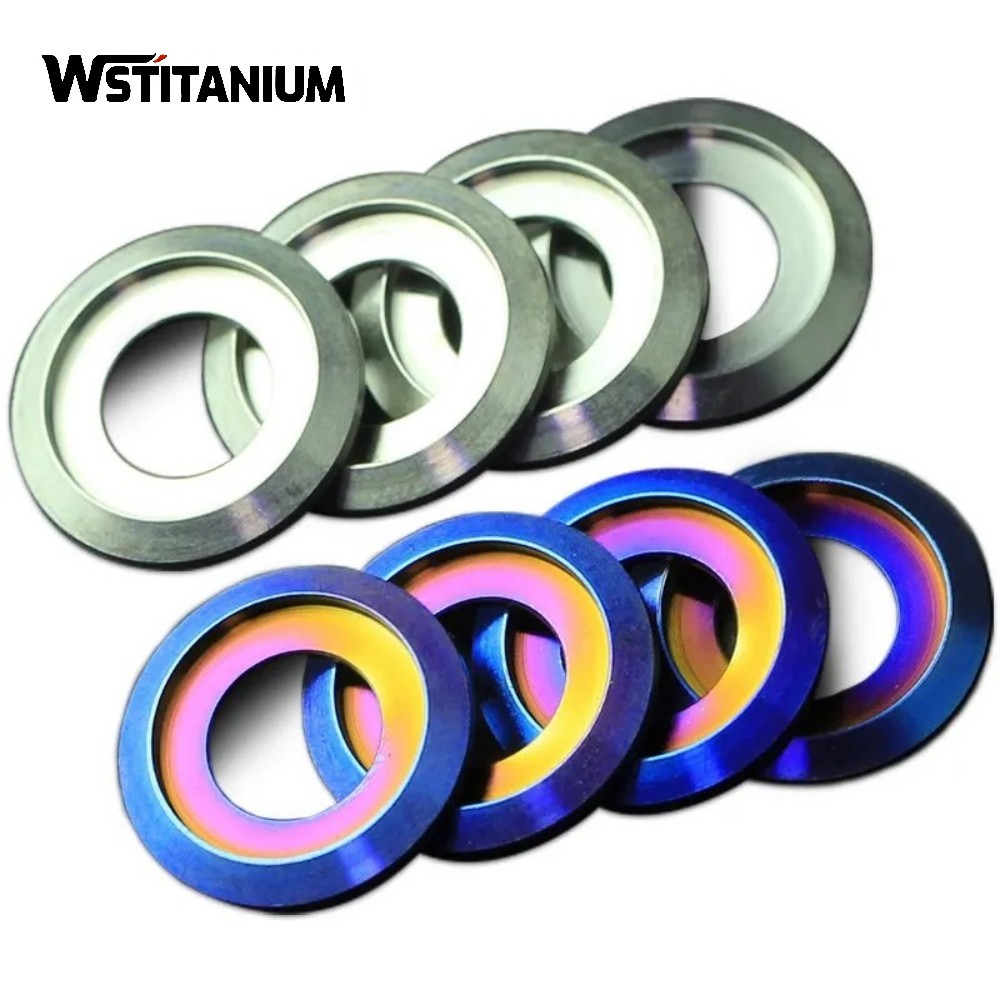

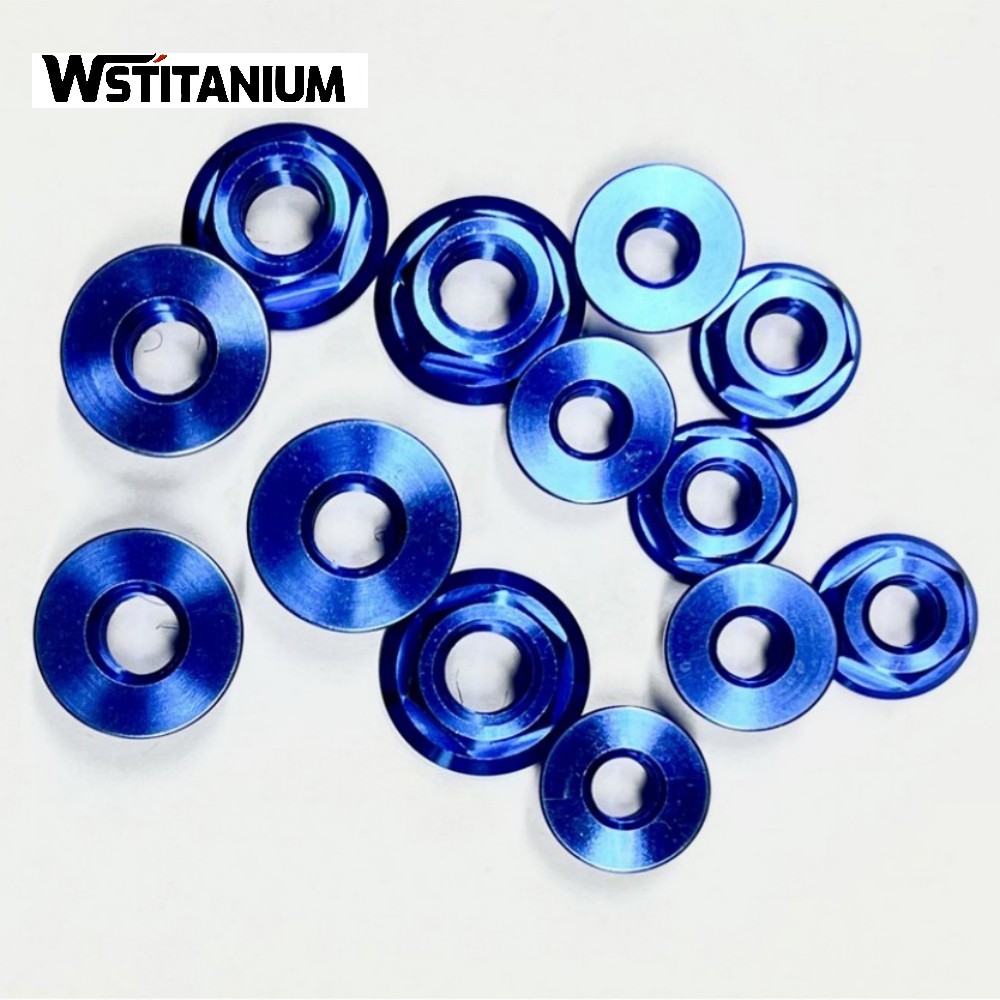

Colored Titanium Washers

Certified: CE & SGS & ROHS

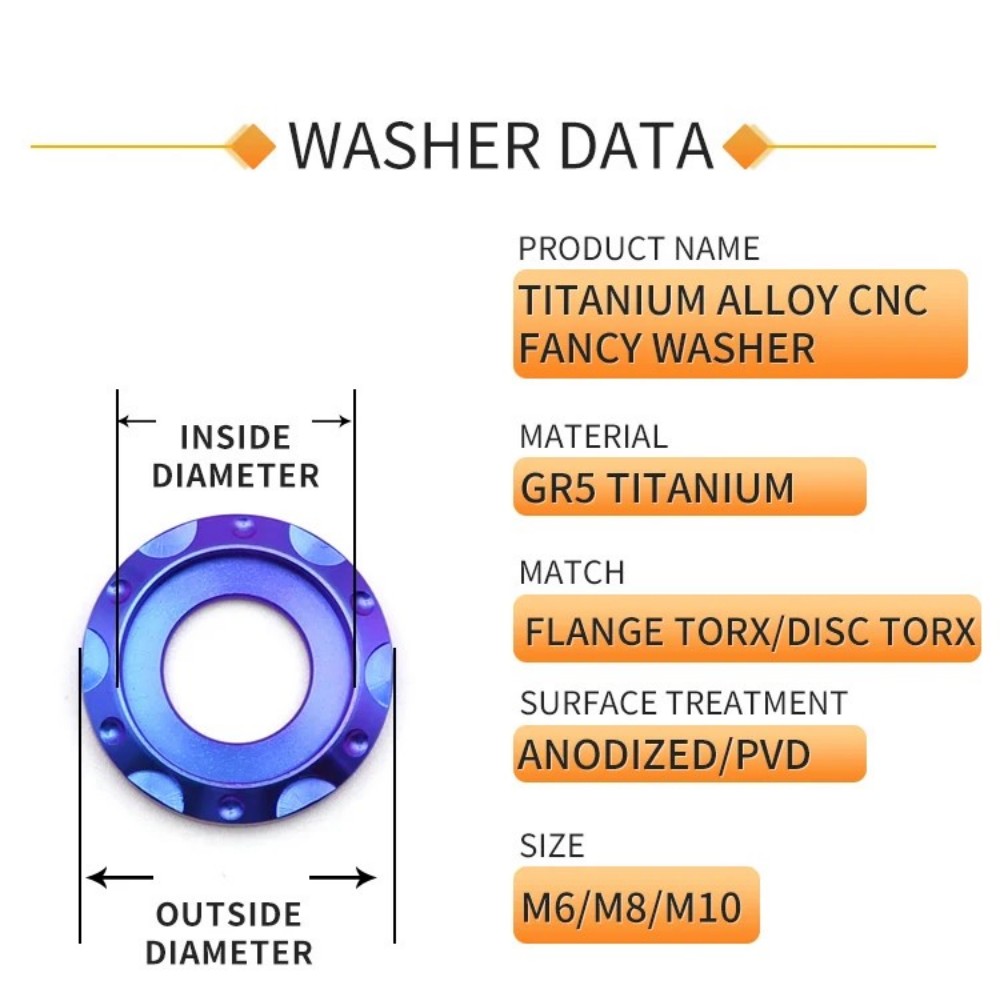

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Titanium washers, as high-performance sealing and connection components, leverage their four core advantages: corrosion resistance, lightweight and high strength, wide temperature range adaptability, and biocompatibility. They have successfully overcome the performance limitations of traditional gaskets in extreme operating conditions. They have become key components in aerospace, medical, chemical, marine engineering, new energy, and other fields. From raw material selection to molding, heat treatment, surface treatment, and rigorous quality inspection, every manufacturing step requires precise control tailored to the specific application requirements to ensure the dimensional accuracy, sealing performance, and long-term reliability of titanium washers.

Different types of titanium washers (flat, corrugated, and serrated) address different sealing requirements. For example, the elastic compensation capabilities of corrugated gaskets are suitable for sealing high-temperature and high-pressure pipes. Special-shaped gaskets meet the specialized structural designs of aerospace and other fields. This “matching type to application” approach further expands the application boundaries of titanium washers. In actual customization, the selection must be comprehensively considered based on the equipment operating conditions (temperature, pressure, and media), structural dimensions, and performance requirements to maximize the value of titanium washers.

Titanium Washers Applications

Whether in extreme high-temperature, high-pressure environments or under the erosion of highly corrosive media, Titanium Washers demonstrate stable and reliable performance, ensuring efficient equipment operation.

(I) Chemical Industry

Reactor Sealing: Chemical reactors often involve chemical reactions at high temperatures, high pressures, and with highly corrosive media. Titanium Washers are used to seal the lid and body of the reactor. They can withstand high temperatures and high pressures, effectively resisting corrosion from various corrosive media such as strong acids and alkalis, and ensuring the reactor’s tightness.

Pipeline Connection Sealing: Chemical pipelines transport a variety of corrosive chemical raw materials and products. Titanium Washers are used in pipeline flange connections, valve seals, and other areas, maintaining excellent sealing performance in harsh chemical environments.

(II) Marine Industry

Offshore Platform Equipment: Offshore oil drilling platforms and offshore wind turbines are exposed to high-salinity and high-humidity marine environments for extended periods of time. Titanium Washers are used in the connections and sealing areas of these equipment, such as the platform’s steel structure connections and the sealing of equipment protective casings. Their excellent seawater corrosion resistance effectively protects against seawater erosion.

Underwater equipment: Submersibles, submarine probes, and other underwater equipment operate in deep-sea environments characterized by high pressure, low temperatures, and corrosive seawater. Titanium washers are used to seal underwater equipment housings and instrument connections, withstand significant water pressure, and maintain excellent sealing performance.

(III) New Energy

Photovoltaic inverters, energy storage battery cabinets, and other equipment are exposed to complex outdoor or indoor environments for extended periods. Titanium washers are used to seal equipment housings and support internal circuit connections. Their weather resistance (resistance to UV rays and temperature fluctuations) extends equipment life, while their corrosion resistance prevents moisture and dust from corroding internal components.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Titanium Nuts