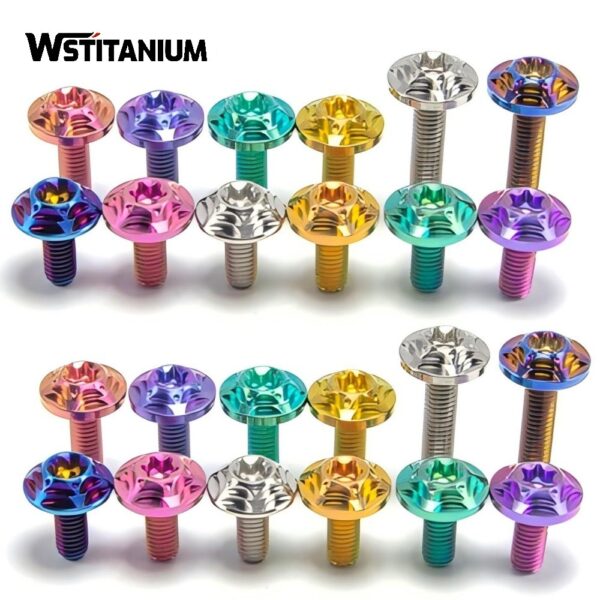

Titanium Fastener Hexagon Screw Nuts

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

As a core component in titanium fastener systems, titanium hex nuts, leveraging the metal’s unique physical and chemical properties, offer irreplaceable advantages in harsh environments where traditional metal nuts struggle. They have become a critical component in fields such as aerospace, marine engineering, and high-end medical applications.

Titanium has a density of only 4.51 g/cm³, approximately 57% that of steel. This allows titanium hex nuts to significantly reduce overall equipment weight while maintaining joint strength. Their tensile strength can reach 441-1470 MPa, comparable to high-strength steel, while offering superior corrosion resistance. In corrosive media such as seawater, strong acids, and alkalis, a dense oxide film (TiO₂) forms on the titanium surface, effectively preventing further corrosion of the substrate. Furthermore, titanium exhibits excellent high-temperature resistance (stable performance at 300-550°C). These properties make titanium hex nuts a preferred fastener in high-end manufacturing.

| Size | M3-M36. or non-standard according to your requirements. |

| Materials | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 |

| Type | Screw/bolts(cap head/socket head/hex head/round head/headless/taper head/shoulder head.etc) |

| Thread | UNC, UNF, UNEF, M, BSW, BSF, TR, ACME, NPT TP |

| Surface Treatment | Anodizing, sandblasting,black oxide, polishing. powder coating, brushing,electroplating, passivation |

| Drawingformat | IGS,STP,STEP,X-T,DXF,DWG,PrO/E,PDF,PNG,JPG |

| Application | Motorcycle,Bicycle,cars |

| Certifications | ISO9001,CE,BV |

| Service | 1,Free samples will be sent to you after confirming the order. |

| 2,Material test report,Hardness test report,Quality Inspection Report as your require. | |

| 3,video and photos with details freely during. | |

| 4,Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.If you don’t have a professional drawing, you can contact us and we will customize it for you according to your requirements. | |

| Euipment | CNC Turning, CNC Milling, CNC 5-axis Turning-milling Compound, CNC Gear Hobbing Machine, CNC Gear Shaping Machine, Manual Milling Machine, Grinding Machine, and Laser Engraving Machine. |

| Quality | Two-dimensional Imager, CCD Image Detection Equipment, Rockwell Hardness Tester, Vickers Hardness Tester, Electron Microscope,Salt Spray Tester,etc. |

| Packing | PE bag,EPE, standardcardboard boxes or plastic trays, sponge trays,cardboard trays,etc |

| Precision | TIR ≤.002″ (0.02mm-5mm) |

| MOQ | In stock:50pcs Custom-made:100pcs |

| Color | Silver, black, red, yellow, green, blue, color, customized according to your requirements |

| Delivery time | In stock : Sample 3days,Bulk goods 7-15days. |

| Custom : Sample 7-10 working days, Bulk goods 15-20 working days. |

Manufacturing Titanium Hex Nuts

The manufacturing of titanium hex nuts is a systematic process that integrates materials science, precision machining, and quality control. It requires multiple key technologies, including raw material screening, forming, CNC machining, and heat treatment. Each step requires rigorous control to ensure product performance.

Raw Materials and Pretreatment

Material quality directly determines the ultimate performance of titanium hex nuts. The choice of titanium alloy grade should be determined based on the performance requirements of the application. Commonly used titanium alloy grades in industry include TA2 (pure titanium), TC4 (Ti-6Al-4V), and TC11 (Ti-6Al-2Zr-1Mo-1V). TC4 is the most widely used titanium alloy grade due to its combination of high strength, good toughness, and processability, making it suitable for a wide range of applications, including aerospace and marine engineering. TA2 pure titanium, due to its excellent corrosion resistance and biocompatibility, is widely used in medical equipment and the chemical industry. TC11, with its excellent high-temperature resistance, is suitable for equipment operating under high-temperature conditions.

Raw materials are typically supplied in the form of titanium rods. The surface is then cleaned of scale, oil, and impurities. Scale can be removed by pickling (typically using a mixture of hydrofluoric acid and nitric acid). Oil can be removed by cleaning with an organic solvent or alkaline degreasing. Finally, the titanium rod is cut into billets of specified length according to the nut size, with a cutting accuracy within ±0.5mm.

Forming

Forming is the process of shaping the titanium billet into the approximate shape of a hexagonal nut. It is primarily divided into two techniques: cold heading and hot heading.

Cold heading is suitable for smaller sizes (typically nominal diameter ≤24mm) and highly ductile titanium alloys (such as TA2 and TC4). It offers a high material utilization rate (over 95%), and the cold work hardening effect improves the surface hardness and strength of the nut. However, titanium alloys have poor room-temperature ductility. Therefore, prior to cold forging, the blank must be annealed (at 700-800°C for 1-2 hours) to improve its ductility. Furthermore, the mold must be made of high-strength carbide (such as WC-Co alloy) and lubricated to reduce friction and prevent cracking of the blank and mold wear.

Hot forging is suitable for larger sizes (nominal diameter > 24mm) or high-strength titanium alloys (such as TC11). This technique involves heating the titanium blank above the recrystallization temperature (typically 750-950°C, depending on the grade) to significantly increase its ductility before proceeding with forging and forming.

CNC Machining

After forming, the semi-finished product undergoes CNC machining to further enhance precision and surface quality. This primarily involves internal threading, hexagonal face finishing, and end-face machining. Common thread processing methods are tapping and rolling. Tapping is suitable for low-volume manufacturing or non-standard threads, employing a low speed (10-20 rpm) and multiple feeds. Thread rolling, on the other hand, is suitable for large-scale production. The rolling wheel extrudes the blank surface to form the thread, resulting in high efficiency and excellent surface quality.

Precision machining of hexagonal faces typically involves CNC milling or grinding to ensure that dimensions such as the width across flats and across corners meet standards (e.g., GB/T 6170-2015, “Type 1 Hexagonal Nuts”). Tolerances are generally controlled within IT8-IT10. End-facing is performed through turning or grinding to ensure parallelism and flatness of both nut faces. The parallelism error must be ≤0.02mm/100mm to ensure uniform force during assembly.

Heat Treatment

The purpose of heat treatment is to adjust the mechanical properties of titanium hexagonal nuts, eliminate processing stresses, and improve their reliability. Common processes include annealing and solution aging. Annealing is the most widely used heat treatment technique, primarily used to eliminate internal stresses generated during cold heading and CNC machining, improving the material’s plasticity and toughness. Heat treatment parameters are determined by the titanium alloy grade: TA2 pure titanium is annealed at 600-700°C, held for 1-3 hours, and then air-cooled; TC4 titanium alloy is annealed at 700-800°C, held for 1-2 hours, and then furnace-cooled. Annealing significantly reduces internal stress in titanium hexagonal nuts, preventing deformation and cracking during subsequent processing or use.

For applications requiring high strength, titanium alloy nuts require solution aging treatment. Taking TC4 as an example, solution treatment is performed at 920-950°C, held for 30-60 minutes, and then water quenched to fully dissolve the alloying elements and form a supersaturated solid solution. Aging treatment is then performed at 450-550°C, held for 4-8 hours, and then air-cooled to precipitate a fine strengthening phase (α phase), increasing the nut’s tensile strength to over 900 MPa. However, solution aging treatment reduces the material’s plasticity, so a balance between strength and toughness must be maintained based on actual operating conditions.

Related products

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Fasteners Manufacturer and Supplier

-

Titanium Fasteners

Anodized Colored Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Nut

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts

-

Titanium Fasteners

Colored Titanium Nuts

-

Titanium Fasteners

Rainbow Titanium Bolt For Cars