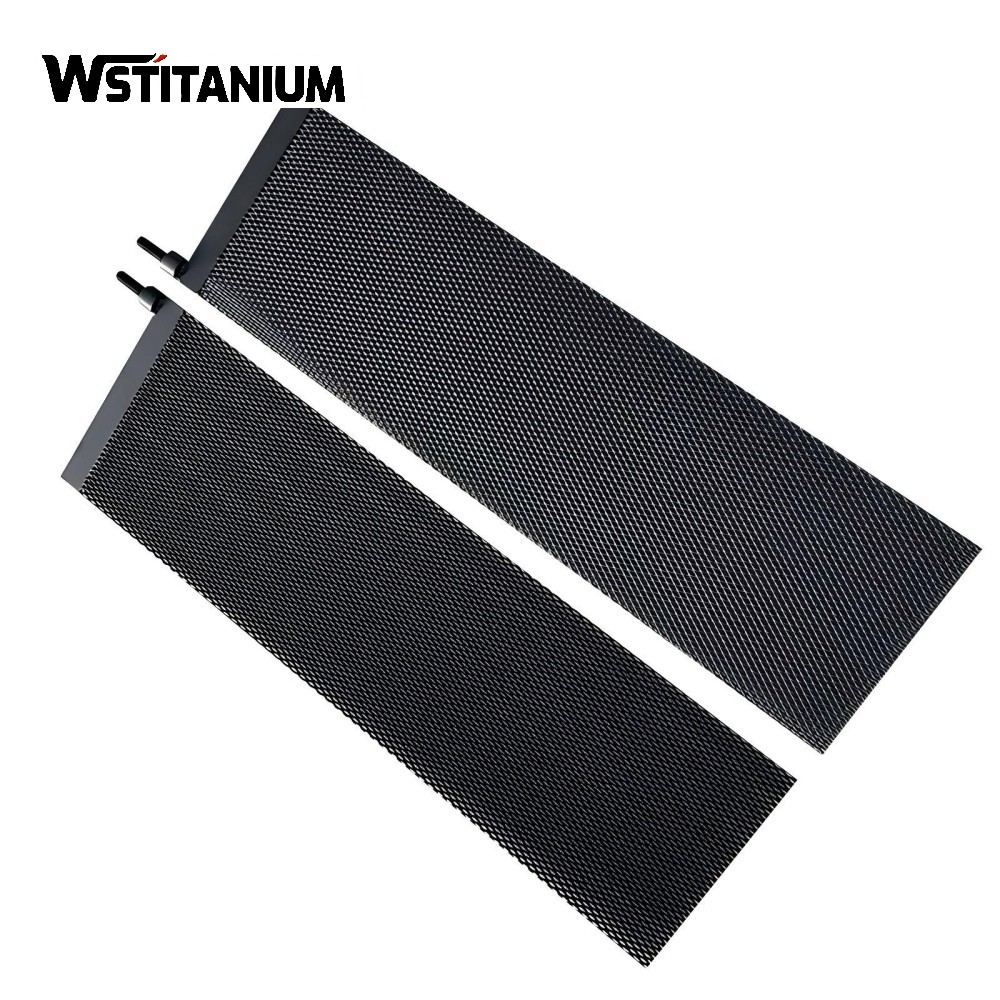

MMO Titanium Anode For Electroplating

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

The core of electroplating is achieving a uniform, dense, and highly adherent coating through precise electrochemical deposition. Within this technological system, the anode directly determines bath stability, coating quality, efficiency, and environmental friendliness, serving as the “powerhouse” of the electroplating system. Mixed metal oxide (MMO) titanium anodes have revolutionized the electroplating industry. In precision electroplating, MMO titanium anodes can improve coating thickness uniformity to 3%, reduce scrap rates by 80%, and reduce energy consumption by 10%-30%.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂), Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Working Principle of MMO Titanium Anodes

The titanium substrate is made of Gr1 or Gr2 titanium with a purity of ≥99.5%. It undergoes a three-step pretreatment process: sandblasting, pickling, and electrolytic polishing. The surface roughness is controlled to Ra1.6-6.3μm, creating a porous structure to enhance coating adhesion.

| Grade I | Grade 2 |

| 0.20% max. | 0.30% max. |

| 0.08% max. | 0.08% max. |

| 0.03% max. | 0.03% max. |

| 0.015% max. | 0.015% max. |

| 0.18% max. | 0.25% max. |

| 0.10% max. | 0.10% max. |

| 0.40% max. | 0.40% max. |

| Remainder | Remainder |

MMO Coating

The coating is 5-40μm thick and consists of active and stabilizing components, with a bonding strength ≥30MPa and a resistivity ≤10⁻⁴Ω·cm. The active components (such as IrO₂ and RuO₂) provide catalysis, reducing the overpotential of oxygen or chlorine evolution reactions; the stabilizing components (such as Ta₂O₅ and TiO₂) form a physical barrier, enhancing the coating’s corrosion and wear resistance. The coating is sintered at 450-550°C to form a crystalline structure, ensuring a balance between catalytic activity and structural stability.

Electroplating Reaction Mechanism

MMO titanium anodes primarily serve as insoluble anodes in electroplating, fulfilling the dual functions of conducting electricity and catalyzing oxidation reactions. The core reactions fall into two categories:

Oxygen evolution: In sulfate and nitrate baths, the iridium-tantalum coating catalyzes the oxidation of water molecules to produce oxygen. The anodic reaction is: 4OH⁻ – 4e⁻ = O₂↑ + 2H₂O (alkaline) or 2H₂O – 4e⁻ = O₂↑ + 4H⁺ (acidic). The coating’s nanoscale active sites significantly reduce the oxygen evolution overpotential by modulating the surface electronic state, reducing energy consumption by 10%-30% compared to lead alloy anodes. Furthermore, its insolubility prevents anode dissolution, ensuring that impurity ion concentrations in the bath are controlled below 5ppm, providing a foundation for a uniform and dense coating.

Chlorine Evolution: In chloride plating baths, the ruthenium-iridium coating preferentially catalyzes the chloride ion oxidation reaction: 2Cl⁻ – 2e⁻ = Cl₂↑. The generated chlorine gas partially reacts with water to form hypochlorous acid, which oxidizes organic impurities in the plating bath, purifying the bath. The high selectivity of this reaction reduces the likelihood of side reactions, maintaining current efficiency above 90%, and reducing energy waste by 5%-10% compared to graphite anodes. In acid copper plating, this mechanism can increase the purity of the copper coating from 99.5% to 99.95%.

Performance Optimization

The low resistance of the titanium substrate and MMO coating ensures uniform current distribution, preventing localized current burns caused by excessive current or uneven deposition caused by low current. Specialized morphology (such as the mesh design) accelerates bubble detachment, reduces aeration on the electrode surface, and reduces ohmic losses. Tests show that the inter-electrode ohmic drop of the mesh anode is 40% lower than that of a plate anode, and the cell voltage fluctuation is controlled within ±2%. The insoluble nature of the anode prevents contamination from heavy metals and carbon powder impurities, extending the life of the plating bath from 3-6 months with traditional anodes to 3-5 years. This reduces bath maintenance costs by 60% and wastewater treatment by 45%.

Wstitanium Advantages

Wstitanium utilizes high-quality titanium with a purity exceeding 99.7%, establishing a comprehensive quality control system from substrate selection to pretreatment. A database of coating formulas covering mainstream electroplating scenarios has been established, enabling precise customization based on bath type, coating type, and production parameters:

Precision Nickel/Copper Plating: Optimized “IrO₂-Ta₂O₅” nano-coating formulas are used. Atomic layer deposition technology is used to control the coating grain size to 50-100nm, reducing oxygen evolution overpotential by 15% and achieving ≤5% performance degradation after 5000 hours of continuous operation at a current density of 1000A/m².

Chlorine-Containing Plating Solution: Developed a “RuO₂-IrO₂-TiO₂” ternary coating with a chloride ion oxidation selectivity of 99%, a corrosion rate as low as 0.01mm/year in a 3.5% NaCl solution, and a lifespan extended by 20% compared to the industry standard.

High-End Gold Plating Solution: Utilizing a platinum-iridium composite modified coating with a thickness controlled at 2-3μm, the coating achieves catalytic activity comparable to pure platinum, yet at a 20% lower cost and a 99.99% purity.

Each batch of coating undergoes X-ray diffraction (XRD) and scanning electron microscopy (SEM) testing to ensure a complete crystal structure and the absence of pinhole defects.

Solution Capabilities

Wstitanium goes beyond a simple product supply model to provide customized solutions for diverse electroplating scenarios:

Deep-hole copper plating on circuit boards: Providing a high-porosity (75%) mesh anode with a pulsed current adaptation design, achieving a 92% coating uniformity within holes with a 10:1 aspect ratio, eliminating the problem of uneven deposition.

Nickel plating for automotive parts: Developing large-scale plate anodes and employing a zoned coating design, we achieve coating thickness variations within 3μm on large workpieces, reducing scrap rates from 8% to 1.5%.

Continuous Electroplating Line: We offer coiled anodes in lengths up to 100 meters. Equipped with an automatic tension control system, we enable uninterrupted production, increasing production efficiency by 30%.

Small Precision Electroplating: We have developed micro tubular anodes (5mm outer diameter) suitable for laboratory and small-batch production needs, improving coating uniformity on tiny parts by 40%.

As a key electroplating material, MMO titanium anodes, leveraging the combined advantages of a titanium substrate’s corrosion resistance and the catalytic properties of an MMO coating, completely solve the issues of traditional lead and graphite anodes, such as contamination of the plating solution, severe wear and tear, and high energy consumption. Based on coating function, they can be categorized as iridium-tantalum (oxygen-evolving), ruthenium-iridium (chlorine-compatible), and platinum (high-end). They can be customized in various configurations, including mesh, plate, and tubular, to precisely meet electroplating needs.

Related products

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

Titanium Fasteners For Bicycles

-

Titanium Fasteners

Titanium Fasteners For Automotive

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Custom Gr5 Titanium Fasteners

-

Titanium Fasteners

Titanium Screws and Bolts

-

Titanium Fasteners

Colored Titanium Washers

-

Titanium Fasteners

Colored Motorcycle Titanium Bolts