Colored Motorcycle Titanium Bolts

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Titanium provides an ideal solution for upgrading and iterating motorcycle bolts. Titanium, with its unique material properties of high strength, low density, and excellent corrosion resistance, has long been widely proven in fields such as aerospace and high-end medical treatment. Motorcycle titanium bolts not only significantly reduce vehicle weight while maintaining joint strength and improving handling responsiveness, but also effectively resist corrosion from harsh riding environments such as rain, mud, and salt, extending component life.

| Size | M3-M36. or non-standard according to your requirements. |

| Materials | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 |

| Type | Screw/bolts(cap head/socket head/hex head/round head/headless/taper head/shoulder head.etc) |

| Thread | UNC, UNF, UNEF, M, BSW, BSF, TR, ACME, NPT TP |

| Surface Treatment | Anodizing, sandblasting,black oxide, polishing. powder coating, brushing,electroplating, passivation |

| Drawingformat | IGS,STP,STEP,X-T,DXF,DWG,PrO/E,PDF,PNG,JPG |

| Application | Motorcycle,Bicycle,cars |

| Certifications | ISO9001,CE,BV |

| Service | 1,Free samples will be sent to you after confirming the order. |

| 2,Material test report,Hardness test report,Quality Inspection Report as your require. | |

| 3,video and photos with details freely during. | |

| 4,Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.If you don’t have a professional drawing, you can contact us and we will customize it for you according to your requirements. | |

| Euipment | CNC Turning, CNC Milling, CNC 5-axis Turning-milling Compound, CNC Gear Hobbing Machine, CNC Gear Shaping Machine, Manual Milling Machine, Grinding Machine, and Laser Engraving Machine. |

| Quality | Two-dimensional Imager, CCD Image Detection Equipment, Rockwell Hardness Tester, Vickers Hardness Tester, Electron Microscope,Salt Spray Tester,etc. |

| Packing | PE bag,EPE, standardcardboard boxes or plastic trays, sponge trays,cardboard trays,etc |

| Precision | TIR ≤.002″ (0.02mm-5mm) |

| MOQ | In stock:50pcs Custom-made:100pcs |

| Color | Silver, black, red, yellow, green, blue, color, customized according to your requirements |

| Delivery time | In stock : Sample 3days,Bulk goods 7-15days. |

| Custom : Sample 7-10 working days, Bulk goods 15-20 working days. |

Motorcycle Titanium Bolt Applications

Motorcycle titanium bolts are designed to achieve performance upgrades in key locations based on the functional requirements and operating conditions of different components.

Engine block and cylinder head: Titanium bolts ensure a tight seal to prevent oil leakage and fuel gas blowby. The high strength of titanium bolts (tensile strength of 800-1200 MPa) ensures a stable connection.

Clutch and transmission housing: Frequent engagement and disengagement during clutch operation and torque fluctuations during transmission shifts place connecting bolts under long-term dynamic loads. The fatigue resistance of titanium alloy (with a fatigue strength approximately 1.5 times that of steel) effectively prevents fatigue fracture caused by long-term vibration, making it particularly suitable for high-speed, high-load performance motorcycles.

Front fork and frame connection: The front fork performs dual functions of steering and shock absorption. Titanium bolts ensure steering flexibility while bearing the weight of the vehicle and road impact.

Swingarm-to-shock absorber connection: The swingarm is a key component for transmitting power and damping to the rear wheel. Titanium bolts must withstand both vertical damping loads and horizontal driving/braking forces.

Brake caliper: When braking, the caliper applies significant clamping force to the brake pads. Friction between the pads and the disc generates high temperatures (up to 300-600°C), which are transferred to the connecting bolts. Titanium alloys (especially heat-resistant grades like TC4 and TC6) maintain stable mechanical properties in temperatures between 200-400°C.

Brake disc-to-wheel connection: The corrosion resistance of titanium bolts prevents brake disc bolts from rusting and seizing. Their lightweight design reduces the wheel’s moment of inertia, improving braking response.

Handlebars and pedals: The wear resistance of titanium bolts (surface hardness of HV300-400, which can be increased to HV800 and above after nitriding) prevents wear on the bolt heads from long-term use, maintaining the component’s cosmetic integrity.

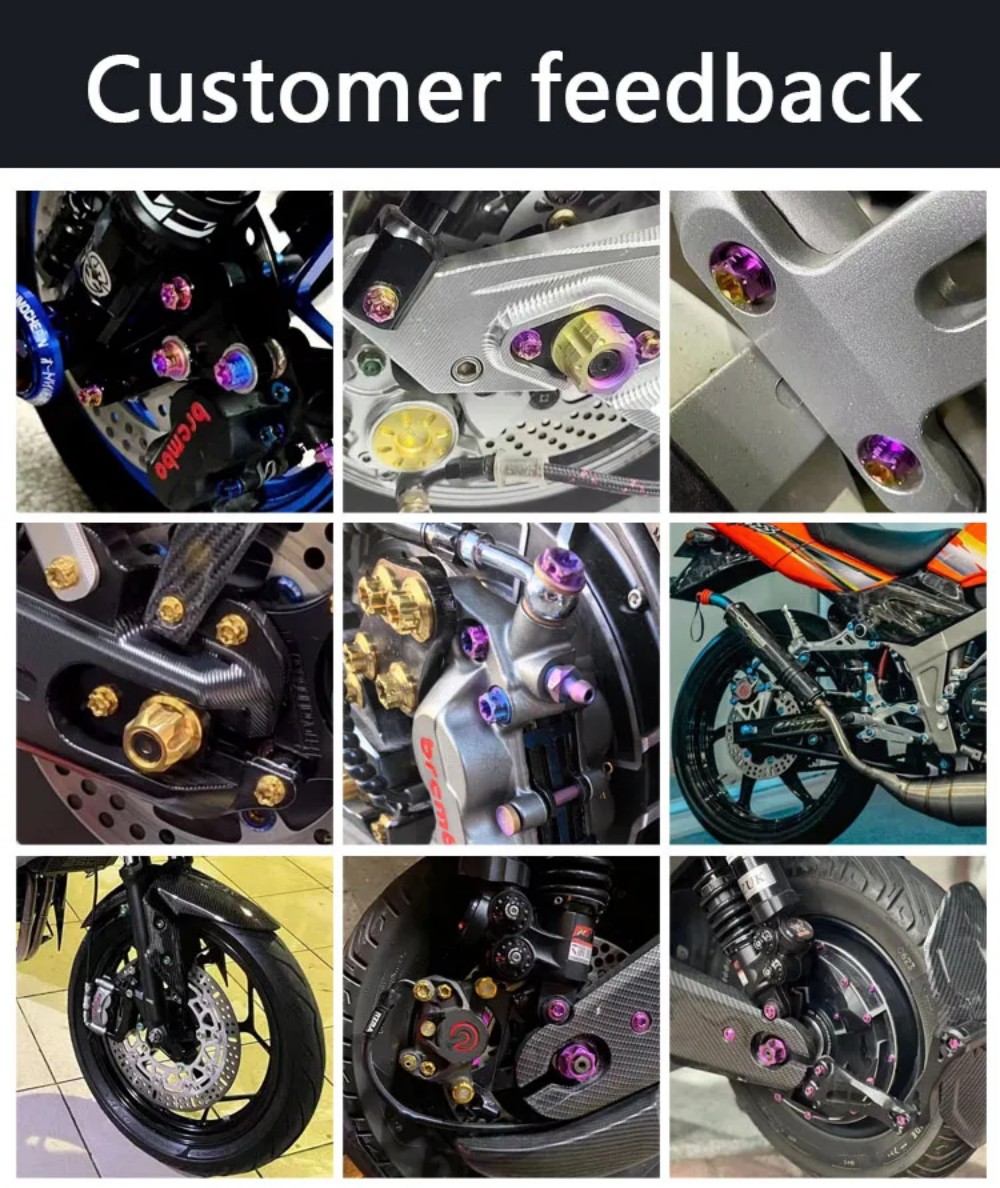

Customizable colors (such as gold, blue, purple, and black) are available to meet the needs of personalized motorcycle modifications. For example, gold anodized titanium bolts are often used on retro-style motorcycles, complementing the chrome-plated bodywork. Blue and purple are more popular with sporty motorcycles, creating a visually appealing contrast with the paint job. Furthermore, the anodized film, with a hardness of up to HV500-600, effectively improves the wear resistance of the bolt head, preventing scratches caused by tool removal.

Related products

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Anodized Colored Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Colored Automotive Titanium Bolts