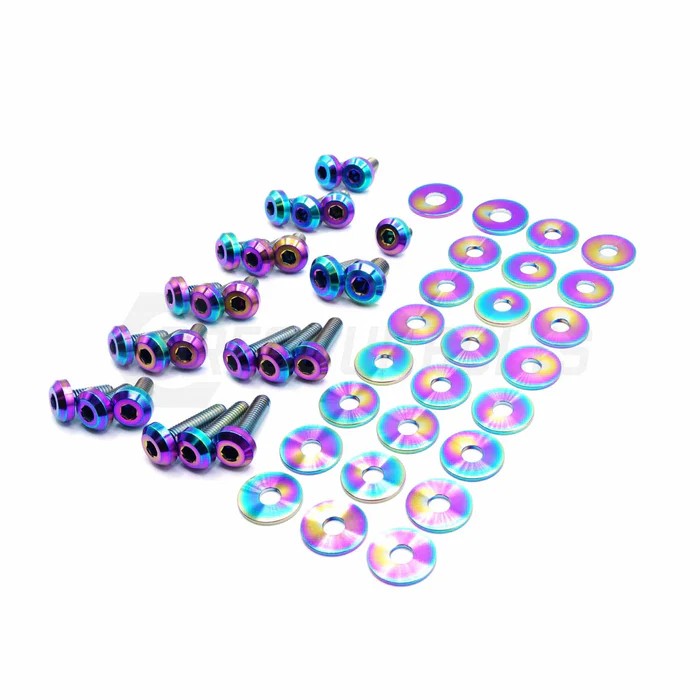

Titanium Washers Manufacturer and Supplier In China

As a titanium washer manufacturer and supplier in China, Wstitanium occupies an important position in the titanium washer market with its advanced manufacturing technology, rich titanium grade options and diverse surface treatment services.

- 24/7 Online Service

- OEM/ODM Support

- DIN、GB、ANSI、ISO、JIS

- SGS, BV and CE Certificates

- 5mm-200mm

- 8000 Tons Capacity

- 10+ Finishing Options

- 15+ Titanium Grade Options

Reputable Titanium Washer Factory - Wstitanium

Wstitanium is a company with an excellent reputation in the field of custom titanium washers manufacturing. It has been focusing on the research and development, production and sales of titanium and titanium alloy products for many years. With advanced technology, strict quality control system and deep understanding of customer needs, Wstitanium has won wide recognition and trust in the global titanium market.

Titanium Washer Design

The performance of titanium washers directly affects the reliability of sealing, connection and operation of equipment. With the continuous advancement of science and technology and the increasing demand for high-performance parts in various industries, it is particularly important to scientifically and rationally design titanium washers.

Titanium Grade For Washers

Titanium alloy is a pure titanium alloy with other elements (such as aluminum, vanadium, molybdenum, etc.) added to it to further improve its performance. Different alloying elements and contents will give titanium alloys different properties. For example, α titanium alloy has good high temperature strength and oxidation resistance, β titanium alloy has high strength and good machinability, and α+β titanium alloy combines the advantages of both and has good comprehensive performance.

Corrosion Application

In environments with strong corrosive media such as marine engineering and chemical industry, titanium materials with strong corrosion resistance should be preferred. For example, industrial pure titanium (Gr1, Gr2). For some more challenging corrosive environments, titanium alloys such as Ti-0.3Mo-0.8Ni (Gr12) containing mold and nickel may be more suitable.

High temperature application

In high temperature application scenarios in aerospace, energy and other fields, titanium alloys with good high temperature performance need to be selected. For example, Ti-6Al-4V (Gr5) titanium alloy can still maintain high strength and good oxidation resistance at high temperatures, and is suitable for high-temperature working environments such as engine parts.

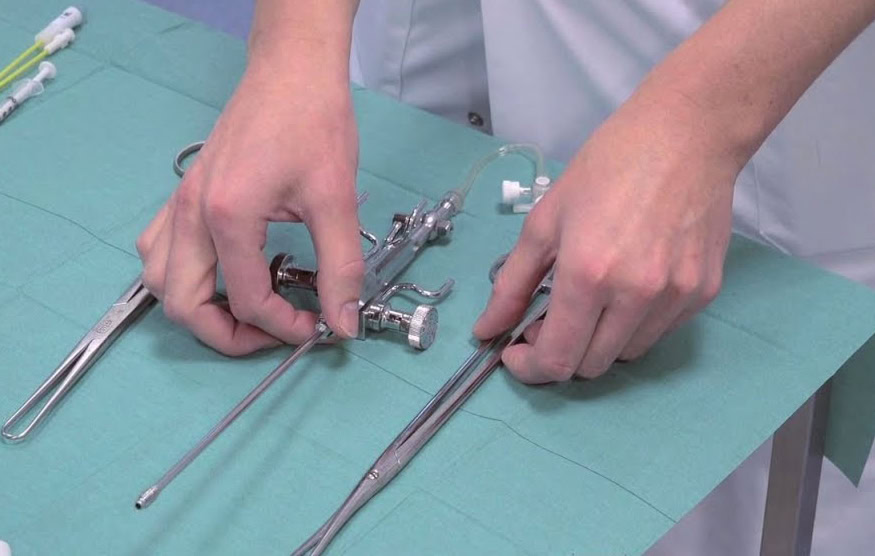

Medical applications

In the medical field, such as artificial joints, dental implants and other applications, the biocompatibility of titanium is a key factor. Pure titanium and some specific titanium alloys (such as Gr2, Gr5) are widely used in the manufacture of gasket parts that come into contact with human tissue due to their good biocompatibility.

Cost

Different grades of titanium have differences in cost and machinability. Generally speaking, industrial pure titanium has a relatively low cost and good machinability, and is suitable for some applications that are cost-sensitive and not particularly demanding in terms of performance. However, some high-performance titanium alloys, such as β-titanium alloys containing more alloying elements, have superior performance but are more expensive and difficult to process, and are usually used in key components with extremely high performance requirements. When designing, it is necessary to comprehensively consider factors such as performance requirements, cost budget and machinability to select the most suitable material.

Inner and outer diameters

The dimensions of the inner and outer diameters of titanium washers require precise measurement and calculation of the dimensions of the mating parts, taking into account the appropriate tolerance range. For example, for washers that fit bolts, the inner diameter should be slightly larger than the diameter of the bolt to ensure that the washers can be installed smoothly while ensuring a certain tightening effect.

Load

The thickness of the washers directly affects their load-bearing capacity. When designing, the appropriate thickness needs to be determined based on the load size that the washers are subjected to. The minimum thickness that meets the strength requirements can be determined through mechanical calculations, such as the pressure and shear force that the washers are subjected to.

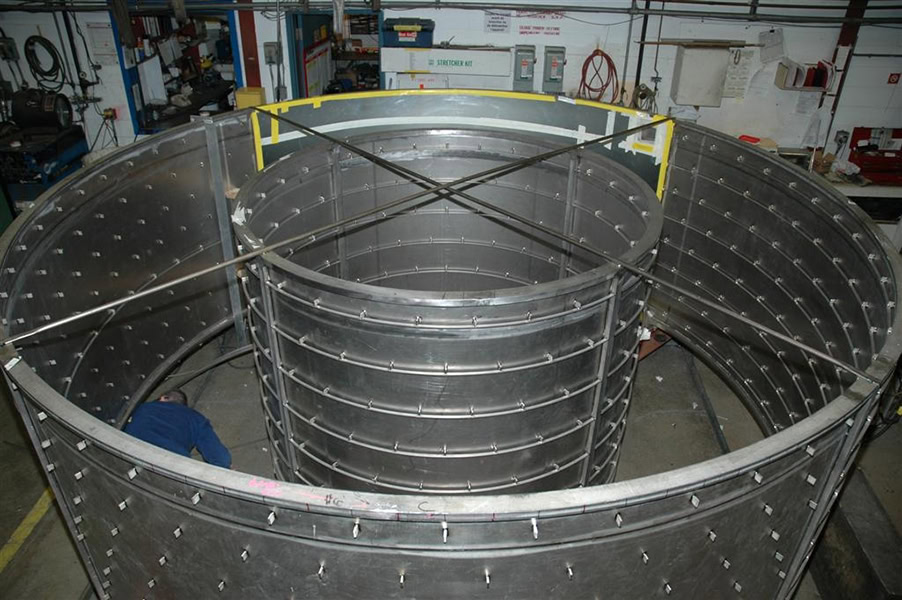

Manufacturing of Titanium Washers

Wstitanium invests in advanced vacuum consumable arc furnaces (VAR) to melt titanium. Multiple melting processes are carried out in a high vacuum environment to ensure that the composition of the titanium liquid is uniform and pure. Impurities and gases are removed by precisely controlling parameters such as melting temperature, time and current. After melting, the titanium liquid is cast into a specific mold to form a titanium ingot. The size and shape of the ingot will be designed according to the needs of subsequent processing to improve material utilization and processing efficiency.

During the forging process, the titanium ingot is forged multiple times by a large forging press to make its internal structure denser and the grains finer, thereby improving the strength and toughness of the titanium material. During the forging process, the forging ratio and deformation temperature are strictly controlled to ensure that the performance of the titanium material meets the requirements. After forging, the titanium material is rolled into the required shape of plates, bars or tubes through a rolling process. During the rolling process, parameters such as rolling speed and reduction are adjusted according to the specifications and performance requirements of the product to obtain ideal dimensional accuracy and surface quality.

Cutting and Forming

According to the design size and shape of the titanium washers, advanced cutting equipment is used to cut the forged and rolled titanium materials. Common cutting methods include laser cutting, wire cutting and plasma cutting. Laser cutting has the advantages of high precision, fast cutting speed and small heat-affected zone, and is suitable for cutting titanium washers with high cutting precision requirements. Wire cutting is suitable for cutting washers with complex shapes. The cut titanium material is then formed by stamping, forging or CNC machining to form the required washer shape. During the forming process, the machining accuracy will be strictly controlled to ensure that the dimensional tolerance of the washer meets the design requirements.

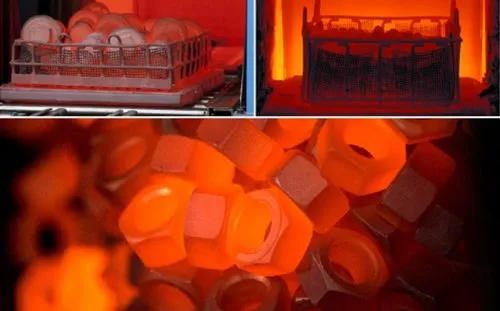

Heat Treatment

In order to further optimize the performance of titanium washers, Wstitanium will perform appropriate heat treatment on the formed washers. Heat treatment processes include annealing, normalizing, quenching and tempering. Annealing can eliminate the internal stress generated by the washers during processing and improve their plasticity and toughness. Normalizing can refine the grains and improve the strength and hardness of the washers. Quenching and tempering can give the washers higher strength and hardness while maintaining a certain toughness. During the heat treatment process, parameters such as heating temperature, holding time and cooling rate are strictly controlled to ensure that the performance of the gasket reaches the best state.

Titanium Washer Application

Titanium washers manufactured by Wstitanium are widely used in aerospace, marine engineering, chemical industry, medical treatment, automobile and energy fields due to their excellent performance and reliable quality, providing strong support for the development of various industries.

In engine systems, titanium washers are used to seal key parts such as combustion chambers and turbine blades to ensure efficient operation and safety of the engine. Its high strength and high temperature resistance can ensure reliability in high temperature and high pressure environments. In addition, titanium washers are also widely used in fuel systems, hydraulic systems, etc. of aerospace equipment to ensure the sealing and reliability of the system.

Ocean

Wstitanium’s titanium washers have become an ideal choice in the field of marine engineering due to their excellent corrosion resistance. On offshore platforms, titanium washers are used to connect and seal various pipes, equipment and structural components, such as oil and gas pipelines, seawater desalination equipment, etc. In addition, titanium washers also play an important role in sealing and connecting marine monitoring equipment, underwater robots, etc.

Chemicals

Wstitanium’s titanium washers can resist the erosion of a variety of chemicals and have been widely used in the chemical industry. In the reactor, titanium washers are used to seal the connection between the reactor cover and the reactor body to ensure the sealing and safety of the reaction process. In addition, in storage containers and heat exchangers of chemical equipment, titanium washers provide a guarantee for safe and stable operation.

Wstitanium titanium washers are used to connect various parts of joint prostheses in artificial joint replacement surgery to ensure the stability and reliability of the prosthesis. Its biocompatibility can better integrate the prosthesis with human tissue and reduce the occurrence of complications. In addition, titanium washers also play an important role in medical devices such as pacemakers and vascular stents.

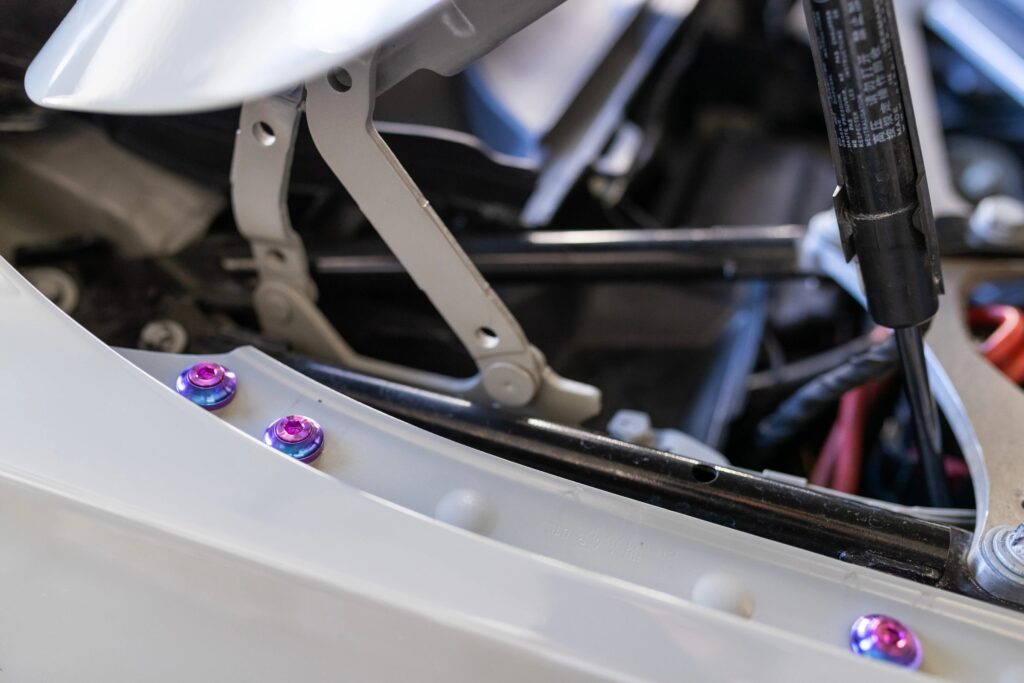

Wstitanium’s titanium washers are used to seal components such as cylinder heads and intake manifolds. Their low density can reduce the weight of the engine and improve fuel efficiency; high strength and high temperature resistance can ensure the reliability of the washers under high engine speed and high temperature environment. In addition, titanium washers can also be used as decorative and functional parts in the interior and exterior parts of automobiles.

Titanium Washers Gallery