MMO Titanium Anode For Surfactants

Certified: CE & SGS & ROHS

Shape: Requested

Diameter: Customized

Drawings: STEP, IGS , X_T, PDF

Shipping: DHL, Fedex, or UPS & Ocean Freight

20+ YEARS EXPERIENCE SENIOR BUSINESS MANAGER

Ask Michin For What You Want?

From laundry to oil extraction, from food processing to pharmaceutical preparation, surfactants permeate numerous key sectors of society and the economy. However, if surfactant contaminants are discharged directly into water bodies without effective treatment, they can not only disrupt the balance of aquatic ecosystems but also threaten human health through the food chain.

MMO titanium anodes (titanium-based mixed metal oxide anodes) have become a key to overcoming the challenges of surfactant treatment. MMO titanium anodes, also known as DSAs (dimensionally stable anodes), utilize a titanium substrate coated with precious metal oxides such as iridium, ruthenium, and tantalum. These anodes combine excellent electrocatalytic activity, chemical stability, and an extremely long service life, providing a solution for the advanced treatment of surfactant wastewater.

| Technical Measurement | Performance |

| Coating Element | Iridium Oxide (IrO₂), Ruthenium Oxide (RuO₂),Platinum |

| Substrate Material | Titanium Gr1 or Gr2 |

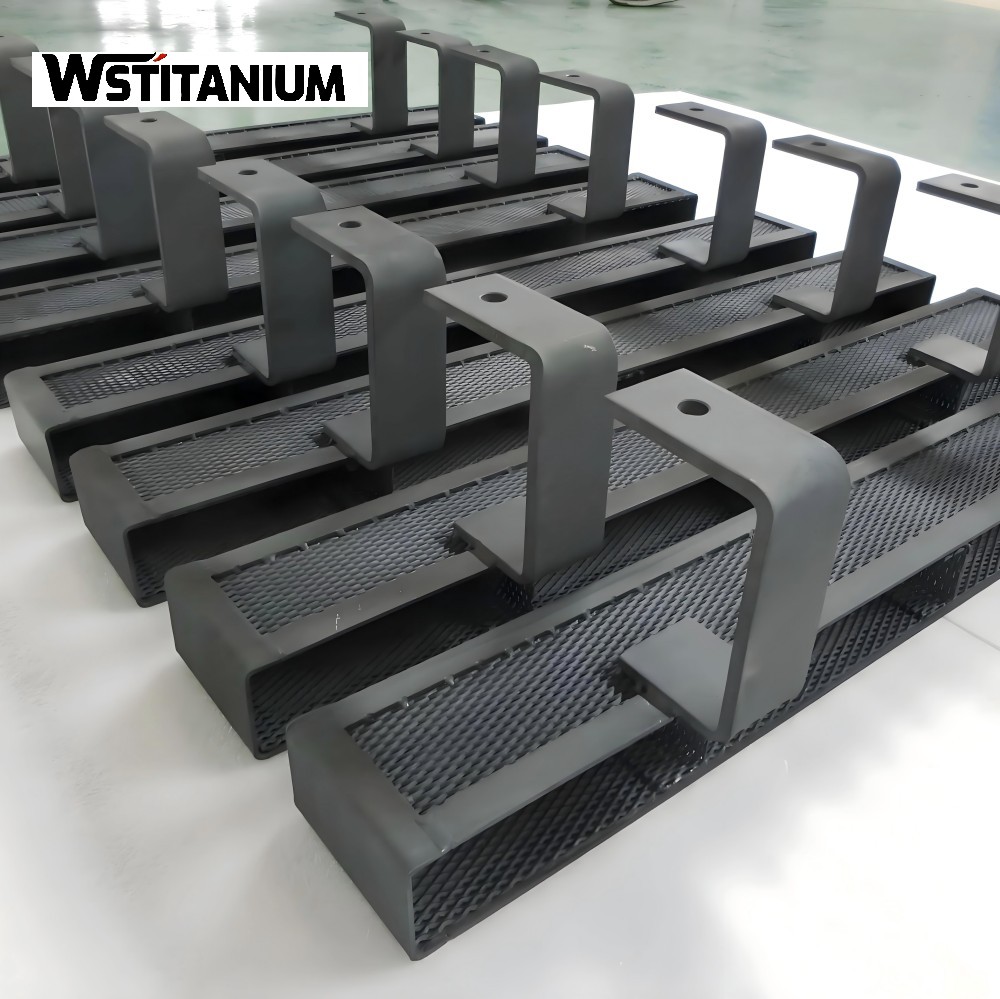

| Titanium Anode Shape | Customized Plate/Mesh/Tube/Rod/Wire/Disc |

| Coating Thickness | 8~20 μm |

| Coating Uniformity | 90% min. |

| Current Density | ≤ 20000 A/m² |

| Operating Voltage | ≤ 24V |

| PH Range | 1~14 |

| Temperature | < 80 °C |

| Fluoride Ion Content | < 50 mg/L |

| Warranty | More than 5 years |

Surfactant Pollution

Surfactants can be divided into four categories based on their molecular structure: anionic, cationic, nonionic, and amphoteric. In daily life, anionic surfactants dominate, with products like alkylbenzene sulfonates and fatty alcohol ether sulfates widely used in laundry detergents, dishwashing liquids, and shower gels. Nonionic surfactants, due to their mildness, are a core ingredient in baby care products and high-end cosmetics. The metal machining industry relies on their rust prevention and degreasing properties, with annual consumption in the machinery manufacturing sector alone reaching hundreds of thousands of tons. Cationic surfactants are used for swimming pool disinfection and wastewater flocculation due to their bactericidal properties. Large-scale discharges of surfactants have become a major source of water pollution.

Regarding ecological hazards: When surfactant concentrations in water exceed 4 mg/L, they significantly reduce surface tension, causing damage to the gill membranes of fish and impairing respiratory function. At concentrations of 10 mg/L, most freshwater fish are unable to survive. More seriously, typical surfactants like sodium alkylbenzene sulfonate (ABS) are potentially teratogenic and can easily cause eutrophication of water bodies, leading to algae blooms and disrupting aquatic ecosystems.

Regarding human health: Residual surfactants in the environment can be ingested through drinking water and food. Long-term accumulation can disrupt the endocrine system, with cationic surfactants in particular potentially adversely affecting the reproductive system. Furthermore, surfactants can enhance the solubility and mobility of other pollutants, making it easier for harmful substances like heavy metals and pesticides to enter organisms, resulting in compound pollution effects.

Working Principle of MMO Titanium Anodes

The core mechanism of MMO titanium anodes in treating surfactant wastewater is to disrupt its molecular structure through electrochemical oxidation reactions, achieving pollutant degradation or mineralization. This process primarily relies on the synergistic effect of direct and indirect oxidation pathways.

(I) Direct Oxidation

Direct oxidation is the process by which surfactant molecules undergo oxidative decomposition on the surface of MMO titanium anodes through electron transfer. The mixed metal oxide coating (such as IrO₂-Ta₂O₅ or RuO₂-TiO₂) on the titanium substrate possesses abundant active sites and excellent electron transfer properties. Surfactant molecules accumulate on the anode surface through physical or chemical adsorption. Their hydrophobic groups form van der Waals forces with the coating surface, while the hydrophilic groups align themselves through electrostatic interactions. Subsequently, chemical bonds within the molecules, such as C-C and ether bonds, break under the attack of electron holes, gradually degrading them into small organic molecules and ultimately oxidizing them to CO₂ and H₂O.

(II) Indirect Oxidation

Indirect oxidation involves the degradation of surfactants through the electrolysis of MMO titanium anodes, generating highly oxidizing intermediates (such as hydroxyl radicals (OH) and active chlorine species). This pathway exhibits non-selective oxidation characteristics and can treat a wide range of complex pollutants.

In chlorine-containing electrolyte systems, the chlorine evolution function of the MMO titanium anode is activated. Cl⁻ in the solution loses electrons at the anode surface to form Cl₂, which further hydrolyzes to form active chlorine species such as HClO and ClO⁻, according to the reaction equation: Cl⁻ → ClO⁻ → HClO. These active chlorine species are highly oxidizing and can attack the hydrophobic chains and polar groups in surfactant molecules, initiating reactions such as desulfonation and chain scission. For high-concentration surfactant wastewater, indirect oxidation contributes approximately 60-80% of the degradation efficiency.

In chlorine-free or low-chlorine systems, the MMO titanium anode generates hydroxyl radicals through the oxygen evolution reaction, according to the reaction equation: H₂O → OH + H⁺ + e⁻. Hydroxyl radicals, with a redox potential as high as 2.80V, can indiscriminately oxidize all types of surfactants. Even difficult-to-degrade nonionic surfactants (such as polyoxyethylene ethers) can be effectively degraded. Research has shown that titanium-based PbO₂-coated anodes can generate hydroxyl radicals at concentrations up to 1.2×10⁻⁴mol/L, with a degradation rate of over 90% for polyoxyethylene octylphenol ether.

MMO Titanium Anode Types

Based on the coating composition and structural characteristics, MMO titanium anodes suitable for surfactant treatment are primarily classified into the following three categories. Each anode type exhibits significant differences in performance, meeting the needs of different operating conditions.

(I) Ruthenium-Iridium MMO Titanium Anodes

Ruthenium-Iridium anodes are currently the most widely used type. Their coating consists of RuO₂ as the primary active component and IrO₂ as a stabilizer, forming a solid solution structure through high-temperature sintering. This type of anode exhibits excellent chlorine evolution and electrical conductivity, performing exceptionally well in the treatment of chlorinated surfactant wastewater, efficiently generating active chlorine species to degrade pollutants.

(II) Iridium-Tantalum MMO Titanium Anodes

Iridium-Tantalum anodes, with IrO₂ as the active component and Ta₂O₅ as the coating stabilizer, offer exceptional chemical stability and corrosion resistance, making them particularly suitable for the treatment of acidic surfactant wastewater. The introduction of Ta₂O₅ significantly improves the crystallinity and density of the coating, enabling the anode to maintain stable performance in highly acidic environments with a pH range of 1-4. This type of anode exhibits a high oxygen evolution overpotential (approximately 1.6V), effectively suppressing the oxygen evolution side reaction and improving oxidative degradation efficiency. It is particularly effective in degrading non-ionic surfactants.

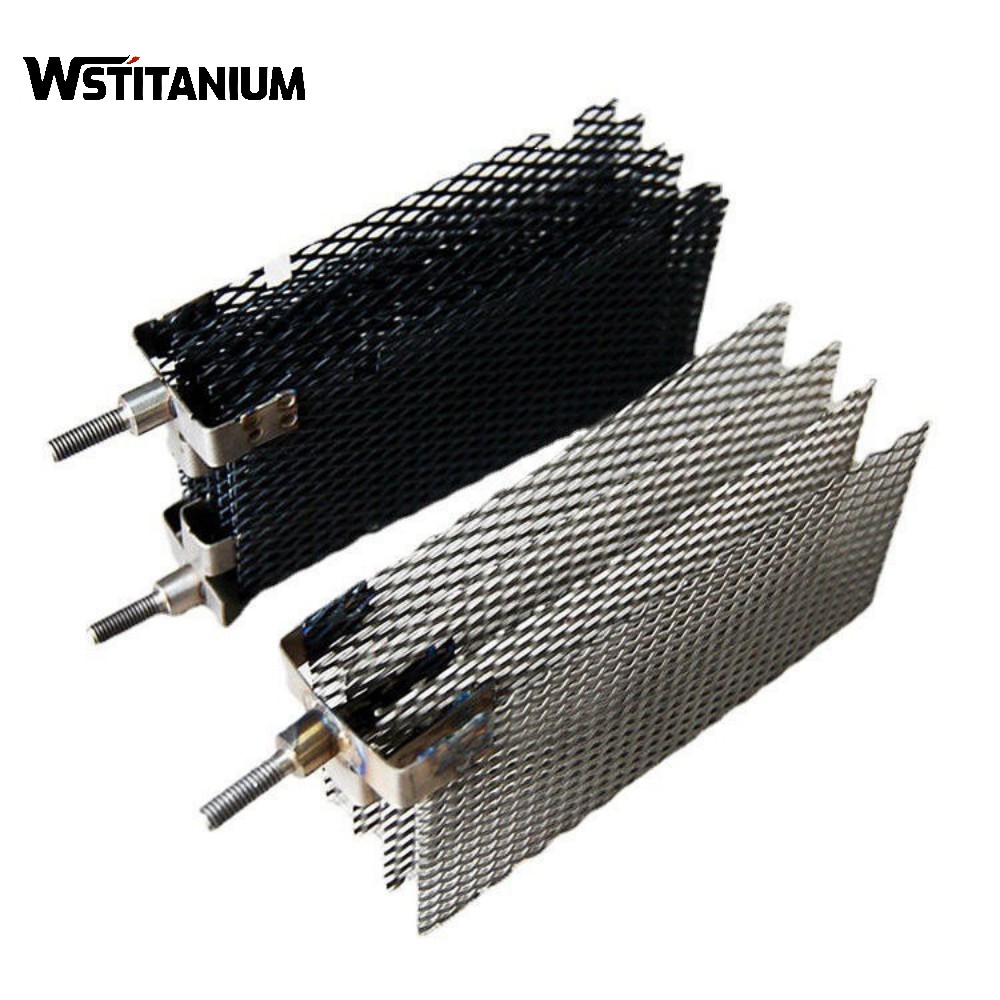

(III) Flexible MMO Titanium Anode

Flexible MMO titanium anodes are braided from Gr1 or Gr2 titanium wires coated with an IrO₂-Ta₂O₅ coating. They exhibit excellent flexibility and formability. This type of anode can be flexibly tailored to the reactor shape, significantly increasing the contact area between the electrode and the wastewater, improving current distribution uniformity, and avoiding localized overvoltage issues. Its current density uniformity surpasses that of rigid anodes, making it particularly effective in complex reactor configurations. It is particularly suitable for compact, mobile surfactant wastewater treatment equipment.

The contradiction between the widespread use of surfactants and environmental pollution has become a key issue hindering the sustainable development of industry. As the core carrier of this technology, the MMO titanium anode, with its excellent electrocatalytic performance, stability, and long life, has revolutionized the treatment of surfactant wastewater.

Through the synergistic action of direct and indirect oxidation, the MMO titanium anode efficiently destroys the molecular structure of various surfactants, achieving complete mineralization of pollutants from large molecules to small molecules, all the way to CO₂ and H₂O. Different types of MMO titanium anodes offer their own advantages: Ruthenium-iridium anodes balance cost and efficiency and are suitable for conventional chlorinated wastewater; Iridium-Tantalum anodes offer outstanding corrosion resistance and are effective for acidic, refractory wastewater; Titanium-based IRO₂ anodes offer strong mineralization capabilities and are suitable for advanced treatment needs; and flexible anodes expand the application of complex equipment.

Related products

-

Titanium Fasteners

Custom Manufacturing Titanium Screws

-

Titanium Fasteners

Titanium Fastener Hexagon Screw Nuts

-

Titanium Fasteners

Titanium Hexagon Head Bolts

-

Titanium Fasteners

Titanium Bolts Supplier

-

Titanium Fasteners

Anodized Titanium Screws

-

Titanium Fasteners

Anodized Titanium Nut

-

Titanium Fasteners

Titanium Wheel Bolts

-

Titanium Fasteners

Colored Gr5 Manifold Titanium Bolts