MMO Titanium Anode For Nitrobenzene

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

As an indispensable organic chemical raw material in modern industry, nitrobenzene plays a key role in dye synthesis, pharmaceutical manufacturing, pesticide production, and explosives preparation. However, the wastewater generated by its production and use is highly toxic and contains a high chemical oxygen demand (COD). Conventional treatment technologies struggle to effectively degrade it, posing a serious threat to the environment and human health.

Electrochemical oxidation technology, due to its high efficiency, controllability, and environmental friendliness, has become a research hotspot and a technological breakthrough for nitrobenzene wastewater treatment. Titanium-based metal oxide-coated electrodes (MMO titanium anodes), with their excellent catalytic activity, chemical stability, and long life, have become a core technology for nitrobenzene wastewater degradation.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

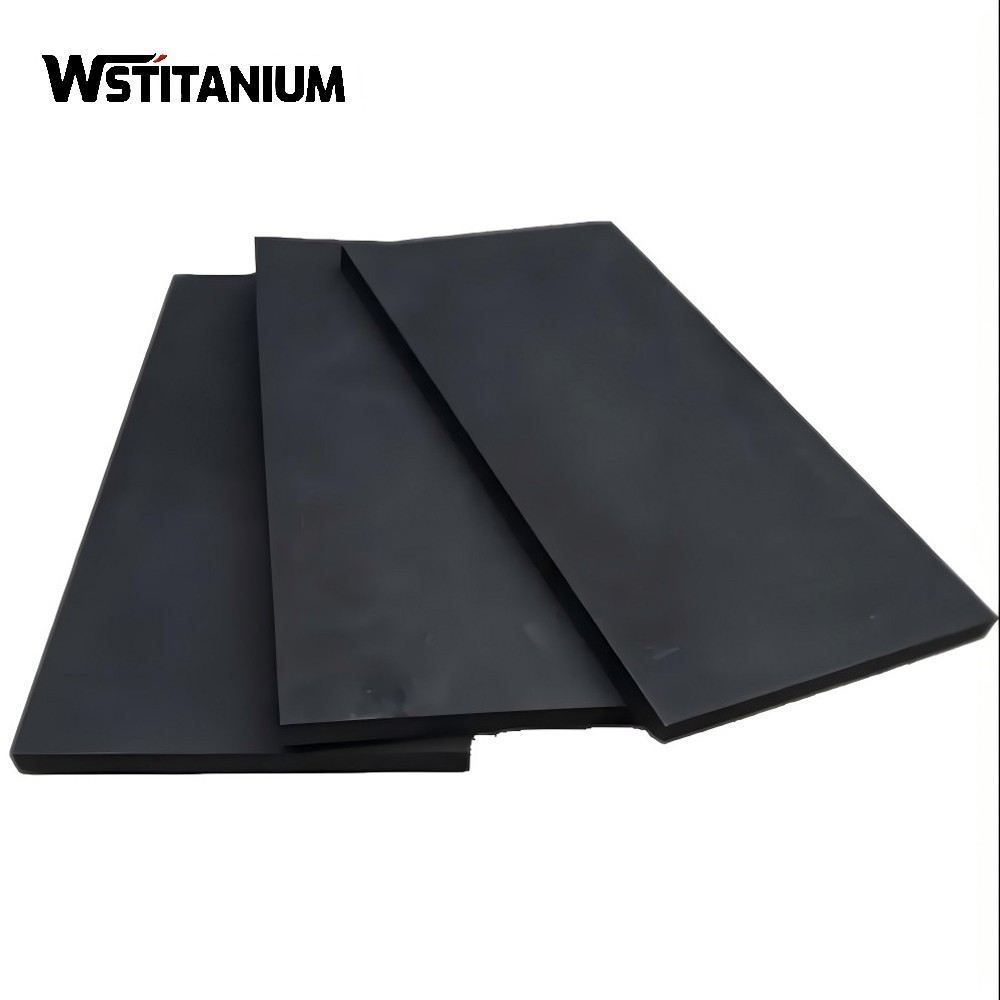

| Substrate Material | Titanium Gr1 or Gr2 |

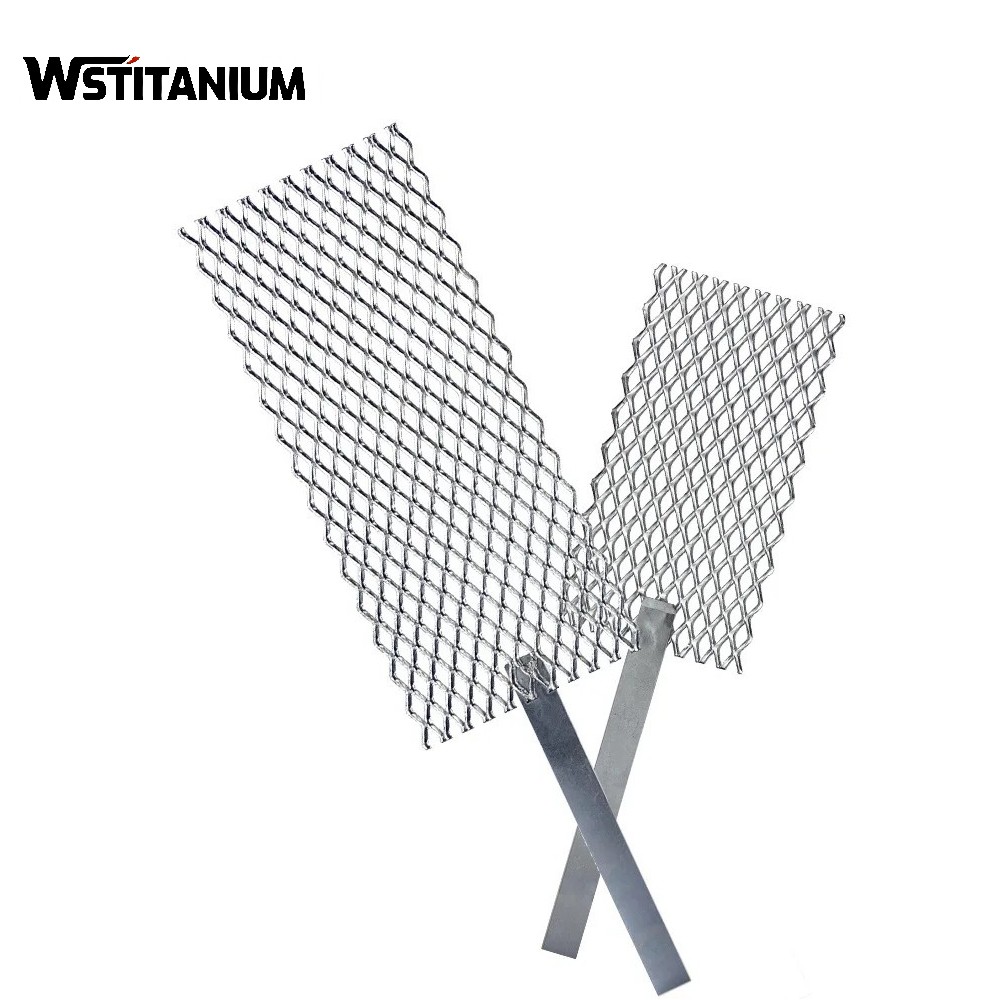

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Nitrobenzene Pollution

As a key intermediate in various synthetic dyes, including azo dyes and anthraquinone dyes, nitrobenzene is a fundamental raw material in the textile printing and dyeing industry chain. It is also used in the synthesis of antipyretic and analgesic drugs like acetaminophen, as well as sulfonamide antibiotics, and is in huge demand in the pharmaceutical and chemical industries. It is also a key raw material for the preparation of agricultural chemicals such as organophosphorus pesticides and herbicides. It is also widely used in explosives manufacturing, rubber vulcanization, and petroleum refining.

Nitrobenzene pollution primarily originates from reaction mother liquors, equipment rinse water, and wastewater during production. Its concentration fluctuates widely, ranging from a few hundred mg/L to tens of thousands of mg/L. For example, testing data from nitrobenzene wastewater from a chemical company revealed COD concentrations as high as 5700 mg/L, nitrobenzene-like substances at 571 mg/L, a chromaticity as high as 2500 times, and a salt content exceeding 39,000 mg/L, making it a typical high-risk industrial wastewater.

Ecological Damage: As a persistent organic pollutant, nitrobenzene is difficult to degrade naturally once it enters water bodies. This can lead to a decrease in dissolved oxygen levels, disrupt the aquatic ecosystem, and cause a decline in aquatic populations and species diversity.

Health Threats: Nitrobenzene has clear “tri-toxic” effects (carcinogenic, teratogenic, and mutagenic). It can enter the human body through skin contact, inhalation, or accumulation in the food chain, damaging the nervous system, liver, kidneys, and other organs, and causing anemia and chronic poisoning.

Corrosion Threats: High-concentration nitrobenzene wastewater is corrosive to industrial equipment. Its toxicity can also interfere with the microbial activity of subsequent treatment systems, impacting production safety and treatment efficiency.

Working Principle of the MMO Titanium Anode

The MMO titanium anode degrades nitrobenzene through electrochemical oxidation. Its core mechanism is the generation of highly oxidizing species on the electrode surface. Through a synergistic effect of direct and indirect oxidation, these species destroy the benzene ring structure, ultimately converting the pollutant into a harmless substance.

(I) Electrocatalysis

The MMO titanium anode is based on industrially pure titanium (TA1/TA2). The surface is coated with a precious metal oxide coating (such as RuO₂ and IrO₂), which exhibits excellent electrocatalytic activity. Under the influence of a DC electric field, the coating catalyzes the oxidation of water molecules, generating a large number of hydroxyl radicals (・OH). These active species have an oxidation potential as high as 2.8V and are capable of indiscriminately attacking the stable structure of nitrobenzene molecules. Simultaneously, a direct electron transfer reaction occurs on the anode surface, directly oxidizing and degrading nitrobenzene molecules adsorbed on the electrode surface.

(II) Nitrobenzene Degradation

The electrochemical degradation of nitrobenzene follows a step-by-step “reduction followed by oxidation” pathway: at the cathode, nitrobenzene is first reduced to the less toxic aniline. This process reduces the biotoxicity of the wastewater and improves its biodegradability. Subsequently, under the action of strongly oxidizing species generated at the anode, aniline is further oxidized into intermediates such as benzoquinone and carboxylic acid, ultimately decomposing into small inorganic molecules such as carbon dioxide, water, and nitrate. This step-by-step degradation mechanism ensures thorough treatment while avoiding the accumulation of highly toxic intermediates.

MMO Titanium Anode Types

Based on the coating composition and structural characteristics, MMO titanium anodes suitable for nitrobenzene wastewater treatment are primarily classified into the following three categories.

(I) Iridium MMO Titanium Anodes

These, typically with an IrO₂-Ta₂O₅ coating system, are highly efficient oxygen evolution electrodes with strong antioxidant properties and chemical stability. Their core advantage lies in their stable operation in complex media, including acidic and alkaline media. Their coating loss rate is less than 0.2μm/year, and their continuous operating life can exceed five years. In nitrobenzene wastewater treatment, this type of electrode efficiently generates hydroxyl radicals. A case study at a fine chemical company demonstrated that this type of electrode can reduce nitrobenzene effluent concentration from 120mg/L to below 0.5mg/L, fully meeting national Class I emission standards. This type of electrode is particularly suitable for treating high-concentration, high-salinity nitrobenzene industrial wastewater.

(2) Ruthenium MMO Titanium Anode

Using RuO₂ as its primary active ingredient, it combines chlorine evolution and oxidation functions, performing exceptionally well in chloride-containing nitrobenzene wastewater. Its operating principle is to catalyze the generation of oxidizing substances such as hypochlorous acid, achieving indirect oxidative degradation of nitrobenzene. It also exhibits excellent conductivity and current efficiency. This type of electrode is relatively low-cost and suitable for small and medium-sized chemical companies with moderate salinity and treatment cost sensitivity. It is widely used in the treatment of pharmaceutical intermediate production wastewater.

(3) Lead Dioxide Coated Titanium Anode

Titanium-based lead dioxide coated anodes exhibit unique advantages in nitrobenzene degradation. The coating exhibits an extremely high oxygen evolution overpotential and strong oxidizing capacity, high hardness, and resistance to acid and alkali corrosion. Current efficiency can reach over 90%, and the service life exceeds two years. Due to the strong oxidizing properties of the lead dioxide coating, this electrode can directly break down the benzene ring structure of nitrobenzene, making it particularly suitable for treating complex wastewater containing various nitrobenzene derivatives. It has demonstrated significant effectiveness in treating dye intermediate production wastewater.

Wstitanium uses industrially pure titanium that meets ASTM B265 Gr1 standards and strictly controls the content of impurities such as carbon, nitrogen, and iron to ensure the base material has excellent conductivity and corrosion resistance. We offer a full range of customized solutions tailored to the specific characteristics of nitrobenzene wastewater in different scenarios. For high-concentration nitrobenzene wastewater, we have developed a high-iridium-content IrO₂-Ta₂O₅ coated electrode, which increases hydroxyl radical yield by 25% and improves treatment efficiency by 40% compared to general-purpose electrodes. For high-salinity wastewater, we optimize the electrode structure design and integrate it with an ion-exchange membrane electrolysis system to achieve simultaneous organic matter degradation and salt resource recovery, reducing the cost per ton of wastewater treatment by 60%. We offer a variety of structural products, including mesh, tubular, and plate, that can be precisely matched to the electrolytic cell size and flow field characteristics to ensure reaction uniformity and mass transfer efficiency.

Related products

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Titanium Bolts For Motorcycle

-

Titanium Fasteners

Motorcycle Titanium Bolts Pin

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Fasteners

Titanium Fasteners For Automotive

-

Titanium Fasteners

Anodized Colored Titanium Fasteners

-

Titanium Fasteners

Gr5 Titanium Wheel Bolts

-

Titanium Fasteners

Colored Bicycle Titanium Bolts