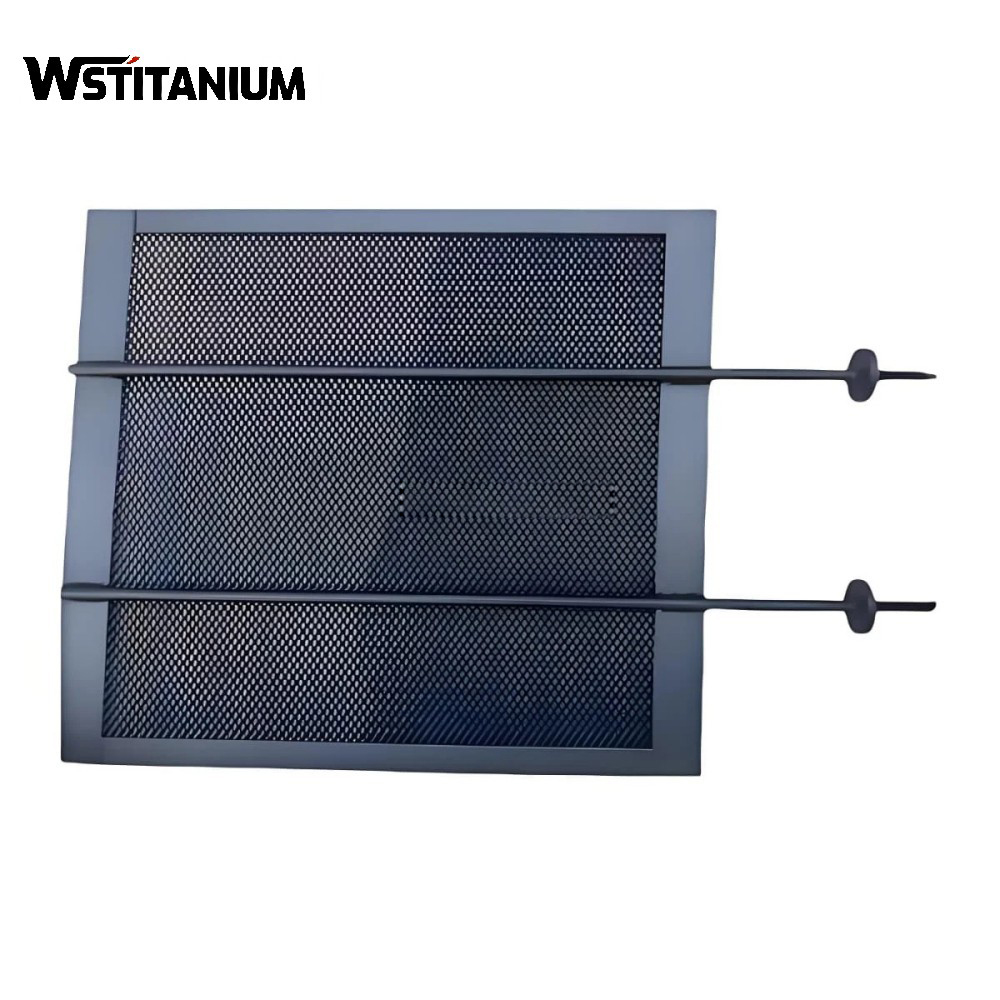

Lead Dioxide Titanium Anode

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

Lead dioxide titanium anode (PbO₂/Ti Anode) is based on pure titanium with a lead dioxide coating on the surface. It combines the high strength and corrosion resistance of titanium with the high electrocatalytic activity and excellent stability of lead dioxide, making it a preferred solution for electrolysis, environmental protection, metallurgy, and other fields. The lead dioxide titanium anode has a service life of 3-5 years. Compared to platinum electrodes, it reduces costs by over 80% while maintaining similar catalytic efficiency, especially in high-concentration pollutant degradation and high current density electrolysis scenarios.

| Parameter | Specification |

| Substrate | Gr1/Gr2 Titanium |

| Coating Type | Lead dioxide |

| Dimension & Shape | Plate, mesh, rod, or customized |

| Coating Thickness | 500~1000 µm |

| Voltage | < 1.13V |

| Current Density | < 5000A/M^2 |

| Work Time | 100-500 hours |

| pH Range | 1-4 |

| Noble Metal Content | 8-13g/㎡ |

| Working Temperature | < 60 °C |

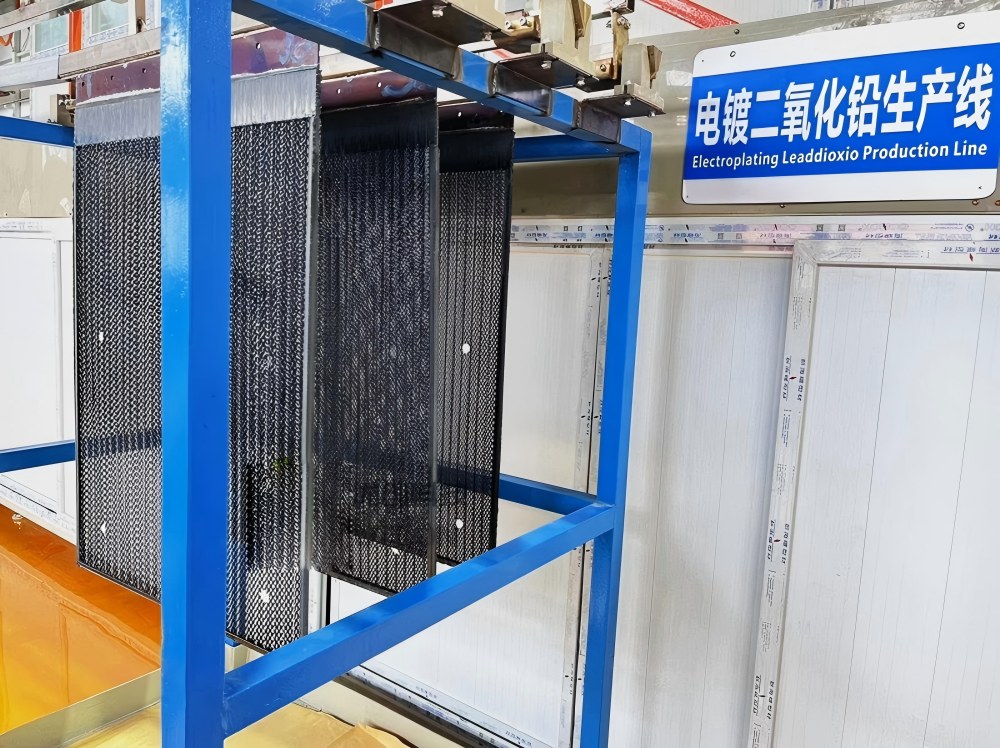

Manufacturing Lead Dioxide Titanium Anodes

Wstitanium, leveraging years of experience in titanium machining and electrochemical technology, is a renowned manufacturer of lead dioxide titanium anodes in China. With ISO 9001 quality system certification and EU CE certification, Wstitanium has become a core supplier to numerous global environmental protection equipment manufacturers and electrolytic metallurgy companies.

(I) Customized Substrates

Wstitanium uses pure titanium (titanium content ≥99.6%) as its substrate material, improving corrosion resistance by over 15% in strong acid and alkaline electrolytes (such as sulfuric acid systems with a pH <1 and sodium hydroxide systems with a pH >13).

Plate electrodes: 1-3mm thick, 0.1-5㎡ in area, suitable for large electrolytic cells (such as industrial wastewater treatment tanks);

Tube electrodes: 10-50mm inner diameter, 0.5-3m in length, suitable for reaction systems with high flow rates and high mass transfer efficiency (such as advanced drinking water treatment);

Mesh electrodes: 2-10mm pore diameter, 50%-70% porosity, suitable for applications requiring uniform electrolyte flow (such as ozone generation by electrolytic oxidation).

| Element | Grade I Titanium | Grade 2 Titanium |

| Iron (Fe) | 0.050% max. | 0.02% max. |

| Carbon (C) | 0.08% max. | 0.05% max. |

| Nitrogen (N) | 0.03% max. | 0.03% max. |

| Hydrogen (H) | 0.015% max. | 0.015% max. |

| Oxygen (O) | 0.18% max. | 0.05% max. |

| Single Impurity (Each) | 0.10% max. | 0.10% max. |

| Other Impurities (Total) | 0.10% max. | 0.03% max. |

| Titanium (Ti) | Remainder | Remainder |

Wstitanium’s titanium substrates utilize a “double acid wash + electrochemical oxidation” process: hydrofluoric acid is used to remove the surface oxide film, followed by deep etching with oxalic acid. Finally, electrochemical oxidation forms a dense TiO₂ transition layer 5-8μm thick. This transition layer has been tested to have a bonding strength exceeding 15MPa, effectively preventing spalling of the active layer.

(II) Coating

Wstitanium first uses a thermal decomposition method to form a 10-20μm thick α-PbO₂ base layer on the titanium substrate. This base layer bonds tightly to the TiO₂ transition layer, blocking electrolyte penetration. A 30-80μm thick β-PbO₂ active layer is then deposited using an acidic electrodeposition method (lead nitrate-nitric acid system). Trace amounts of fluoride ions (0.1-0.5g/L) and cobalt ions (0.05-0.1g/L) are added to the electrolyte. Fluoride ions refine the β-PbO₂ grains and increase catalytically active sites, while cobalt ions enhance the active layer’s oxidation resistance, slowing the dissolution of lead dioxide at high potentials.

Wstitanium’s lead dioxide titanium anodes have a service life of over 4.5 years at a current density of 1000A/㎡ in a 20% sulfuric acid electrolyte at 60°C. At the same time, when degrading industrial wastewater with a COD concentration of 500mg/L, its current efficiency can reach 85%, a 10%-15% improvement over traditional electrodeposition electrodes.

(III) Quality Control

Wstitanium has established a comprehensive quality control system. Key tests include:

Raw Material Testing: Each batch of pure titanium undergoes composition analysis (ICP-MS to detect impurity content) and mechanical property testing (tensile strength and elongation) to ensure that the substrate purity and strength meet standards.

Semi-finished Product Testing: After substrate pretreatment, the surface porous structure is observed using a scanning electron microscope (SEM) to ensure that the pore size and porosity meet the requirements. After the intermediate layer is prepared, the bonding strength is tested using an adhesion tester.

Finished Product Testing: Finished electrodes undergo three core tests: ① Electrochemical Performance Testing (Linear Sweep Voltammetry to measure oxygen potential, ensuring ≤1.65V vs. SCE); ② Corrosion Resistance Testing (Neutral Salt Spray Test for 720 hours without corrosion); and ③ Life Simulation Testing (Estimating service life under accelerated conditions with an error of ≤5%).

As an excellent insoluble electrode, the lead dioxide titanium anode, through its composite structure of a “titanium substrate + lead dioxide active layer,” achieves a balance of high catalytic activity, long life, and low cost. It has demonstrated significant application value in fields such as electrolytic metallurgy, environmental treatment, chemical synthesis, and drinking water purification.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Anodized Titanium Nut

-

Titanium Fasteners

Colored Automotive Titanium Bolts