Titanium Fasteners For Automotive

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Titanium fasteners, as key components with unique advantages, are gradually emerging in the automotive industry, providing a powerful impetus for performance improvements and lightweighting. Titanium, with its exceptional properties, including low density, high strength, excellent corrosion resistance, and outstanding high-temperature performance, has become a favorite among automotive engineers. While reducing vehicle weight, titanium fasteners can significantly improve the strength and durability of key components, thereby enhancing overall vehicle performance, fuel efficiency, and handling stability.

From high-end luxury cars to competitive racing cars, from everyday commuters to new energy vehicles, titanium fasteners are ubiquitous. They are not only used in critical components with extremely high performance requirements, such as engines, suspension systems, and braking systems, but also play an indispensable role in lightweight design and innovative manufacturing.

| Size | M3-M36. or non-standard according to your requirements. |

| Materials | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 |

| Type | Screw/bolts(cap head/socket head/hex head/round head/headless/taper head/shoulder head.etc) |

| Thread | UNC, UNF, UNEF, M, BSW, BSF, TR, ACME, NPT TP |

| Surface Treatment | Anodizing, sandblasting,black oxide, polishing. powder coating, brushing,electroplating, passivation |

| Drawingformat | IGS,STP,STEP,X-T,DXF,DWG,PrO/E,PDF,PNG,JPG |

| Application | Motorcycle,Bicycle,cars |

| Certifications | ISO9001,CE,BV |

| Service | 1,Free samples will be sent to you after confirming the order. |

| 2,Material test report,Hardness test report,Quality Inspection Report as your require. | |

| 3,video and photos with details freely during. | |

| 4,Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.If you don’t have a professional drawing, you can contact us and we will customize it for you according to your requirements. | |

| Euipment | CNC Turning, CNC Milling, CNC 5-axis Turning-milling Compound, CNC Gear Hobbing Machine, CNC Gear Shaping Machine, Manual Milling Machine, Grinding Machine, and Laser Engraving Machine. |

| Quality | Two-dimensional Imager, CCD Image Detection Equipment, Rockwell Hardness Tester, Vickers Hardness Tester, Electron Microscope,Salt Spray Tester,etc. |

| Packing | PE bag,EPE, standardcardboard boxes or plastic trays, sponge trays,cardboard trays,etc |

| Precision | TIR ≤.002″ (0.02mm-5mm) |

| MOQ | In stock:50pcs Custom-made:100pcs |

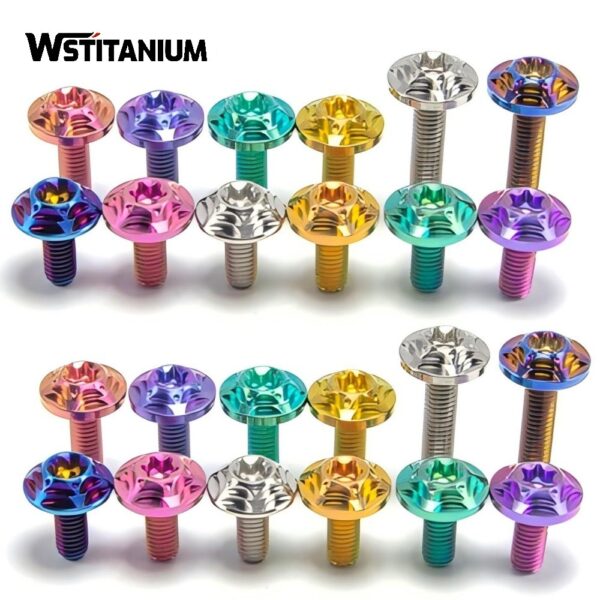

| Color | Silver, black, red, yellow, green, blue, color, customized according to your requirements |

| Delivery time | In stock : Sample 3days,Bulk goods 7-15days. |

| Custom : Sample 7-10 working days, Bulk goods 15-20 working days. |

Manufacturing of Automotive Titanium Fasteners

Common titanium grades used in the manufacture of automotive titanium fasteners include Gr5 (Ti-6Al-4V) and Gr2 (Ti-3Al-1.5Mn). Gr5 is the most widely used titanium alloy, offering excellent overall performance, with strength exceeding 900 MPa, excellent corrosion resistance, and excellent machinability. It meets the stringent performance requirements of titanium fasteners for various automotive components.

Cold Heading

Cold heading is a core technology in the manufacture of titanium fasteners. It utilizes a cold heading machine to apply impact force to titanium alloy bars or wire at room temperature, causing plastic deformation within the die and rapidly forming the desired fastener shape, such as bolts or nuts.

Threading

Threads are a critical component of titanium fasteners, enabling them to connect. Thread quality directly impacts fastener performance. Common threading methods include CNC turning and rolling. CNC turning is suitable for threads with special specifications or extremely high precision requirements, achieving highly precise thread shapes and dimensions, but with relatively low production efficiency. Rolling, on the other hand, involves rolling a pre-formed fastener blank, causing the surface material to plastically flow and form the threads. Rolling produces threads with high strength, excellent surface quality, and high production efficiency, making it widely used in threading titanium fasteners for automotive applications. During the rolling process, precise control of parameters such as roller pressure, speed, and feed rate ensures that the thread profile, pitch, and accuracy meet design requirements, guaranteeing reliable connections for titanium fasteners.

Heat Treatment

Heat treatment is an important method for improving the performance of titanium fasteners, further optimizing the microstructure and properties of titanium alloys, enhancing their strength, hardness, toughness, and fatigue life. Common heat treatments include solution treatment and aging. Taking TC4 titanium alloy as an example, solution treatment is generally performed at temperatures between 900 and 950°C to fully dissolve the strengthening phases in the alloy into the matrix. The alloy is then rapidly cooled to form a supersaturated solid solution. Aging treatment, on the other hand, is performed between 500 and 600°C to precipitate the solute atoms in the supersaturated solid solution, forming a dispersed strengthening phase, thereby increasing the alloy’s strength and hardness.

Surface Treatment

To further enhance the corrosion resistance, wear resistance, and aesthetics of titanium fasteners, surface treatment is often required. Common surface treatment methods include anodizing, spraying, and sandblasting. Spraying involves applying a protective coating, such as titanium nitride, to the fastener surface to improve wear and corrosion resistance. Sandblasting can improve the surface roughness and adhesion of titanium fasteners, while also eliminating residual stress and increasing the fatigue life of the part.

Related products

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Motorcycle Titanium Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts