MMO Titanium Anode For Electrolyzed Water

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

As a core means of achieving energy conversion and water purification, water electrolysis has been widely adopted in key areas such as green hydrogen production, seawater desalination, wastewater treatment, and disinfection. Mixed metal oxide (MMO) titanium anodes demonstrate outstanding advantages in water electrolysis, including low overpotential, high current efficiency, and long life. Compared to graphite anodes, MMO titanium anodes reduce energy consumption in water electrolysis systems by 10%-20% and extend their service life by more than eight times. Their global penetration rate in the chlor-alkali industry and other sectors has exceeded 70%.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂), Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Working Principle of the MMO Titanium Anode

The MMO titanium anode’s operating mechanism is based on a “substrate-coating” synergistic effect, achieving efficient water molecule conversion through precise electrocatalysis. Its core principles encompass three key aspects: structural support, charge conduction, and reaction catalysis.

Titanium Substrate

The titanium substrate serves as the structural support core and is made of Gr1 or Gr2 titanium with a purity of ≥99.7%. Its surface is sandblasted or electropolished to a roughness of Ra1.6-6.3μm, creating a porous structure that enhances coating adhesion.

| Element | Grade I | Grade 2 |

| Iron (Fe) | 0.20% max. | 0.30% max. |

| Carbon (C) | 0.08% max. | 0.08% max. |

| Nitrogen (N) | 0.03% max. | 0.03% max. |

| Hydrogen (H) | 0.015% max. | 0.015% max. |

| Oxygen (O) | 0.18% max. | 0.25% max. |

| Single Impurity (Each) | 0.10% max. | 0.10% max. |

| Other Impurities (Total) | 0.40% max. | 0.40% max. |

| Titanium (Ti) | Remainder | Remainder |

MMO Coating

This functional layer, composed of active and stabilizing components, has a thickness of 5μm-20μm, a bonding strength of ≥30MPa, and a resistivity of ≤10⁻⁴Ω·cm. Active components (such as IrO₂ and RuO₂) provide catalytic sites, reducing the activation energy of the reaction; stabilizing components (such as Ta₂O₅ and TiO₂) enhance the coating’s corrosion resistance and prevent spalling during electrolysis. The coating is prepared by a thermal decomposition method: a solution of precious metal salts is applied to a titanium substrate and sintered at 450-550°C to form a crystalline structure, ensuring a balance between catalytic activity and structural stability.

Chlorine Evolution Reaction

In a chlorine-dominated reaction (high-chloride environment), the ruthenium-based coating preferentially catalyzes the oxidation of chloride ions in a chlorine-containing electrolyte (such as seawater or saline). The anodic reaction is: 2Cl⁻ – 2e⁻ = Cl₂↑. The generated chlorine gas further reacts with water to form disinfectants such as hypochlorous acid: Cl₂ + H₂O ⇌ HCl + HClO. The d-orbital electronic structure of the ruthenium-based coating enables efficient charge transfer with chloride ions, resulting in a chlorine evolution overpotential as low as below 1.0V and a current efficiency exceeding 95%.

Oxygen Evolution Reaction

In acidic or pure aqueous solutions, iridium-based coatings catalyze the oxidation of water molecules to produce oxygen. The anodic reaction is: 4OH⁻ – 4e⁻ = O₂↑ + 2H₂O (alkaline) or 2H₂O – 4e⁻ = O₂↑ + 4H⁺ (acidic). In hydrogen electrolysis systems, the anodic oxygen evolution reaction and the cathodic hydrogen evolution reaction proceed synergistically, with the overall reaction being: 2H₂O = 2H₂↑ + O₂↑. Iridium-based coatings regulate the surface electronic state to keep the oxygen evolution overpotential below 0.3V, significantly reducing electrolysis energy consumption. In ozone production, specially formulated iridium-tantalum coatings enable the anodic reaction to produce O₃, increasing current efficiency to over 20%.

Types of MMO Titanium Anodes

The performance differences of MMO titanium anodes are primarily determined by the coating composition and morphology. Different types exhibit specific compatibility in water electrolysis environments, requiring precise selection based on the electrolyte composition, reaction type, and equipment structure.

Ruthenium-Coated Titanium Anodes

Ruthenium (Ru) oxide is the primary active component, typically doped with elements such as iridium (Ir) and tin (Sn) to adjust performance. Their core advantage is their efficient catalytic performance in the chloride ion oxidation reaction. At a current density of 1 A/cm², their chloride evolution overpotential is 140 mV lower than that of graphite anodes, making them particularly suitable for electrolysis applications with high chloride content electrolytes.

Iridium-Coated Titanium Anodes

Iridium (Ir) oxide is the core active component, combined with stabilizing components such as tantalum (Ta) oxide, to form a classic composite system such as “IrO₂-Ta₂O₅” (Ir oxide accounts for 10%-30%). This type of anode focuses on catalyzing the oxygen evolution reaction by the oxidation of water molecules. Its oxygen evolution potential is typically below 1.40V (1 mol/L H₂SO₄ system), making it the preferred anode for applications such as water electrolysis, hydrogen production, and ozone generation.

Platinum-Coated Titanium Anode

A 1-5μm thick platinum (Pt) coating is formed on a titanium substrate through electroplating, combining the extremely high catalytic activity of platinum with the structural stability of titanium. Due to the high cost of platinum, it is primarily used in specialized water electrolysis applications requiring extremely high product purity, such as electronic-grade ultrapure water production. Its initial investment is 3-5 times that of an iridium-based anode.

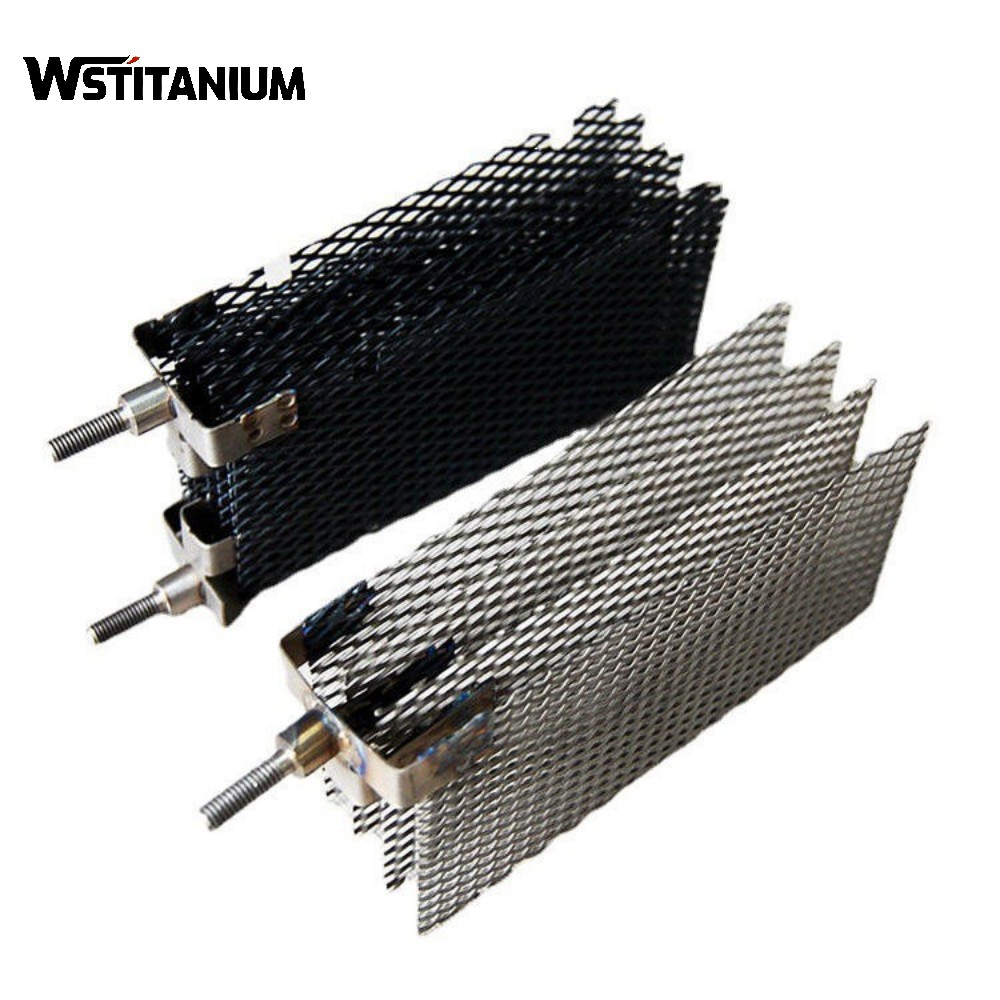

Mesh MMO Titanium Anode

Composed of titanium conductive strips welded together into a grid pattern, the mesh size can be customized (e.g., 12.7×4.5mm or 6×3mm), enabling wide-area current distribution. Its hollow structure facilitates the rapid detachment of bubbles generated by electrolysis from the electrode surface, reducing the “bubble shielding effect” and lowering the inter-electrode ohmic drop by approximately 700mV. It is widely used in large-scale water electrolysis hydrogen production cells and wastewater treatment electrolysis equipment.

Tubular/Rod MMO Titanium Anodes

Featuring a hollow or solid cylindrical structure with an outer diameter of 10mm-50mm, these anodes can be customized up to 6m in length and extended via flange connections. This design is ideal for specialized applications such as deep-well electrolysis and pipeline lining water treatment. In seawater desalination electrolytic desalination modules, tubular anodes achieve high surface area per unit volume, increasing desalination efficiency by 30%. With a wall thickness of 0.5mm-3mm, they can withstand operating pressures of 0.1MPa-1.0MPa, making them suitable for high-pressure water electrolysis environments.

Flexible MMO Titanium Anodes

Made with a flexible conductive polymer substrate and a composite MMO coating, they can conform to complex curved surfaces such as tank linings and irregularly shaped electrolytic reactors. Their high flow density and easy installation make them particularly advantageous for use in small, portable electrolytic disinfection equipment, overcoming the poor adaptability of traditional rigid anodes. Flexible anodes achieve 92% current uniformity in irregular electrolysis spaces, far exceeding the 75% achieved by rod-shaped anodes.

Strips MMO Titanium Anode

Standard specifications are 6.35mm wide and 0.635mm thick, with roll lengths up to 150 meters. These strips are primarily used in continuous water electrolysis systems, such as assembly-line disinfectant water production equipment. Continuous laying enables long-distance electrolysis, and combined with gypsum powder backfill to optimize current distribution, they can reduce specific energy consumption by 15% in large-scale sodium hypochlorite production.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Flanged Hex Bolt

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

CNC Machining Titanium Fasteners

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs

-

Titanium Fasteners

Burnt Titanium Wheel Bolt