Titanium Rods / Bar at Competitive Prices In China

Titanium rods, inheriting the advantages of titanium, play an increasingly critical role with their unique physical and chemical properties and excellent performance. They are widely used in many fields such as aerospace, medical equipment, chemical industry, marine engineering, sporting goods, etc., and have become an important support for promoting technological progress and upgrading in various industries.

- Gr.1

- Gr.2

- Gr.3

- Gr.4

- Gr.5

- Gr.7

- Gr.9

- Gr.10

- Gr.11

- Gr.12

- Gr.16

- Gr.17

- Gr.23

- Gr.27

- Gr.29

- Surface: Pickled or Polished

- Vickers Hardness:830–3420 MPa

- Form: Round,Square, Hexagonal Etc

- Customization available upon request

- End: Plain End, Beveled End, Threaded

Your Resource of Titanium Rod Factory - Wstitanium

As a material with excellent performance, titanium rods play an irreplaceable role in many fields such as aerospace, medical equipment, chemical industry, and marine engineering. From the titanium grade characteristics and type classification of titanium rods, to the complex manufacturing process, to the wide range of application cases and future development trends, every link reflects the unique value and significance of titanium rods. In the manufacturing of titanium rods, Wstitanium strictly controls raw materials, advanced manufacturing processes, comprehensive quality inspections, and perfect packaging and transportation management to ensure high-quality titanium rods to meet your diverse needs.

- Standard : ASTM B348 / ASME SB348

- Chamfering:Available in 30°, 45° & 60°

- Size : Dia6.0-600mm x Length1000-6000mm

- Dimensions : EN, DIN, JIS, ASTM, BS, ASME, AISI

- Certified: ISO9001:2015 & ISO13485:2016, SGS, TUV

- Tolerance : H8, H9, H10, H11, H12, H13K9, K10, K11, K12

- Finish : Black, Bright Polished, Rough Turned, Matt Finish

- Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging

α Titanium Rod

α titanium rod has good thermal stability and welding performance. The typical one is Ti-5AL-2.5Sn, which can still maintain high strength and oxidation resistance at about 500℃.

α + β Titanium Rod

α + β titanium rod is the most popular one with Gr5 (Ti – 6Al – 4V). It has excellent comprehensive performance, high strength, and tensile strength of more than 900MPa.

β Titanium Rod

β titanium rod, mainly β phase, has high strength, high toughness and good formability. It is used to manufacture aerospace parts, medical implants, and eyeglass frames.

Titanium Rods for Medical

Titanium rods are non-toxic, non-allergic, and have good compatibility with human tissues, making them ideal materials for manufacturing medical devices. They are used to manufacture implants such as artificial joints, bone plates, screws, pacemaker housings, vascular stents, etc.

Titanium Rods for Chemical

Titanium rods have excellent corrosion resistance and are used to manufacture chemical pipelines, reactors, heat exchangers, storage tanks, etc. Titanium rods play an important role in highly corrosive chemical industries such as the chlor-alkali industry, sulfuric acid industry, and nitric acid industry.

Titanium Rods for Marine

Titanium rods are used to manufacture ship propellers, seawater valves, propeller shafts, platform support columns, frame structures, etc. with their excellent seawater corrosion resistance and high strength, and withstand the combined effects of waves, sea breezes, and seawater corrosion.

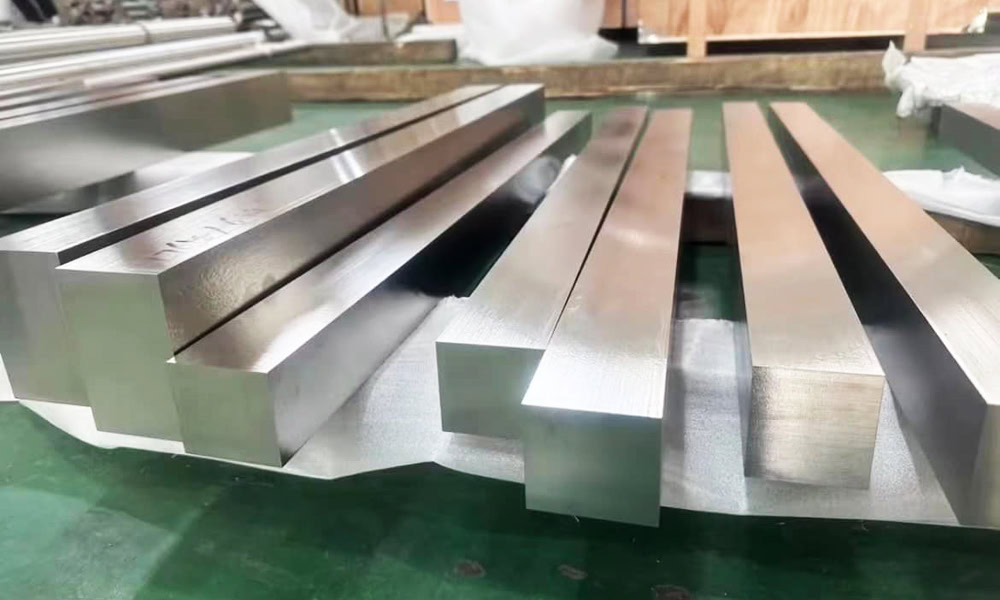

Square Titanium Rod

The cross section of square titanium rod is square. When it is necessary to withstand large shear forces and bending moments, the square cross section of square titanium rod can provide a larger bending and shear section modulus.

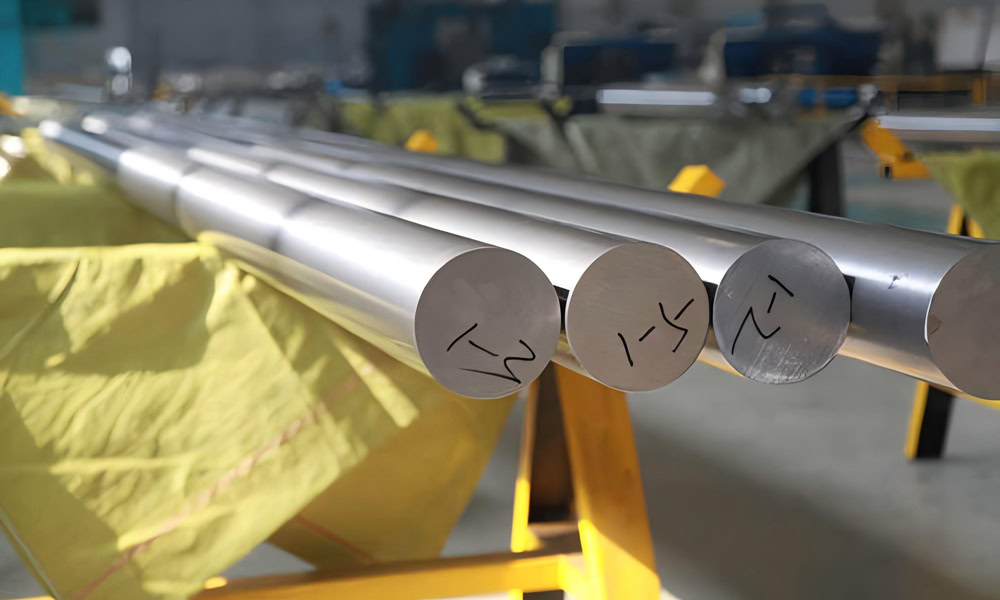

Round Titanium Rod

Round titanium rod is the most common titanium rod shape, with a circular cross section and good symmetry and mechanical properties. It is often used to manufacture shaft parts, such as motor shafts, machine tool spindles, etc.

Custom Titanium Rods

Customized titanium rods have a diameter of 0.5-400 mm and a length of up to 3000 mm. Its manufacturing integrates forging, heat treatment, surface treatment, etc. to ensure accurate dimensions and excellent performance.

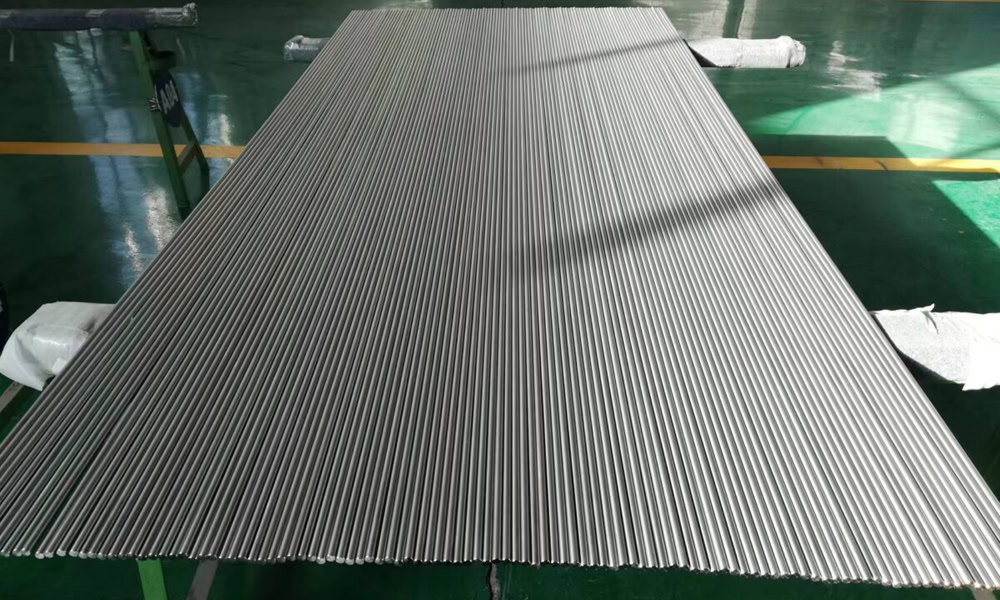

Small diameter titanium rod

Small diameter titanium rods usually refer to those with a diameter less than 10mm. They can be used to manufacture pins, connectors, and medical minimally invasive surgical instruments, such as puncture needles and micro-scalpels.

Medium diameter titanium rod

Medium diameter titanium rods generally have a diameter of 10-100mm and can be used to manufacture chemical pipelines, support structures for reactors, and propulsion shafts for ships and support columns for offshore platforms.

Large diameter titanium rod

Large diameter titanium rods have a diameter greater than 100mm and are used in nuclear power, marine engineering, heavy machinery, etc. For example, columns for large pressure vessels, drilling platforms, and keels and main shafts for large ships.

Wstitanium knows that the quality of raw materials is the basis for determining the quality of titanium rods, so it has established strict standards and processes for the selection of raw material suppliers. First, check whether there are obvious defects such as cracks, pores, slag inclusions, etc. on the surface of titanium ingots or titanium billets.

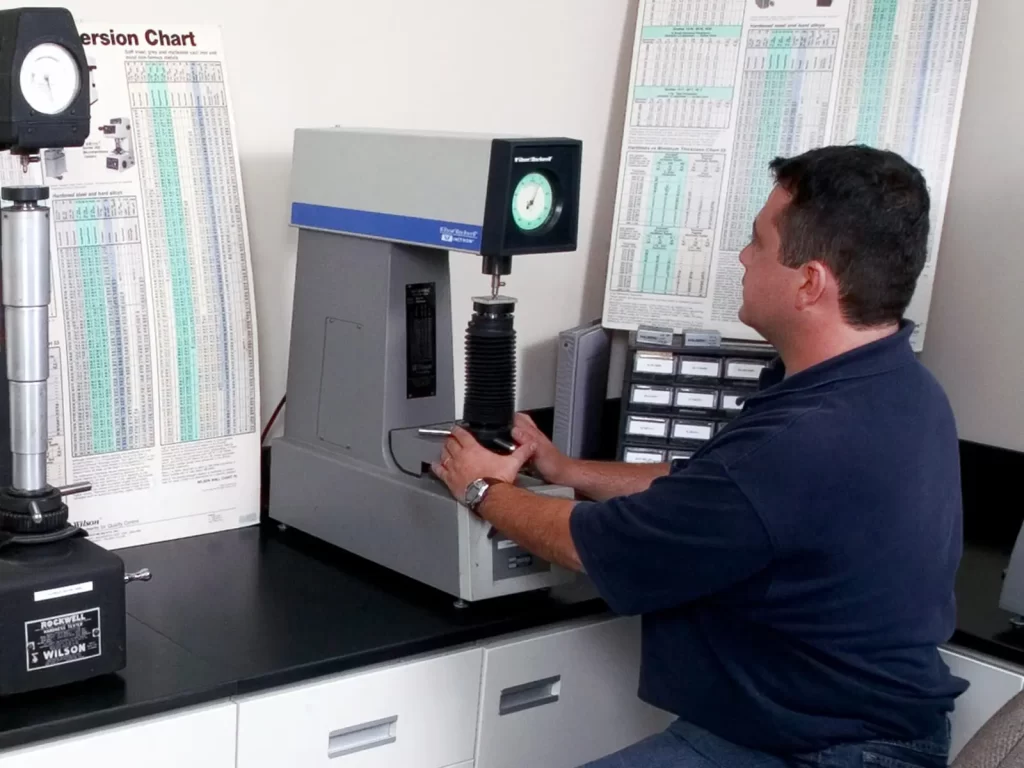

Then, chemical composition analysis is carried out, and advanced spectral analysis equipment (such as direct reading spectrometer, inductively coupled plasma mass spectrometer, etc.) is used to accurately determine the content of various elements in titanium raw materials. Then physical properties testing is carried out, including hardness testing, density measurement, etc. Finally, metallographic structure inspection is carried out. Metallographic specimens are prepared by sampling, and the microstructure of titanium raw materials is observed under a metallographic microscope to check the grain size, distribution uniformity, and whether there are abnormal structures. The quality of the metallographic structure directly affects the mechanical properties of titanium rods. Only raw materials with metallographic structures that meet the requirements can enter the subsequent manufacturing links.

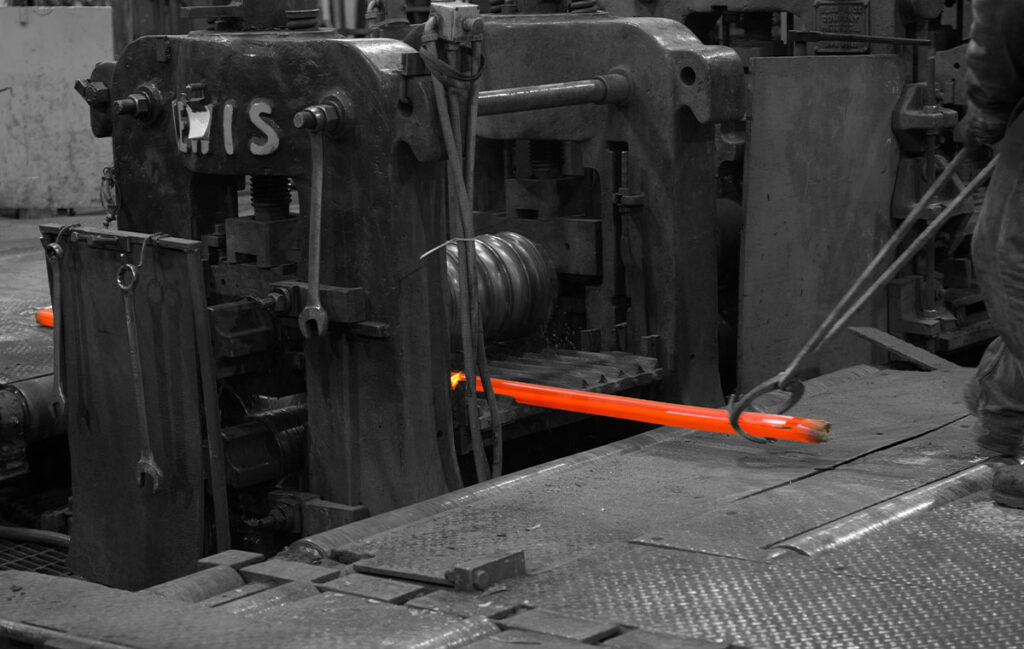

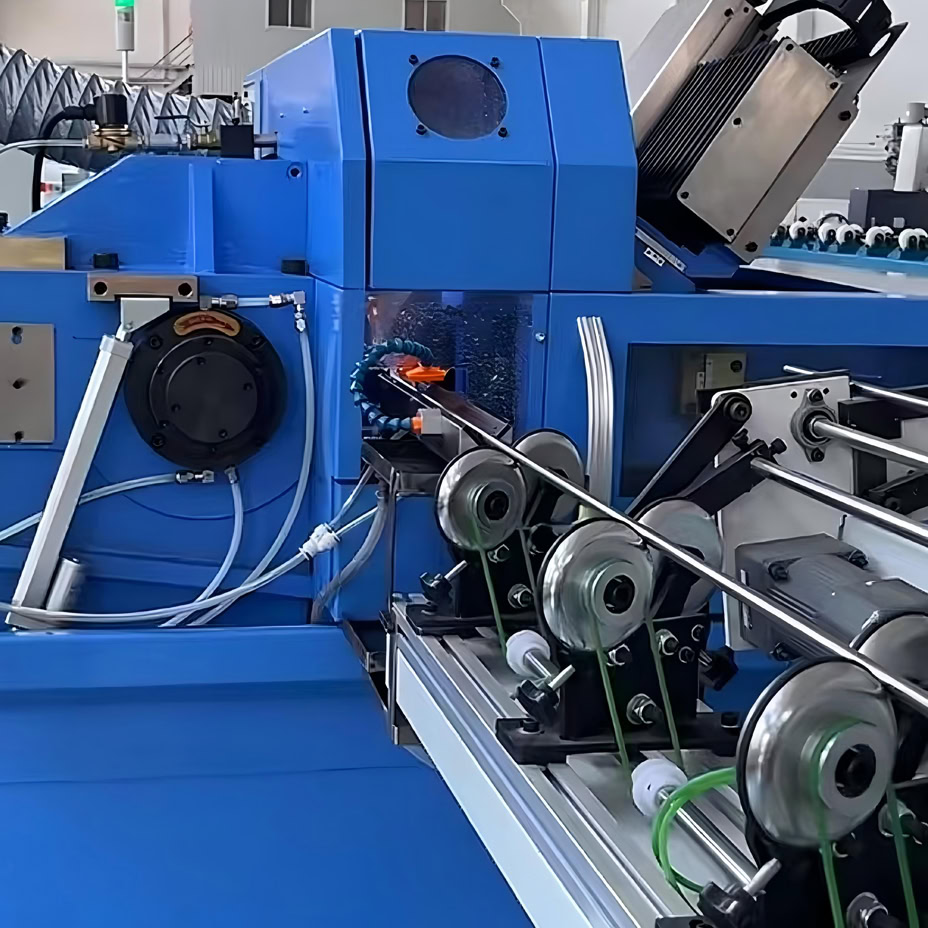

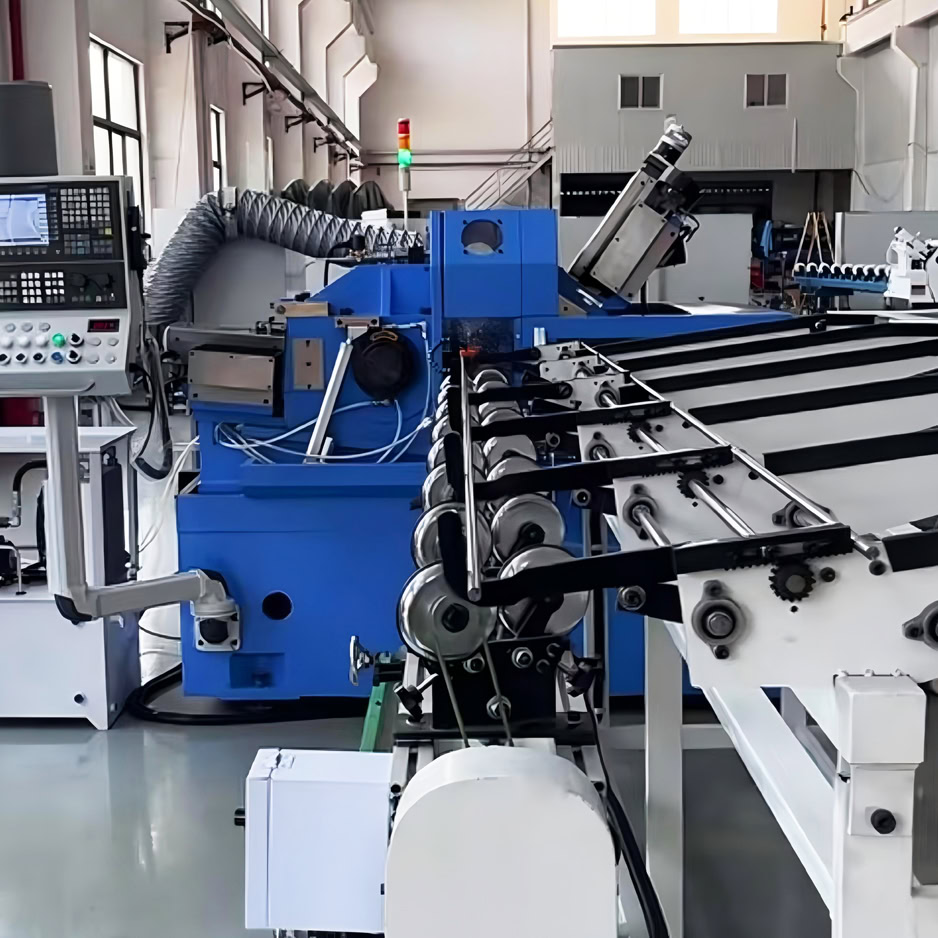

Wstitanium forging is divided into several stages. The first is heating, heating the ingot or billet to the appropriate temperature. Different titanium alloy grades have different forging temperature ranges. During heating, advanced heating equipment (such as electric heating furnace, gas heating furnace, etc.) is used, and equipped with a high-precision temperature control system to ensure that the titanium billet is evenly heated to the target temperature to avoid local overheating or overcooling.

After heating is completed, it enters the forging stage. According to the specifications and shape requirements of the titanium rod, select appropriate forging equipment, such as free forging hammer, die forging press, etc. In free forging, the shape and size of the titanium billet are changed by multiple upsetting and drawing, and its internal structure is improved. For example, upsetting breaks the coarse original grains and refines the grains. Drawing improves the streamline distribution of the titanium billet and improves the mechanical properties. In die forging, the heated titanium billet is placed in the mold cavity, and the press applies pressure to form the titanium billet in the mold cavity to obtain a titanium bar billet of the desired shape and size. Die forging can produce titanium bars with complex shapes and high dimensional accuracy.

Before rolling, the forged titanium bar blank needs to be pre-treated, such as surface cleaning and straightening. Surface cleaning is to remove impurities such as scale and oil from the blank to prevent these impurities from entering the titanium bar during rolling. Straightening is to straighten the bent blank to ensure that the blank can be smoothly rolled through the rolling mill.

The rolling mill rolls are designed and adjusted according to the shape and size requirements of the titanium bar, and the diameter of the titanium bar is gradually reduced or its cross-sectional shape is changed through multiple rolling passes. During rolling, parameters such as rolling temperature, rolling speed, and roll pressure are monitored and controlled in real time. For example, as rolling progresses, the temperature of the titanium bar will gradually decrease. When the temperature drops to a certain level, the titanium bar needs to be reheated to ensure the smooth progress of the rolling process and the quality of the titanium bar. At the same time, the deformation and dimensional accuracy of the titanium bar are controlled by adjusting the roll pressure and speed.

Cold rolling is mainly to further improve the dimensional accuracy and surface quality of the titanium bar on the basis of hot rolling. Before cold rolling, the hot-rolled titanium rod is annealed to eliminate hardening and restore plasticity. During cold rolling, a high-precision cold rolling mill is used to gradually reduce the size of the titanium rod through multiple cold rolling passes, and the surface finish and dimensional accuracy of the titanium rod are improved through tension control, lubrication and other measures. During the cold rolling process, the size and surface quality of the titanium rod are tested in real time, and the rolling parameters are adjusted in time to ensure that they meet quality requirements.

Extrusion

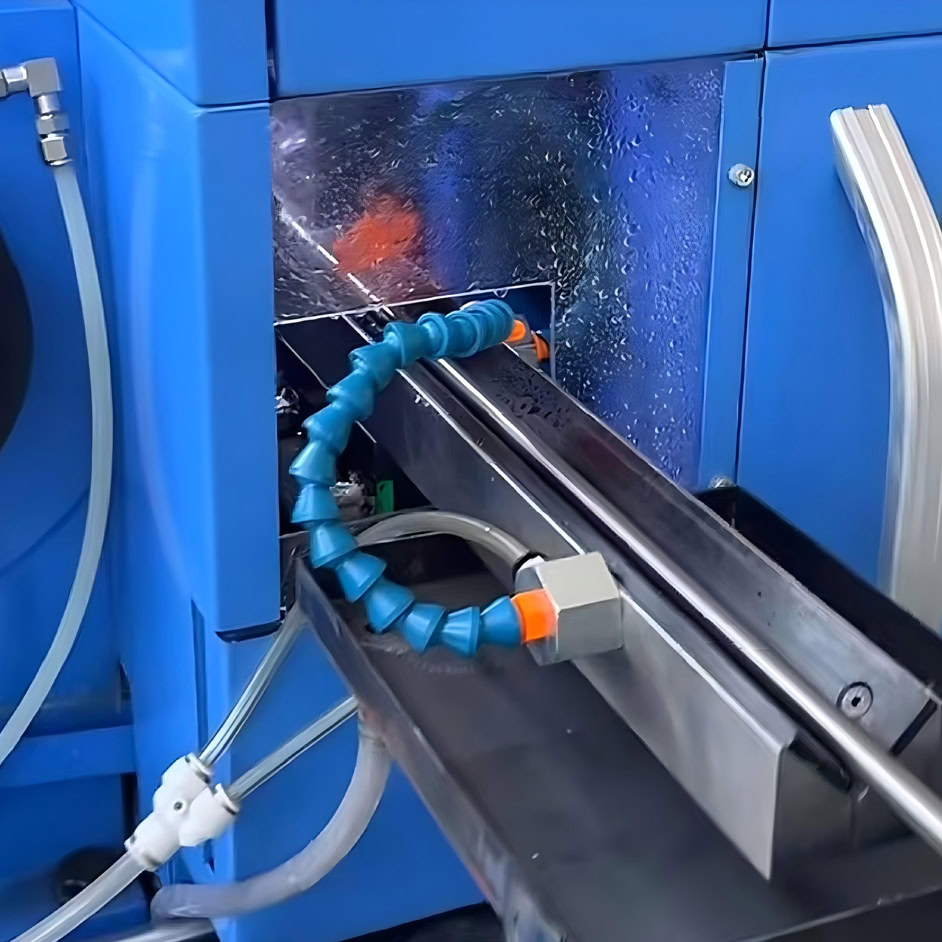

Extrusion is designed and manufactured according to the shape and size requirements of the titanium rod. In the mold design, the fluidity and deformation resistance of the titanium alloy are considered, and the structure and size parameters of the mold are optimized to ensure that the titanium rod can be smoothly extruded and obtain the required shape and size.

The pre-treated titanium billet is placed in the extrusion barrel, and pressure is applied through the extrusion rod to extrude the titanium billet from the die hole of the mold. In extrusion, it is crucial to control parameters such as extrusion temperature, extrusion speed and extrusion force. Excessively high extrusion temperature will cause severe oxidation on the surface of the titanium rod and coarse grains. Extrusion temperature that is too low will increase the extrusion force and easily cause defects such as cracks. Wstitanium controls the extrusion temperature within a suitable range by precisely controlling the heating system and cooling system.

Heat Treatment

Heat treatment is a key technology to optimize the performance of titanium rods. It changes its internal structure to meet different application requirements. Annealing eliminates stress, refines grains, and improves the plasticity and toughness of titanium rods. Quenching and aging treatments significantly improve the strength and hardness of titanium rods, enabling them to play a high-performance advantage in aerospace, high-end machinery manufacturing and other fields. Solution treatment can enhance the solubility of alloy elements and improve comprehensive mechanical properties.

In heat treatment, precise control of parameters such as temperature, time, and cooling rate is crucial. Different types of titanium alloys (such as α, β, and α+β) require different heat treatment technologies due to differences in phase structure.

Surface Treatment

Surface treatment is to improve the surface quality of titanium rods by mechanical machining. Common methods include grinding, polishing and CNC turning. Grinding is mainly used to remove defects such as scale, burrs, scratches on the surface of titanium rods to make the surface smoother.

Through turning, milling, etc., the size and shape of titanium rods are precisely machined. It is very important to choose the right tool material, cutting speed, feed rate, cutting depth, etc. Since titanium alloy has poor machinability, it is easy to produce hardening, severe tool wear and other problems. Wstitanium uses advanced tool materials (such as carbide tools, ceramic tools, etc.) and optimized cutting parameters to reduce cutting force and cutting heat, and improve machining accuracy and surface quality.Polishing is to further improve the gloss and finish of the titanium rod surface. For some titanium rods with high surface quality requirements, such as titanium rods for medical devices or titanium rods for decoration, mechanical polishing, electrolytic polishing or chemical polishing will be used.

Quality inspection

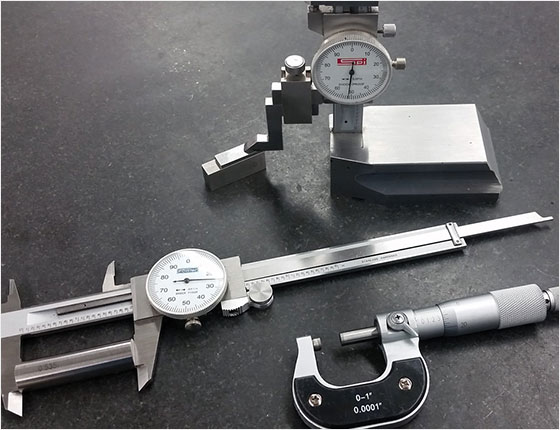

Dimensional accuracy inspection is an important part of ensuring that titanium bars meet design requirements. Wstitanium uses a variety of high-precision measuring instruments to inspect the dimensions of titanium bars. For linear dimensions such as diameter and length, vernier calipers, micrometers, laser rangefinders, etc. are used. Vernier calipers and micrometers are suitable for precise measurement of smaller dimensions, and can be accurate to 0.01mm or even higher. Laser rangefinders are suitable for rapid measurement of larger length dimensions, and have the advantages of high measurement accuracy and fast measurement speed.

Mechanical property inspection

Mechanical property inspection is a key indicator for evaluating the quality of titanium rods. Wstitanium mainly conducts tensile tests, hardness tests, and impact tests. Tensile tests are used to determine the mechanical properties of titanium rods, such as tensile strength, yield strength, and elongation. Impact tests are used to determine the impact toughness of titanium rods, that is, the ability of materials to resist damage under impact loads.

Metallographic structure inspection

Metallographic structure inspection can intuitively reflect the internal structure of titanium rods, which is of great significance for evaluating the quality and performance of titanium rods. Wstitanium uses metallographic microscopes and electron microscopes for metallographic structure testing. Under the metallographic microscope, observe the grain size, shape, distribution, and whether there are defects such as segregation, inclusions, and cracks of the titanium rod. According to different titanium alloy grades and standard requirements, judge whether the grain size meets the requirements.

Titanium rods are popular because of their excellent properties. Its density is only 4.51g/cm³, which is about 60% of steel, but it has the same strength as high-strength steel. This “lightweight and high-strength” property makes it an ideal choice in the weight-sensitive aerospace field. At the same time, titanium rods have excellent corrosion resistance and are stable in a variety of corrosive environments such as seawater, humid atmosphere, and oxidizing acids. They have significant advantages in the fields of marine engineering and chemical industry. In addition, titanium also has good biocompatibility, is non-toxic, non-magnetic, and has no allergic reactions. It can be safely implanted in the human body and is a high-quality material for manufacturing medical devices. Wstitanium comprehensively and deeply analyzes the relevant knowledge of titanium rods, from the titanium grade and type of titanium rods to the manufacturing process, etc., to present you with a complete titanium rod knowledge system.