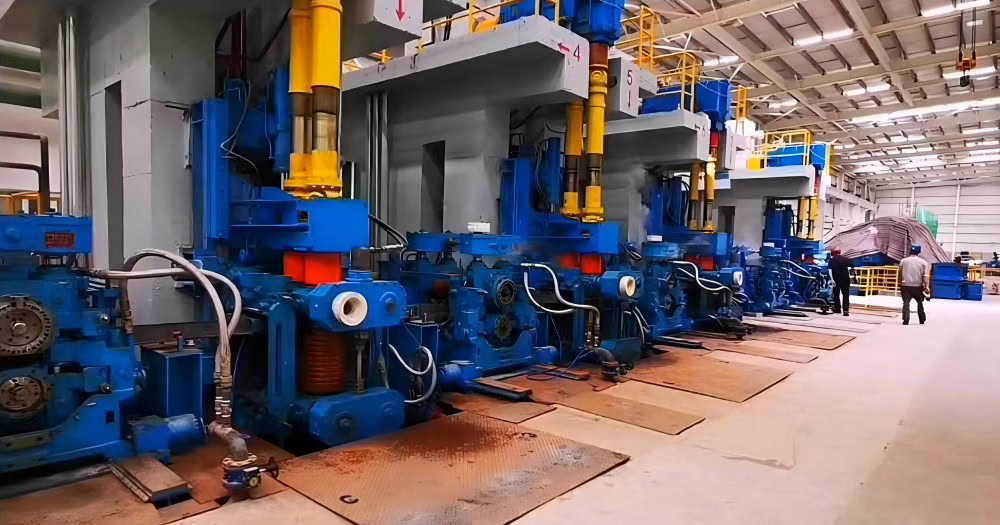

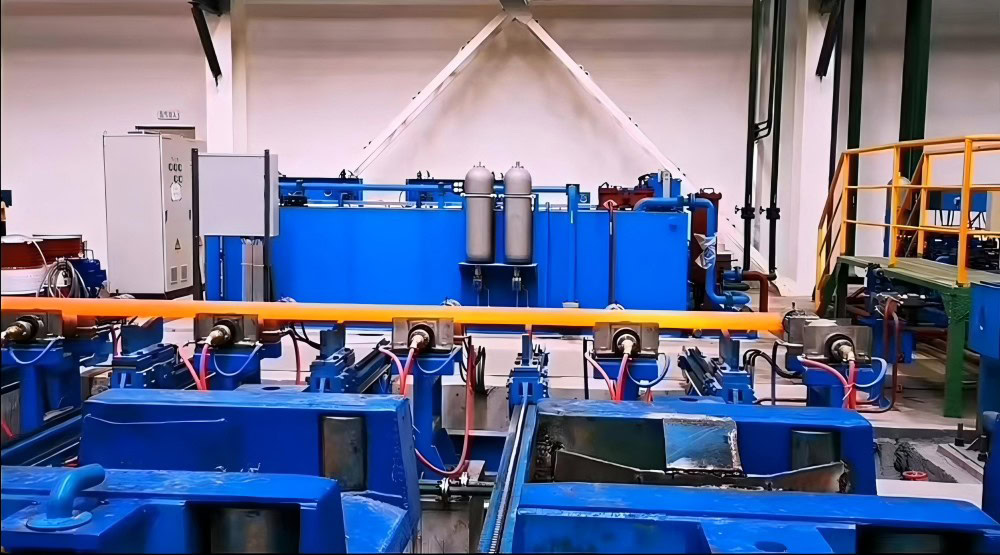

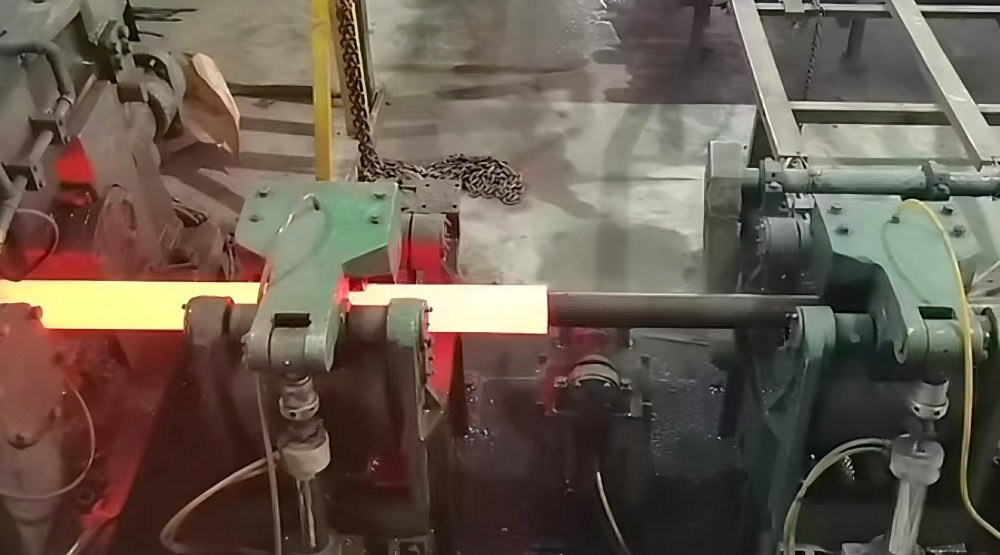

WSTITANIUM FACTORY

Our Powerful Facilities

Titanium Rolling Forging Manufacturer

Titanium rolling plays an important role in the technology of manufacturing titanium products. Titanium products with specific shapes, sizes and properties are obtained by applying pressure to plastically deform titanium billets. From high-end parts in aerospace to implantable devices in daily medical care, titanium rolled products are widely used in various fields, promoting the technological progress and development of related industries. As a leading titanium rolling company in China, Wstitanium provides you with high-quality titanium bars, titanium wires, titanium plates, titanium foils, titanium tubes, etc.

What is Titanium Rolling?

Titanium rolling is a process in which rotating rollers apply pressure to titanium billets to cause them to undergo plastic deformation, thereby changing their shape, size and internal structure. During the rolling process, the pressure of the rollers compresses the titanium billet in the thickness direction and extends it in the length and width directions, following the law of constant volume. According to the rolling temperature, it can be divided into hot rolling and cold rolling.

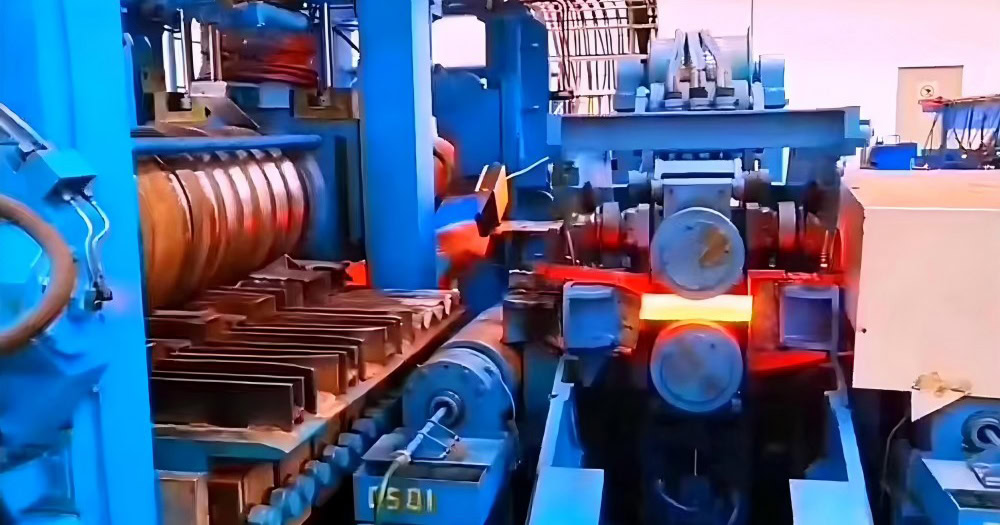

Hot Rolling

Hot rolling is carried out above the recrystallization temperature of titanium. Usually, the hot rolling temperature range of titanium and titanium alloys is 800-1100℃. Under the strong pressure of the rollers, the internal cast structure of the billet is broken and refined, and the coarse grains are gradually transformed into a fine and uniform grain structure, thereby improving the comprehensive performance of the titanium material. Hot rolling can effectively eliminate the casting defects inside the titanium billet, such as pores and shrinkage, and improve the density of the material. At the same time, by controlling the rolling parameters, the titanium material can obtain good mechanical properties, such as high strength and toughness.

Cold Rolling

Cold rolling is a rolling process carried out at room temperature or below the recrystallization temperature of titanium. During the cold rolling process, since there is no recrystallization process, titanium is mainly deformed by the slip of dislocations. As the deformation increases, the resistance to dislocation movement increases, causing titanium to harden, that is, the strength and hardness are significantly improved, while the plasticity and toughness decrease. In order to obtain good product performance, annealing is usually required to eliminate work hardening and restore the plasticity of the material. Cold rolling can produce titanium products with precise control of dimensions and extremely high surface finish.

Advantages of titanium rolling

Improve Titanium Performance

Rolling can break the coarse grains of titanium cast structure, making it refined and evenly distributed. Eliminate internal defects such as pores and shrinkage, improve material density and uniformity, and enhance comprehensive performance. After rolling titanium alloy, its yield strength can reach 800-1200MPa, while the elongation can still be maintained between 10%-20%.

Precise Size and Shape

According to different rolling processes and molds, titanium products of various specifications and shapes can be manufactured. Cold rolling can accurately control the thickness, width and flatness of the plate, produce high-precision titanium foil, and the thickness tolerance can be controlled within a very small range. Through hole rolling, profiles with specific cross-sectional shapes can also be manufactured.

Improve Production Efficiency

Rolling is a continuous and large-scale production process that can efficiently process billets into required products. The output per hour can reach several tons or even tens of tons. Compared with other processing methods, the rolling speed is fast and the output is high, which is suitable for large-scale production, reducing production costs and improving economic benefits.

Cost Saving

As the titanium material after rolling has precise dimensions, good surface quality and mechanical properties, it reduces the subsequent processing steps and difficulty, thus reducing the total cost. For example, high-precision cold-rolled titanium plates can be directly used to manufacture the housing of electronic equipment without additional milling, grinding, etc., saving time and cost.

Wstitanium Rolled Titanium Products

Wstitanium has invested in world-class titanium rolling equipment, including high-precision rolling mills, advanced heating and cooling systems, and automated plate processing production lines. Among them, the 12-roll rolling mill has extremely high rolling accuracy and strong rolling force, and can stably produce titanium plates, titanium plates, titanium foils, titanium rods, titanium wires, titanium seamless tubes, and titanium rings with a tight tolerance of ±0.002mm, meeting the stringent requirements for dimensional accuracy in aerospace, high-end electronics and other fields. At the same time, the advanced induction heating furnace can achieve rapid and uniform heating of titanium billets, ensuring the fluidity and uniformity of the metal during the rolling process, and effectively improving product quality.

Wstitanium rolled titanium plates cover a variety of specifications and grades, with thicknesses ranging from 0.1mm to 100mm. Excellent strength, plasticity and corrosion resistance, widely used in the aerospace field, such as manufacturing aircraft fuselages, wing skins and other structural components, effectively reducing the weight of aircraft; in the chemical industry, used to make reactors, storage containers, pipelines and other equipment, can resist the erosion of various corrosive media.

Wstitanium’s titanium bars have a diameter range of 0.2mm to 600mm. The bars have good comprehensive mechanical properties and are widely used in the medical field, such as manufacturing artificial joints, fracture fixation devices and other implants; in the machinery manufacturing industry, titanium bars are used to manufacture key components such as shafts and screws of high-end machinery and equipment, and can withstand high-load and high-speed working conditions.

Titanium Strip

Wstitanium titanium strips have a thickness of 0.01mm-4.0mm and a width of 20mm-1400mm, which can meet the needs of different fields. For example, it is used to make electronic equipment housings, capacitor electrodes and flexible circuit boards. The housing protects the internal components and has both heat dissipation and electromagnetic shielding functions; the electrodes improve the performance of the capacitor; and the flexible circuit boards realize the miniaturization and multifunctionality of electronic equipment.

Wstitanium titanium foil is extremely thin, with the thinnest reaching 0.002mm, and has excellent flatness and surface finish. Titanium foil can be used to manufacture shielding materials for electronic components, effectively shielding electromagnetic interference and improving the performance stability of electronic equipment; in the battery industry, titanium foil as a carrier of electrode materials can improve the charging and discharging performance and cycle life of batteries.

Wstitanium titanium wire covers a wide range of specifications, such as φ0.1mm-φ13.0mm, including the commonly used eyeglass titanium wire φ1.0mm-φ6.0mm. For example, it is used to make sutures, orthodontic wires and heart stents. Sutures can gradually degrade after wound healing, reducing the risk of secondary surgery; orthodontic wires can help with precise tooth correction with good elasticity and corrosion resistance.

Wstitanium rolled titanium pipes include seamless pipes and welded pipes, which have excellent corrosion resistance, pressure resistance and sealing. The wall thickness can be customized according to your needs. In the field of marine engineering, titanium pipes are widely used in heat exchange tubes for desalination equipment, oil and gas pipelines for offshore oil and gas production, etc., and can operate stably for a long time in harsh marine environments.

Quality Inspection

Wstitanium has established a complete and strict quality control system, starting from the purchase of raw materials, and strictly testing the chemical composition and physical properties of each batch of titanium sponge to ensure that it meets high standards. During the production process, advanced online testing equipment is used to monitor and adjust the temperature, pressure, plate shape and other parameters in the rolling process in real time to ensure the stability and consistency of the production process. Through a variety of advanced testing methods, such as ultrasonic flaw detection, metallographic analysis, mechanical property testing, etc., each product is fully tested to ensure that the product quality is foolproof.

Wstitanium is well aware of your diverse needs for titanium product specifications, performance and application scenarios, so it is committed to providing customized solutions. Whether it is customizing high-strength, lightweight titanium alloy plates for aerospace, or manufacturing high-precision, high-flatness titanium foils for the electronics industry, Wstitanium can meet your personalized needs with rich experience and professional technology.