Custom Manufacturing Titanium Fasteners

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

In core sectors such as aerospace, marine engineering, and medical equipment, standard titanium fasteners are no longer able to meet the stringent requirements for structural adaptability, performance specificity, and environmental tolerance in specific scenarios. For example, connecting components in high-temperature areas of aircraft engines must withstand temperatures exceeding 600°C and be resistant to gas corrosion. Fasteners on deep-sea drilling platforms must withstand high pressure and severe seawater corrosion at depths of thousands of meters. These specialized operating conditions place personalized demands on the size, structure, and material properties of titanium fasteners, making custom manufacturing a necessity.

Titanium and titanium alloys, due to their low density, high strength, excellent corrosion resistance, and mechanical stability over a wide temperature range, are the preferred base materials for custom fasteners. However, titanium alloys’ poor thermal conductivity, high chemical activity, and significant work-hardening effects make custom manufacturing challenging, including difficulties in structural molding, precision control, and ensuring consistent performance.

| Size | M3-M36. or non-standard according to your requirements. |

| Materials | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 |

| Type | Screw/bolts(cap head/socket head/hex head/round head/headless/taper head/shoulder head.etc) |

| Thread | UNC, UNF, UNEF, M, BSW, BSF, TR, ACME, NPT TP |

| Surface Treatment | Anodizing, sandblasting,black oxide, polishing. powder coating, brushing,electroplating, passivation |

| Drawingformat | IGS,STP,STEP,X-T,DXF,DWG,PrO/E,PDF,PNG,JPG |

| Application | Motorcycle,Bicycle,cars |

| Certifications | ISO9001,CE,BV |

| Service | 1,Free samples will be sent to you after confirming the order. |

| 2,Material test report,Hardness test report,Quality Inspection Report as your require. | |

| 3,video and photos with details freely during. | |

| 4,Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.If you don’t have a professional drawing, you can contact us and we will customize it for you according to your requirements. | |

| Euipment | CNC Turning, CNC Milling, CNC 5-axis Turning-milling Compound, CNC Gear Hobbing Machine, CNC Gear Shaping Machine, Manual Milling Machine, Grinding Machine, and Laser Engraving Machine. |

| Quality | Two-dimensional Imager, CCD Image Detection Equipment, Rockwell Hardness Tester, Vickers Hardness Tester, Electron Microscope,Salt Spray Tester,etc. |

| Packing | PE bag,EPE, standardcardboard boxes or plastic trays, sponge trays,cardboard trays,etc |

| Precision | TIR ≤.002″ (0.02mm-5mm) |

| MOQ | In stock:50pcs Custom-made:100pcs |

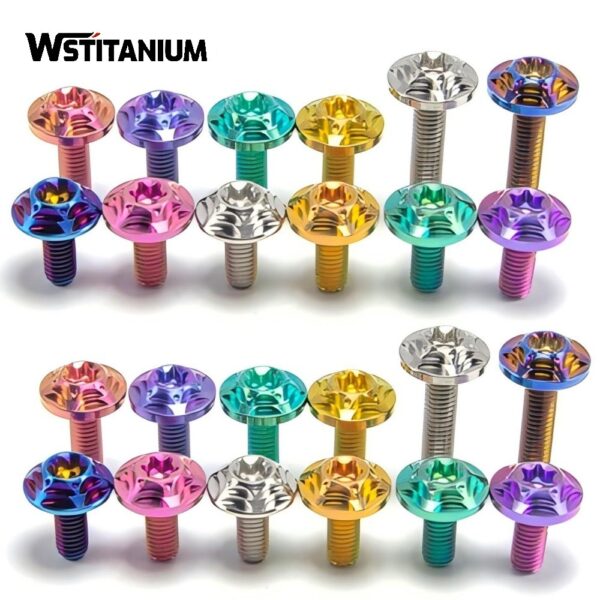

| Color | Silver, black, red, yellow, green, blue, color, customized according to your requirements |

| Delivery time | In stock : Sample 3days,Bulk goods 7-15days. |

| Custom : Sample 7-10 working days, Bulk goods 15-20 working days. |

Core Technologies of Custom Manufacturing

The core premise of custom manufacturing is to precisely match material properties with operating conditions. Titanium alloy grades must be selected based on parameters such as the operating environment, load conditions, and media characteristics. Material selection requires a “working conditions – performance – grade” mapping system. For high-load aerospace structures, TC4 (Ti-6Al-4V) titanium alloy is preferred, boasting a tensile strength of 900-1100 MPa and excellent toughness. For high-temperature environments (300-500°C), TC11 (Ti-6.5Al-3.5Mo-1.5Zr-0.3Si) is preferred, achieving a high-temperature strength retention rate of over 85%. For marine engineering and chemical industries, TA2 pure titanium or Ti-6Al-4V-ELI are preferred, offering a seawater corrosion rate of less than 0.001 mm/year. For medical implants, Ti-6Al-7Nb is used, offering excellent biocompatibility.

For extreme requirements such as ultra-high temperature and ultra-high strength, material modification technology is needed to enhance performance: β heat treatment is used to refine the grains of TC21 titanium alloy, which can increase the tensile strength to more than 1200MPa; Al₂O₃ ceramic coating is prepared on the surface of titanium fasteners through plasma spraying technology, and the temperature resistance limit can exceed 800℃; laser surface alloying treatment can increase the surface hardness from HRC30 to HRC55 or above, enhancing wear resistance.

Core Technologies of Custom Manufacturing

The core premise of custom manufacturing is to precisely match material properties with operating conditions. Titanium alloy grades must be selected based on parameters such as the operating environment, load conditions, and media characteristics. Material selection requires a “working conditions – performance – grade” mapping system. For high-load aerospace structures, TC4 (Ti-6Al-4V) titanium alloy is preferred, boasting a tensile strength of 900-1100 MPa and excellent toughness. For high-temperature environments (300-500°C), TC11 (Ti-6.5Al-3.5Mo-1.5Zr-0.3Si) is preferred, achieving a high-temperature strength retention rate of over 85%. For marine engineering and chemical industries, TA2 pure titanium or Ti-6Al-4V-ELI are preferred, offering a seawater corrosion rate of less than 0.001 mm/year. For medical implants, Ti-6Al-7Nb is used, offering excellent biocompatibility.

For extreme requirements such as ultra-high temperature and ultra-high strength, material modification technology is required to enhance performance: β heat treatment is used to refine the grains of TC21 titanium alloy, which can increase the tensile strength to more than 1200MPa; Al₂O₃ ceramic coating is prepared on the surface of titanium fasteners through plasma spraying technology, and the temperature resistance limit can exceed 800℃; laser surface alloying treatment can increase the surface hardness from HRC30 to HRC55 or above, enhancing wear resistance.

(1) Forging

It is suitable for customized fasteners with large head volume and the need to ensure the continuity of metal streamlines (such as large flange bolts). Isothermal forging is used to heat the billet and the mold to the same temperature (usually 700-900℃), and slowly apply pressure to make the billet fit the mold cavity, which can effectively avoid the cracking problem caused by the poor low-temperature plasticity of titanium alloy. The head forming accuracy can reach ±0.5mm, and the metal streamlines are distributed along the head contour. The fatigue life is increased by more than 40% compared with ordinary forging.

(2) CNC Machining

For customized requirements of special-shaped structures (such as eccentric heads, combined threads, hollow rods) and high-precision tolerances (≤±0.005mm), CNC composite machining technology is used. The 5-axis linkage machining center realizes integrated turning, milling, drilling, and tapping, reducing the number of clamping times (single clamping can complete multiple processing steps), and the positioning error is controlled within 0.003mm. Paired with carbide coated tools (such as TiAlN coating) and a high-pressure internal cooling system, it can effectively solve the problems of tool sticking and chip build-up in titanium alloy machining, and the surface roughness can be as low as Ra0.2μm.

(3) 3D printing

Adaptive fasteners with extremely complex structures (such as internal flow channels, lattice structures) and small batch customization. Using selective laser melting (SLM) technology, titanium alloy powder is used as raw material, and laser sintering is performed layer by layer. The molding accuracy can reach ±0.02mm, which can realize special-shaped structure design that cannot be completed by traditional processing. After printing, hot isostatic pressing (HIP) treatment is required to eliminate internal porosity defects and achieve a density of more than 99.8%, with mechanical properties comparable to forgings.

Surface Treatment

The service life and reliability of customized fasteners depend largely on surface properties, and targeted surface treatment is required based on corrosion, wear, sealing and other requirements.

(1) Anti-corrosion

In corrosive environments such as marine and chemical industries, micro-arc oxidation technology is used to form a ceramic oxide film with a thickness of 5-20μm on the surface, which can resist neutral salt spray corrosion for more than 5000 hours; for mildly corrosive environments, phosphating treatment is performed to form a phosphate conversion film, which can improve the adhesion of subsequent coatings. Combined with the coating of polytetrafluoroethylene coating, it has both anti-corrosion and friction reduction functions.

(2) Wear resistance

For customized fasteners used to connect moving parts, laser cladding technology is used to prepare WC-Co metal ceramic coatings on threads or contact surfaces. The surface hardness can reach HV1200, and the wear resistance is 5-8 times higher than that of the base material; for low-load wear scenarios, nitriding treatment is used to form a nitride layer with a thickness of 0.1-0.3mm, which can effectively reduce the friction coefficient.

(3) Sealing

In high-pressure sealing scenarios, anaerobic adhesive coating is applied to the threaded parts, which forms an elastic sealing layer after curing, and the sealing pressure can reach more than 30MPa; for fasteners in a vibration environment, the thread micro-deformation structure is formed by surface rolling, or nylon anti-loosening coating is applied to achieve permanent anti-loosening, and the anti-loosening performance meets the requirements of GB/T 10431-2008 standard.

Quality Inspection

Customized fasteners must pass the whole process inspection to ensure that the performance meets the standards, and establish a three-level inspection system of “raw materials – semi-finished products – finished products”. At the raw material stage, the chemical composition is detected by a spectrometer to ensure the purity of the titanium alloy grade (the content of impurity elements Fe is ≤0.3%, and the content of O is ≤0.2%); at the semi-finished product stage, the dimensional accuracy is detected by a three-coordinate measuring machine, and the geometric tolerance measurement resolution reaches 0.001mm; at the finished product stage, mechanical performance testing (tensile strength, yield strength, impact toughness), non-destructive testing (ultrasonic detection of internal defects, magnetic particle detection of surface cracks) and working condition simulation testing (high temperature endurance test, corrosion fatigue test) are carried out to ensure that the customized requirements are met.

Wstitanium has introduced high-end equipment, including a German-imported 5-axis CNC machining center, SLM 3D printers, and isothermal forging lines. CNC machining achieves positioning accuracy of ±0.001mm, and 3D printing achieves a density of ≥99.8%, meeting the needs of complex structures and high-precision customization. A full-process quality control system has been established, utilizing an MES system to record machining parameters (cutting speed, feed rate, heat treatment temperature, etc.) in real time, ensuring traceability of every product. Equipped with testing equipment such as a three-dimensional measuring machine, a universal material testing machine, and a salt spray test chamber, the company implements 100% dimensional inspection, 100% surface defect detection, and spot-checked mechanical property testing, resulting in a consistently high product qualification rate exceeding 99.5%.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Custom Gr5 Titanium Fasteners

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts