Titanium Screw Manufacturer and Supplier In China

Wstitanium is a leading Chinese manufacturer that provides customized titanium screw solutions for industry. Strict quality inspections are followed, including dimensions, mechanical properties, surface quality and non-destructive testing, to ensure that titanium screws meet high standards.

- 24/7 Online Service

- OEM/ODM Support

- DIN、GB、ANSI、ISO、JIS

- SGS, BV and CE Certificates

- M1.6 – M48

- 8000 Tons Capacity

- 10+ Finishing Options

- 15+ Titanium Grade Options

Respectable Titanium Screw Company in China - Wstitanium

Wstitanium provides reliable titanium screw solutions for customers in various industries with excellent quality, innovative strength and strong manufacturing capabilities. From smelting, forging, rolling, CNC machining, cold or hot upsetting, surface treatment, each process is a condensation of professionalism and focus. Vacuum consumable arc furnace smelting improves the purity of titanium alloy, forging optimizes the organizational structure to enhance performance, and surface treatment gives screws better corrosion resistance and aesthetics.

Strong Manufacturing Capabilities

Wstitanium’s investment in advanced internal equipment is the cornerstone of its strong manufacturing capabilities. The CNC turning center is one of its core equipment, which has high-precision processing capabilities and can perform precise turning operations on titanium alloy materials. When manufacturing titanium screws, the CNC turning center can accurately cut forged titanium alloy bars according to the preset program to produce screws that meet strict dimensional tolerance requirements.

CNC Swiss machine tools are known for their excellent processing performance and versatility, and can achieve complex processing technology. For example, for some special specifications and high-precision customized titanium screws, the CNC Swiss machine tool can complete multiple processes in one clamping through its multi-axis linkage function, greatly improving production efficiency and precision. It can also perform fine processing on the threads of titanium screws to produce high-precision threads, ensuring the connection strength and reliability of the screws.

Titanium Screw Types

Wstitanium manufactures a wide variety of titanium screws with their own characteristics. For example, hexagonal head screws are widely used and easy to operate with a wrench, achieving stable connection of parts in many industries such as machinery, construction, and automobiles. Cross recessed countersunk head screws are favored in electronic equipment, furniture and other fields that pursue a smooth appearance because their heads can sink into the surface of the connected parts. Self-tapping screws have special threads that can be tapped directly on materials without prefabricated holes, making installation efficient. High-temperature resistant screws use technology that can maintain stable performance in high-temperature environments such as aircraft engines and chemical equipment.

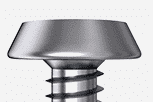

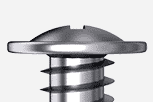

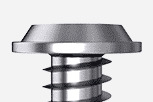

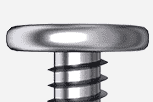

Bugle

C.S.K

H.W.F

Hex

Cap

Oval

Pan

Pan Framing

Truss

Wafer

Hinge

Pancake

Round

Large Wafer

Custom titanium screws are manufactured according to your specific requirements for shape, size, material, performance, etc., and are high-quality titanium screws that meet special needs. With various surface treatments, including Anodizing, Black Phosphated, Grey Phosphated, White Blue Zinc Plated, Yellow Zinc Plated, White Zinc Plated, Black Zinc Plated, Nickel Plated, Hot Dip Galvanized, Black Oxide, Ruspert, Dacromet, and more.

Titanium Screws In Stock

Fine Thread Drywall Screws

Chipboard Screws

Farmer | Roofing Screws

Flat Head Wood Screw

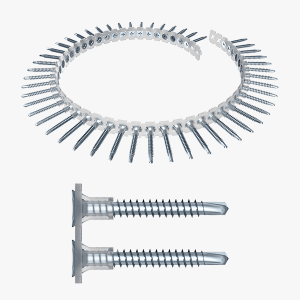

Self Drilling Screw

Self Drilling Drywall Screws

Pan Head Self Drilling Screw

Countersunk Self Drilling Screws

Pan Head Self Tapping Screw

Pan Framing Head Self Drilling Screw

Confirmat Screw

Oval Head Self Tapping Screw

Truss Head Self Tapping Screw

Pan Framing Head Self Tapping Screw

Flat Head Self Tapping Screw

Hex Head Wood Screws

Coarse Thread Drywall Screws

Hex Head Self Tapping Screw

Flat Head Concrete Screws

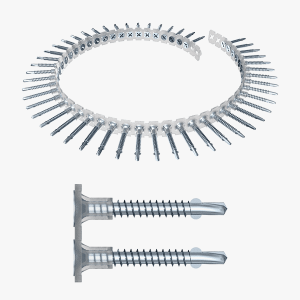

Collated Drywall Screw

Collated Chipboard Screw

Flat Head Machine Screw

Hex Head Self Drilling Screw

Wing Tek Screws

Hanger Bolt

Dowel Screw

Diamond Head Screws

Sandwich Panel Screws

Hex Flange Head Self Drilling Screw

Wing Collated Screw

Collated Self Drilling Screws

Collated Drywall Screw With Drill Point

Titanium Grades for Screw Manufacturing

Wstitanium has in-depth research and application experience on different grades of titanium materials. From the commonly used TC4, TA1, TA2 to the special TC11, Ti-5Al-2.5Sn and other grades, each material has its own unique chemical composition, performance characteristics and application areas.

| Titanium Screw Grade | Main Chemical Composition (%) | Some Titanium Screw Standards | Common Size Range of Titanium Screws |

|---|---|---|---|

TC4(Ti-6Al-4V) | Ti (balance), Al approximately 6, V approximately 4, Fe ≤ 0.3, O ≤ 0.2, N ≤ 0.05, etc. | GB/T 22578 (General Technical Conditions for Titanium and Titanium Alloy Screws, Bolts and Studs)ASME B18.3 (American Standard for Hex Socket Head Cap Screws), etc. | Thread Diameter: M2 – M50Length: 5mm – 300mm |

| TA1 | Ti ≥ 99.5, Fe ≤ 0.20, O ≤ 0.18, N ≤ 0.03, etc. | GB/T 3621 (Titanium and Titanium Alloy Sheets)GB/T 16598 (Titanium and Titanium Alloy Cakes and Rings), etc. (Some standards related to titanium materials can be associated with screw manufacturing) | Thread Diameter: M2 – M48Length: 3mm – 250mm |

| TA2 | Ti ≥ 99.0, Fe ≤ 0.30, O ≤ 0.25, N ≤ 0.05, etc. | GB/T 13810 (Titanium and Titanium Alloy Processed Materials for Surgical Implants)GB/T 2672 (Hexalobular Socket Head Self-tapping Screws), etc. (Partially related) | Thread Diameter: M3 – M40Length: 4mm – 200mm |

| TC11 | Ti (balance), Al approximately 6.5, Mo approximately 3.5, Zr approximately 1.5, Si approximately 0.35, etc. | GB/T 2965 (Titanium and Titanium Alloy Bars)HB 5422 (Titanium and Titanium Alloy Bars for Aerospace Use), etc. | Thread Diameter: M4 – M36Length: 6mm – 180mm |

| Ti-5Al-2.5Sn | Ti (balance), Al approximately 5, Sn approximately 2.5, Fe ≤ 0.25, O ≤ 0.15, etc. | GB/T 13810 (Titanium and Titanium Alloy Processed Materials for Surgical Implants, partially applicable)ASTM F1295 (Standard Specification for Processed Ti-5Al-2.5Sn Alloy for Surgical Implants), etc. | Thread Diameter: M3 – M30Length: 5mm – 150mm |

Considerations in Titanium Screw Design

Titanium screw design requires comprehensive consideration of multiple factors to ensure that performance, safety and cost requirements are met. In terms of material properties, different grades of titanium alloys are accurately matched according to requirements such as strength, toughness, corrosion resistance and biocompatibility. For example, high-strength TC4 is selected for aerospace, corrosion-resistant TA1 and TA2 are selected for marine environments, and TC4 with good biocompatibility is selected for medical devices. Mechanical performance analysis is crucial. By calculating axial tension, shear force and evaluating fatigue performance, the structure is optimized to reduce stress concentration and ensure stable operation under complex loads.

Thread Specifications

Select appropriate thread specifications based on the material, thickness, and connection strength requirements of the connected parts. Small-size threads (such as M2-M5) are often used in electronic equipment and small precision instruments. Large-size threads (M10 and above) are used for large mechanical equipment and building structures. When designing, the thread standard (such as metric and imperial) should be considered to ensure universality and interchangeability.

Length

The length of the titanium screw should be determined based on factors such as the total thickness of the connected parts and the installation space. Generally speaking, the length of the screw should ensure that the threaded part can completely pass through the connected parts after tightening, and a certain length (2-3 teeth) is exposed to ensure the reliability of the connection. But at the same time, the screw should not be too long to avoid affecting the appearance or causing safety hazards.

The size and specification design should be adapted to the connected parts, and the thread specifications and length should be selected according to the force and installation space, taking into account universality and reliability. When designing the structure, select the head shape according to the tool, space and aesthetics, and design special structures to enhance the function as needed. Consider the feasibility of the manufacturing process, simplify the structure to reduce the difficulty of processing, reasonably select the surface treatment and reserve the processing allowance. In terms of cost control, choose the right material grade, optimize the size, simplify the design and process, balance performance and cost, and create a high-quality and economical titanium screw design.

Surface Treatment

Select the surface treatment process according to the use environment and performance requirements. For example, passivation, nickel plating, and chrome plating can be performed in a corrosive environment. For easy installation and anti-loosening, lubricant coatings such as molybdenum disulfide and polytetrafluoroethylene can be applied. When designing, consider the effect of surface treatment on the dimensional accuracy and appearance quality of the screws.

Cost

The prices of different grades of titanium alloys vary greatly. Under the premise of meeting the performance, try to choose materials with lower costs. For example, in some general industrial applications where the strength requirements are not particularly high, relatively low-priced pure titanium TA1 and TA2 can be used to replace higher-cost titanium alloys. At the same time, optimize the design size to avoid material waste caused by excessive design and reduce material procurement costs.