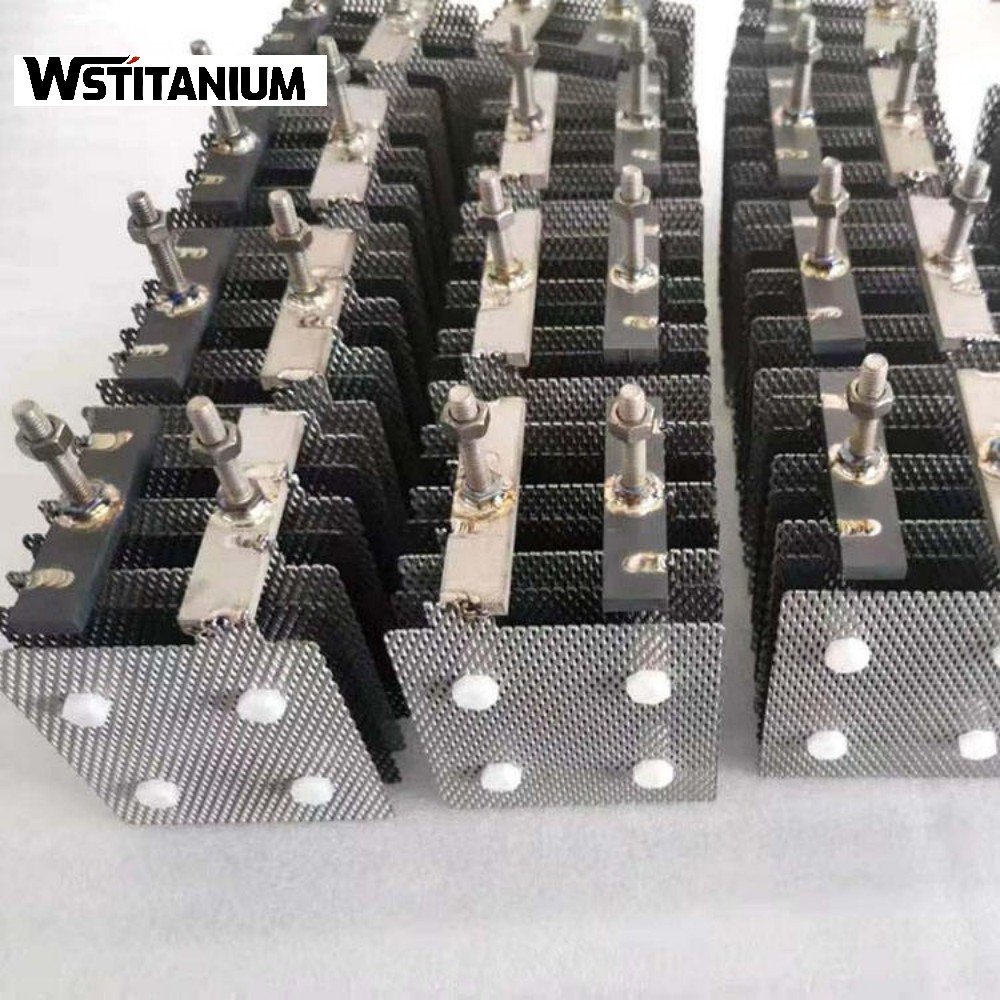

MMO Titanium Anode For Phenolic

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

As an important chemical raw material, phenolic formaldehyde is widely used in key sectors such as plastics manufacturing, coatings production, and adhesive research and development. However, the use of phenolic formaldehyde inevitably leads to the discharge of highly toxic wastewater. Pollutants such as phenol and formaldehyde contained in phenolic formaldehyde are highly biotoxic and difficult to degrade, posing a serious threat to the ecological environment and human health.

The mixed metal oxide titanium electrode (MMO titanium anode), a next-generation dimensionally stable anode (DSA), utilizes an industrially pure titanium substrate and utilizes a precision-coated precious metal oxide functional layer to create a highly efficient catalytic system. It demonstrates significant advantages in the treatment of difficult-to-degrade organic wastewater. Its core properties, including high electrocatalytic activity, excellent corrosion resistance, and long-term stability, perfectly match the treatment requirements of phenolic formaldehyde wastewater, which is characterized by high salinity, high toxicity, and difficult-to-degrade properties.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Phenolic Formaldehyde Pollution

The resin manufacturing industry is the primary application area for phenolic compounds. The production of thermoplastic and thermosetting phenolic resins covers a wide range of applications, from everyday plastics to industrial materials. The production of thermoplastic phenolic resins alone generates significant amounts of phenolic and formaldehyde-containing wastewater. Phenolic compounds serve as key reaction substrates in dye intermediate synthesis and pharmaceutical raw material preparation, and their production wastewater is often accompanied by a variety of toxic byproducts. Phenolic formaldehyde pollution, primarily carried by wastewater, exhibits the typical characteristics of complex composition, high toxicity, and resistance to degradation.

Severe Toxicity: Wastewater contains not only unreacted phenol (concentrations can reach thousands of mg/L) and formaldehyde, but also methanol, low-molecular-weight resins, and reaction byproducts. Phenol can cause protein denaturation and coagulation. Formaldehyde, as a protoplasmic toxin, can cause cell inactivation and gene mutations, and both are listed as priority pollutants.

High Pollutant Concentration: Wastewater CODcr levels generally exceed 10,000 mg/L, and under extreme conditions can reach tens of thousands of mg/L. The strong inhibitory effects of phenol and formaldehyde on microorganisms typically result in wastewater B/C ratios below 0.2.

High Salt: The use of acidic catalysts such as sulfuric acid in the production of thermoplastic phenolic resins leads to significantly elevated sulfate content in wastewater, further inhibiting microbial activity.

Environmental Hazards: If phenol-containing wastewater is discharged untreated, concentrations exceeding 100 mg/L can lead to crop yield reductions. Concentrations above 500 mg/L pose a serious threat to aquatic life, and pollutants accumulate through the food chain, ultimately endangering human health.

Working Principle of the MMO Titanium Anode

The MMO titanium anode degrades phenolic pollutants through electrochemical oxidation. Its core mechanism is based on the synergistic effect of “direct oxidation + indirect oxidation.” The functional layer of precious metal oxides, such as iridium and ruthenium, coated on the surface of the MMO titanium anode plays a central role in the catalytic reaction. By regulating the coating composition, a balance between electrocatalytic activity and stability is achieved.

(I) Direct Oxidation

Under the influence of an external DC power source, when phenolic wastewater contacts the anode surface, pollutant molecules diffuse and adsorb onto the active sites of the MMO coating, resulting in a direct electron transfer reaction. Strongly adsorbed hydroxyl radicals (・OH) generated on the anode surface attack the benzene ring structure of phenol, breaking the C-O and C-C bonds, and gradually oxidizing it to intermediates such as benzoquinone and carboxylic acid, ultimately mineralizing to CO₂ and H₂O. This process requires the anode potential to be higher than the decomposition potential of the pollutant. The low oxygen evolution overpotential of the MMO coating (1.385V vs. mercurous sulfate) effectively suppresses the oxygen evolution side reaction and improves pollutant oxidation efficiency.

(II) Indirect Oxidative Degradation

Based on the water quality characteristics of phenolic wastewater, indirect oxidation pathways can be divided into two main types:

Chlorine-based oxidation system: For high-salinity, chlorinated phenolic wastewater, a chlorine evolution reaction occurs on the MMO anode surface (2Cl⁻ – 2e⁻ = Cl₂↑). The generated chlorine gas rapidly reacts with water to form hypochlorous acid (HClO). As a strong oxidant, hypochlorous acid can effectively degrade formaldehyde and phenolic derivatives, especially low-concentration phenolic pollutants.

Oxygen-based oxidation system: In a chlorine-free or low-chlorine environment, an oxygen evolution reaction occurs at the anode (4OH⁻ – 4e⁻ = O₂↑ + 2H₂O). The generated reactive oxygen species oxidize the pollutants. By manipulating the coating composition (such as increasing the iridium content), the oxygen evolution potential at the anode can be increased, promoting the generation of strong oxidizing free radicals and enhancing the ability to degrade difficult-to-degrade phenolic compounds.

MMO Titanium Anode Types

To address the diverse characteristics of phenolic wastewater, MMO titanium anodes are available in a variety of specialized types through differentiated coating compositions and structural designs. The core classification is based on the compatibility of the coating system with the application scenario.

Ruthenium-Iridium Anodes: With RuO₂-IrO₂ as the core active components, these anodes are optimized versions of chlorine-evolving anodes. These anodes can improve chlorine evolution efficiency by over 30% in chlorine-containing environments, rapidly generating hypochlorous acid to degrade phenolic pollutants, making them particularly suitable for treating high-salinity phenolic wastewater.

Iridium-Tantalum Anodes: With IrO₂-Ta₂O₅ as the primary coating components, these anodes are highly stable oxygen-evolving anodes. The addition of tantalum oxide significantly enhances the coating’s acid corrosion resistance and oxidation resistance, enabling stable operation in strong acid media such as sulfuric acid. They can directly oxidize and degrade difficult-to-degrade phenols by generating a high oxygen potential. This type of anode is suitable for treating acidic phenolic wastewater generated in industries such as electroplating and chemical engineering. Its oxygen evolution potential can be controlled below 1.40V, and its energy efficiency is excellent.

Reticulated MMO titanium anode: Featuring a three-dimensional mesh structure, it offers a large surface area and high mass transfer efficiency, effectively reducing concentration polarization and is suitable for the continuous treatment of medium- and low-concentration phenolic wastewater.

Tubular MMO titanium anode: Featuring a hollow tubular structure, it offers strong pollution resistance and flexible installation. It can be directly inserted into reactors or deep wells to treat high-concentration phenolic wastewater. Its outstanding corrosion resistance makes it widely used in wastewater treatment around phenolic storage tanks. It can withstand corrosion from a variety of chemical media and maintain a stable current output.

Plate MMO titanium anode: Featuring a flat plate structure, it is simple to manufacture and maintain, making it suitable for miniaturized phenolic wastewater treatment equipment. Multiple plates can be combined to adjust the reaction area to meet varying treatment capacity requirements. However, its disadvantage is its relatively low mass transfer efficiency, requiring a stirring device.

Leveraging its core advantages of high catalytic activity, strong stability, and wide adaptability, the MMO titanium anode effectively overcomes the difficult-to-degrade and highly toxic nature of phenolic compounds through the synergistic effects of direct and indirect oxidation, becoming a preferred alternative to traditional treatment technologies.

Related products

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Titanium Fastener Hexagon Screw Nuts

-

Titanium Products

Titanium Fasteners For Motorcycles

-

Titanium Fasteners

Anodized Colored Titanium Fasteners

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Colored Motorcycle Titanium Bolts

-

Titanium Fasteners

Colored Automotive Titanium Bolts

-

Titanium Fasteners

Colored Titanium Springs